Method for producing low freezing point biodiesel by employing waste animal and vegetable oil coupling and special device

A technology for discarding animals, plants and biodiesel, applied in the field of biodiesel preparation, can solve the problems of reducing biodiesel, unusable, complicated process, etc., and achieves the effect of reducing raw material cost, increasing reaction yield and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Raw materials: take 300 parts by weight of waste oil, and measure the acid value of the oil to be 146 mgKOH / g.

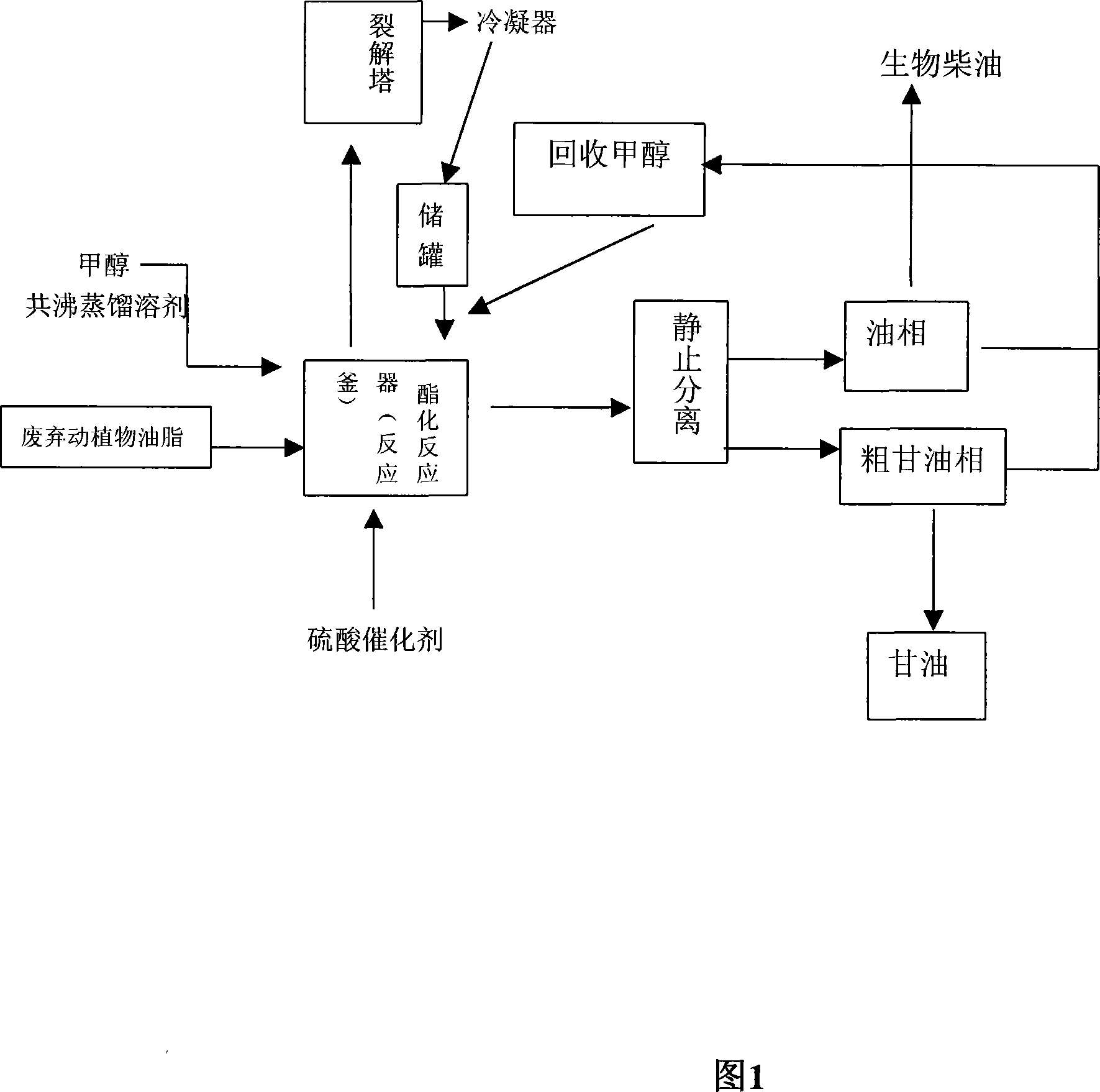

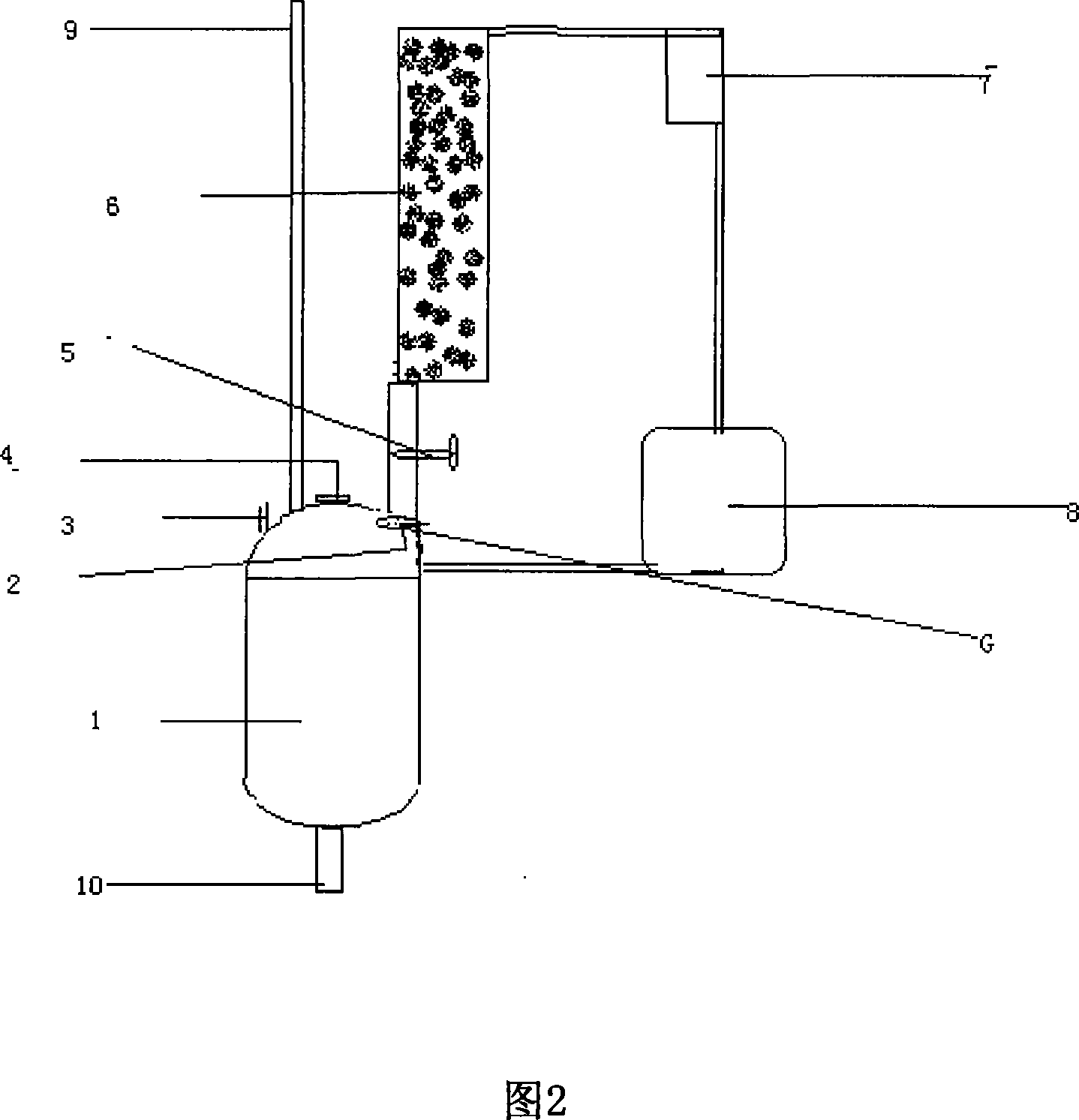

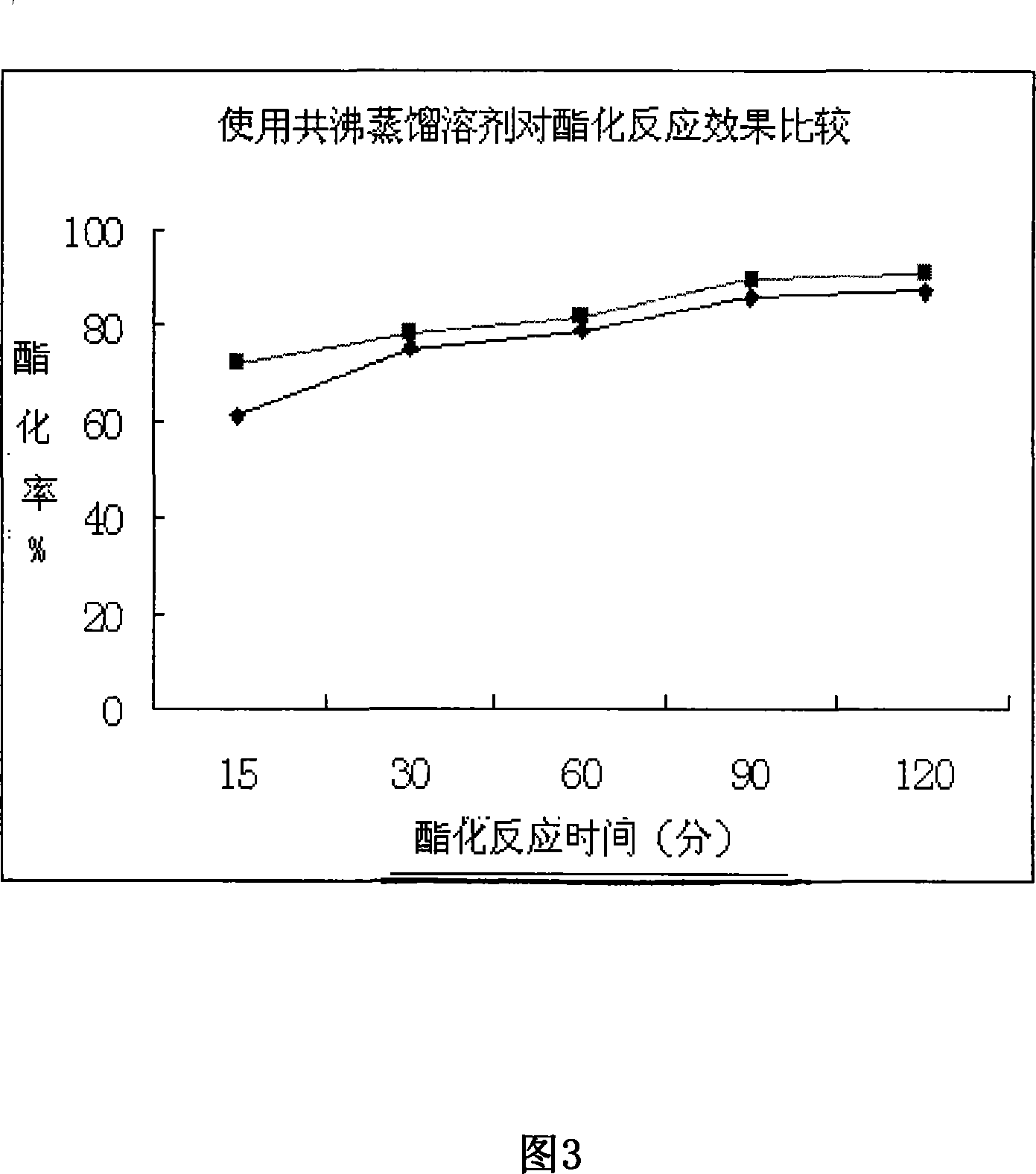

[0021] According to the technical route and device shown in accompanying drawings 1 and 2 of the specification and the technical steps and reaction conditions shown in the "Summary of the Invention" of this specification, the waste oil of this embodiment has been subjected to two major parts of thermal cracking and esterification. Put the 500mL three-necked bottle into the electric heating mantle, and install a thermal cracking tower, an electric stirrer and a thermometer successively on the