Catalyst for Fischer-Tropsch oriented synthesis for gasoline and method for preparing catalyst

A technology of directional synthesis and catalyst, which is applied in the preparation of liquid hydrocarbon mixtures, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of increasing the complexity of catalyst preparation, increasing the cost, and requiring higher pore structure characteristics of the pretreatment carrier, etc., to achieve Improve the poor quality of Fischer-Tropsch synthetic gasoline distillates, reduce pipeline blockage, reduce investment costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

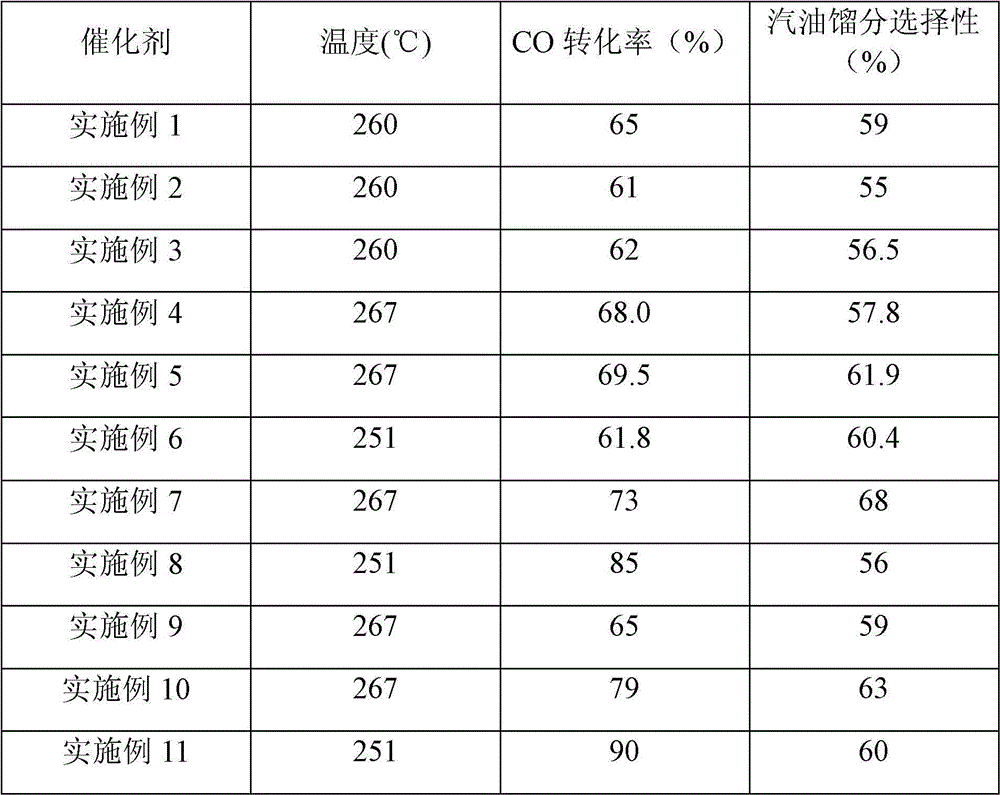

Examples

Embodiment 1

[0040]Preparation of cobalt-based catalyst 10Co / HZSM-5: Weigh 4.93 g of commercially available cobalt nitrate hexahydrate and add it to 30 ml of deionized water, while stirring for 10 minutes to form a cobalt nitrate solution. Weigh 10 g of ZSM-5 molecular sieve with a silicon-aluminum ratio of 100, add it into the above-mentioned cobalt nitrate solution, and stir at room temperature for 6 hours. Then the solvent in the above suspension was evaporated to dryness, and the evaporated solid was dried in an oven at 80° C. for 12 hours. The dried solid was heated in a muffle furnace to 550°C at a heating rate of 5°C / min, and calcined in an air atmosphere for 4h to obtain a cobalt-based catalyst 10Co / HZSM-5, in which the content of Co was 10% by weight of the catalyst support.

Embodiment 2

[0042] Preparation of cobalt-based catalyst 10Co / HZSM-34: Weigh 4.93 g of commercially available cobalt nitrate hexahydrate and add it to 30 ml of deionized water while stirring for 10 minutes to form a cobalt nitrate solution. Weigh 10 g of ZSM-34 molecular sieve with a silicon-aluminum ratio of 10, add it into the above-mentioned cobalt nitrate solution, and stir at room temperature for 6 h. Then the solvent in the above suspension was evaporated to dryness, and the evaporated solid was dried in an oven at 80° C. for 12 hours. The dried solid was heated in a muffle furnace to 550°C at a heating rate of 5°C / min, and calcined in an air atmosphere for 4h to obtain a cobalt-based catalyst 10Co / HZSM-34, in which the Co content was 10% by weight of the catalyst support.

Embodiment 3

[0044] Preparation of cobalt-based catalyst 10Co / HZSM-12: Weigh 4.93 g of commercially available cobalt nitrate hexahydrate and add it to 30 ml of deionized water, while stirring for 10 minutes to form a cobalt nitrate solution. Weigh 10 g of ZSM-12 molecular sieve with a silicon-aluminum ratio of 50, add it into the above-mentioned cobalt nitrate solution, and stir at room temperature for 6 h. Then the solvent in the above suspension was evaporated to dryness, and the evaporated solid was dried in an oven at 80° C. for 12 hours. The dried solid was heated in a muffle furnace to 550°C at a heating rate of 5°C / min, and calcined in an air atmosphere for 4h to obtain a cobalt-based catalyst 10Co / HZSM-12, in which the Co content was 10% by weight of the catalyst support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com