Walnut breaking machine

A shell breaking machine and walnut technology, which is applied in the field of agricultural and forestry machinery, can solve the problems affecting the development of the walnut industry, the high price of walnut kernels, and high labor intensity, so as to reduce the artificial screening process, improve the efficiency of shell breaking, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

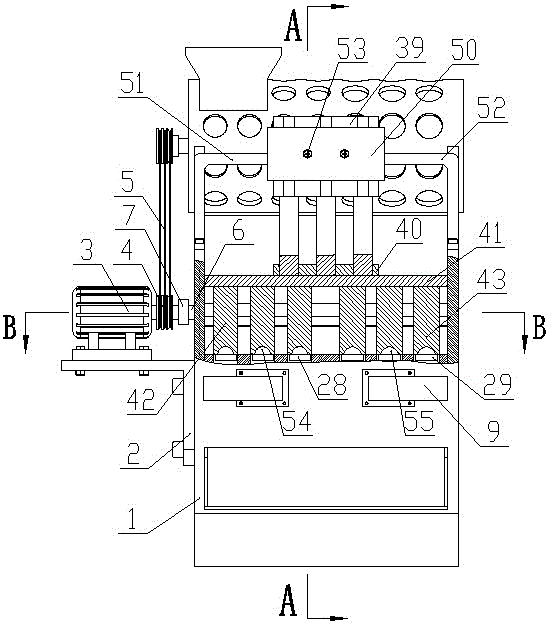

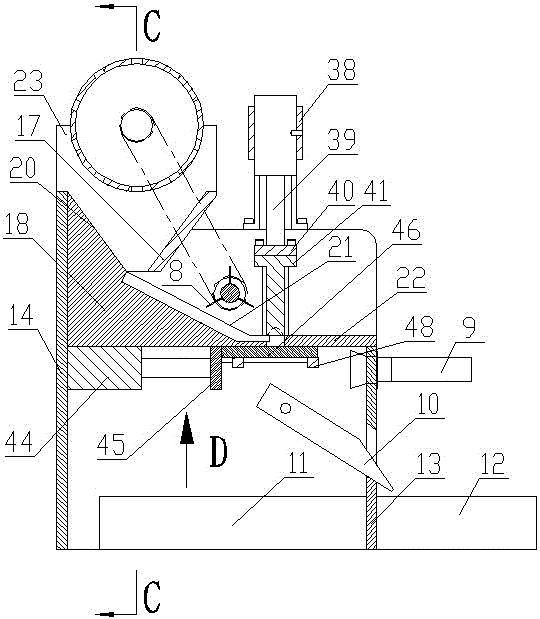

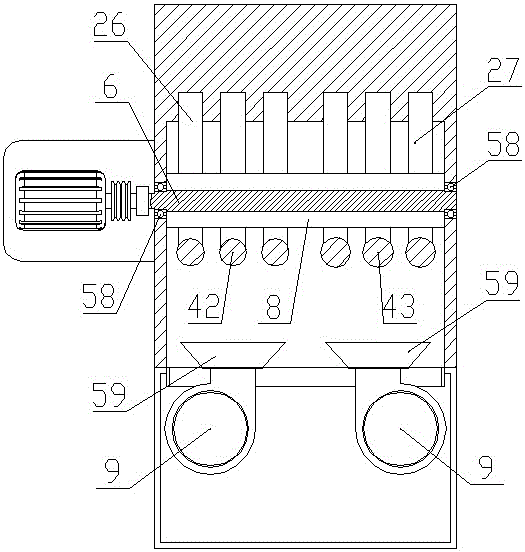

[0028] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 The shown walnut shelling machine includes a frame 1, a screw feeding device is arranged horizontally on the top of the rear end of the frame 1, a support frame 2 is fixed on the left side wall of the frame 1, and a motor is fixed on the support frame 2. 3. The main shaft of the motor 3 is fixed with a first pulley 4, and the first pulley 4 is covered with a belt 5. The motor 3 is connected to the power input end of the screw feeding device through the belt 5. The inside of the frame 1 The rotation is provided with a lower rotating shaft 6 and the left end of the lower rotating shaft 6 stretches out from the left side of the frame 1, the left end of the lower rotating shaft 6 is fixedly provided with a coupling 7, and the lower rotating shaft 6 is fixedly connected with the right end of the main shaft of the motor 3 through the coupling 7, Three distribution plates 8 are evenly f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com