Patents

Literature

36results about How to "Improve cutting and crushing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

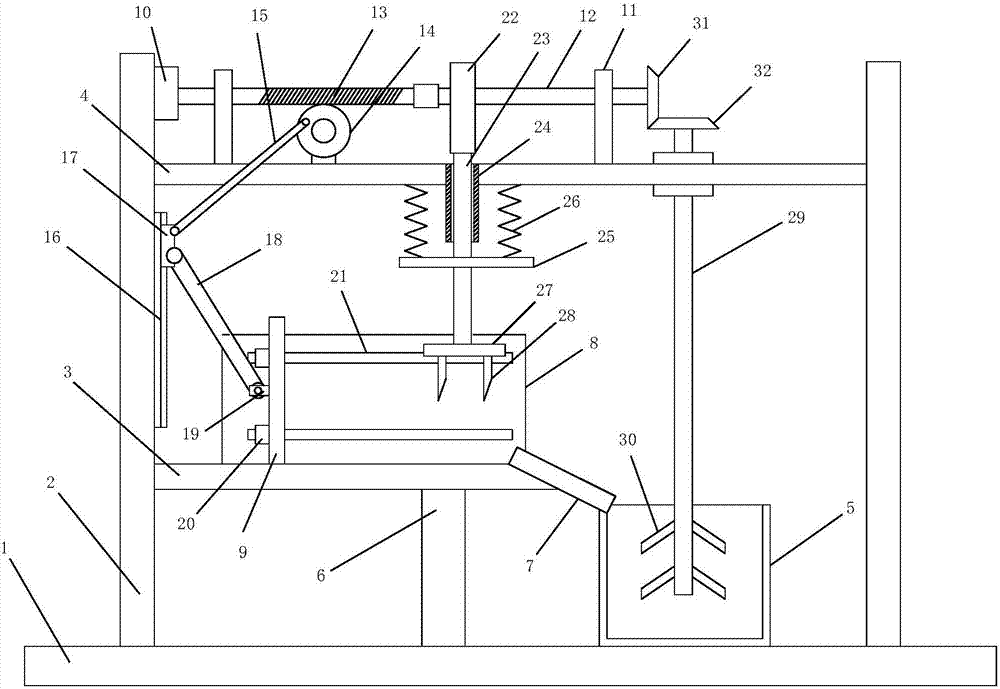

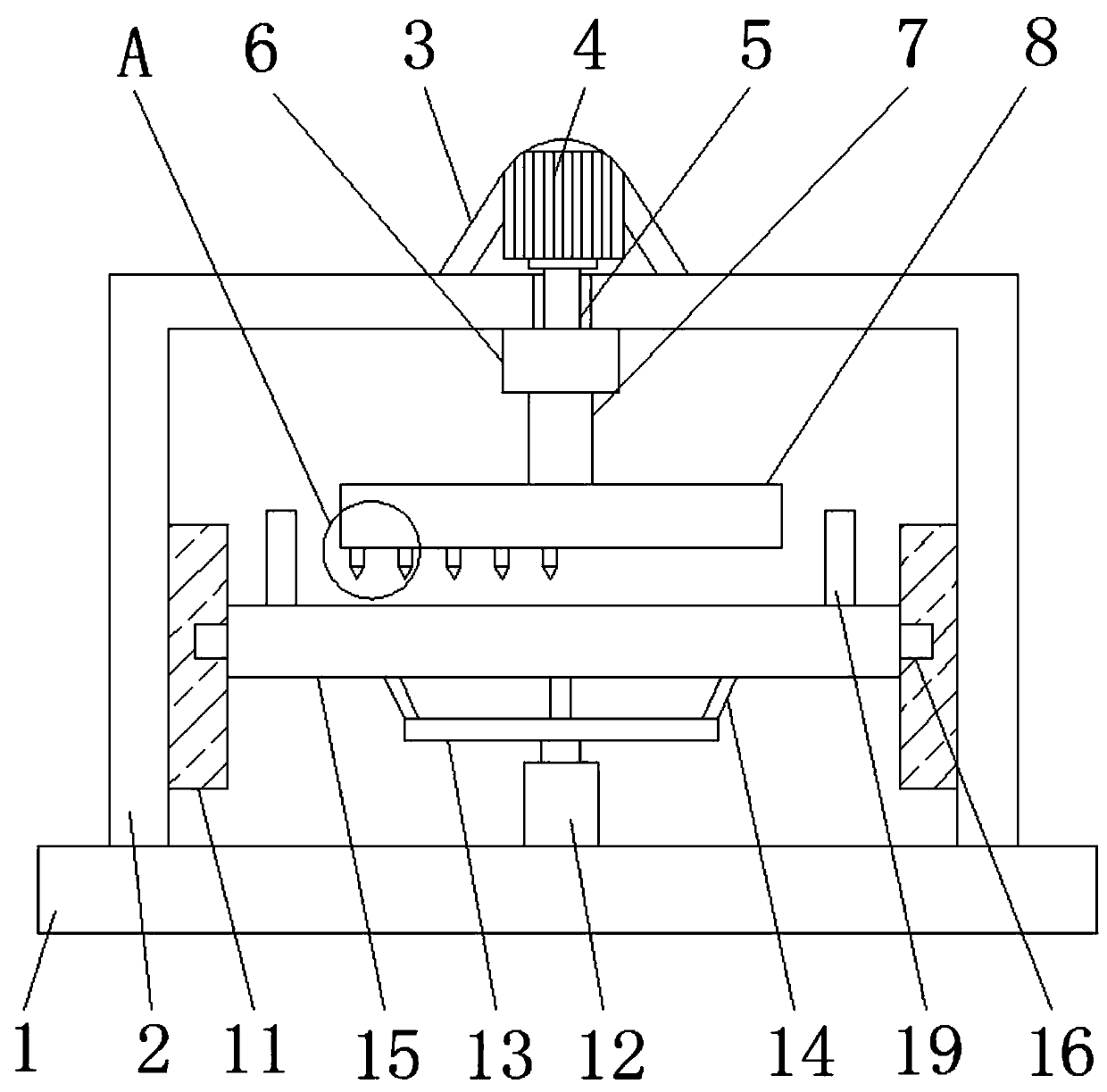

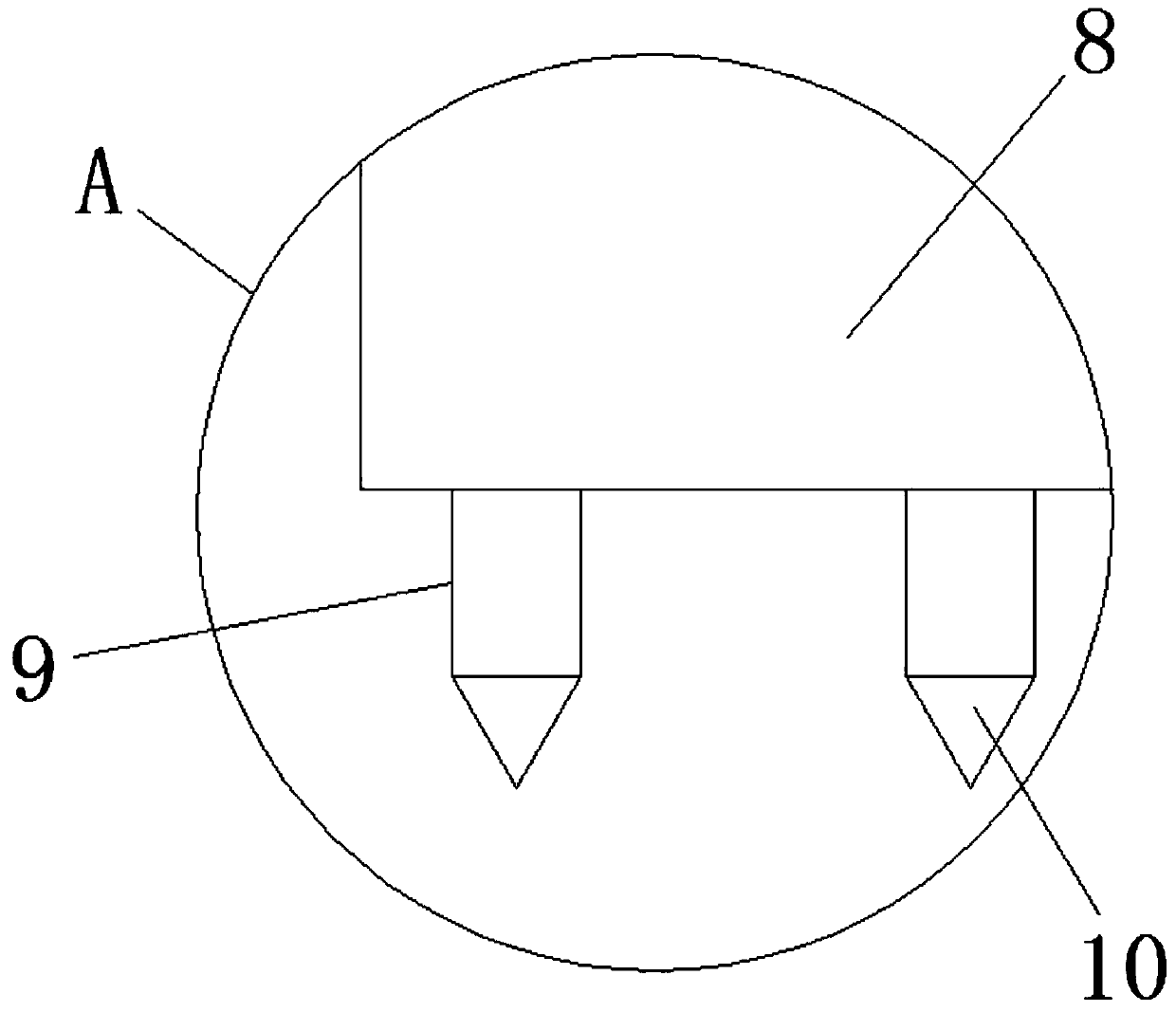

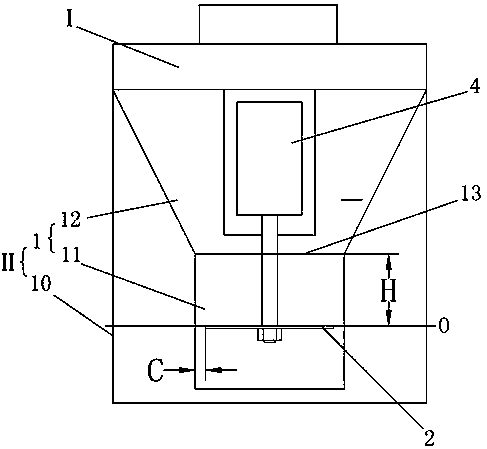

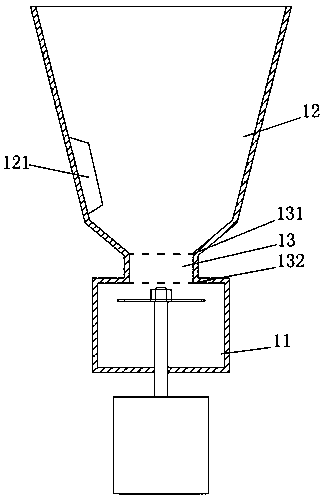

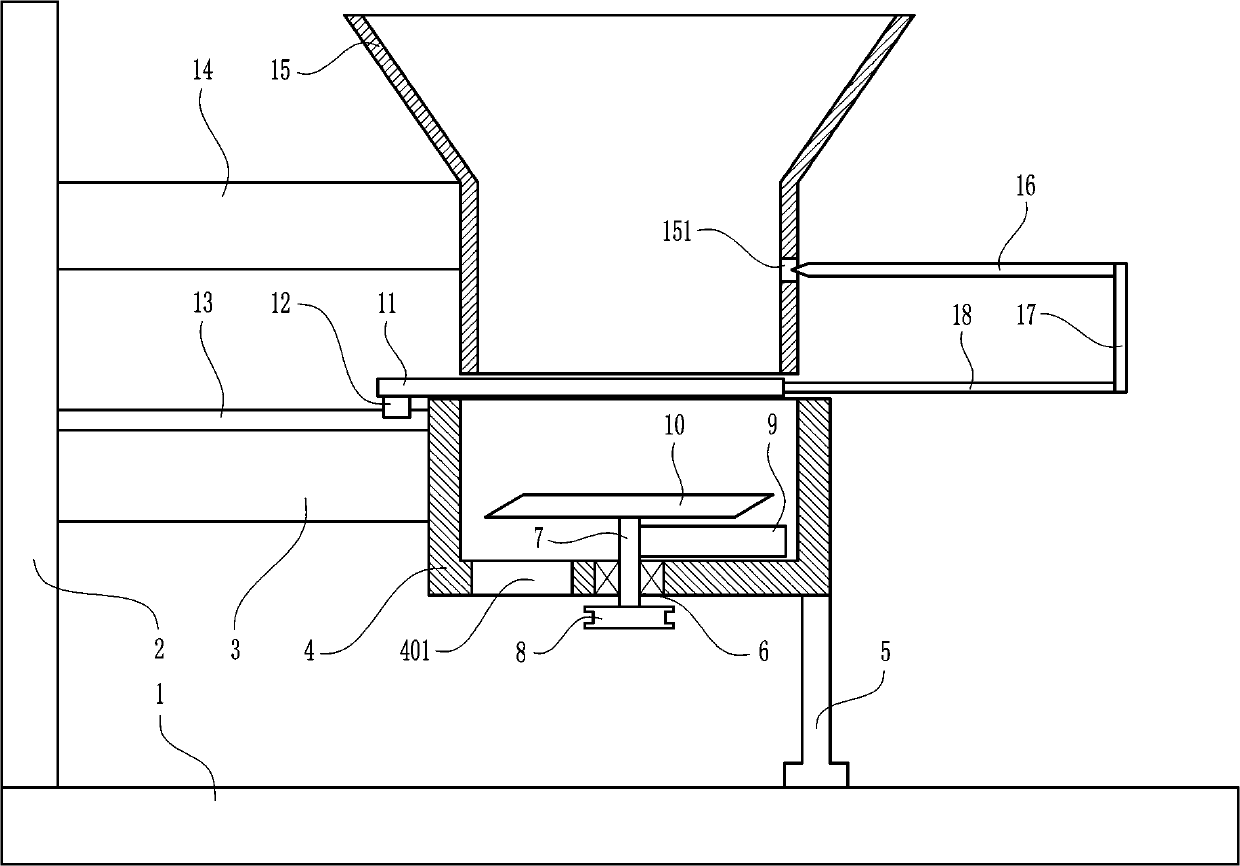

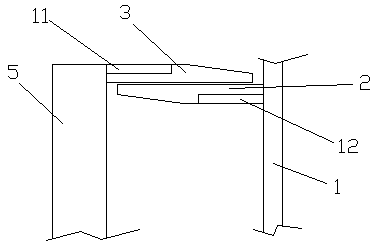

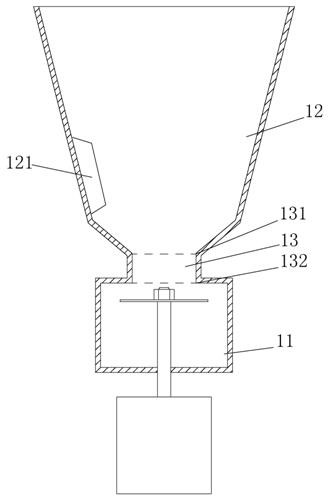

Efficient straw cutting and crushing device for animal husbandry

InactiveCN106900300AImprove cutting and crushing efficiencyHigh cutting and crushing efficiencyCuttersCamAnimal husbandry

The invention discloses an efficient straw cutting and crushing device for animal husbandry. The efficient straw cutting and crushing device comprises a bottom plate, an obliquely downward connecting groove is formed in a right side of a supporting plate, a rotating shaft and a worm are respectively arranged on two brackets, a worm wheel engaged with the worm is arranged below the worm, a first connecting rod is arranged on a side face of the worm wheel, a vertically downward slide rail is arranged on a vertical plate, a vertical push plate is arranged on an upper end face of the supporting plate, baffles are arranged on two sides of the push plate, a second connecting rod having one end hinged with a mounting frame is arranged on the mounting frame, a cam is arranged on one end of the rotating shaft close to the worm, a vertically downward push rod is arranged on a lower end of the cam, a cutting tool is installed on a tool mounting frame, a crushing rotating shaft is arranged on a top plate, and a crushing tool is installed on the lower end of the crushing rotating shaft. The efficient straw cutting and crushing device disclosed by the invention has a simple structure and can cut and crush straws at the same time, the straw cutting and crushing efficiency is relatively high, the crushing effect is good, and no manual operation is required, thereby saving labor. The practicability is relatively high.

Owner:惠安县长捷机械科技有限公司

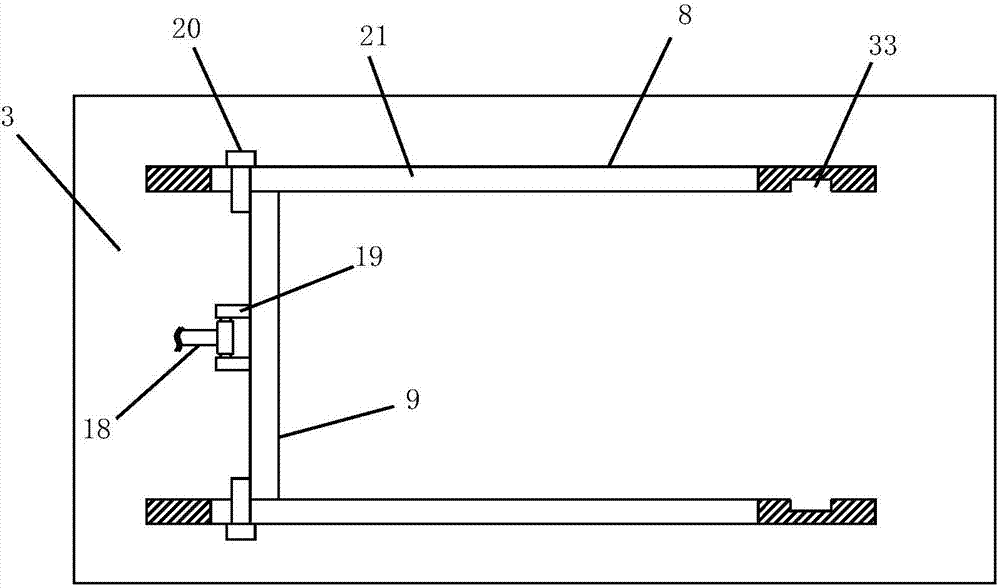

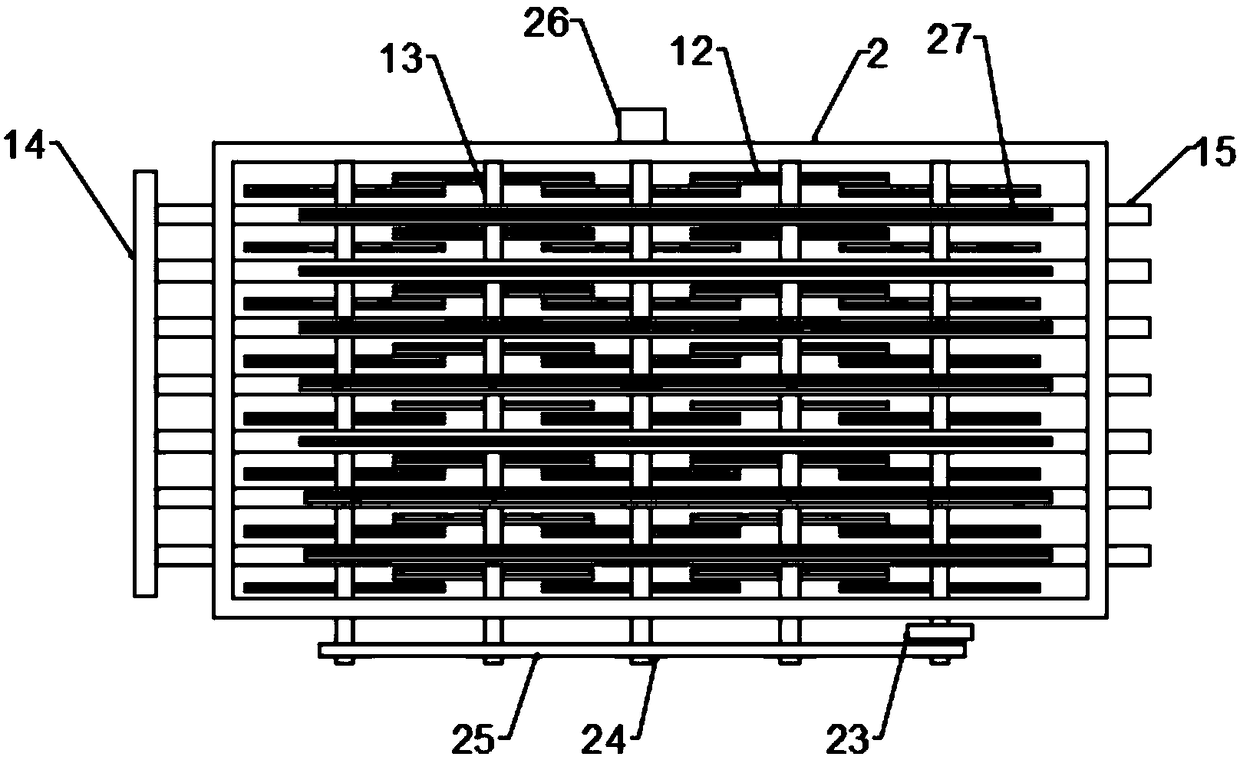

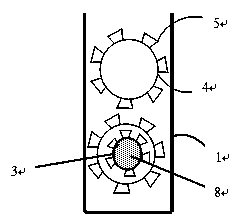

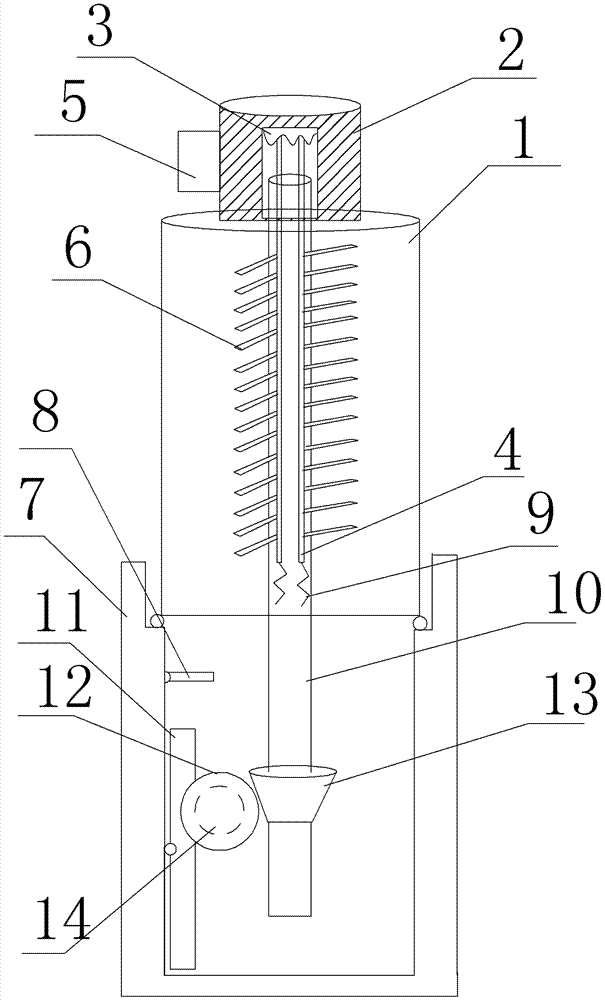

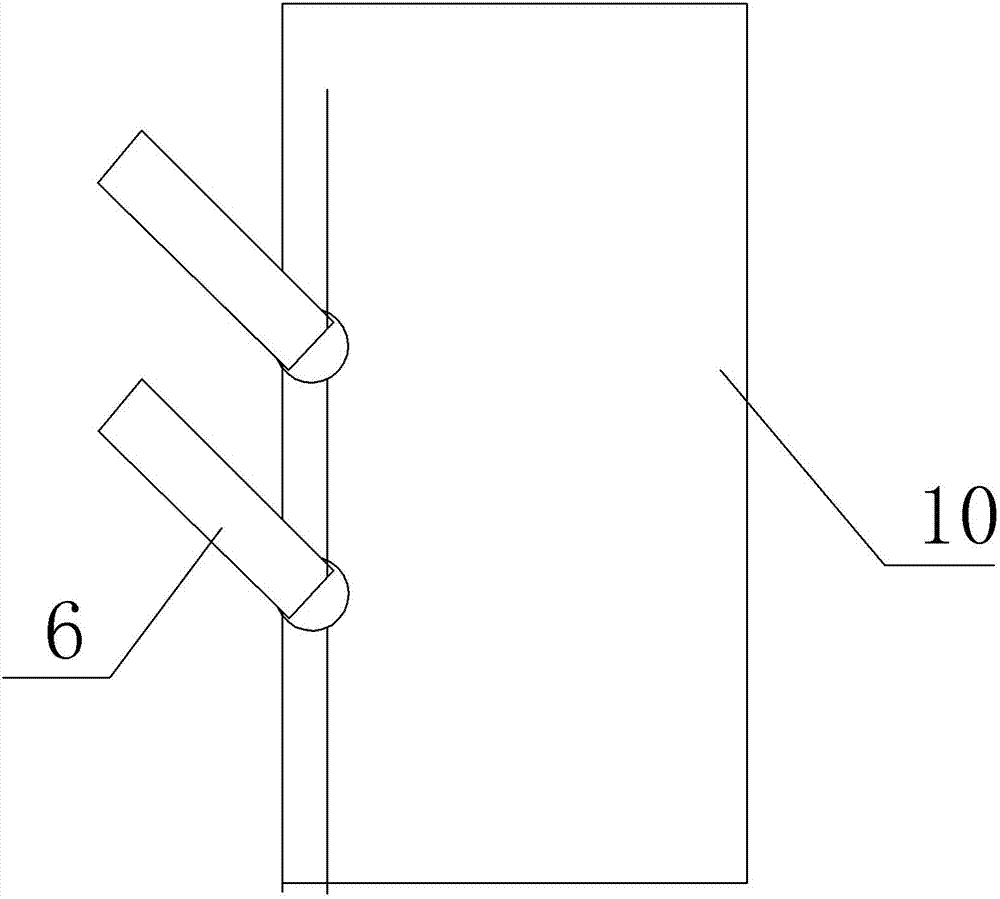

Straw crushing device for livestock breeding

InactiveCN107624387AFully crushed and refinedGuaranteed normal cuttingShaking/oscillating/vibrating mixersUsing liquid separation agentSlagScrew thread

