Balanced metal detection device and method based on matrix coil

A metal detection, balanced technology, applied in measuring devices, radio wave measurement systems, electrical/magnetic exploration, etc., can solve problems such as production occasions that cannot be processed with bulk raw materials, to overcome strong electromagnetic interference and ensure detection. Accuracy, the effect of increasing the detection height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

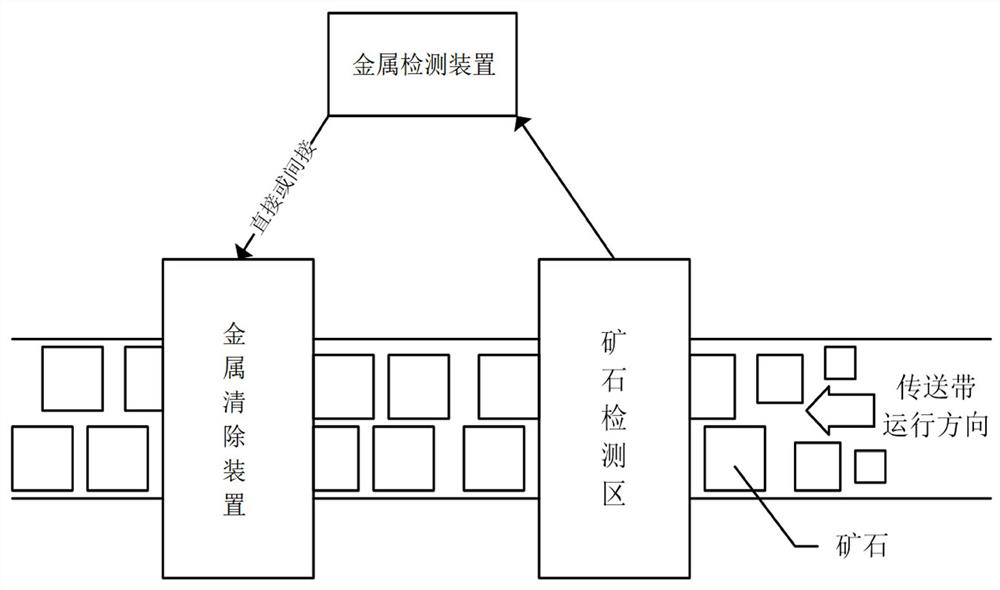

[0042] Such as figure 1 and figure 2 Commonly shown, a balanced metal detection device based on a matrix coil is installed in the ore detection area to detect whether there is a metal detection object in the ore raw material, and to directly or indirectly control the metal removal device. A balanced metal detection device based on matrix coils includes a detection circuit module, a transmitting coil module, and a receiving coil module that are electrically connected to each other.