there-necked bottle, then add 300 parts by weight of waste oil in the there-necked bottle, and put it under the condition of negative pressure (0.1MPa). Waste oil is heated to 200 ℃ to vaporize, and oil gas enters through pipeline and is equipped with solid cracking catalyst (adopts the molecular sieve impregnated and adsorbed ZnCl2, GaCl3 and fatty acid calcium, and this ...

Embodiment 2

[0028] With reference to the method and device of Example 1, the conditions in this example are as follows: Cottonseed acidified oil (acid value 192 mgKOH / g) produced in Xinjiang.

[0029] Raw materials in parts by weight: cottonseed acidified oil: 300 parts, sulfuric acid 2.4 parts, diisopropyl ether 45 parts, methanol 150 parts, solid cracking catalyst adopts impregnation adsorption ZnCl 2 , GaCl 3 and molecular sieves of fatty acid calcium salts (purchased from China Shanghai Petrochemical Catalyst Research Institute, model 5A). Obtain biodiesel: 226.3 parts, still residue: 52.2 parts.

[0030] The technical parameters of the reaction conditions are as follows: the reaction temperature is 65°C, the reaction time is 4h,

[0031] The acid value of the final product biodiesel was determined to be 0.85 mgKOH / g, and the actual freezing point of the final product biodiesel was -15°C. The conversion rate of biodiesel was 75.33%.

Embodiment 3

[0033] Preparation with reference to the method and device of Example 1.

[0034] Raw materials Raw materials are calculated in parts by weight: 300 parts of lard (acid value 6mgKOH / g), 4.5 parts of sulfuric acid, 35 parts of diisopropyl ether, 100 parts of methanol, and the solid cracking catalyst is impregnated with ZnCl 2 , GaCl 3 and fatty acid calcium molecular sieves.

[0035] The parameters of the reaction conditions are as follows: the reaction temperature is 70°C, the reaction time is 2h,

[0036] In this example, 239.3 parts of biodiesel and 47.2 parts of still residue were obtained. The acid value of the final product biodiesel was determined to be 0.5 mgKOH / g, and the actual freezing point of the final product biodiesel was -12°C. The conversion rate of biodiesel was 79.76%.

[0037] The comparison between the present invention and the existing method for the condensation point of biodiesel prepared from different feedstock oils is shown in Table 2.

[0038] Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com