The invention discloses a straw crushing device for livestock breeding. The straw crushing device includes an operating room, a horizontal rod is fixedly arranged inside the operating room in a horizontal mode, a sliding rod is arranged penetratingly on the horizontal rod in a vertical sliding mode, the upper end of the sliding rod is connected with the end, away from a hanging rod, of a rotatingplate in a hinged mode, a number of cutting blades are arranged at equal spacing on the bottom of a connecting plate, locking screws are arranged on screw holes in a penetrating mode, and the lockingscrews are connected with the connecting plate in threaded fit; a number of crushing blades are arranged on the surface of a rotating shaft uniformly, and a water inlet pipe connected with an externalwater source is arranged on a water drawing sleeve. The straw crushing device for livestock breeding is ingenious in structure and convenient to operate, and a first crushing effect is achieved through straws receiving the cutting handling of the cutting blade and then receiving the rotary cutting and crushing of the crushing blades, the situation that longer straws clamp crushing blades is avoided, meanwhile the straws receive full crushing refinement, the straws sandwiched between the cutting blades or stuck on the cutting blades can be removed through the removal of a slag filter plate, and the normal cutting of the straws by the cutting blades is ensured.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

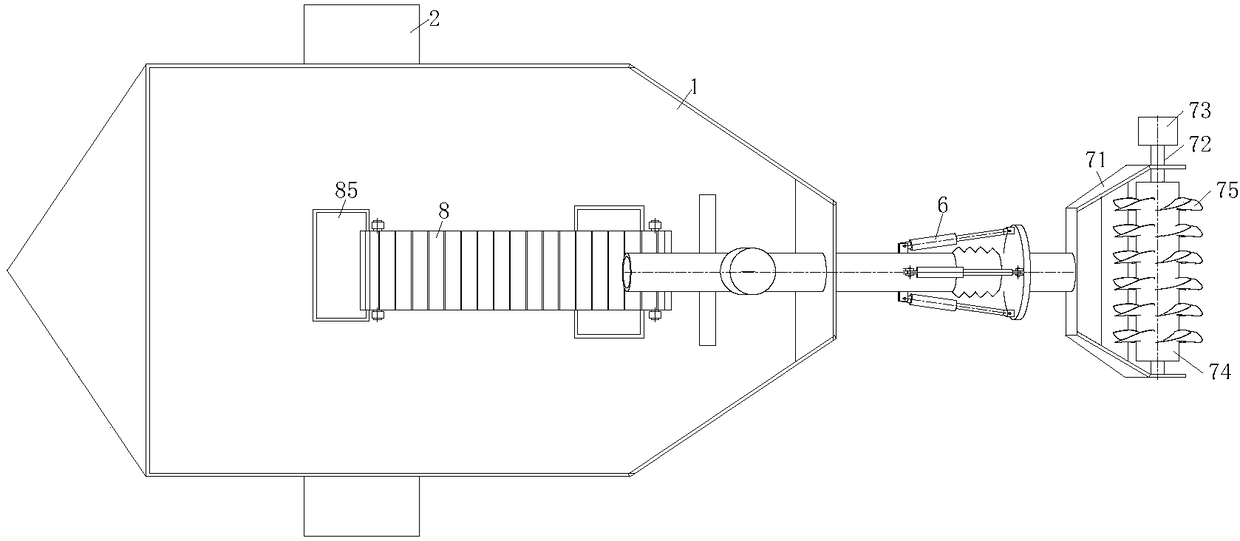

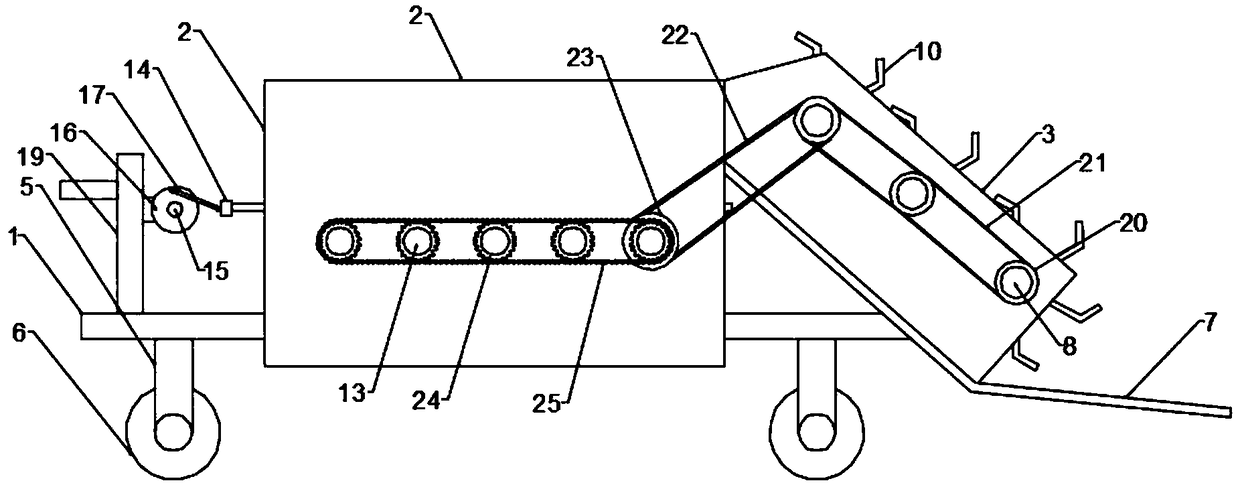

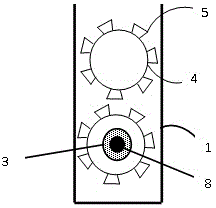

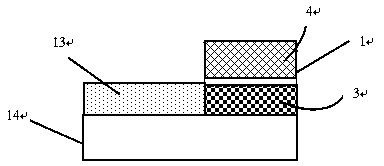

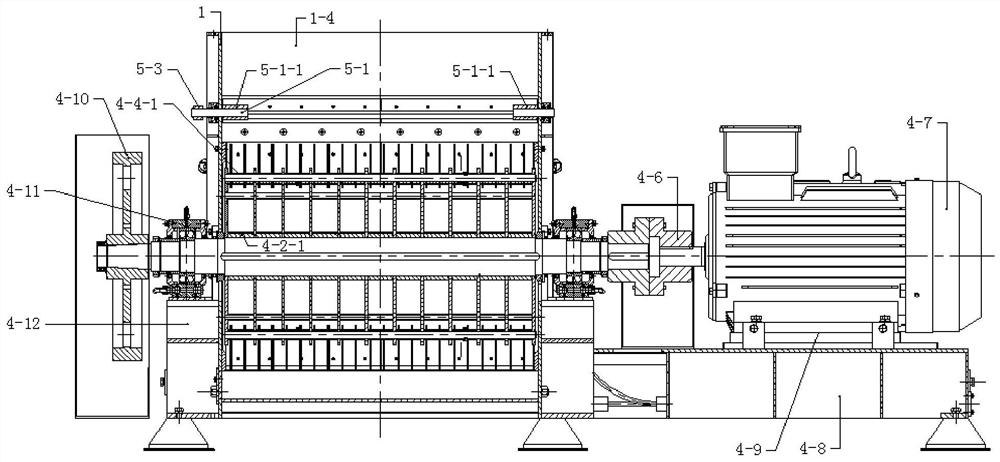

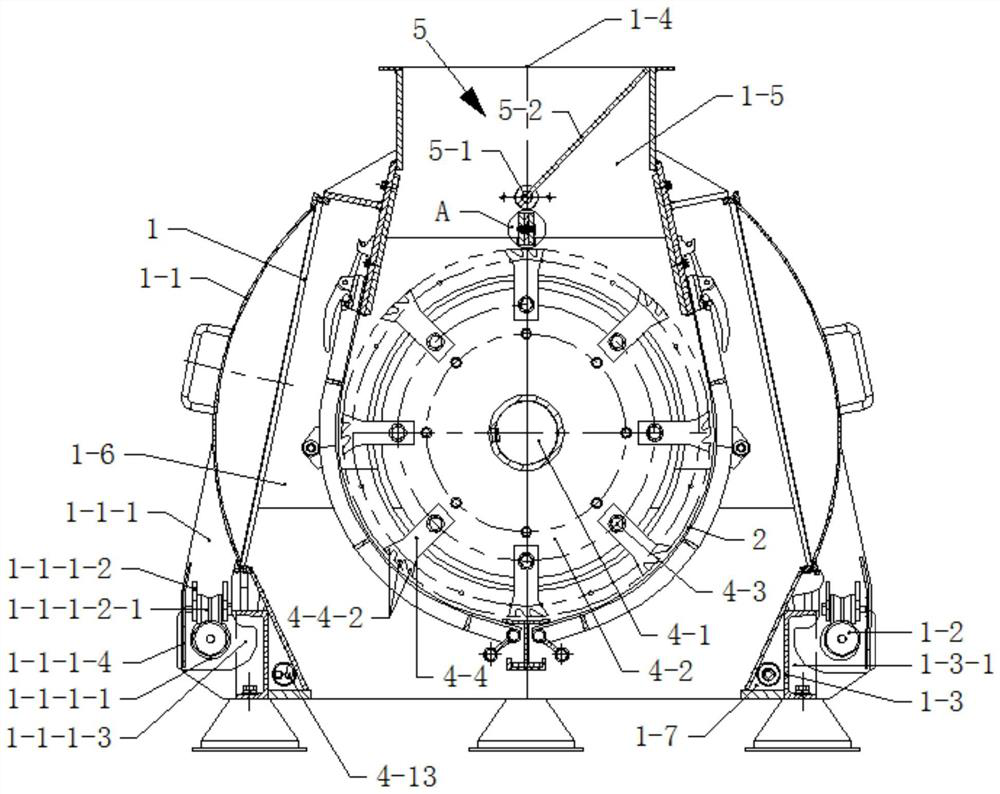

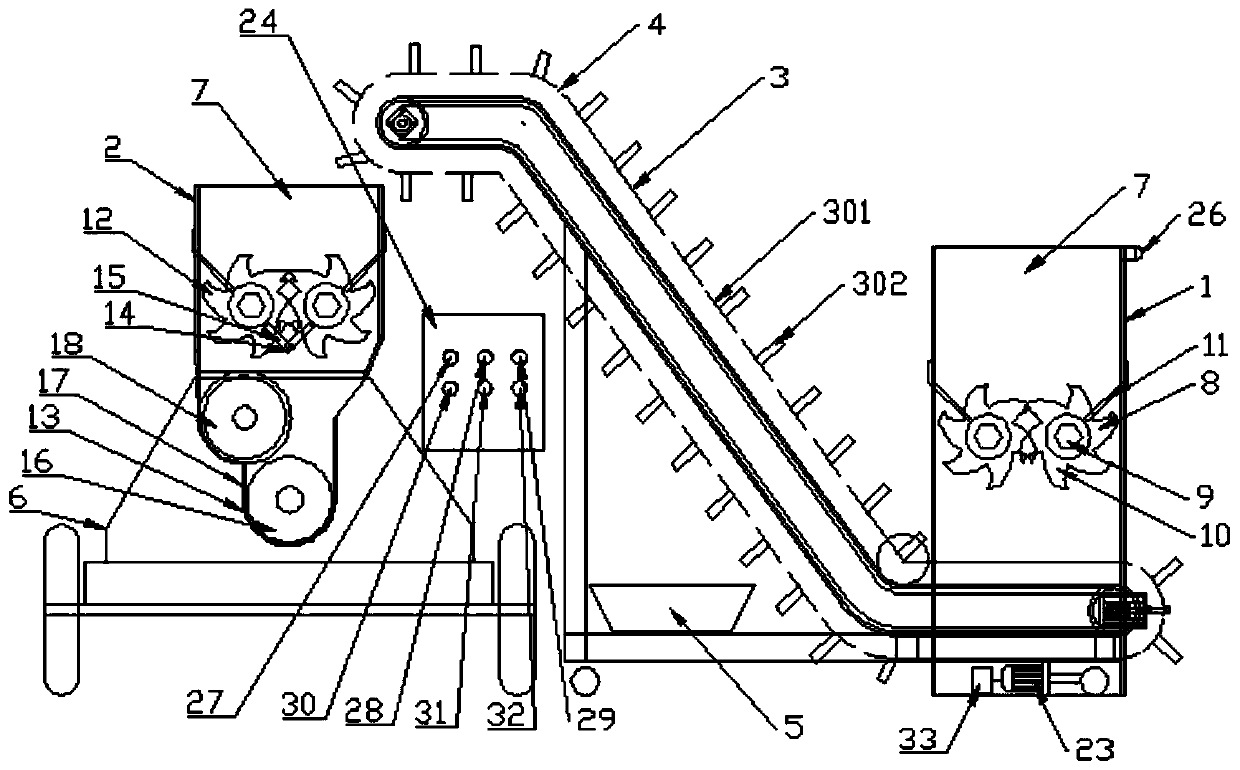

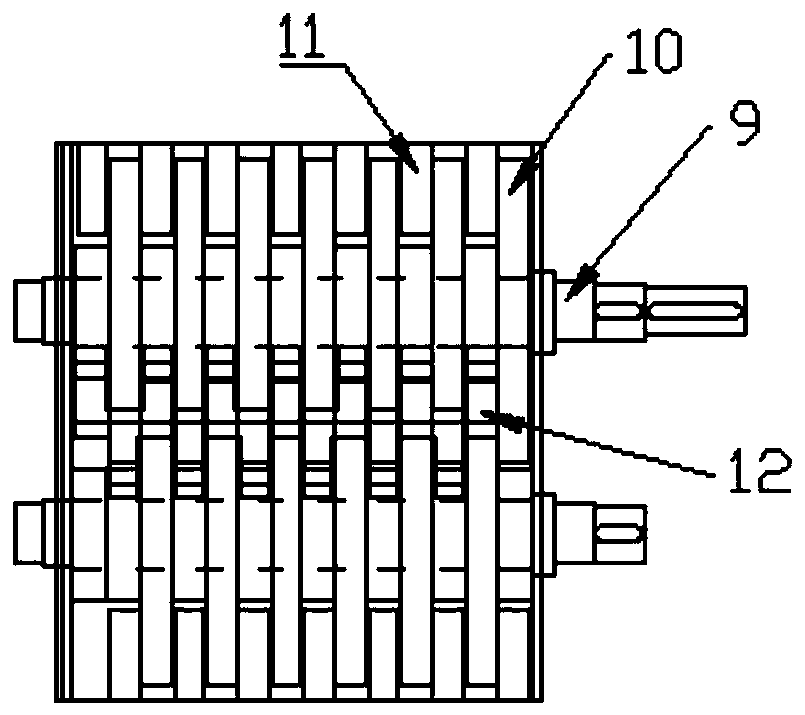

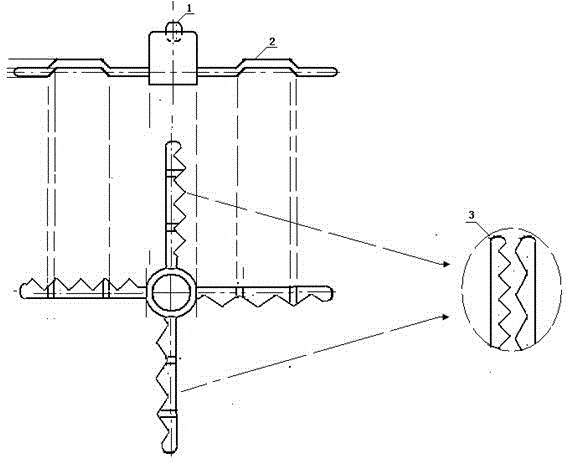

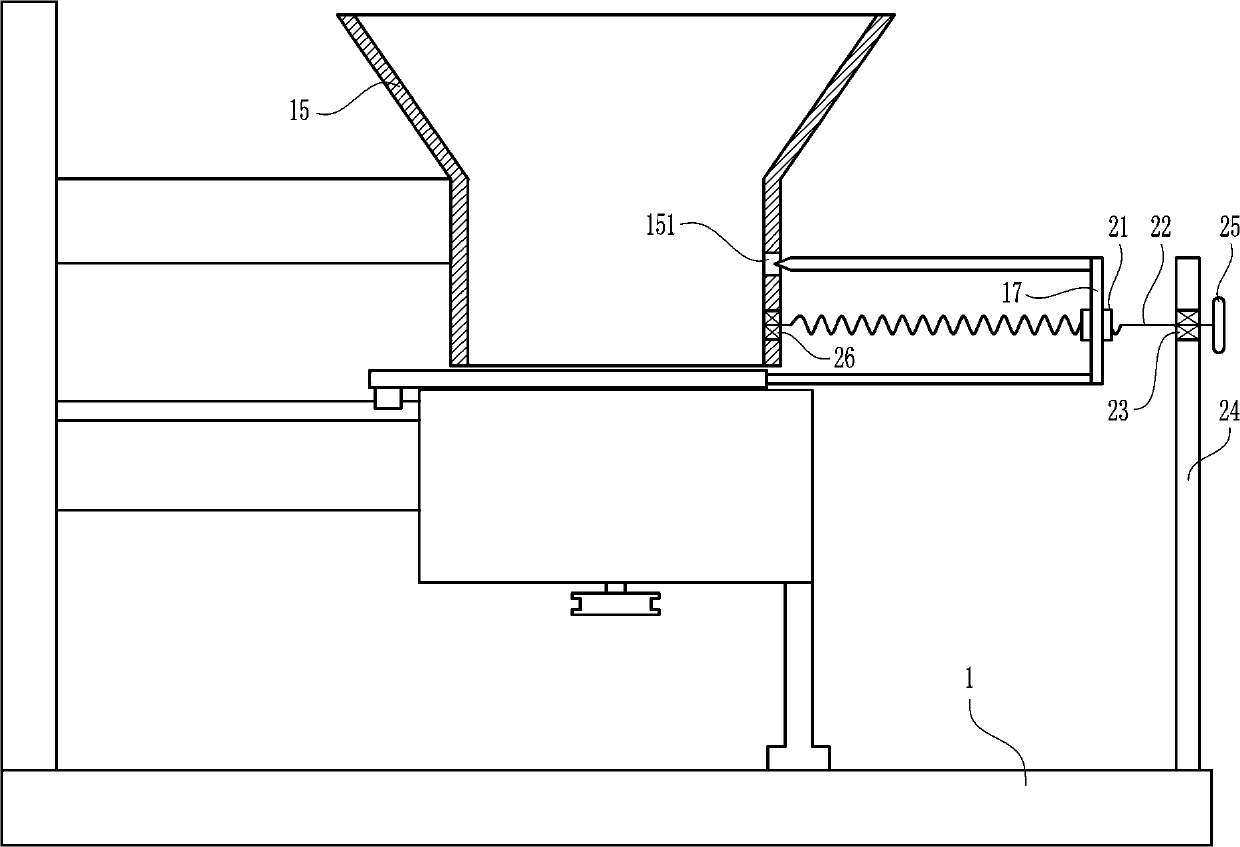

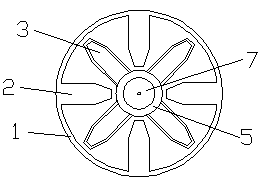

Smashing device and smashing and squeezing integrated device with same

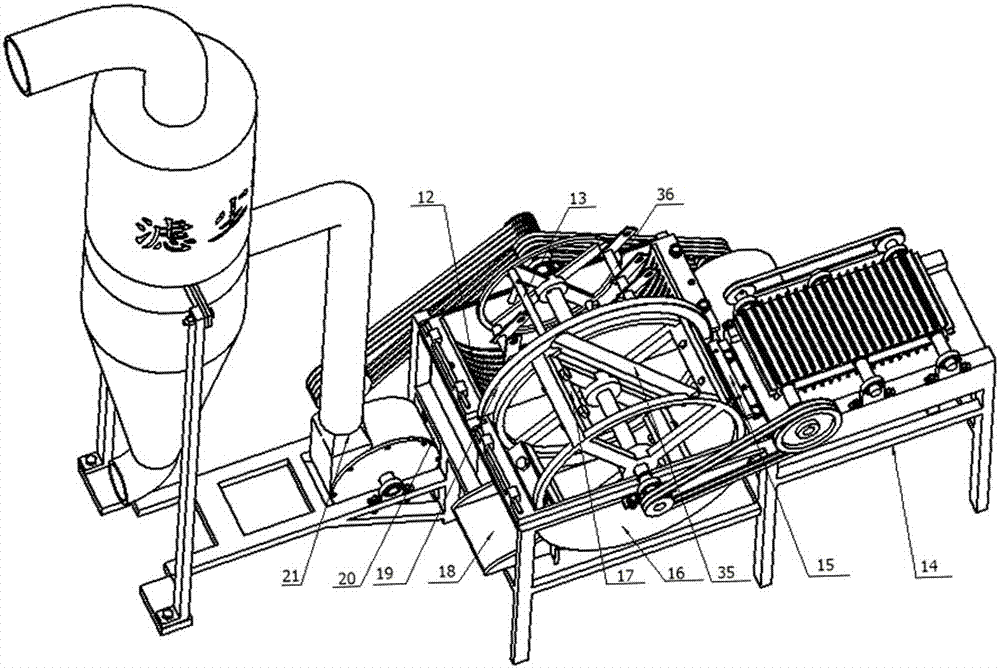

ActiveCN106733074AImprove cutting and crushing efficiencyAvoid entanglementFeeding-stuffGrain treatmentsEngineeringMachine

The invention belongs to the field of feed processing devices and particularly relates to a smashing device and a smashing and squeezing integrated device with the smashing device. The smashing device comprises a machine frame and two rollers which are arranged below a feeding port and rotate oppositely. Each roller is provided with wheel tooth type movable cutters arranged spirally. The movable cutters on the two rollers are mutually staggered in the axial direction of the rollers. Upper fixed cutters are installed on the machine frame at intervals and located on the two sides of the portion below the feeding opening. The upper fixed cutters are meshed with the movable cutters. According to the smashing device and the smashing and squeezing integrated device with the smashing device, the double rollers are adopted and conduct smashing and cutting oppositely, the upper fixed cutters are also arranged, so that the problem that when straws of bananas and other crops are smashed and cut, the straws slide and are not prone to being cut off is solved, and the cutting and smashing efficiency is improved. The whole smashing and squeezing integrated device with the smashing device is simple in structure and easy to maintain, and intelligent control can be achieved for different working conditions at the same time; the whole smashing and squeezing integrated device with the smashing device can be disassembled, disassembled devices can be independently used, the feed processing efficiency and machining quality can be greatly improved, and the smashing device and the smashing and squeezing integrated device with the smashing device are particularly suitable for machining of banana straws.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

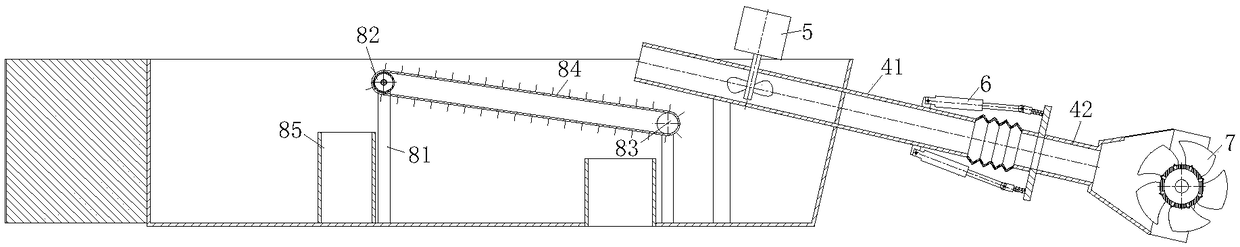

Ship for clearing alternanthera philoxeroides in complex water area

ActiveCN108082402AEasy to cleanRealize multi-angle rotationWater cleaningWaterborne vesselsDrive wheelMarine engineering

The invention belongs to the technical field of clearing of harmful aquatic plants and particularly relates to a ship for clearing alternanthera philoxeroides in a complex water area. The ship comprises a ship body, driving wheels, a support, a conveying pipe, a centrifugal pump, direction adjusting units, a cutting module and a collecting unit; the driving wheels are arranged on the two sides ofthe ship body; the support is arranged on the front portion of the ship body; the conveying pipe is fixedly connected to the upper end of the support; the centrifugal pump is arranged at the upper endof the conveying pipe; the direction adjusting units are arranged in the middle of the conveying pipe and each comprise an elastic rubber sheet, an air cylinder, a universal joint, a telescopic rod and a damping spring; the cutting module is arranged at one end of the conveying pipe and comprises a shell, a rotating shaft, a waterproof motor, a rolling shaft and a cutting piece; angular transformation of the cutting module can be achieved through the direction adjusting units; the collecting unit is arranged at the other end of the conveying pipe; and the centrifugal pump conveys the alternanthera philoxeroides crushed by the cutting module to the collecting unit for storage. The ship is suitable for clearing work of the alternanthera philoxeroides in the complex water area, the structureis simple, and the working efficiency is high.

