Internal heating spiral propulsion type waste plastic cracking device

A screw propulsion and cracking device technology, applied in the petroleum industry, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of untreated sulfur, large environmental pollution, small heat exchange area, etc., saving manpower and material resources, good oil quality, The effect of high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

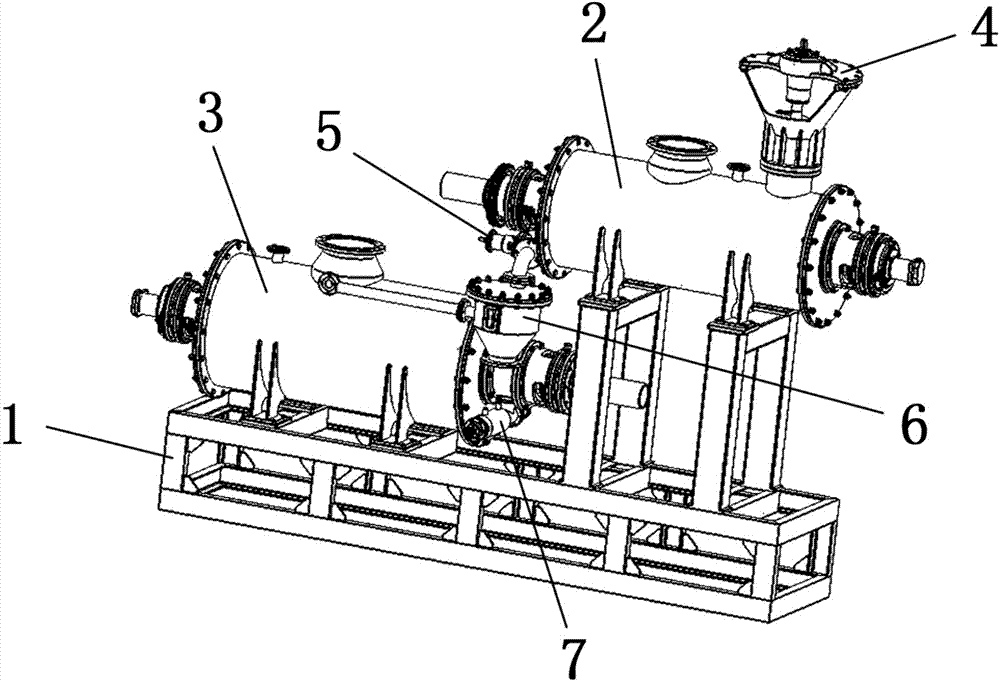

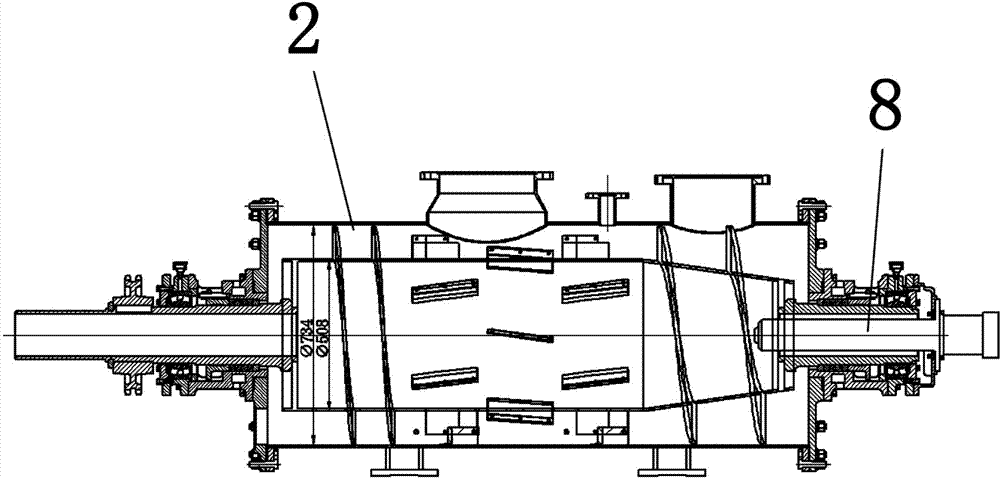

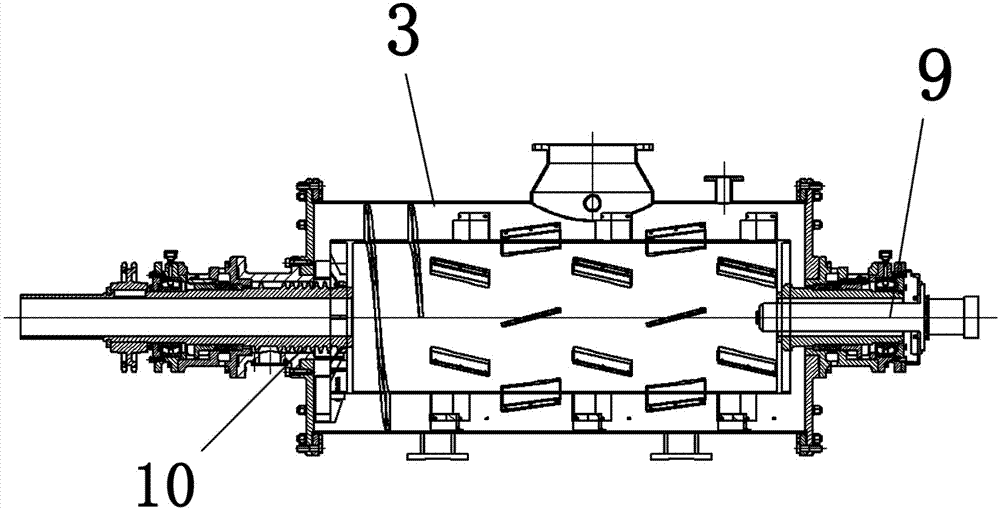

[0019] Such as figure 1 , figure 2 and image 3 As shown, an internal heating spiral propulsion type waste plastic pyrolysis device is characterized in that it includes a support 1, and the support 1 is provided with a liquefaction furnace 2 and a gasification furnace 3, and the liquefaction furnace 2 is provided with a burner or a burner 8. The gasification furnace 3 is provided with a burner or burner 9 for heating, the top of the liquefaction furnace 2 is provided with a screw feeder 4, the bottom of the liquefaction furnace 2 is provided with a screw discharge pump 5, and the screw The discharge pump 5 is connected to the filter barrel 6 , the filter barrel 6 is connected to the gasifier 3 , and the gasifier 3 is connected to the shaft-type spiral slagging device 10 and the spiral slagging device 7 .

[0020] When working, the raw material enters the liquefacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com