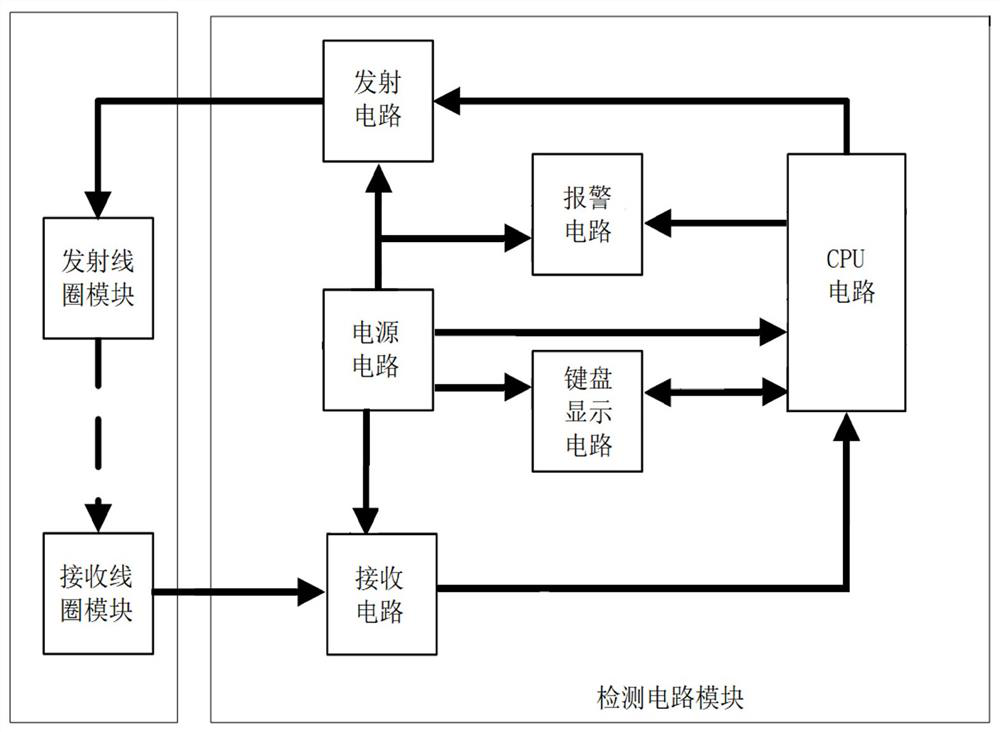

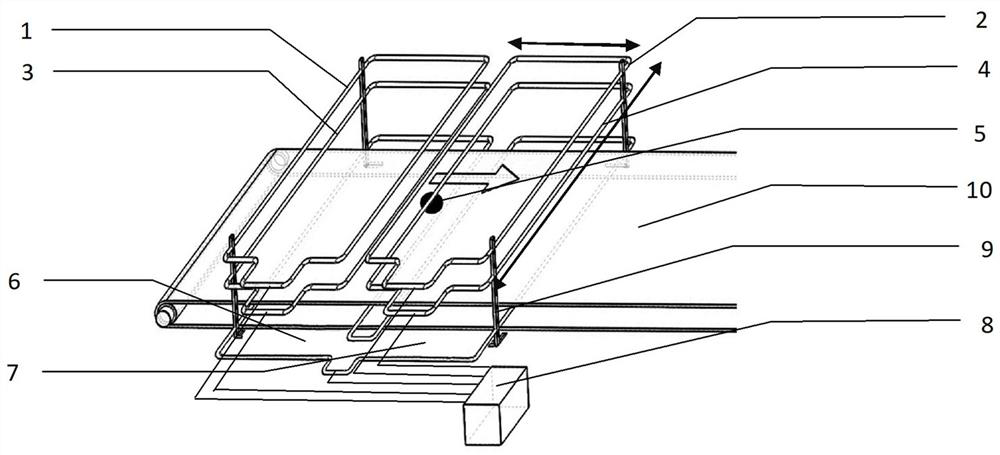

[0043] Such as figure 2 and image 3Commonly, as shown, the detection circuit module 8 is composed of a casing (not shown in the figure) and an internal circuit board. The shell is made of metal material, and the width, height, and depth of the shell are 45*70*30mm respectively. It is installed on one side of the conveyor belt 10 and connected with the transmitting coil module and the receiving coil module by wire. The internal circuit board includes a CPU circuit and a transmitting circuit, ...

Embodiment 2

[0055] The detection method formed by a balanced metal detection device based on matrix coils described in Embodiment 1 includes the following steps:

[0056] S1. The CPU circuit generates a continuous wave excitation signal to the transmitting circuit, and the continuous wave excitation signal generated by the transmitting circuit is output to the transmitting coil module. The transmitting coil module sends four continuous wave excitation signals in groups, and the receiving coil module receives the induced electromotive force EMF of the metal detection object. signal and transmit it to the receiving circuit.

[0057] S2. The receiving circuit receives the induced electromotive force EMF signal of the metal detection object obtained by the receiving coil module, performs differential calculation, circuit conditioning, two-stage amplification and filtering on the obtained signal, and then sends it to the CPU circuit for calculation.

[0058] S3. The CPU circuit converts the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com