Owner:解波

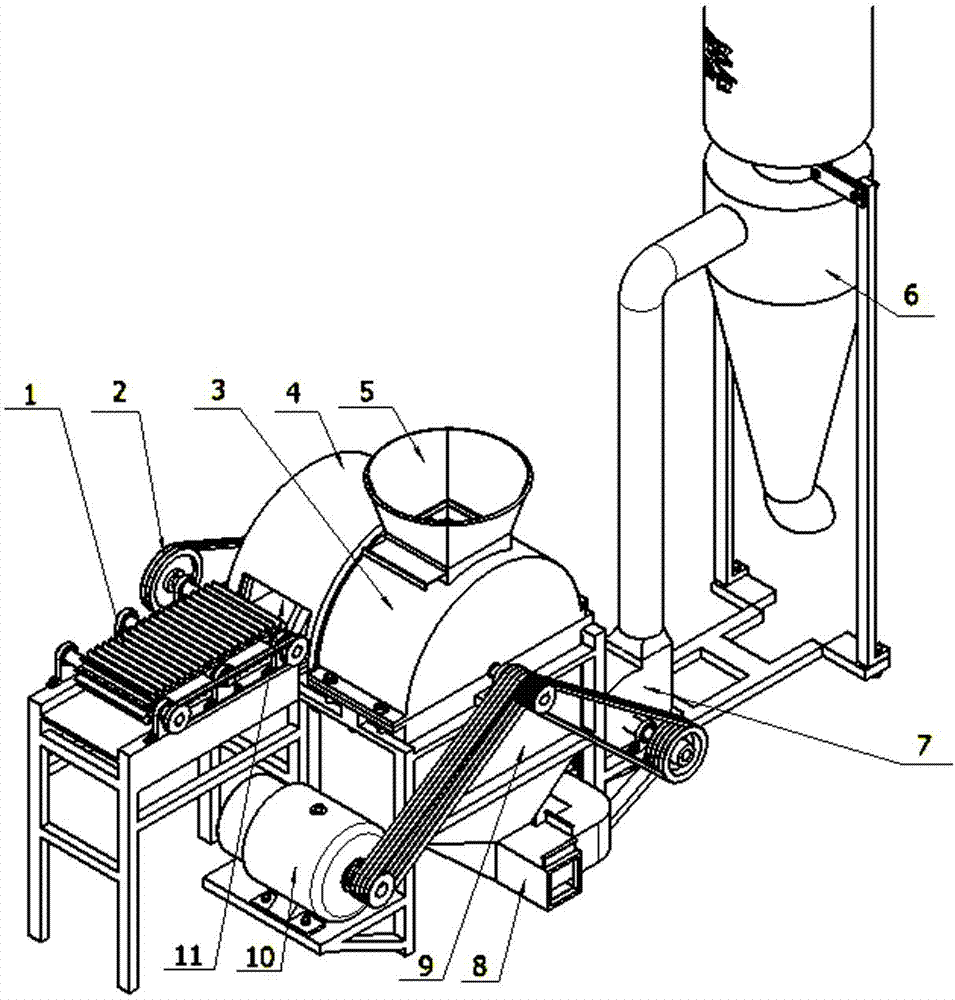

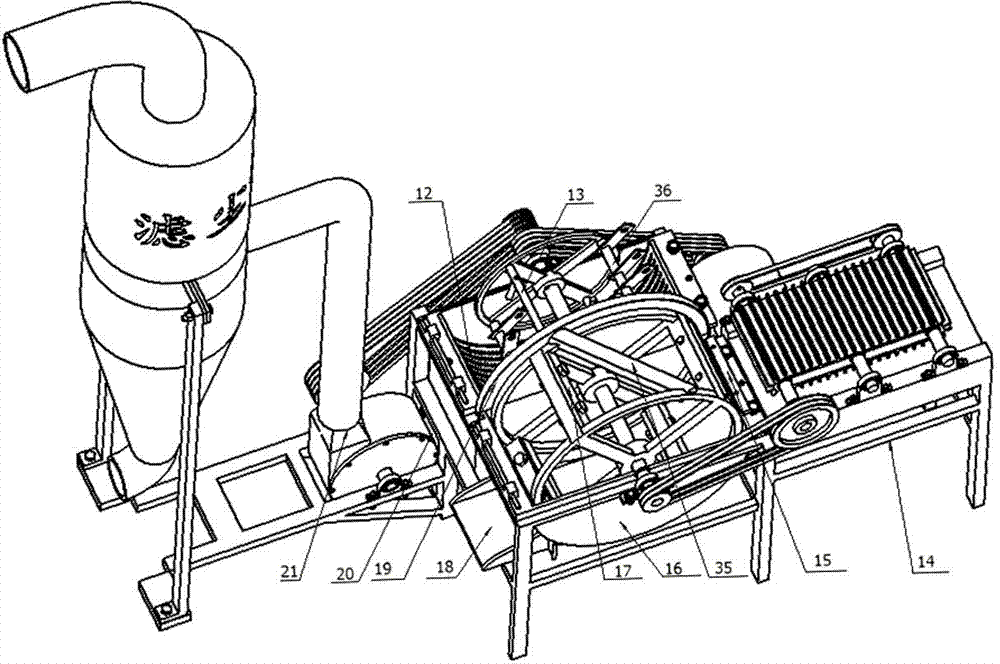

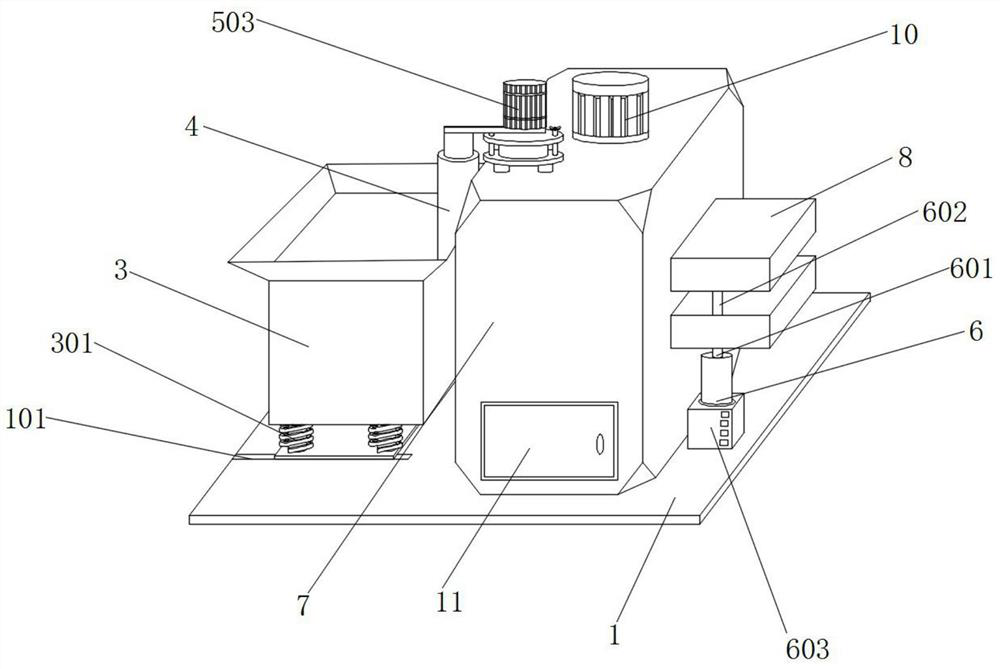

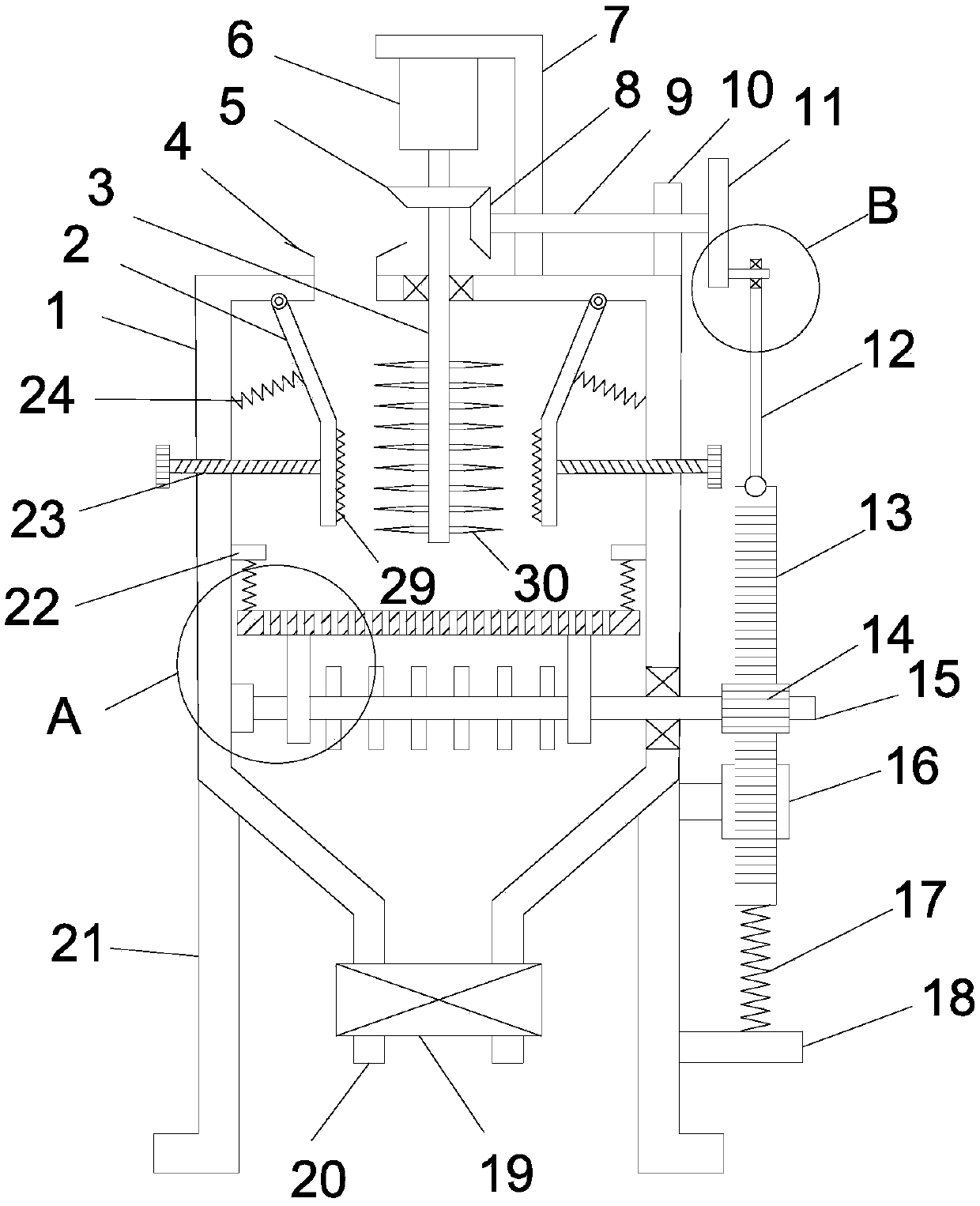

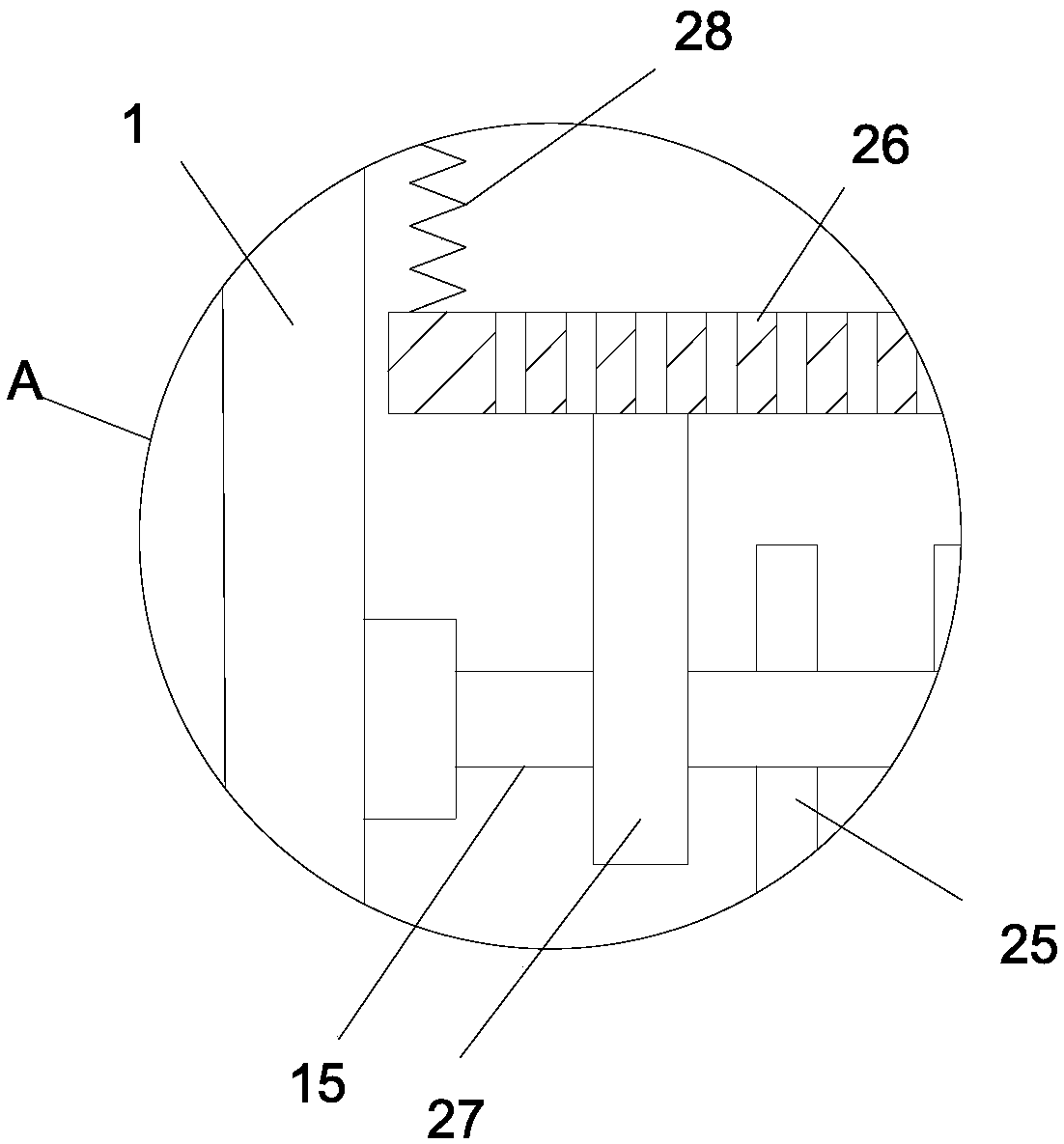

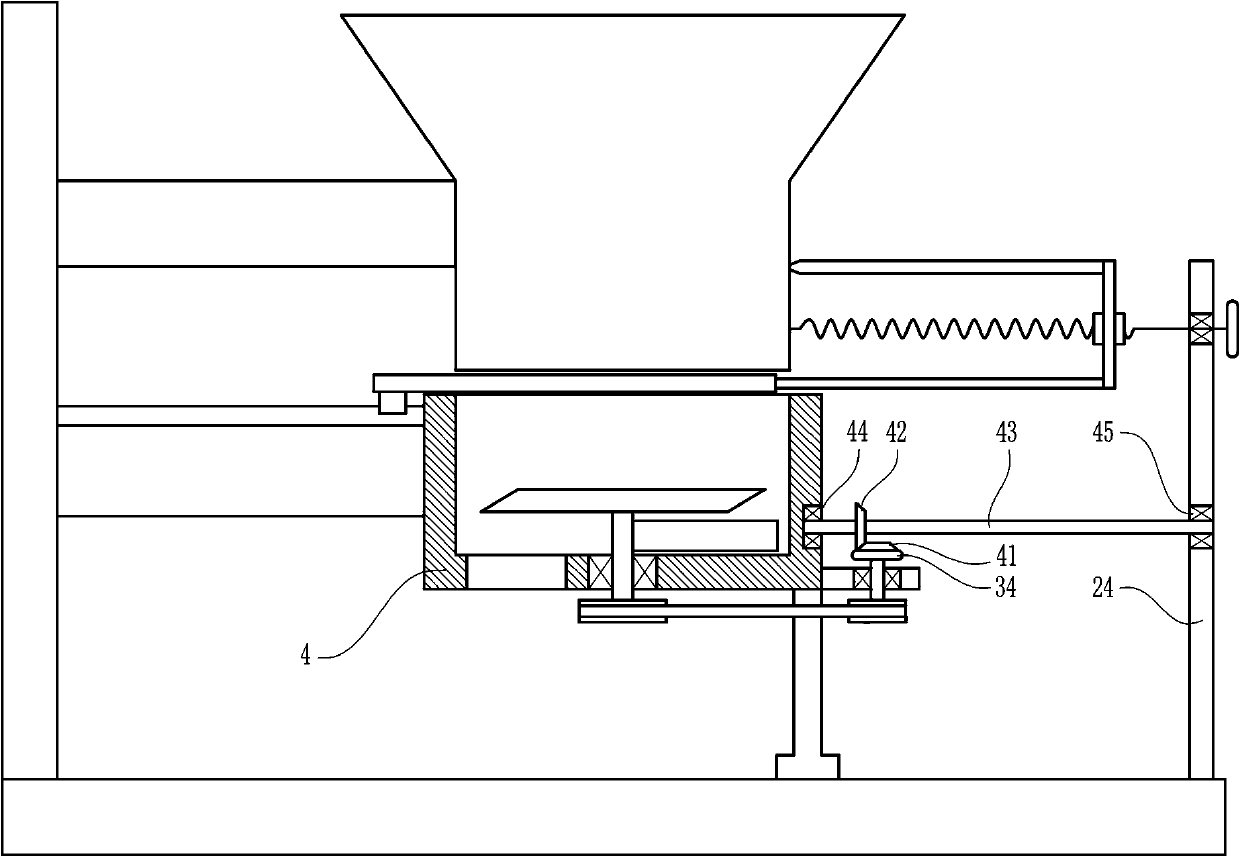

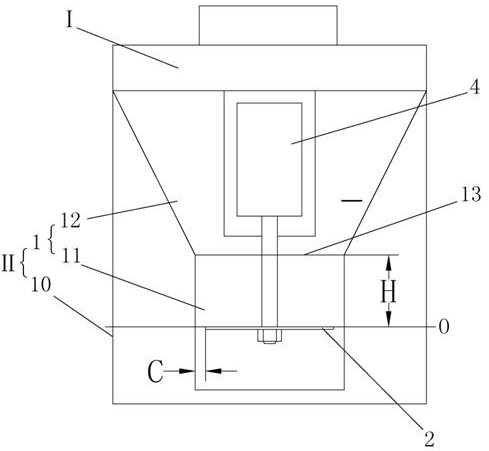

Novel crushing and dehydrating feed processing equipment

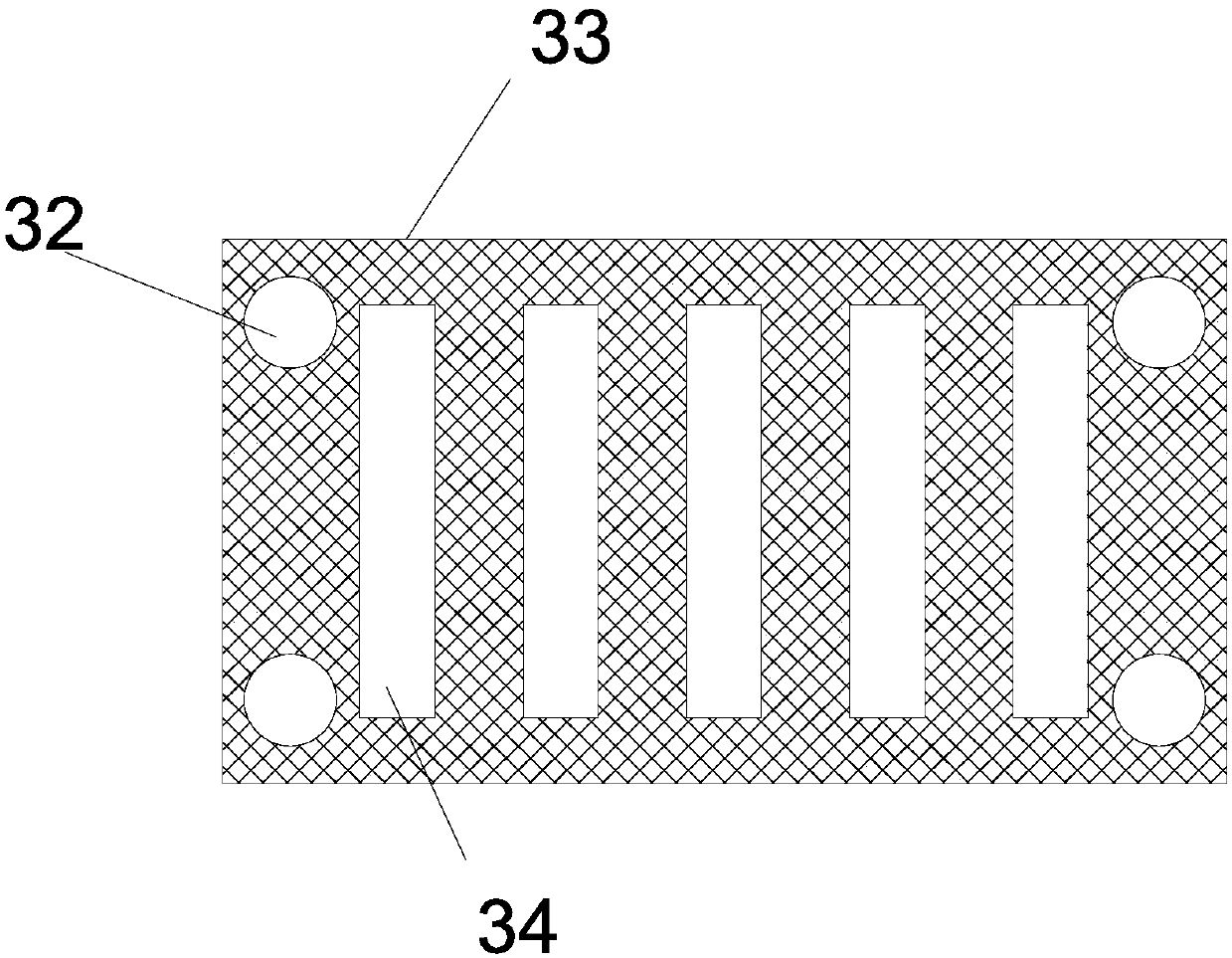

InactiveCN105618213AImprove cutting and crushing efficiencyImprove dehydration efficiencyFeeding-stuffGrain treatmentsFeed processingEngineering

