T-shaped sensitive body of vector hydrophone

A vector hydrophone and sensitive body technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of vector detection and high sensitivity of the vector hydroacoustic sensor, and achieve the best power consumption. Low cost, low processing cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

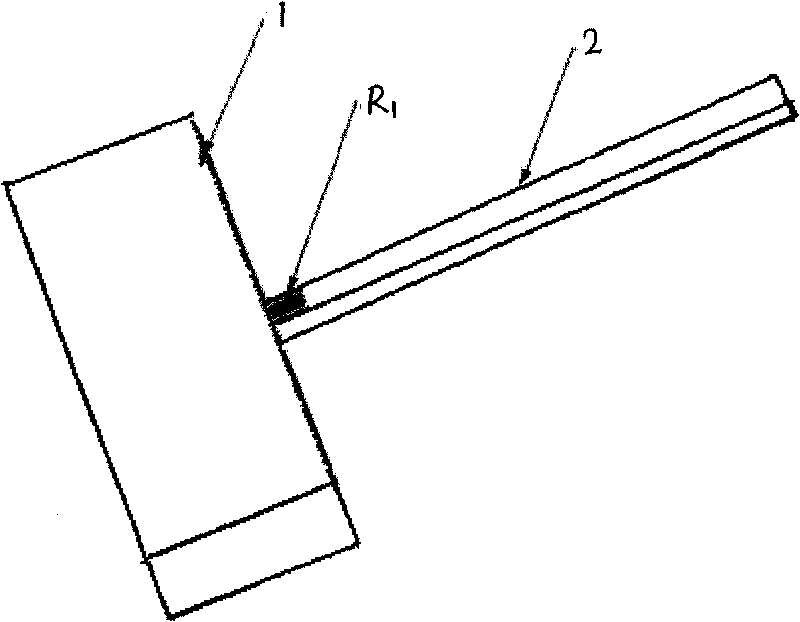

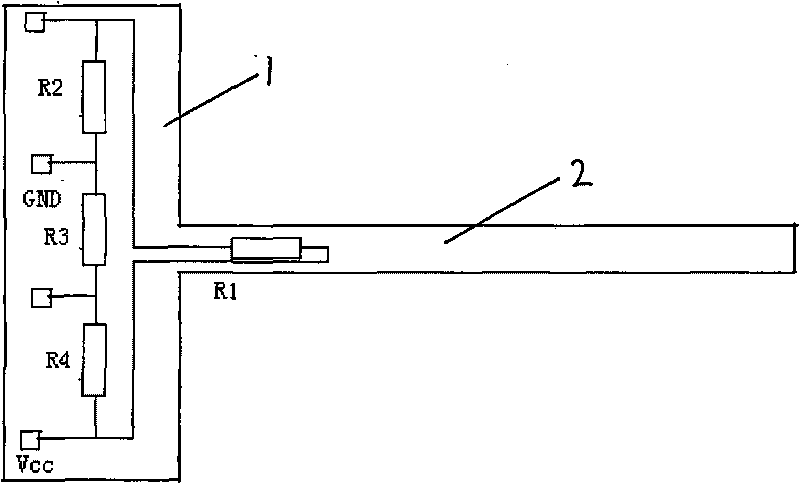

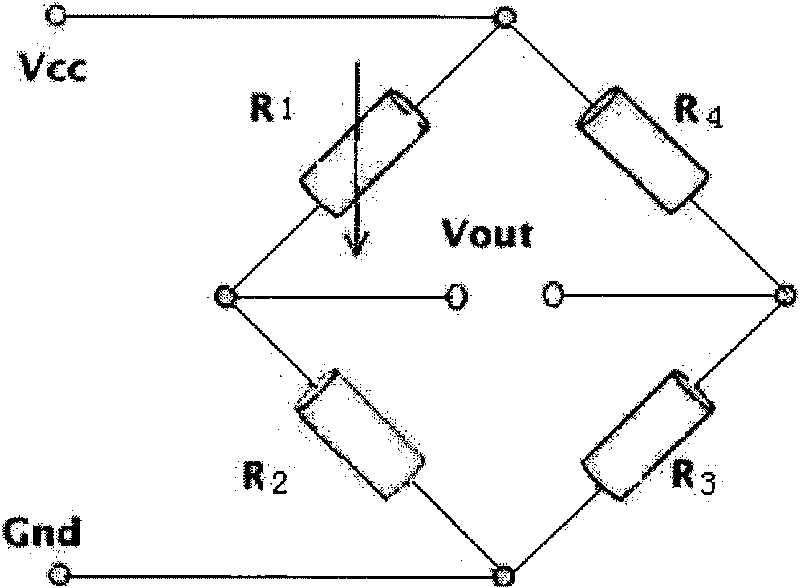

[0032] Such as Figure 1-3 As shown, the T-shaped sensitive body of the vector hydrophone includes a T-shaped body processed by silicon-based MEMS processing technology with silicon wafers as the processing material. Composed of rectangular parallelepiped columns 2, three reference resistors R2, R3, R4 with equal resistance are processed on the rectangular parallelepiped base 1 by diffusion process, strained piezoresistor R1 is processed on the rectangular parallelepiped column 2 by diffusion process, and the strained piezoresistor R1 Located at the root of the cuboid column 2 (that is, the end of the cuboid column close to the cuboid base), the resistance of the strain varistor R1 is equal to the resistance of the reference resistor, and the strain varistor R1 is connected to the reference resistors R2, R3, and R4 to form a In the Wheatstone bridge, the three reference resistors R2, R3, and R4 are respectively used as the unilateral reference bridge arm of the Wheatstone brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com