Phenol-ammonia coal gasification sewage treatment method

A technology for coal gasification sewage and treatment methods, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Unbearable and other problems to achieve the effect of solving scaling and clogging problems, reducing steam consumption and reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

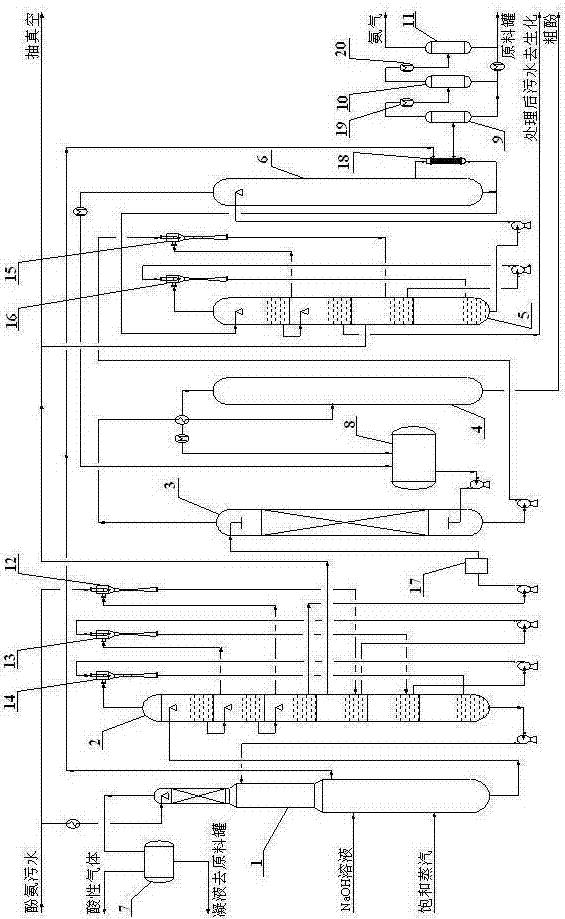

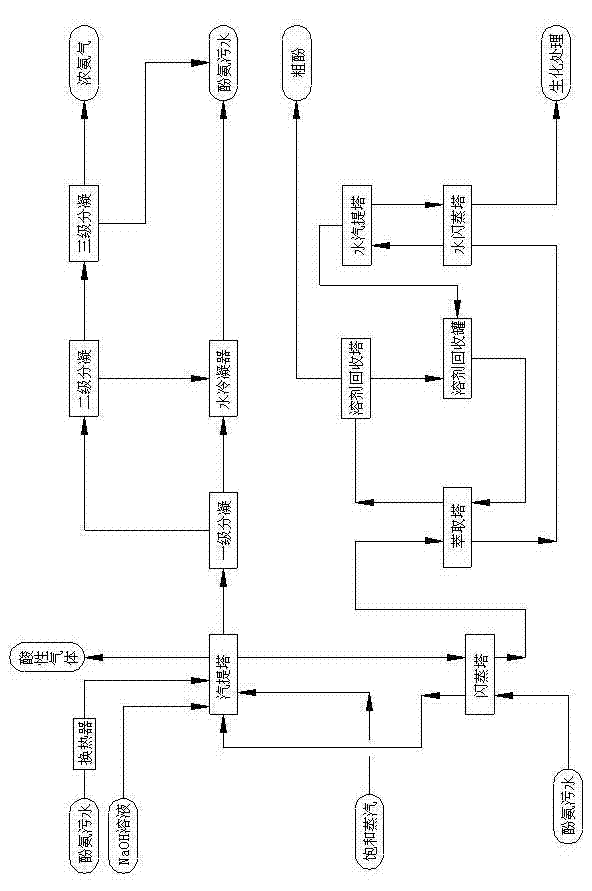

[0024] Such as figure 1 , 2 Shown, the phenolic ammonia coal gasification sewage treatment method, this method comprises the following steps:

[0025]①Single-tower stripping deacidification and deamination: the phenol ammonia coal gasification sewage from the sewage pump is divided into two streams and enters the stripping tower 1 with side line extraction: one stream of raw material water is cooled to 48°C and used as cold feed Enter the upper part of the packing section at the top of the stripping tower 1, the operating pressure at the top of the tower is 0.2MPa, and the operating temperature is 43°C; the other stream of raw water and the deacidified and deammoniated sewage that enters the flash tower 2 are flashed out After three times of heat exchange, the steam enters the first layer of trays under the packing section of the stripper 1 as a hot feed; the weight ratio of the raw material water-cooled feed to the hot feed is 0.15:1; the cold feed passes through the strippe...

Embodiment 2

[0030] Such as figure 1 , 2 Shown, the phenolic ammonia coal gasification sewage treatment method, this method comprises the following steps:

[0031] ①Single-tower stripping deacidification and deamination: the phenol ammonia coal gasification sewage from the sewage pump is divided into two streams and enters the stripping tower 1 with side line extraction: one stream of raw material water is cooled to 30°C and used as cold feed Enter the upper part of the packing section at the top of the stripping tower 1, the operating pressure at the top of the tower is 0.55MPa, and the operating temperature is 80°C; the other stream of raw water and the deacidified and deammoniated sewage that enters the flash tower 2 are flashed out After three times of heat exchange, the steam enters the first layer of trays under the packing section of the stripper 1 as a hot feed; the weight ratio of the raw material water-cooled feed to the hot feed is 0.9:1; the cold feed passes through the stripp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com