The invention belongs to the field of feed processing equipment, and in particular, provides novel crushing and dehydrating feed processing equipment. The equipment comprises a frame, a feed port, a discharge port, a crushing mechanism and a dehydrating mechanism; the crushing mechanism includes two rotating shafts relatively rotating from top to bottom and from outside to inside, and movable cutter sets arranged at intervals in the axial directions of the rotating shafts; the dehydrating mechanism includes a spiral shaft and an annular filter screen arranged at the outer periphery of the spiral shaft; and the dehydrating structure is positioned below the crushing mechanism. The equipment adopts two rods to oppositely crush and cut, so that such problems as slip of such crop straws as bananas and difficult cutting-off are solved, and the cutting and crushing efficiency is improved; and the equipment adopts spiral dehydration, so that the dehydrating efficiency is higher. The whole equipment is simple and compact in structure and low in cost, can improve the feed processing efficiency and processing quality, and is specifically suitable for such medium and small silage processing enterprises as cooperatives.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

Float removing device used for water treatment

InactiveCN111139807ARelieve pressureImprove cleaning efficiencyWater cleaningGrain treatmentsElectric machineryWater treatment

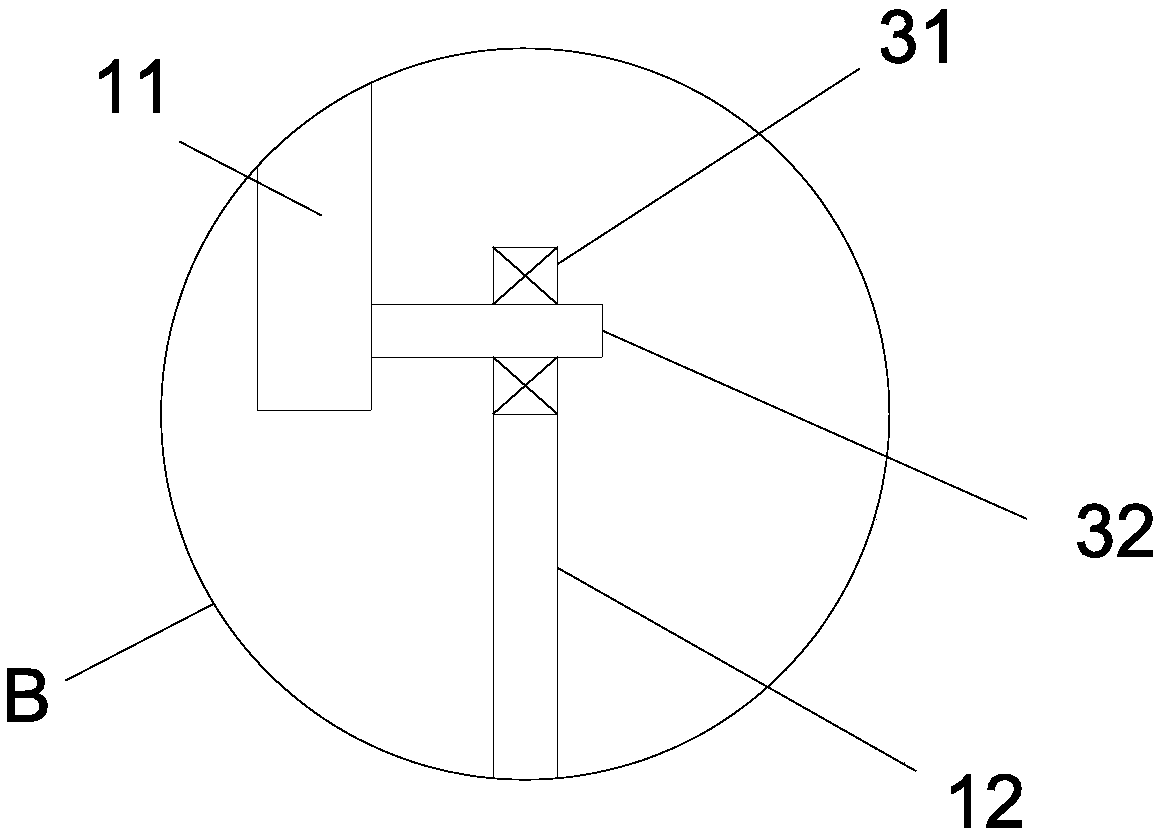

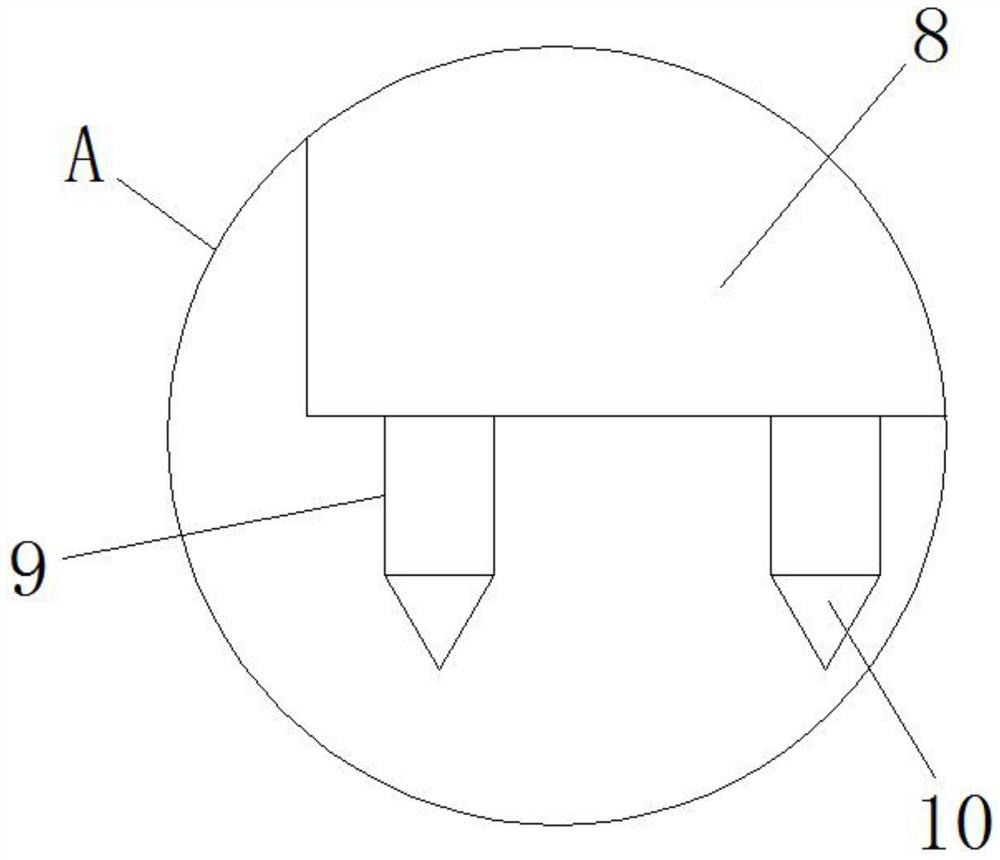

The invention relates to the field of environment-friendly equipment and particularly discloses a float removing device used for water treatment. The float removing device comprises a shell, a floating cylinder, a smashing device and a box body. A first channel communicating with the interior of the box body is arranged at one end of the shell, and a second channel communicating with the interiorof the box body is arranged at the other end of the shell. A breaking device is further arranged at the end, provided with the first channel, of the shell. The breaking device comprises a first motor,a cutting tool and a breaking tool which are arranged on the shell. The vertical breaking tool is arranged below the cutting tool which is transversely arranged. A drive device is arranged in the second channel, and when the drive device pushes the float removing device used for water treatment to move in water, negative pressure can be generated in the box body and in the first channel, and floats smashed by the smashing device are sucked into the box body. By means of the float removing device used for water treatment, in the moving process, the floats in water are sucked into the shell andthe box body and are collected through the box body, various floats in water can be removed, the water quality is optimized, and the water body cleaning efficiency is improved.

Owner:CHENGDU HENGLIDA TECH

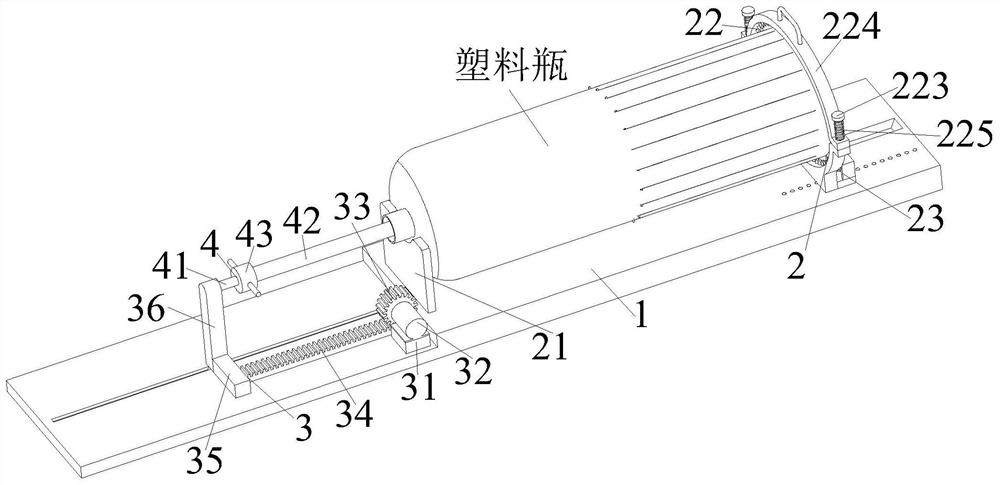

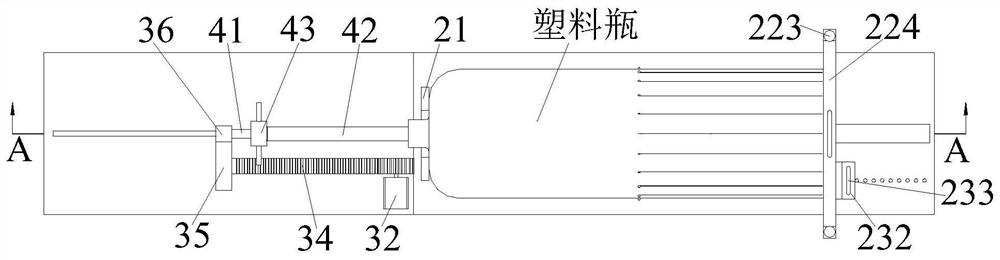

Waste plastic bottle recycling treatment method

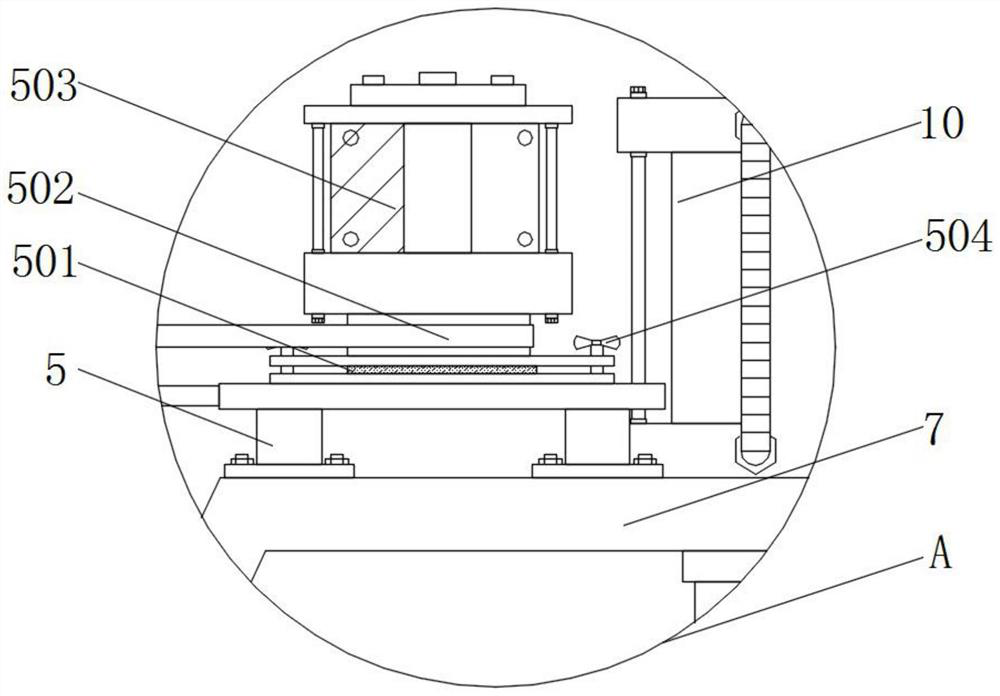

InactiveCN112476861AImprove cutting and crushing efficiencyAvoid injuryPlastic recyclingMechanical material recoveryProcess engineeringPolluted environment

The invention relates to a waste plastic bottle recycling treatment method. The method comprises a bottom plate, a clamping device, a moving device and a cutting device, wherein the clamping device isarranged at the right side of the upper end of the bottom plate,; the moving device is arranged at the left side of the clamping device; the moving device is arranged at the left side of the upper end of the bottom plate; and the cutting device is arranged at the upper end of the right side of the moving device. The waste plastic bottle recycling treatment method provided by the invention solvesthe problems that during manual crushing, the crushing process is tedious, workers are prone to being hurt in the crushing process, and consequently the waste plastic bottle recycling efficiency is low, and when existing waste plastic bottle recycling equipment recycles waste plastic bottles, the waste plastic bottles are directly cut and crushed through the cutting device, the waste plastic bottles are prone to being crushed to be small in size in the cutting and crushing process of the cutting device, the crushed waste plastic is lost in the cleaning process, the crushed waste plastic bottles with the small size pollute the environment and the like.

