Silage processing equipment

A technology for processing equipment and silage, applied in feed, food science, application and other directions, can solve problems such as unfavorable processing and animal consumption, and achieve the effect of improving rolling efficiency, improving breaking efficiency, and small and uniform materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

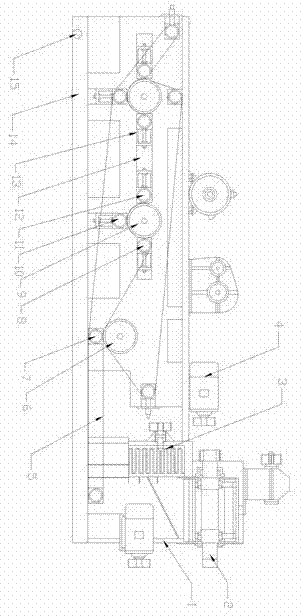

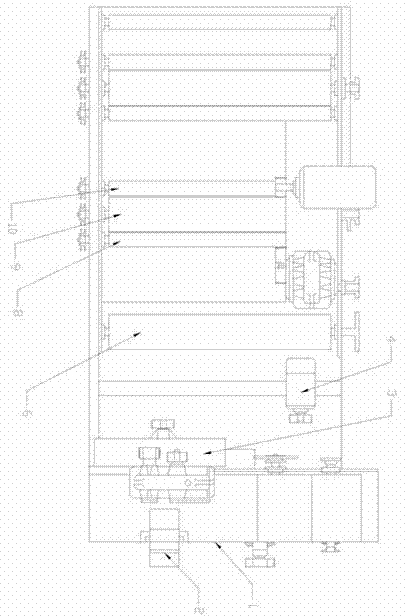

[0029] A silage processing equipment includes a frame 1, a conveyor belt 5, a cutting device 2, a breaking device 3, and a rolling device connected in sequence.

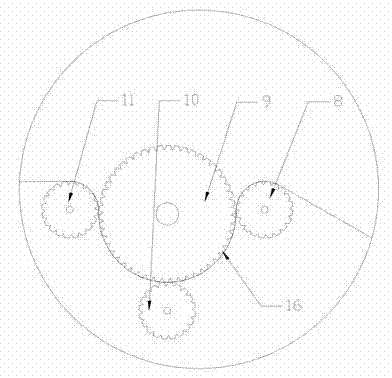

[0030] The rolling device includes three groups of pressing rollers connected successively. The first pressing roller group is composed of an upper pressing roller 6 and a lower pressing roller 7, and is connected with the breaking device 3 through a conveyor belt 5. The second and third pressing rollers The pressure roller wheel set is composed of four pressure rollers, namely the driving roller 9 driven by the motor 4, the first driven pressure roller 11 and the second driven pressure roller 8 located on the left and right sides and below the driving roller 9 respectively. And the third driven pressure roller 10. The conveyor belt 5 passes through the gap between the upper and lower pressure rollers of the first pressure roller group and the gap between the driving roller and the driven pressure roller of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com