Modified strengthened and toughened polyethylene solid-wall pipe and preparation method thereof

A technology of strengthening and toughening polyethylene, which is applied in the direction of rigid pipes, pipes, mechanical equipment, etc., can solve problems such as loss of technical interoperability and weakening of innovation awareness, and achieve the effects of expanding applications, ensuring quality, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

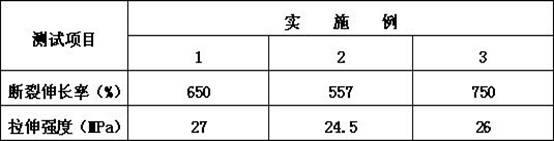

Embodiment 1

[0032] A) Material preparation, weigh 100 parts of waste recycled high-density polyethylene (granule), 20 parts of linear low-density polyethylene (granule), 15 parts of polyethylene primary color and metallocene catalyst (granule) by weight 6 parts, obtain raw material, the high-density polyethylene that the waste and old recycling described in this step is by the waste and old high-density polyethylene imported from Thailand, and the index of this waste and old high-density polyethylene is as follows: melt index is 0.65-0.75g / 10min ·5kg·190℃, the ash content is 1% (the ash content can also be called impurities), and the density is 0.965g / ㎝ 3 , the water content is ≤0.1%, and the tensile strength is 27MPa / ㎝ 2 , the linear low-density polyethylene described in this step selects the linear low-density polyethylene that does not contain anti-blocking agent and lubricant by the trade mark that China Daqing Petrochemical General Plant Plastic Factory produces and sells, ...

Embodiment 2

[0037] Only change the index value of waste recycled high-density polyethylene (waste high-density polyethylene) in step A) to: melt index of 0.55-0.65g / 10min·5kg·190°C, ash content of 2%, and density of 0.955 g / ㎝ 3 , the water content is 0.05%, and the tensile strength is 24MPa / ㎝ 2 , change the parts by weight of linear low-density polyethylene to 18 parts, change the parts by weight of polyethylene primary color material to 11 parts, and select the brand of JHMGC100S produced and sold by Jilin Petrochemical Branch of China National Petroleum and Natural Gas Co., Ltd. For polyethylene primary pigments, change the parts by weight of the metallocene catalyst to 3 parts; only change the speed of the mixer in step B) to 20n / min, and change the mixing time to 2min; only change the drying temperature in step C) to Change the moisture content of the mixture to 0.08%; only change the temperature of the first zone to the fourth zone in step D): 170°C for the first zone, 180°...

Embodiment 3

[0039] Only change the index value of the waste recovered high-density polyethylene in step A), that is, the waste high-density polyethylene: the melt index is 0.75-0.85g / 10min·5kg·190°C, the ash content is 1.5%, and the density is 0.960 g / ㎝ 3 , the water content is 0.08%, and the tensile strength is 25.5MPa / ㎝ 2 , change the parts by weight of linear low density polyethylene to 30 parts, change the parts by weight of polyethylene primary pigment to 8 parts, and change the parts by weight of metallocene catalyst to 4.5 parts; only change the parts by weight of step B) Change the speed of the mixer to 22n / min, and change the mixing time to 3min; only change the drying temperature in step C) to 55°C, and change the moisture content of the mixture to 0.06%; The temperature of the zone was changed to: 172°C in the first zone, 175°C in the second zone, 180°C in the third zone, and 160°C in the fourth zone. All the other are the same as the description to embodiment 1.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com