Owner:南京研塑环保科技有限公司

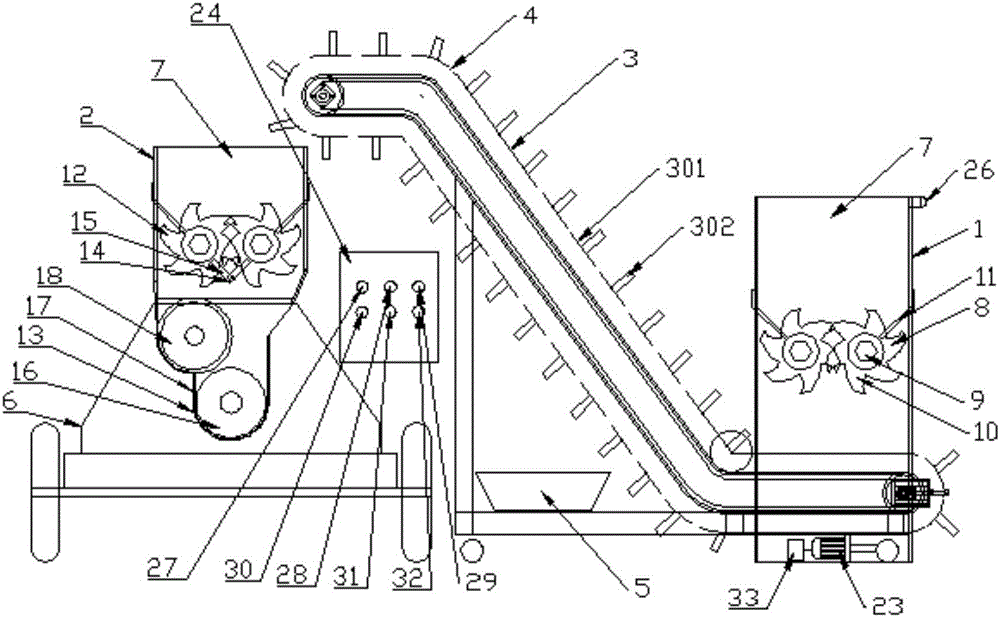

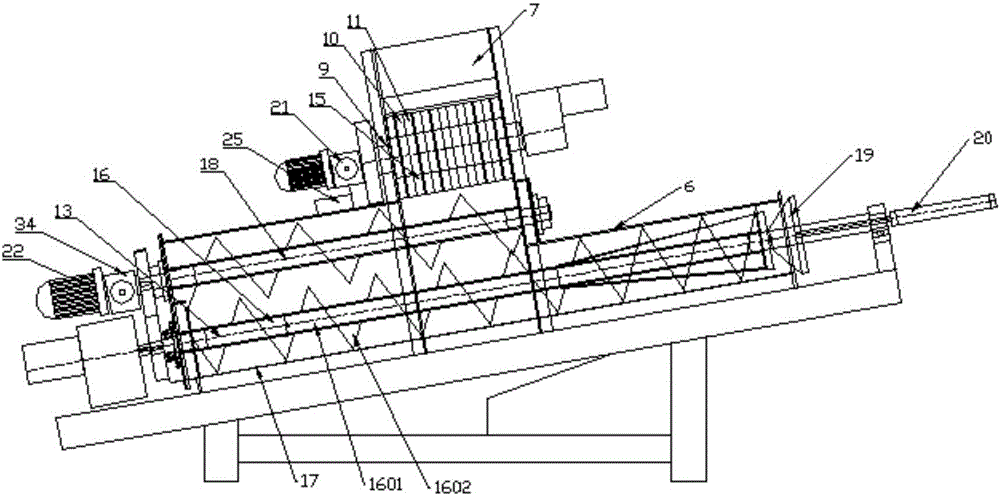

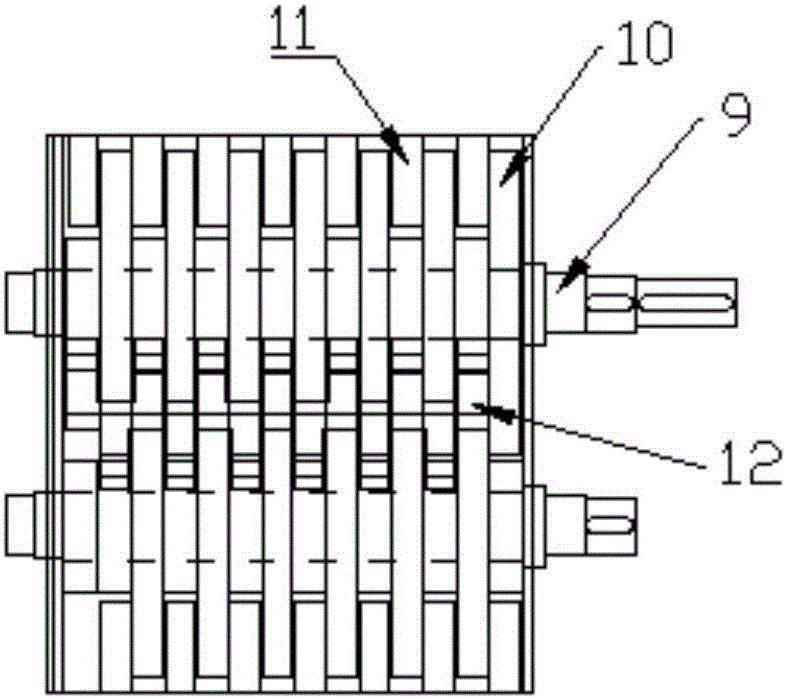

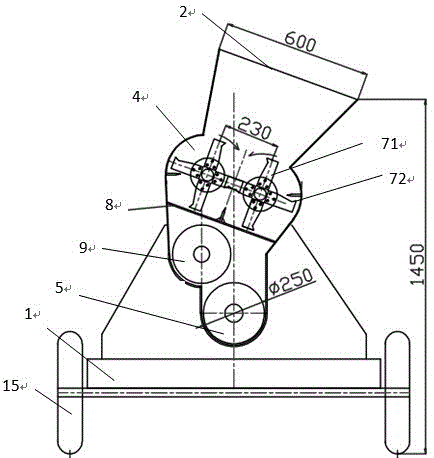

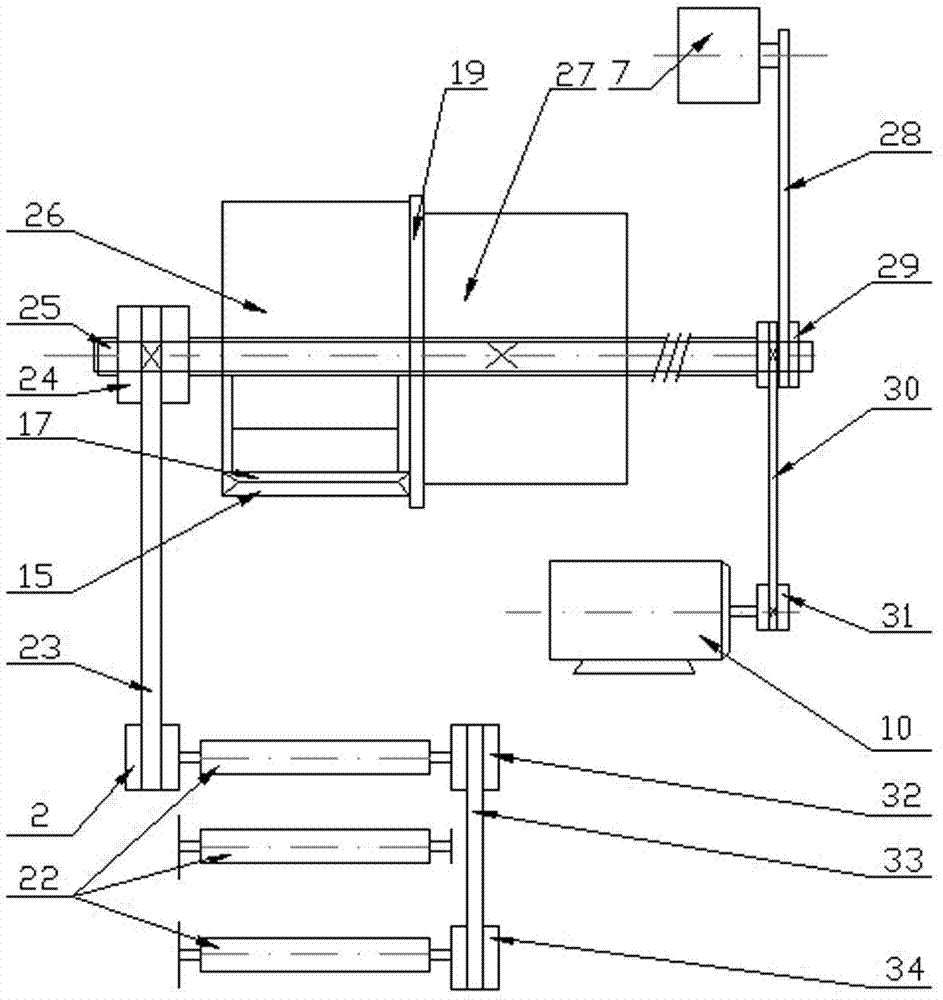

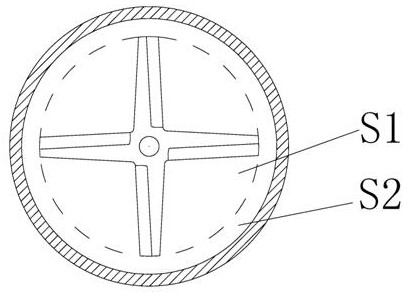

Universal type feed grinder

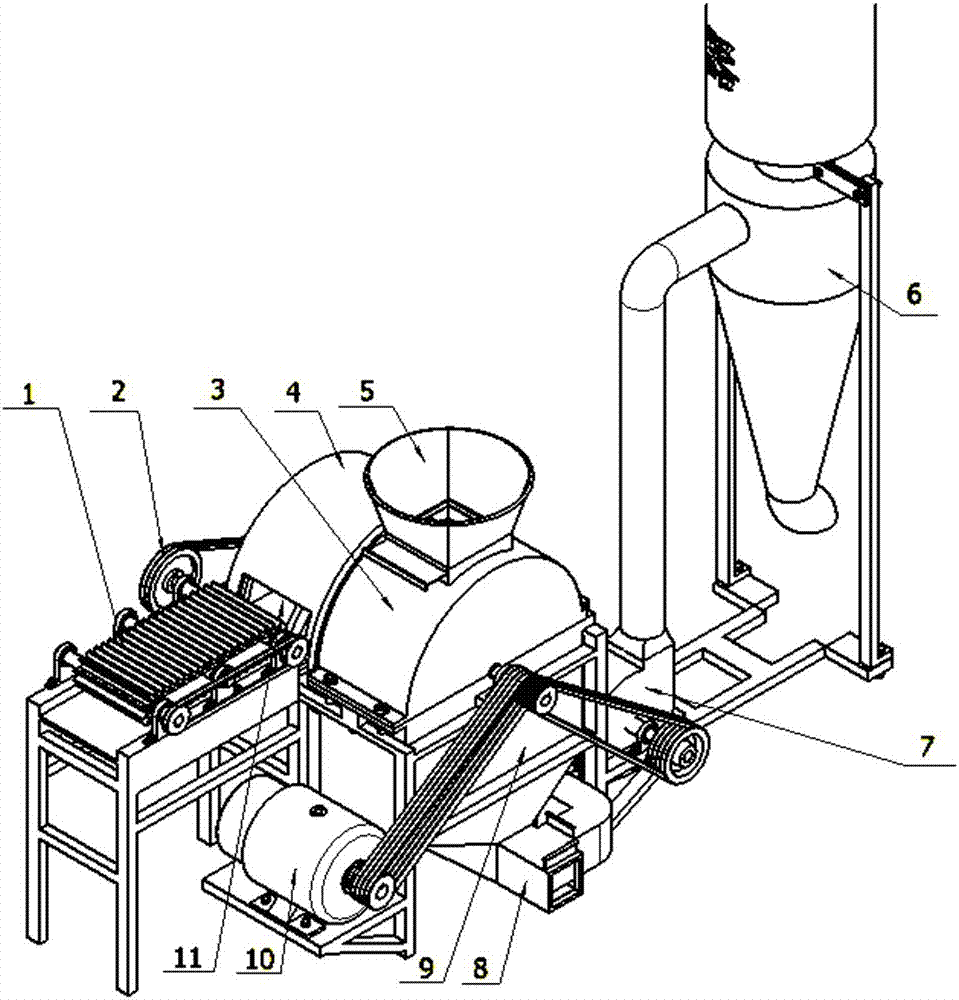

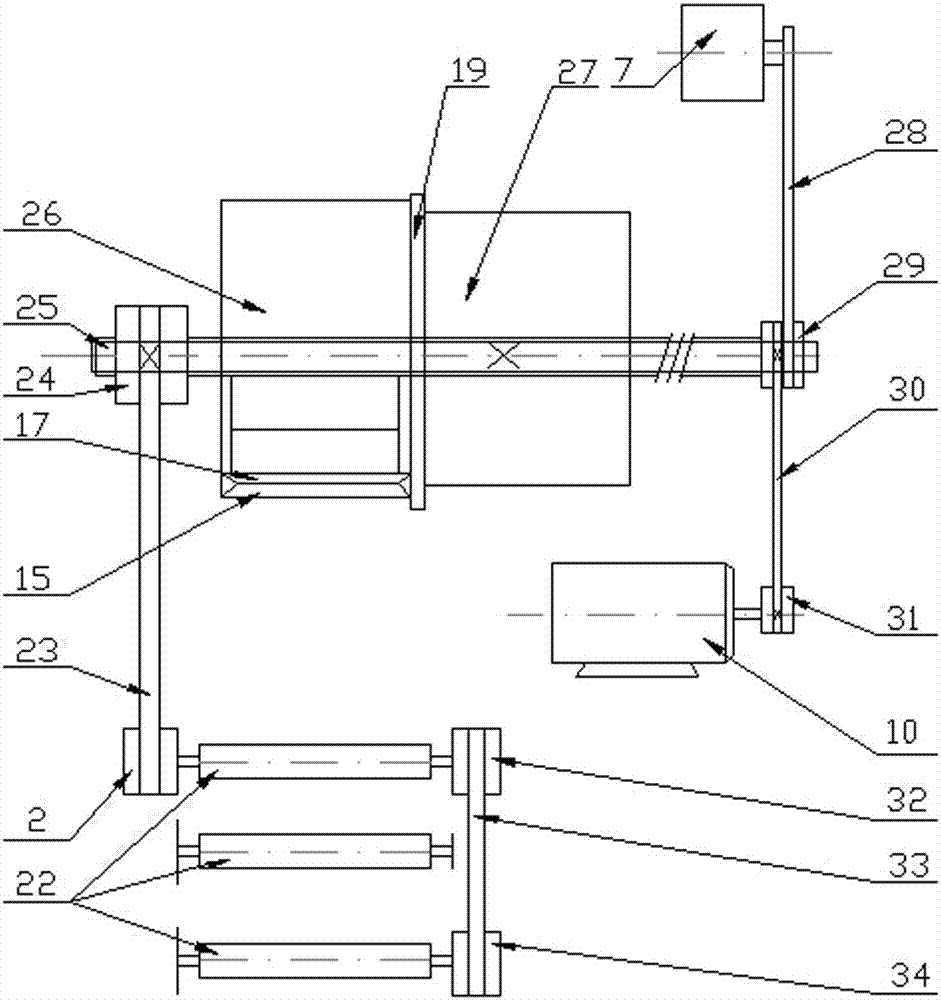

InactiveCN104722380AEnsure safetyCompact structureFeeding-stuffGrain treatmentsProcess engineeringHigh water content

The invention provides a universal type feed grinder. The universal type feed grinder can be used for processing straw type materials with high water content, dry straw, blocky materials such as soybean cakes and granular materials such as corn, and is capable of guaranteeing the feeding safety. The universal type feed grinder provided by the invention has the advantages that the structures of a cutting working chamber and a grinding working chamber are compact, the design of an internal cutter is novel, the cutting and grinding efficiency is high, and the layout of a feeding hole, a discharging hole and a fan joint is reasonable; by coordination of the two working chambers, the requirement on diversity of processed objects can be met, so that the universality is high; and the feeding is finished by a conveying belt, so that the safety in the feeding process can be improved.

