Nanometer composite silicon carbide ceramic and preparation method thereof

A technology of composite silicon carbide and silicon carbide, which is applied in the field of nanocomposite silicon carbide ceramics and its preparation, can solve the problems affecting the performance of nanocomposite ceramics, the inability of uniform dispersion of nanoparticles, and the difficulty of industrial production, etc., to achieve increased toughness, The size is small and uniform, and the effect of inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A preparation method of nanocomposite silicon carbide ceramics, with 85 parts of silicon carbide, 5 parts of yttrium aluminum garnet, 5 parts of nano silicon carbide and 5 parts of nano titanium carbide as the main raw materials, the following steps are carried out in sequence:

[0028] 1) Add the above-mentioned main raw materials, 2 parts of phenolic resin, 0.5 parts of PVA and 1 part of PEG into 200 parts of deionized water, and mix them by ball milling for 5 hours to prepare a water-based silicon carbide slurry;

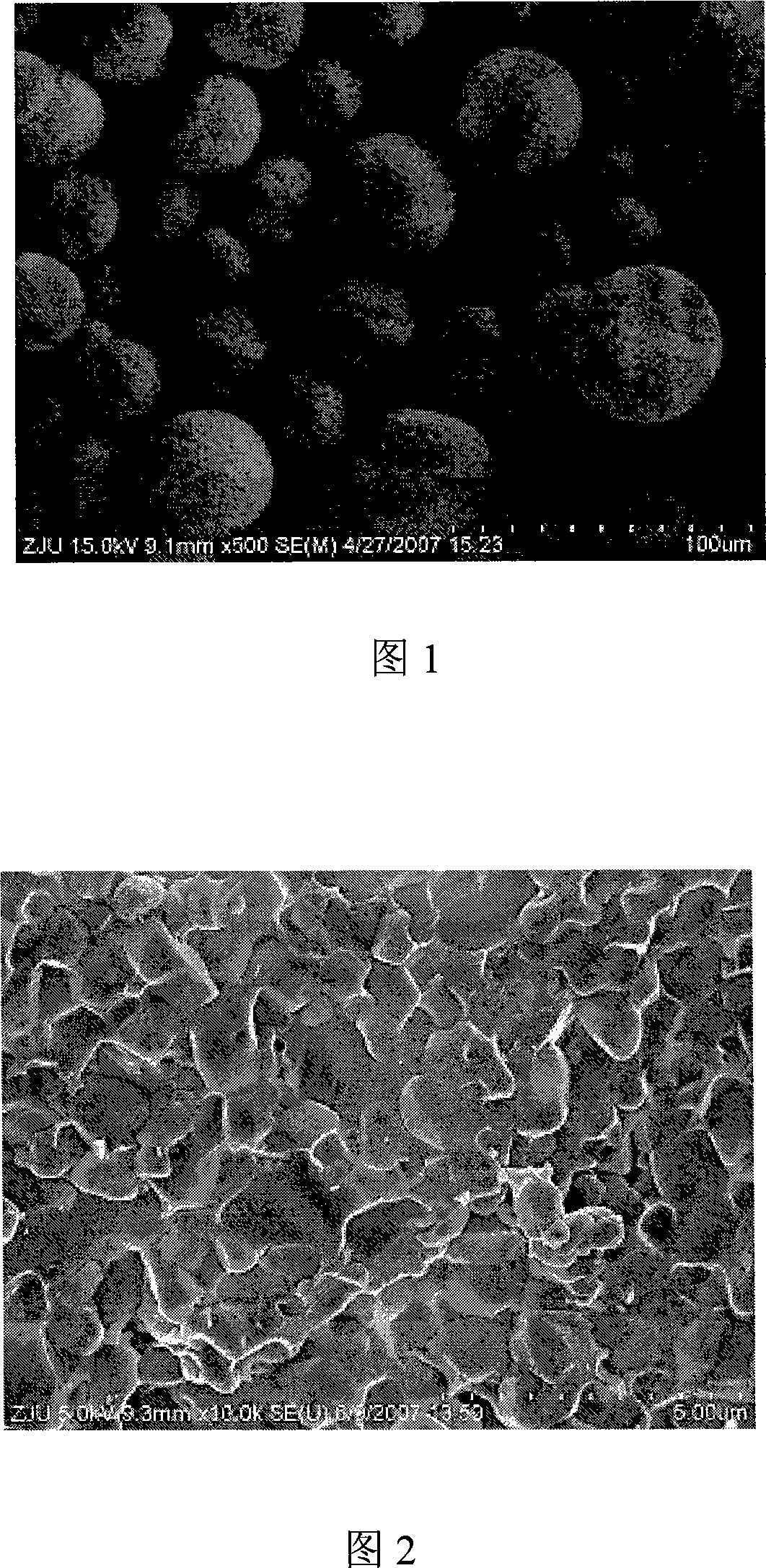

[0029] 2) Spray-dry the above-mentioned water-based silicon carbide slurry by spray granulation process to obtain silicon carbide powder granules; the process conditions of spray granulation are as follows: the slurry flow rate is 6Kg / h, and the hot air inlet temperature is 200°C;

[0030] 3) The above-mentioned silicon carbide powder granules are molded in a two-step manner of 100MPa dry pressure pre-pressure and 250MPa cold isostatic final p...

Embodiment 2

[0033] Embodiment 2: A preparation method of nanocomposite silicon carbide ceramics, with 80 parts of silicon carbide, 8 parts of yttrium aluminum garnet, 5 parts of nano silicon carbide, 2 parts of nano titanium carbide and 5 parts of nano titanium nitride as the main raw materials, Follow the steps in order:

[0034] 1) Add the above-mentioned main raw materials, 3 parts of phenolic resin, 2 parts of PVA and 1.5 parts of PEG into 150 parts of deionized water, and mix them by ball milling for 10 hours to prepare a water-based silicon carbide slurry;

[0035] 2) Spray-dry the above-mentioned water-based silicon carbide slurry by using a spray granulation process to obtain silicon carbide powder granules; the process conditions of the spray granulation are as follows: the slurry flow rate is 4Kg / h, and the hot air inlet temperature is 225°C;

[0036] 3) The above-mentioned silicon carbide powder granules are molded in a two-step manner of 100MPa dry pressure pre-pressure and 25...

Embodiment 3

[0039] Embodiment 3: A kind of preparation method of nanocomposite silicon carbide ceramics, with 75 parts of silicon carbide, 10 parts of yttrium aluminum garnet, 5 parts of nano-silicon carbide, 5 parts of nano-titanium carbide and 5 parts of nano-titanium nitride to form the main raw material, Follow the steps in order:

[0040]1) Add the above-mentioned main raw materials, 0.5 parts of dextrin, 1 part of PVA and 0.5 parts of TMAH into 90 parts of deionized water, and mix them by ball milling for 20 hours to prepare a water-based silicon carbide slurry;

[0041] 2) Spray-dry the above-mentioned water-based silicon carbide slurry by using a spray granulation process to obtain silicon carbide powder granules; the process conditions for spray granulation are as follows: the slurry flow rate is 3Kg / h, and the hot air inlet temperature is 250°C;

[0042] 3) The above-mentioned silicon carbide powder granules are molded in a two-step manner of 100MPa dry pressure pre-pressure and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Body dense | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com