Owner:SHENYANG POLYTECHNIC UNIV

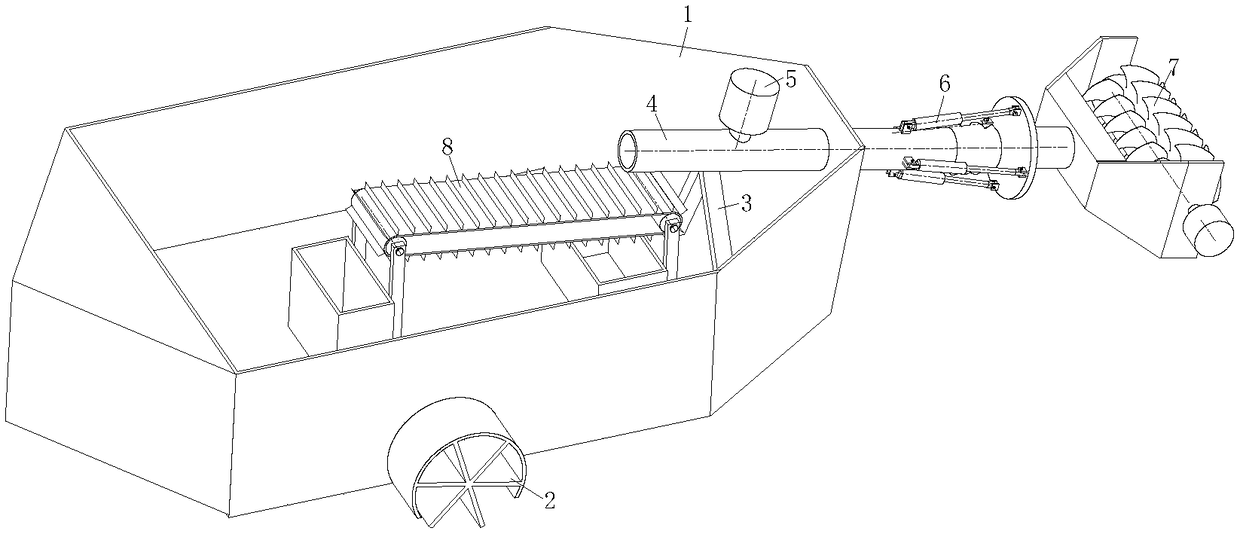

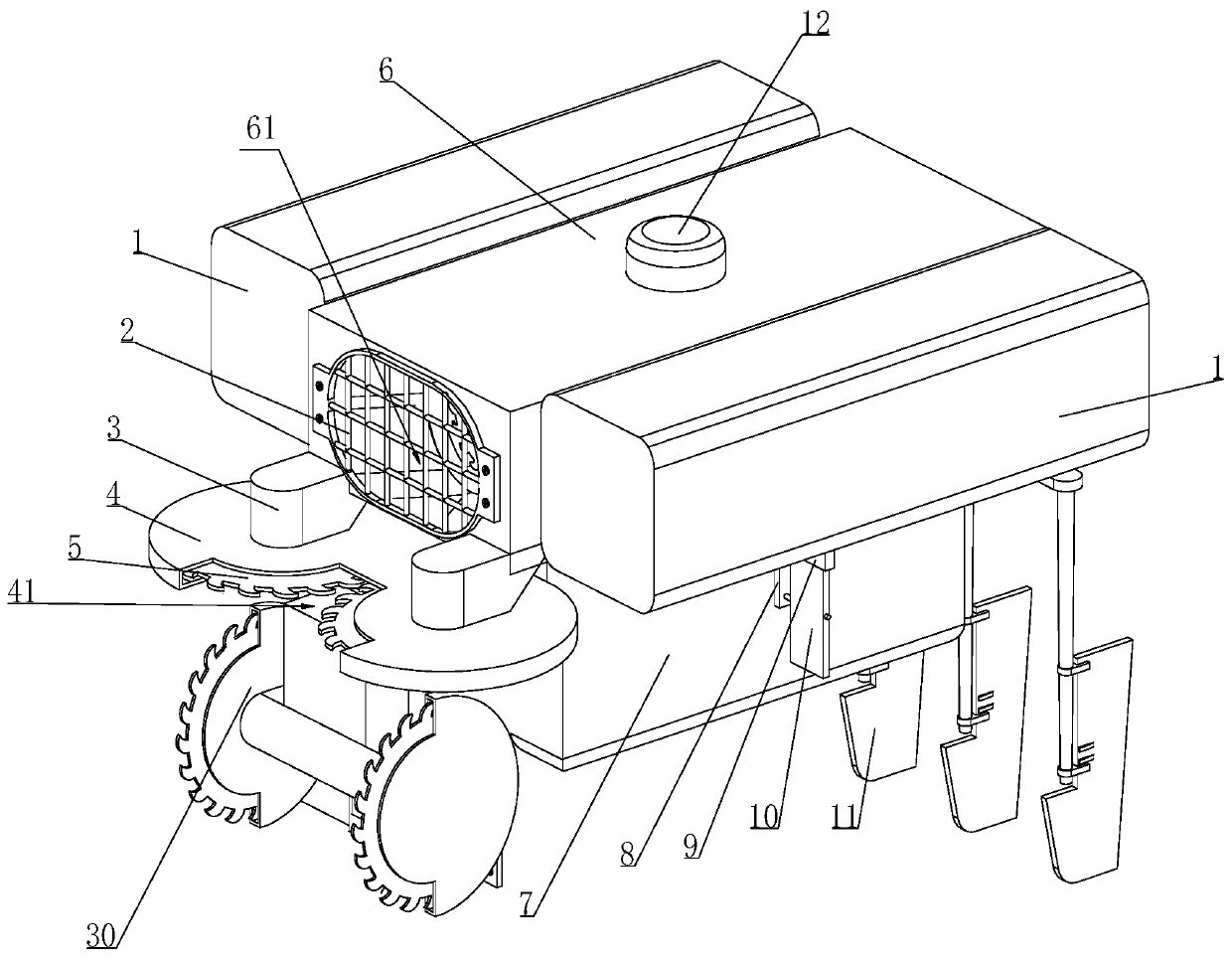

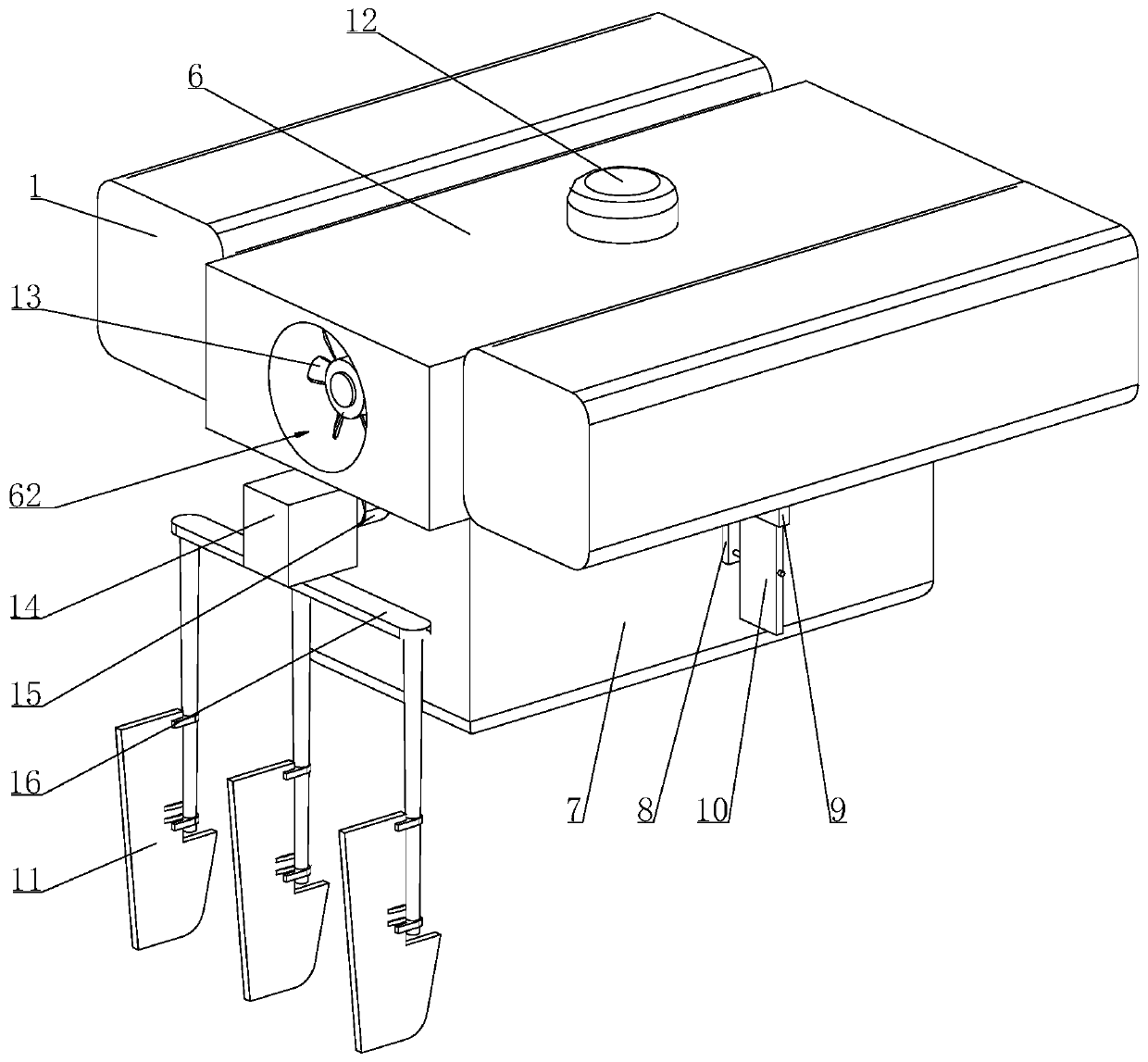

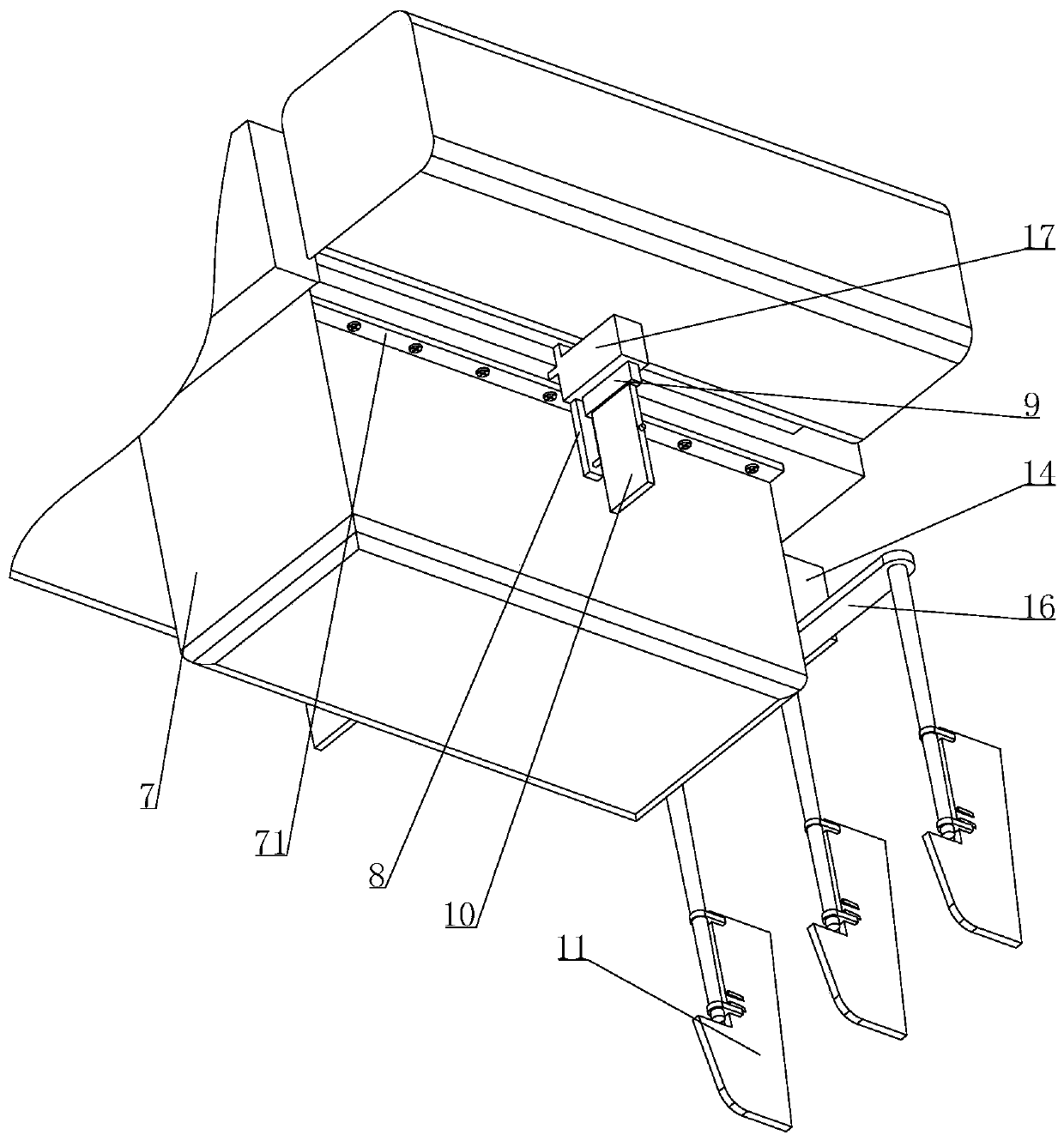

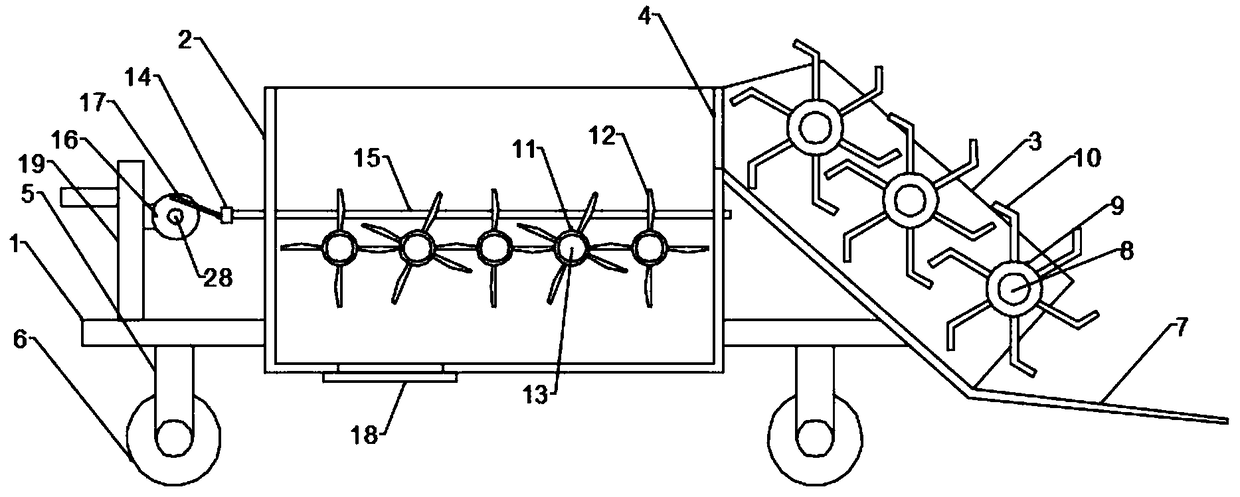

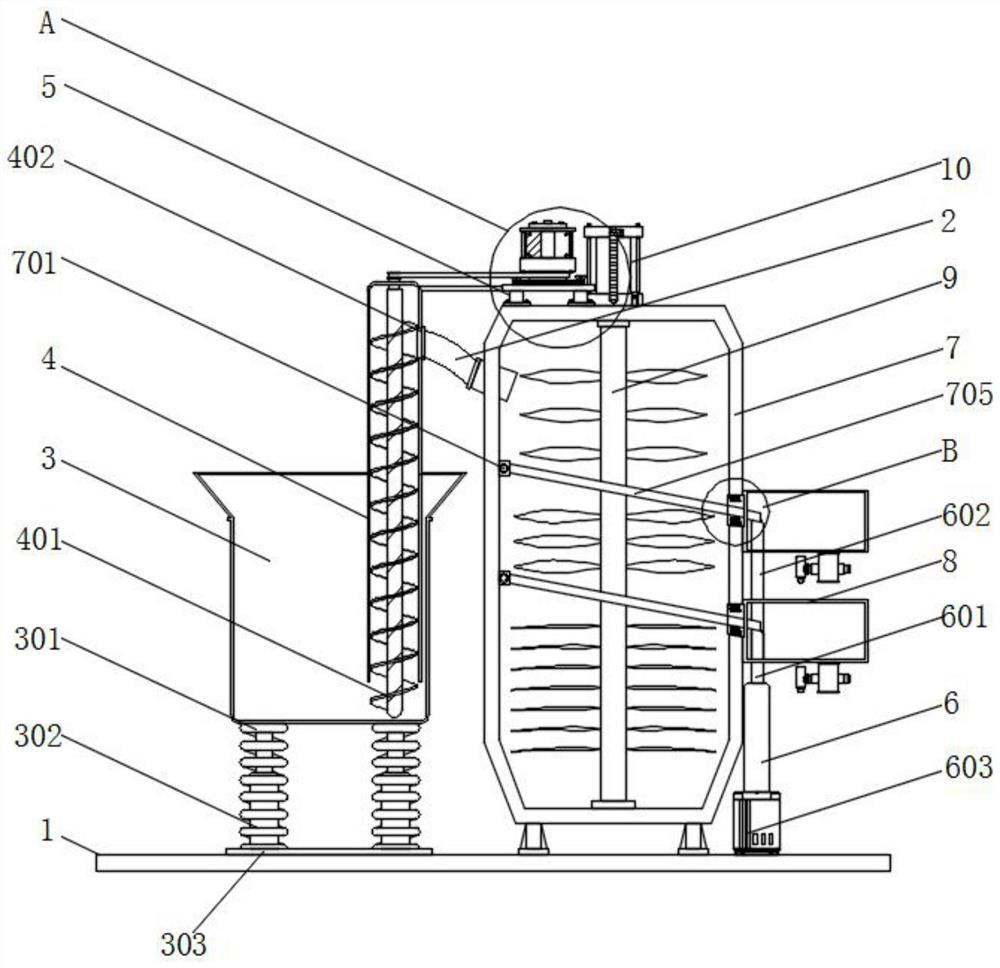

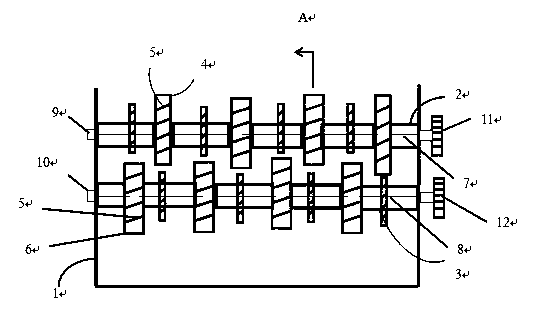

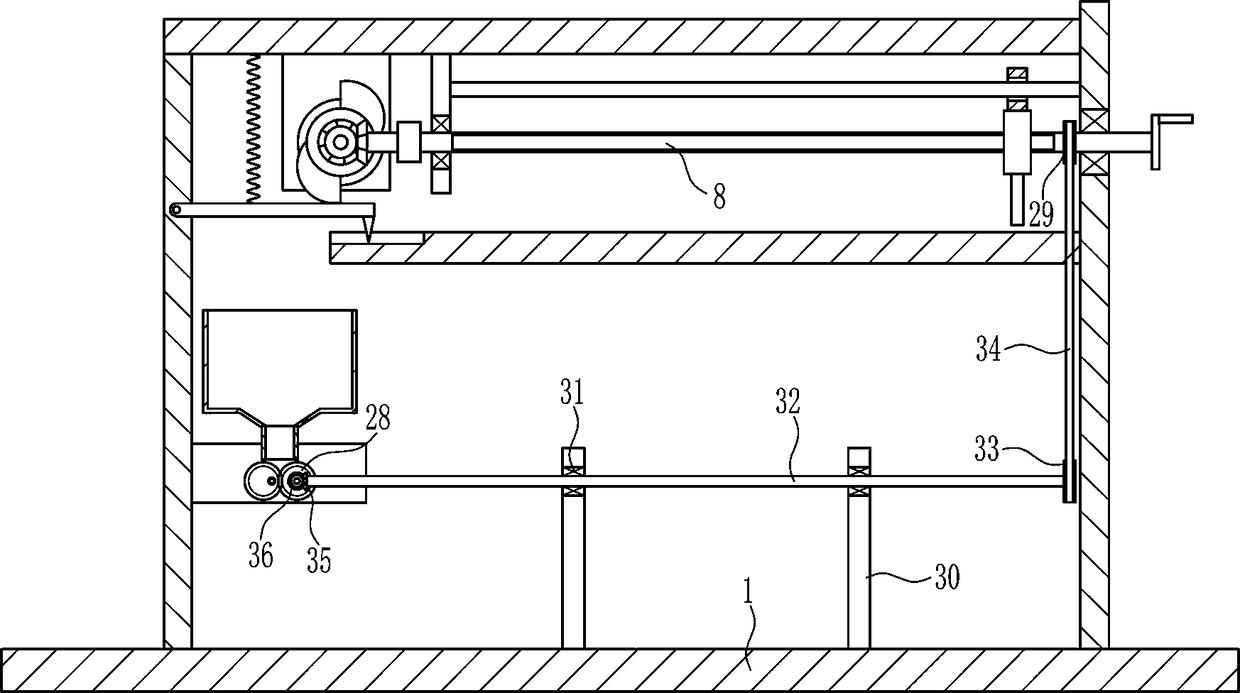

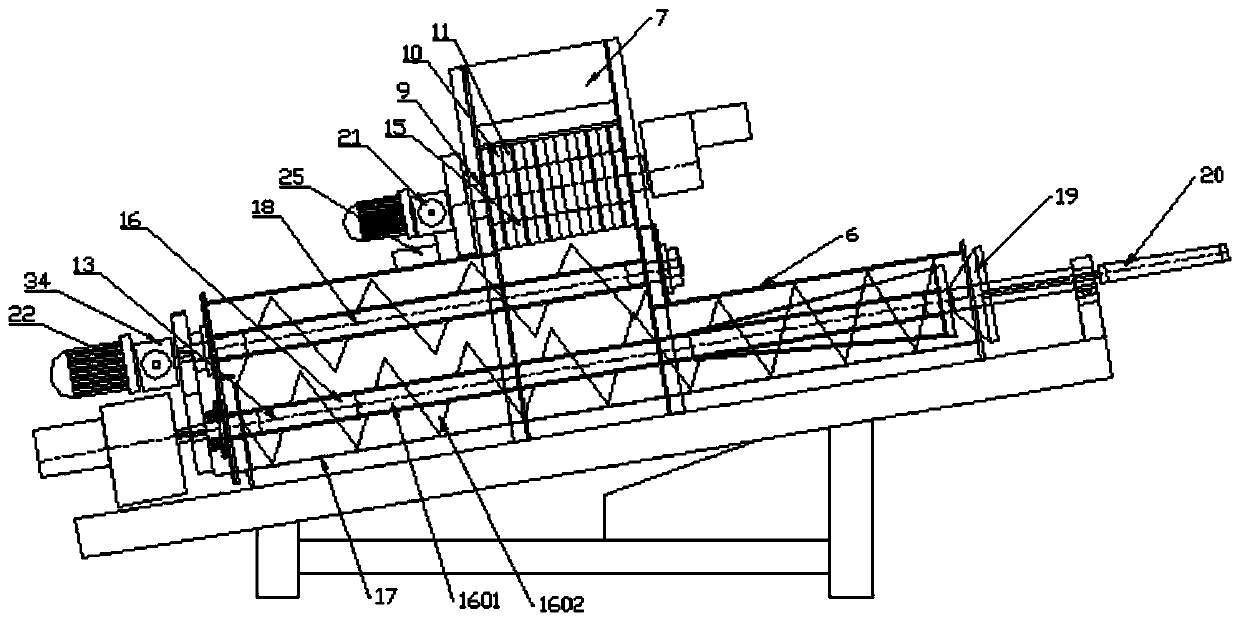

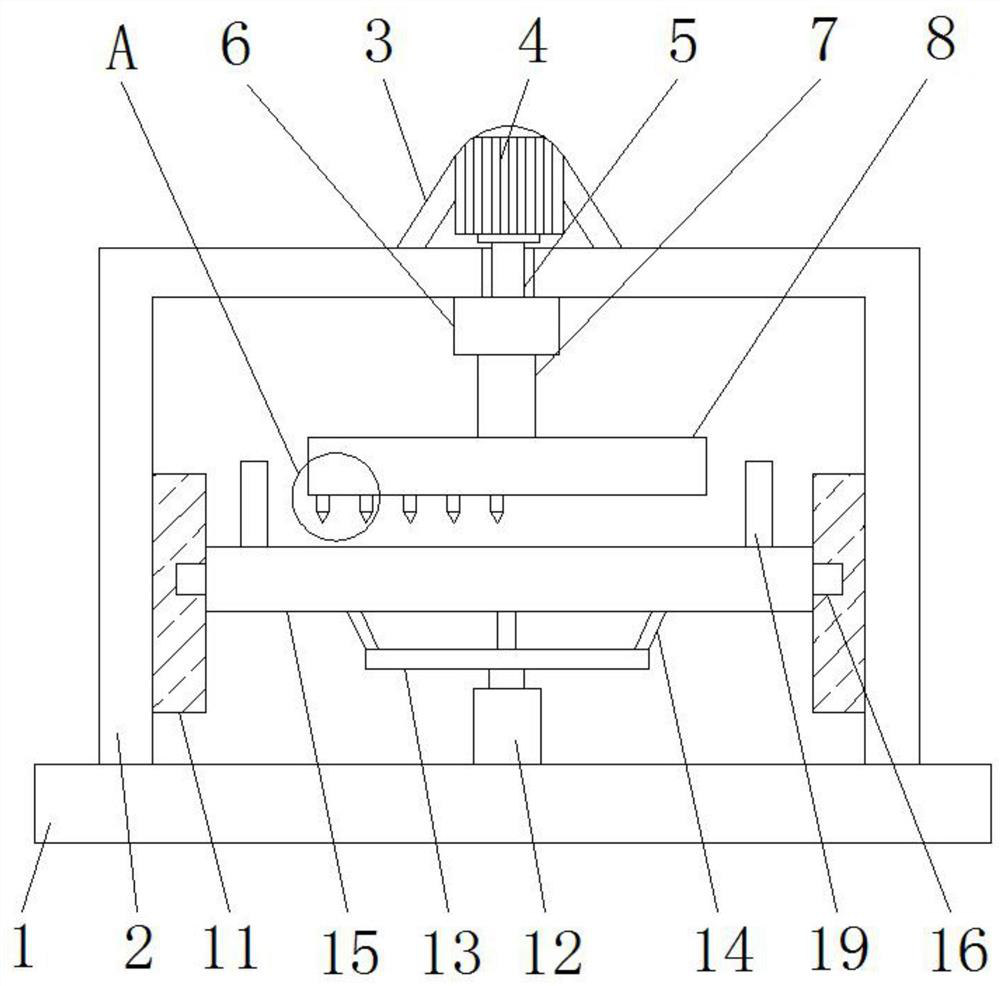

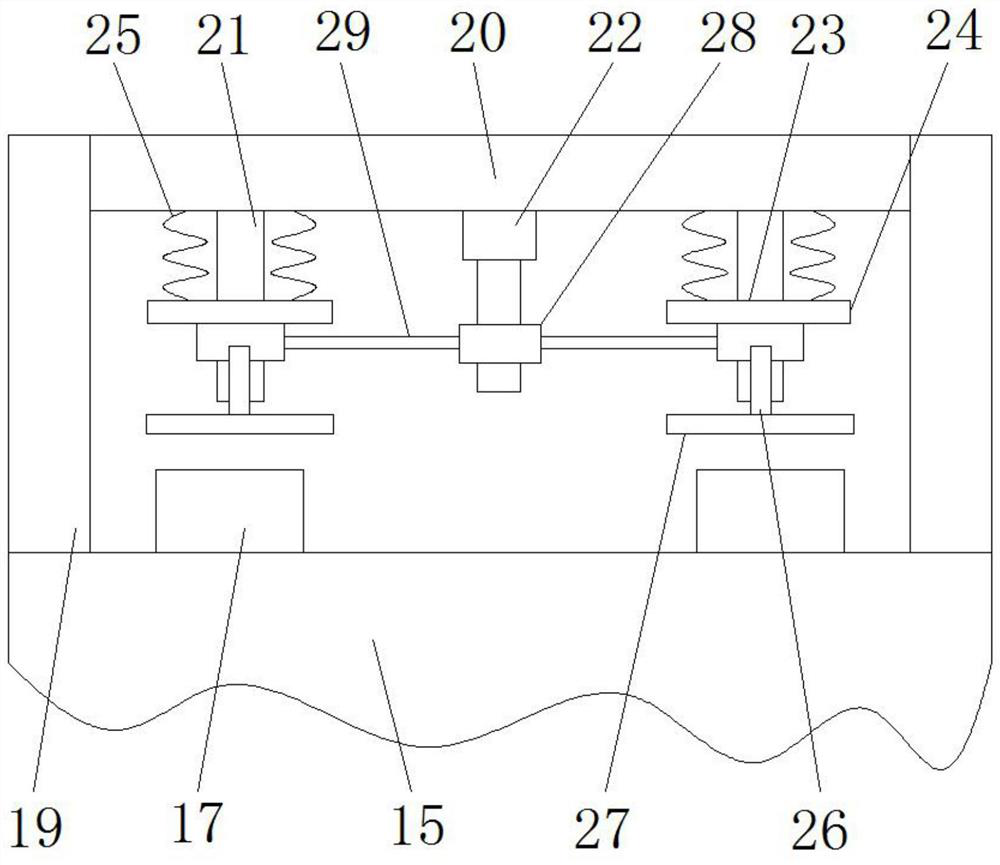

Straw recovery-crushing integrated device used for agriculture

ActiveCN108901324AImprove cutting and crushing efficiencyImprove work efficiencyMowersCuttersPush pullEngineering

The invention discloses a straw recovery-crushing integrated device used for agriculture. The device comprises a supporting transverse plate; the lower end of a conveying box body is fixedly connectedwith a shovelling plate, and the shovelling plate is fixedly connected with the bottom wall of the conveying box body; the interior of the conveying box body is provided with a plurality of shiftingrod shafts, wherein two ends of each shifting rod shaft are rotatably connected with the conveying box body, one fixing sleeve sleeves each shifting rod shaft, and the outer side end of each fixing sleeve is provided with a plurality of bent shifting rods; rotating cutting cutters of two adjacent rotating rod shafts are staggered from one another; the interior of a cutting and crushing groove is provided with a plurality of blocking rods, and the upper end wall of each blocking rod is provided with strip-shaped cutting edges for cutting straw; and the end surface of a push-pull rod is hinged with the end surface of a rotating plate, the hinged place is eccentric, and the other end of the push-pull rod is hinged with the wall of the connecting transverse rod. The device disclosed by the invention has a simple structure, and can cut and crush the straw while recovering the straw; and the device can operate continuously, and has higher working efficiency, simple and convenient operation,and higher practicability.

Owner:安徽正基生态农业有限公司

Primary smashing equipment for fiber cloth for glass fiber powder production

The invention discloses primary smashing equipment for fiber cloth for glass fiber powder production. The primary smashing equipment comprises a base, and the top of the base is fixedly provided witha U-shaped frame; the middle of the U-shaped frame is provided with a through hole, and two symmetric machine frames are fixedly installed on the upper surface of the U-shaped frame; a motor is fixedly installed between the tops of the two machine frames; a rotary shaft is fixedly installed at the output end of the motor, and the end, away from the motor, of the rotary shaft penetrates through thethrough hole and is fixedly connected with a speed reducer; a rotary rod is fixedly installed at the output end of the speed reducer, and the bottom of the rotary rod is fixedly provided with a disc;the bottom of the disc is fixedly provided with strip-shaped blocks, and the bottoms of the strip-shaped blocks are provided with cutters; the sides, close to each other, of the U-shaped frame are provided with slide grooves; a hydraulic cylinder is fixedly installed in the middle of the upper surface of the base; a support plate is fixedly installed at the output end of the hydraulic cylinder, and the top of the support plate is provided with supporting rods. According to the primary smashing equipment for the fiber cloth for glass fiber powder production, the fiber cloth is fixed, the cutters on the lower portion of the disc are driven to rotate through the rotary rod, and the fiber cloth is subjected to annular cutting.

Owner:天长市天意玻璃制品有限公司

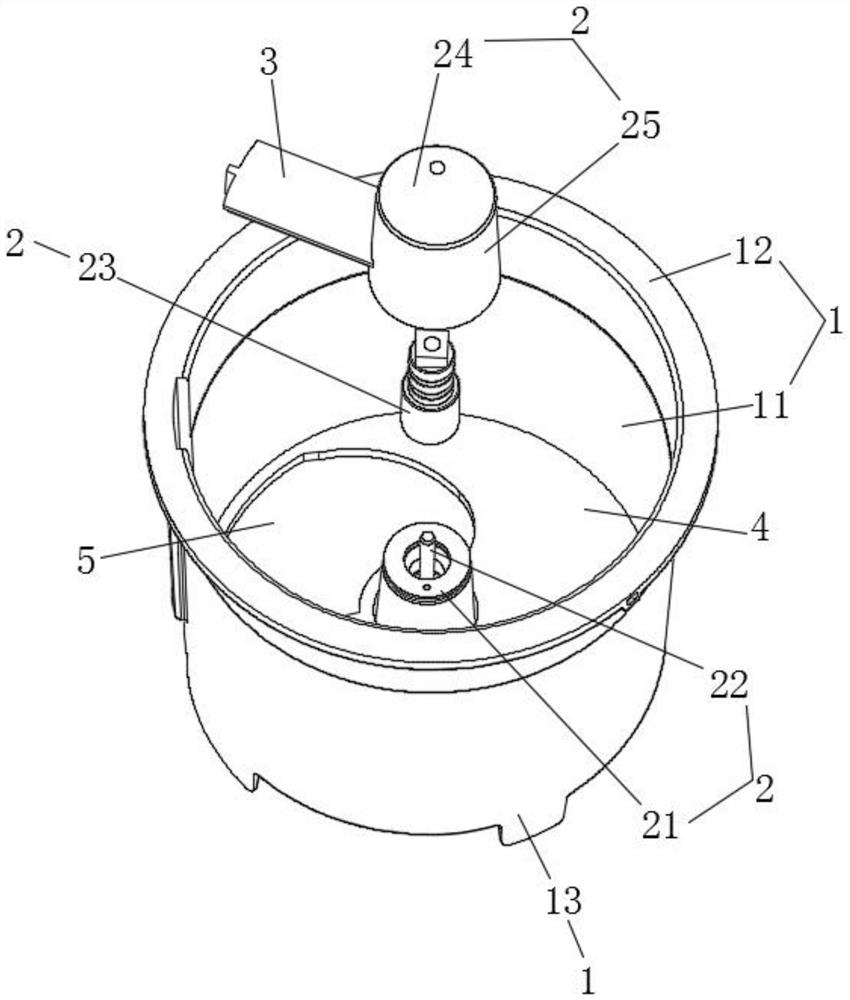

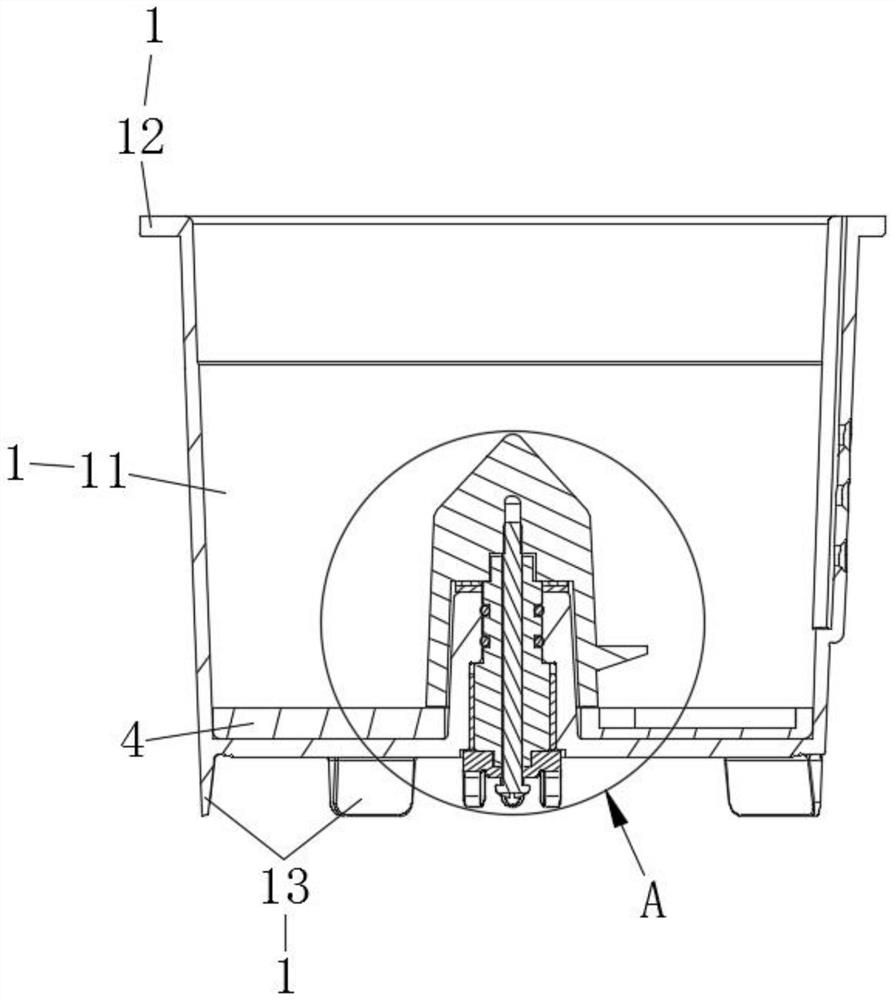

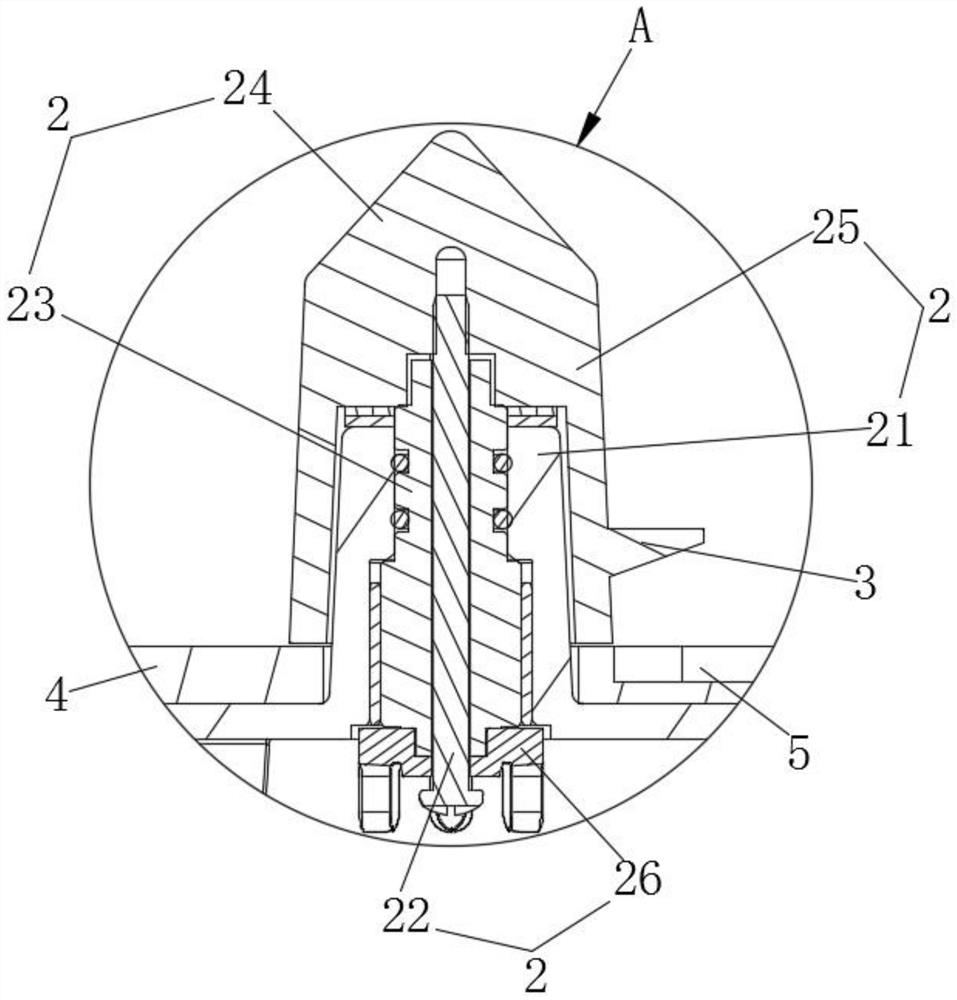

Kitchen garbage crushing combined cutter

The invention discloses a kitchen garbage crushing combined cutter. The kitchen garbage crushing combined cutter comprises a material barrel, a cutting assembly, a fixed blade and a bottom notch, wherein, the fixed blade is fixed at the bottom in the material barrel; the cutting assembly comprises a movable blade; a rotating assembly capable of rotating is mounted at the bottom inside the material barrel; the rotating assembly rotates with the axis of the material barrel as the center; the movable blade is fixed on the lower half section of the rotating assembly; the movable blade is arranged above the fixed blade; at least one side of the fixed blade is provided with the bottom notch which is provided with an edge part and faces the cutting edge of the movable blade; and one ends of the bottom notches extend towards the center of the bottom of the material barrel. According to the kitchen garbage crushing combined cutter, harder garbage blocks can be cut through self-adaptive adjustment of a shearing force arm and shearing force, and the use performance is obviously improved; frequent cutter clamping and cutter damage in the cutting process are effectively avoided, manual intervention is reduced, the treatment process is smoother, and the effect is better; and the length of the cutting working section is increased, so that more garbage is cut at the same time, and the cutting and crushing efficiency is improved.

Owner:ANHUI JIANGHANG ENVITEK ENVIRONMENTAL TECH CO LTD

Crushing and nail-removing machine for building plastic template

InactiveCN106269112AReduce volumeReduce noisePlastic recyclingGrain treatmentsEngineeringMechanical engineering

The invention provides a crushing and nail-removing machine for a building plastic template. The machine comprises a support, a feeding bench, an upper knife roller, and a lower knife roller. A plurality of upper cutter heads and lower cutter heads are arranged on upper and lower knife roller supports at an interval, respectively. Each lower cutter head is provided with a plurality of cutting tools, and the upper cutter heads arranged on the upper knife roller support and the lower cutter heads arranged on the lower knife roller support are in spaced staggered arrangement. An axis of the upper knife roller support is higher than the feeding bench, and an axis of the lower knife roller support is lower than the feeding bench. Ends of the upper and lower knife roller supports are located on the support through bearing pedestals. Since the rotary speeds of the upper and lower knife roller supports are different, a building plastic template is dragged in the place between the upper and lower knife roller supports. When the building plastic template enter the place between the upper and lower knife roller supports, the knife rollers drive the cutter heads to rotate, and the cutting tools arranged on the cutter heads crush the template at different time. Through the spaced staggered arrangement of the upper cutter heads of the upper knife roller support and the lower cutter heads of the lower knife roller support, nails in the template can be separated.

Owner:田涛

Automatic control production equipment with convenient feeding

The invention discloses automatic control production equipment with convenient feeding. The automatic control production equipment comprises a working bottom plate, a connecting pipe, a charging barrel, a feeding pipe, an electric telescopic rod, a telescopic sleeve and a crushing barrel, wherein the charging barrel is welded to the top of the telescopic rod, the bottom of the charging barrel is connected with the top of an extension spring, the smashing barrel is installed at the top of the working bottom plate through a supporting frame, a cutting rod is mounted in the crushing barrel through a bearing, a vibration motor is mounted at the top of the working bottom plate, and the telescopic sleeve is mounted at the output end of the vibration motor. By arranging the charging barrel, when the weight of raw materials in the charging barrel is reduced, the extrusion effect on the extension spring is weakened, then the extension spring drives the telescopic rod to move upwards under the reset effect, so as to drive the charging barrel to ascend, and therefore the raw materials at the bottom of the charging barrel can make contact with the bottom of a screw rod, and can also be fed into the crushing barrel, raw material residues are avoided, and the feeding efficiency of the device is improved.

Owner:广州渺钛新材料科技有限公司

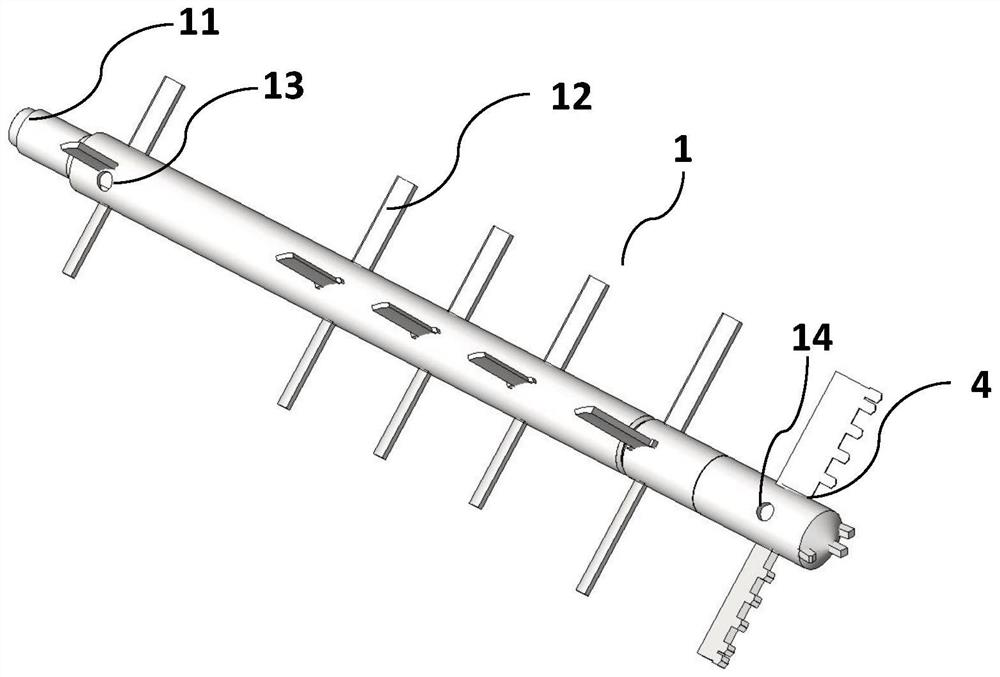

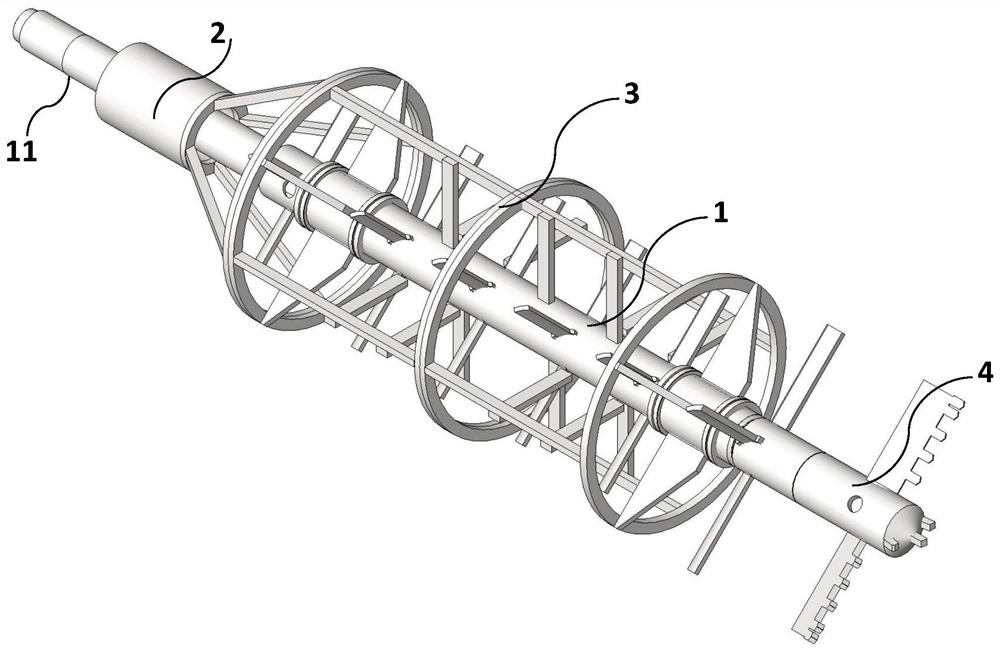

Single-shaft deep mixing pile drilling tool with inner-layer and outer-layer mixing teeth

PendingCN112627174AImprove cutting and crushing efficiencyImprove efficiencyBulkheads/pilesEnvironmentally friendlyGeotechnical engineering

The invention discloses a single-shaft deep mixing pile drilling tool with inner-layer and outer-layer mixing teeth. A drill rod of the single-shaft deep mixing pile drilling tool is of a double-layer structure, a mixing shaft and a drill bit are arranged at the lower end of the inner-layer drill rod, and the outer-layer drill rod is connected with a mixing cover; the outer-layer mixing teeth are arranged on the cylindrical hollowed-out mixing cover, and the inner-layer mixing teeth are arranged on the hollow mixing shaft; the inner-layer and outer-layer mixing teeth are arranged in a staggered mode in space and engaged with each other; the mixing cover covers the inner-layer mixing shaft; and a top slurry spraying opening is formed in the upper portion of the mixing shaft, and a bottom slurry spraying opening is formed in the drill bit. Rock-soil particles are efficiently broken and fully mixed with soil hardening agent slurry to form fluid hardened soil. The single-shaft deep mixing pile drilling tool has the social benefits of being environmentally friendly, safe and reliable, meanwhile, the manufacturing cost can be reduced, the construction period can be shortened, and great economic value is achieved.

Owner:王琪

Smashing nail removing machine for building plastic formwork

The invention provides a smashing nail removing machine for a building plastic formwork. The smashing nail removing machine comprises a support, a feeding platform, an upper cutter roller and a lower cutter roller. Multiple cutter discs are arranged on each of an upper cutter roller frame and a lower cutter roller frame at intervals, and each cutter disc is provided with multiple cutters. The cutter discs on the upper cutter roller frame and the cutter discs on the lower cutter roller frame are arranged at intervals and in a staggered mode. The axis of the upper cutter roller frame is higher than the feeding platform, and the axis of the lower cutter roller frame is lower than the feeding platform. Two ends of each of the upper and lower cutter roller frames are arranged on the support through bearing blocks. According to the smashing nail removing machine for the building plastic formwork, the building plastic formwork is pulled into the position between the upper cutter roller frame and the lower cutter roller frame through the feeding platform through different rotation speeds of the upper and lower cutter roller frames, the cutter rollers rotate to drive the cutter discs to rotate when the building formwork enters the position between the upper cutter roller and the lower cutter roller, and the cutters on the cutter discs cut and smash the formwork at different moments. Meanwhile, the cutter discs on the upper cutter roller frame and the cutter discs on the lower cutter roller frame are arranged at intervals and in the staggered mode so that nails in the building plastic formwork can be separated.

Owner:XIAN HAORUI ELECTRONICS TECH

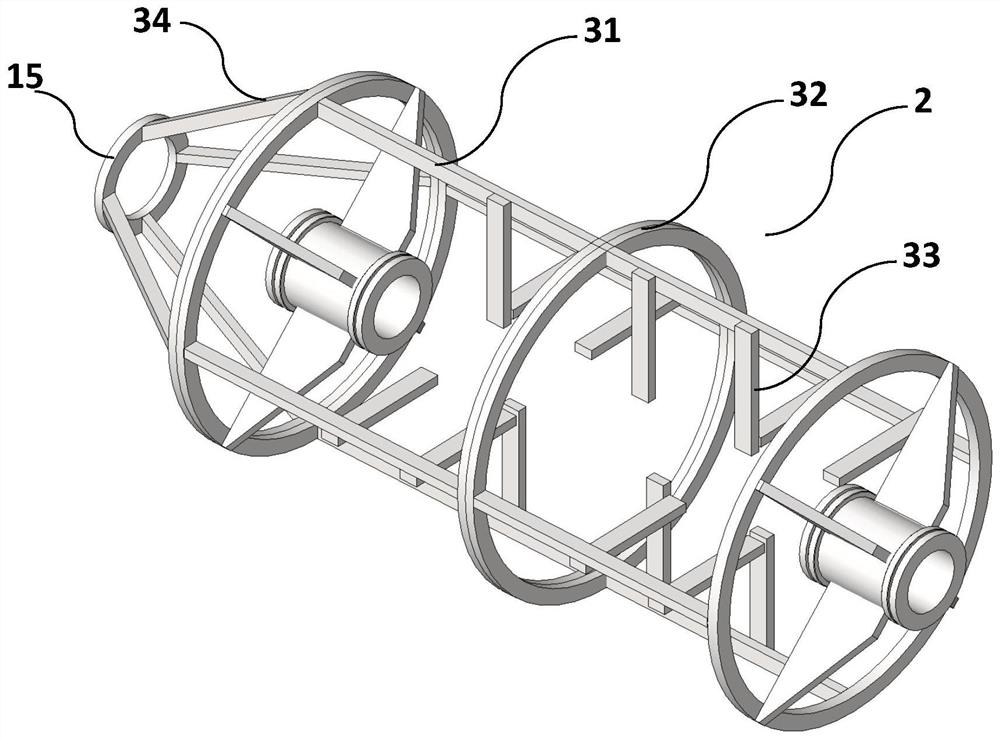

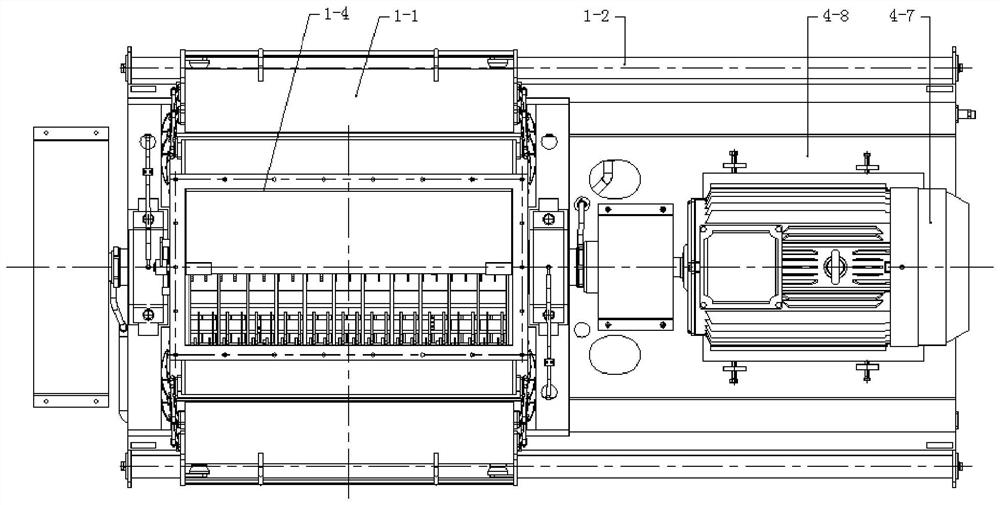

Breaking machine

PendingCN112718167AImprove cutting and crushing efficiencyExtended service lifeGrain treatmentsEngineeringMachine

The invention discloses a breaking machine. The breaking machine comprises a machine shell, wherein an operation door is arranged on the side wall of the machine shell; a screen used for dividing an inner cavity of the machine shell into a breaking chamber and a collecting chamber is arranged in the machine shell; the breaking chamber is communicated with a feeding port formed in the upper end of the machine shell; the screen is connected with the machine shell through a screen pressing mechanism; a rotor is arranged in the breaking chamber and connected with the machine shell; the rotor comprises a rotor shaft, multiple cutter heads, multiple cutter shafts and multiple blades; the cutter heads are arranged on the rotor shaft; each cutter shaft is connected with all the cutter heads; all the cutter shafts are evenly distributed in the circumferential direction of the cutter heads; the blades are arranged on the portions, between every two adjacent cutter heads, of the cutter shafts; and multiple cutting teeth are arranged at the cutting ends of the blades. According to the breaking machine, the service life of the blades can be prolonged.

Owner:SHANDONG JIEFENG MACHINERY MFG

A device for crushing and screening medicinal materials for traditional Chinese medicine processing

The invention discloses a medicinal material crushing and screening device for traditional Chinese medicine processing. The device comprises a crushing box. A motor rack is fixedly mounted on the topof the crushing box; two adjusting plates are rotatably arranged in the crushing box in symmetry of a driving shaft; a lead screw is horizontally arranged through the side wall of the crushing box through threaded connection, the lead screw extends into the crushing box and leans against the adjusting plates, and a second limiting spring is connected between a sieve plate and an extension plate. By rotating the adjusting plates, the traditional Chinese medicinal materials can be closer to a cutting blade, so that the cutting and crushing efficiency of the cutting blade is improved greatly; meanwhile, the device is convenient to adjust and suitable for crushing medicinal materials of different sizes; a horizontal shaft drives a cam to rotate, so that the sieve plate vibrates up and down toenable the crushed medicinal materials to be uniformly paved to the sieve plate, and meanwhile, finely-divided medicinal material powder penetrates through the sieve plate quickly to be screened, flowing of an air flow in the crushing box is accelerated as a vane rotates, so that sieve pores of the sieve plate can be prevented from being blocked by the medicinal materials and the screening efficiency of the medicinal materials is increased.

Owner:甘肃康乐药业有限责任公司

Universal Feed Grinder

InactiveCN104722380BEnsure safetyCompact structureFeeding-stuffGrain treatmentsEngineeringHigh water content

The invention provides a general-purpose feed grinder, which can not only process straw raw materials with high water content, but also dry straw. It can also process massive raw materials such as soybean bean cakes and granular materials such as corn, and can ensure the safety of feeding. The cutting studio and crushing studio of the feed grinder described in the present invention are compact in structure, the internal cutters are novel in design, the cutting and crushing efficiency is high, and the arrangement of the feed port, the discharge port and the fan interface is reasonable. By coordinating the two working rooms, it can meet the diverse requirements of processing objects and has high versatility. Conveyor belt feeding can improve the safety of the feeding process.

Owner:SHENYANG POLYTECHNIC UNIV

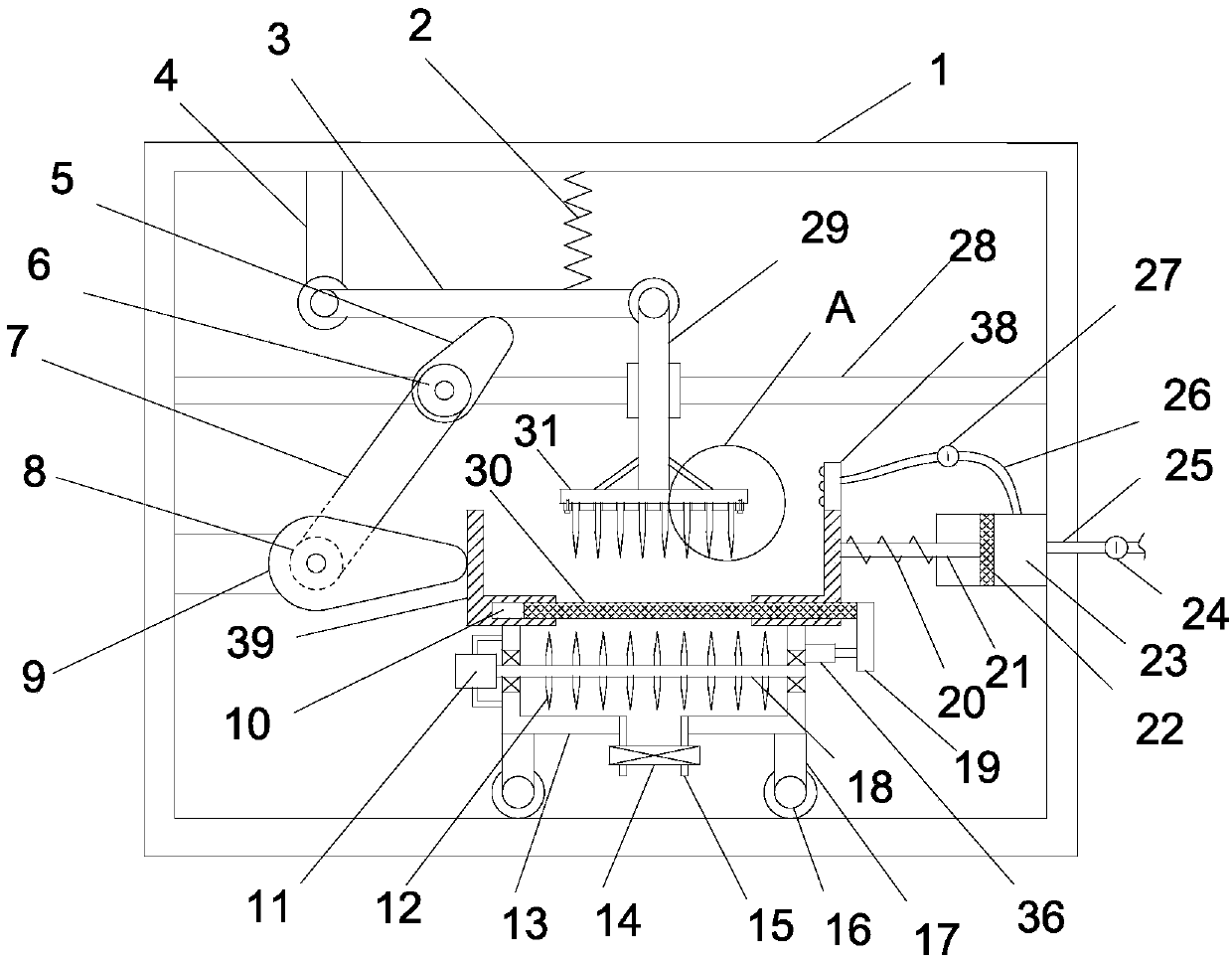

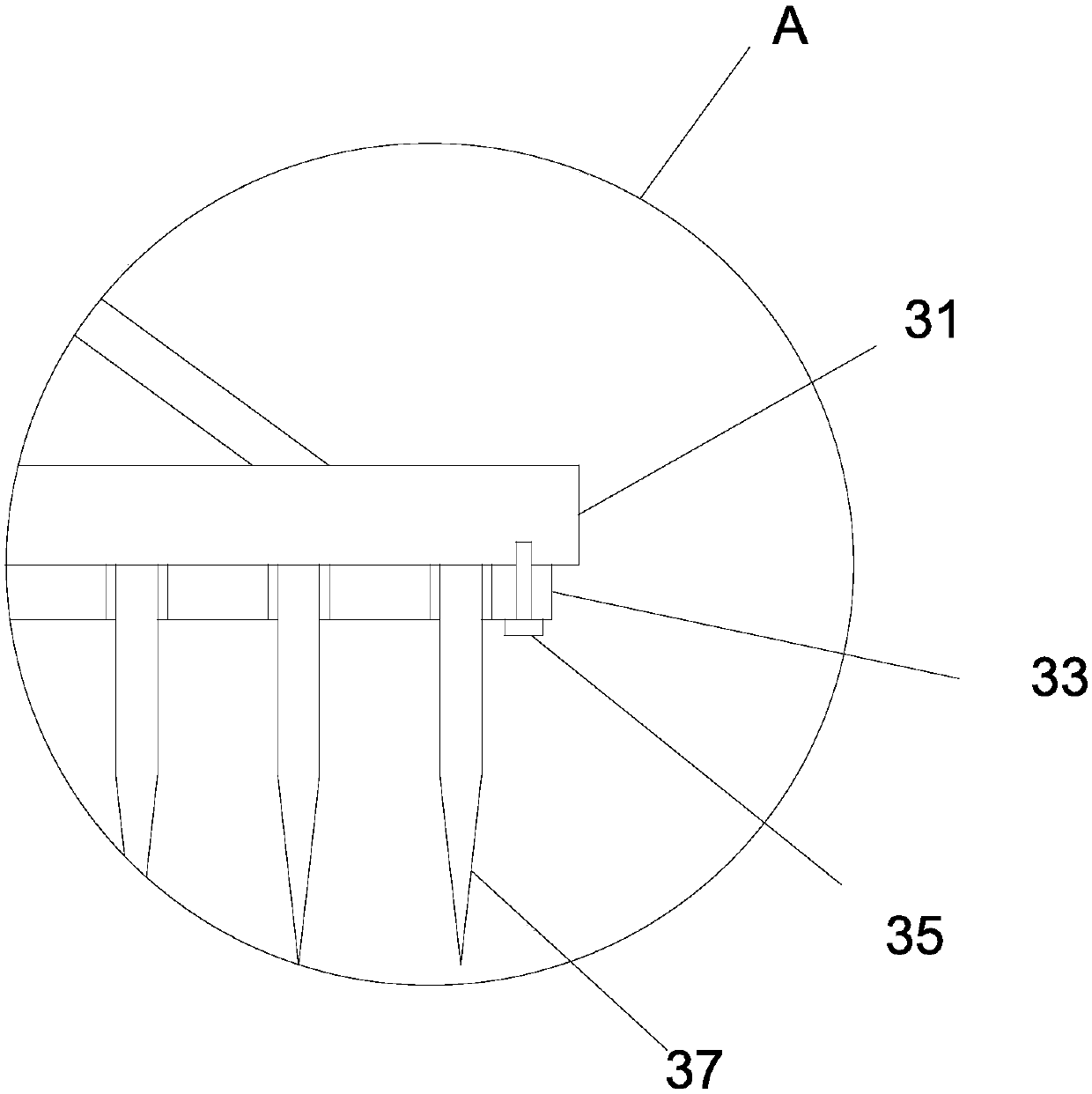

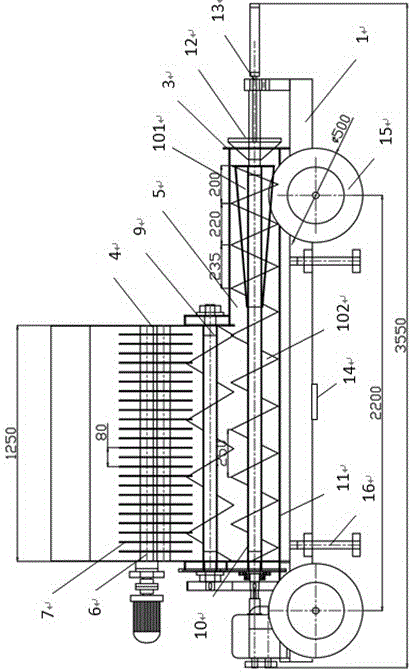

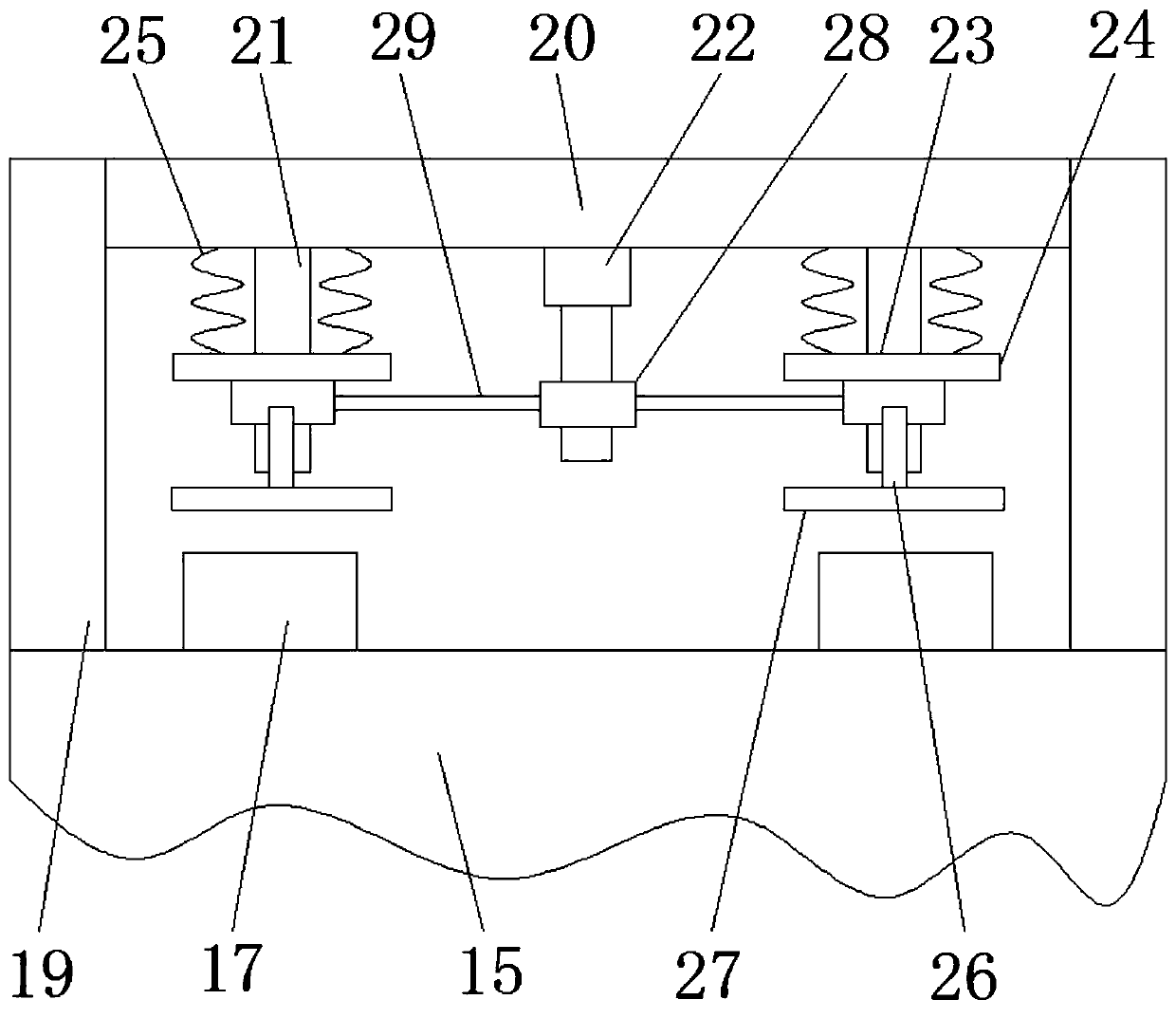

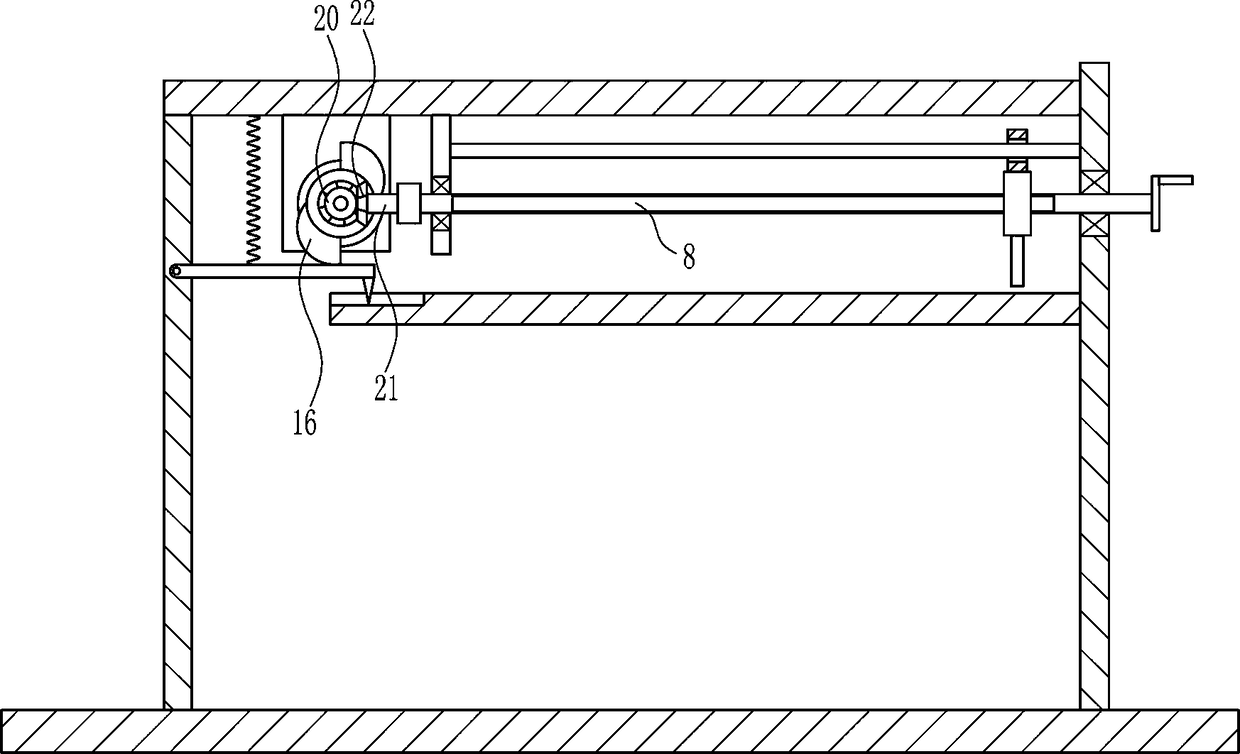

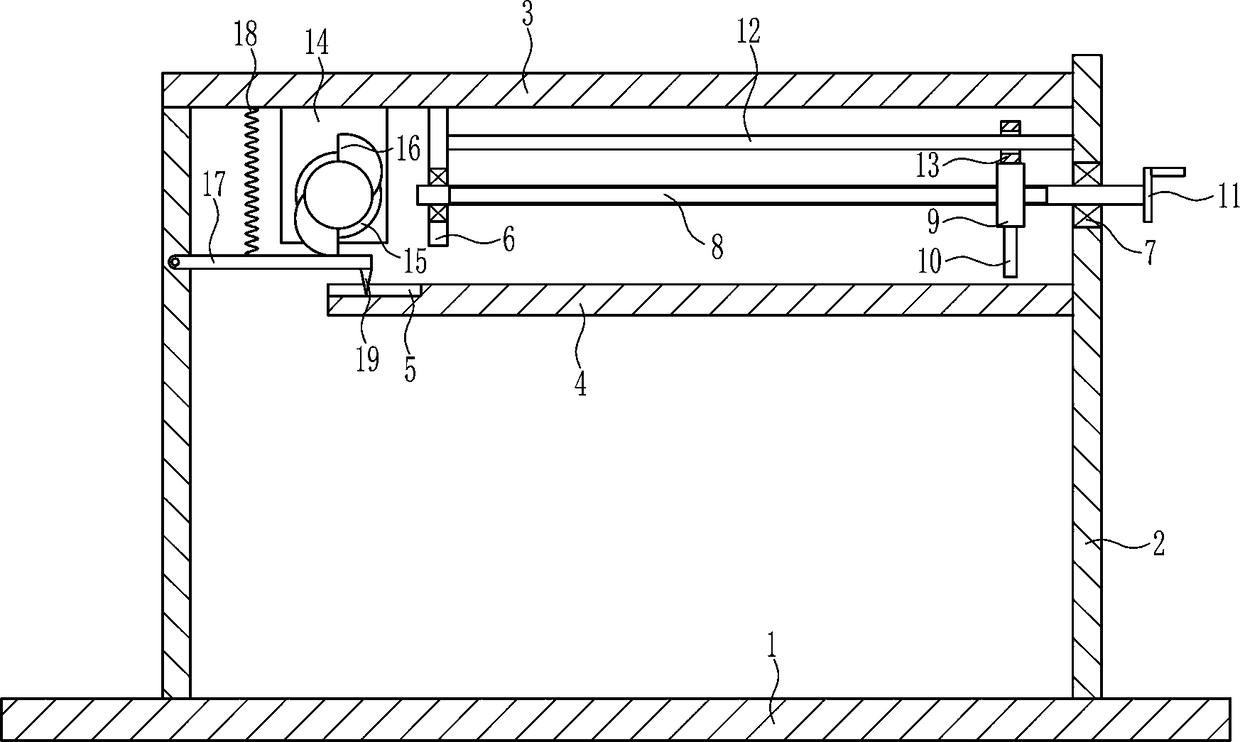

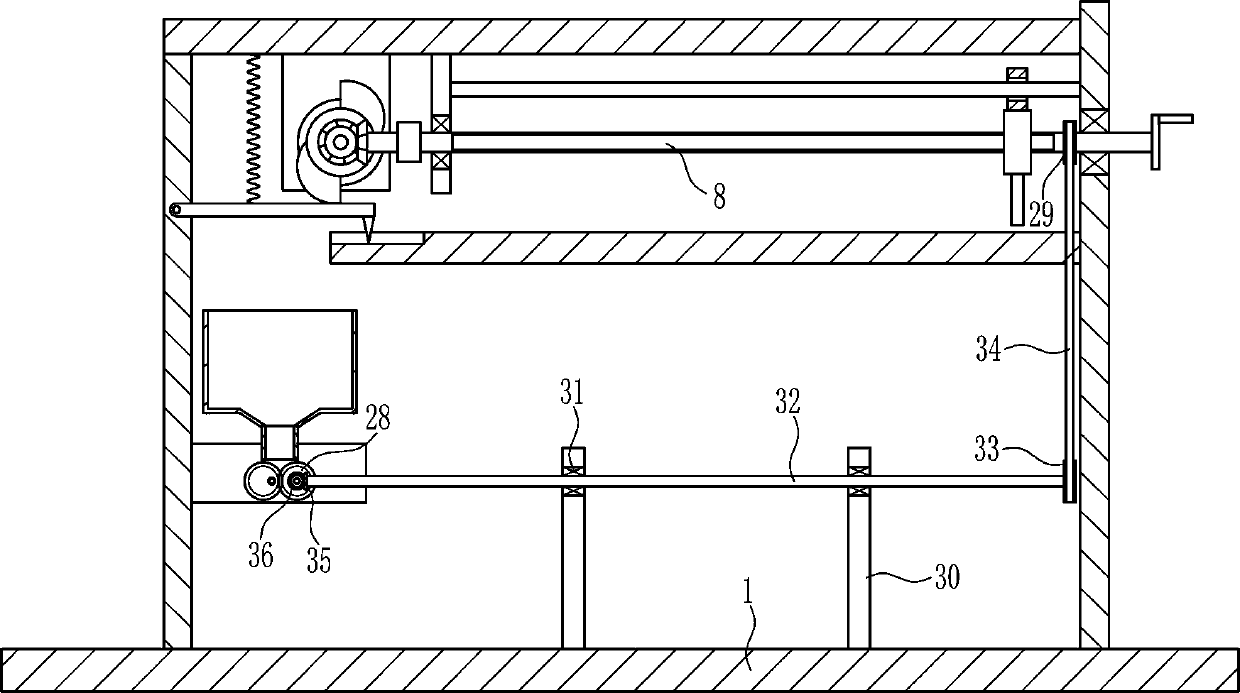

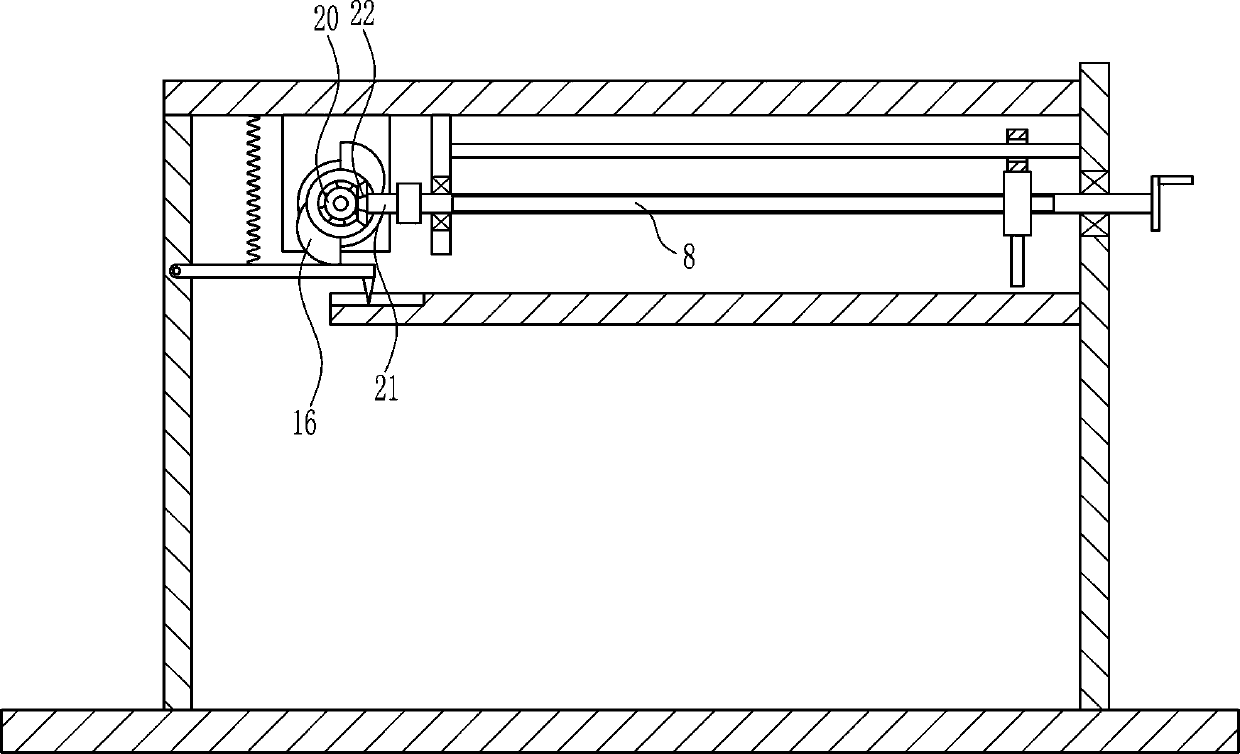

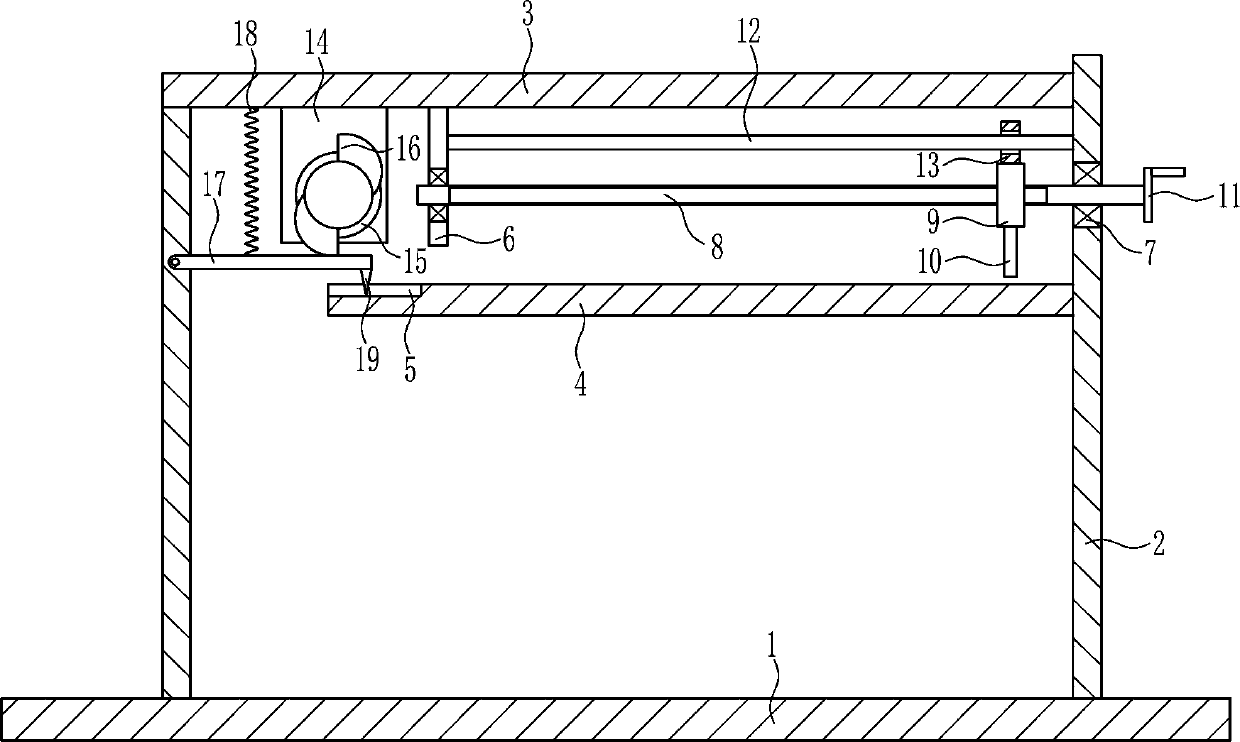

Reed cutting equipment for papermaking

InactiveCN108560298AImprove cutting efficiencyReduce labor intensityRaw material divisionPapermaking

The invention relates to reed cutting equipment for papermaking, in particular to reed cutting equipment for papermaking. The technical problem to be solved by the invention is to provide the reed cutting equipment with simple operation for the papermaking capable of reducing labor intensity and improving cutting and pulverizing efficiency. The reed cutting equipment for the papermaking comprisesa bottom plate, vertical plates, a top plate, a placing plate, a first connecting plate, a first bearing seat, a screw rod, a nut, a baffle plate, a handle and the like; left and right sides of the bottom plate are connected with the vertical plates, the top plate is connected between the tops of the two vertical plates, the upper portion of the left side surface of the vertical plate of the rightside is connected with the placing plate, and a groove is formed in the left side of the top of the placing plate. Reeds can be cut by moving a cutter up and down, the cut reeds can be pulverized through rotating cooperation of first crushing teeth and second crushing teeth, and the effects of labor intensity reduction, improved cutting and pulverizing efficiency and simple operation are achieved.

Owner:林金印

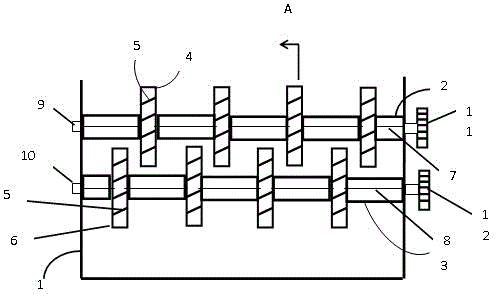

A crushing device and integrated crushing and pressing equipment including it

ActiveCN106733074BImprove cutting and crushing efficiencyAvoid entanglementFeeding-stuffGrain treatmentsStructural engineeringMachine

The invention belongs to the field of feed processing devices and particularly relates to a smashing device and a smashing and squeezing integrated device with the smashing device. The smashing device comprises a machine frame and two rollers which are arranged below a feeding port and rotate oppositely. Each roller is provided with wheel tooth type movable cutters arranged spirally. The movable cutters on the two rollers are mutually staggered in the axial direction of the rollers. Upper fixed cutters are installed on the machine frame at intervals and located on the two sides of the portion below the feeding opening. The upper fixed cutters are meshed with the movable cutters. According to the smashing device and the smashing and squeezing integrated device with the smashing device, the double rollers are adopted and conduct smashing and cutting oppositely, the upper fixed cutters are also arranged, so that the problem that when straws of bananas and other crops are smashed and cut, the straws slide and are not prone to being cut off is solved, and the cutting and smashing efficiency is improved. The whole smashing and squeezing integrated device with the smashing device is simple in structure and easy to maintain, and intelligent control can be achieved for different working conditions at the same time; the whole smashing and squeezing integrated device with the smashing device can be disassembled, disassembled devices can be independently used, the feed processing efficiency and machining quality can be greatly improved, and the smashing device and the smashing and squeezing integrated device with the smashing device are particularly suitable for machining of banana straws.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

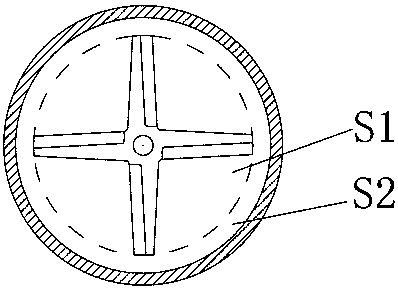

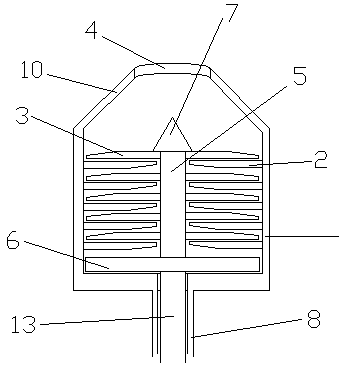

Food processing machine

ActiveCN108309085ALiquid level stabilityNot prone to splashingKitchen equipmentSlurryMechanical engineering

The invention relates to a kitchen small household appliance, in particular to a food processing machine. A crushing device for the food processing machine comprises a container, and is characterizedin that the container comprises a crushing cavity, a mixing cavity and a flow gathering opening; the crushing cavity is positioned at the bottom of the container; the mixing cavity is arranged above the crushing cavity; the flow gathering opening is used for communicating the crushing cavity and the mixing cavity; a crushing cutter blade is arranged in the crushing cavity; a downward pressing partfor driving the slurry to move towards the crushing cavity is arranged on the crushing cutter blade; the volume of the crushing cavity is 22 to 380 mL. The material can be concentrated in the small space crushing cavity; in addition, the crushing cutter blade is arranged in the crushing cavity, so that most materials can be concentrated in the crushing cavity to be crushed. Compared with the prior art, the kitchen small household appliance has the advantages that the structure is simple; the cost is low; in addition, the crushing device can be used for concentrated crushing on the materials;the crushing efficiency is high; the block formation phenomenon cannot occur; the cleaning is convenient.

Owner:JOYOUNG CO LTD

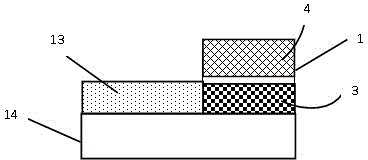

Thick and thin matched blades of rotary grinder

InactiveCN105618220AReduce wearImprove cutting and crushing efficiencyGrain treatmentsCentrifugal forceTechnical design

The invention discloses thick and thin matched blades of a rotary grinder. The thick and thin matched blades are made of stainless steel; shapes of the blades are matched according to the thickness; the blades are mounted in a 180-degree axially symmetric mode, so that the rotary centrifugal force is equal; the efficiency of the blades is relatively high, the service life of a motor is prolonged, the time is saved, the electric energy is saved; and the thick and thin matched blades are easy to manufacture and mount, and are more reasonable in technical design.

Owner:XIAN SHENKE ELECTRONICS RES INST

A Chinese herbal medicine crushing device for medical respiratory medicine

InactiveCN109046642BReduce the burden onPromote recoveryGrain treatmentsMetal working apparatusBiomedical engineeringMedical treatment

The invention relates to a crushing device of medical traditional Chinese medicine materials, in particular to a crushing device of traditional Chinese medicine materials in a medical respiratory medicine department. The crushing device of the traditional Chinese medicine materials in the medical respiratory medicine department can cut and crush the traditional Chinese medicine materials for multiple times, the labor intensity is low, and the burden of medical workers can be relieved; according to the technical scheme, the crushing device of the traditional Chinese medicine materials in the medical respiratory medicine department comprises a base, a large supporting plate, a first large connecting plate, a crushing cylinder, a small support, a first bearing, a first large rotating shaft, afirst belt wheel, a material pushing plate, a crushing cutter and the like, wherein the large supporting plate is connected to the left end of the top of the base. According to the device, the crushing device of the traditional Chinese medicine materials in the medical respiratory department can cut and crush the traditional Chinese medicinal materials for multiple times, so that the cutting andcrushing effects are good, the cutting and crushing efficiency is high, the labor intensity is low, time and labor are saved, the burden of the medical workers can be relieved, and rehabilitation andtreatment of a patient can be facilitated.

Owner:QINGDAO CENT HOSPITAL

Reed cutting equipment for papermaking

InactiveCN108560298BReduce labor intensityImprove cutting and crushing efficiencyCuttersGrain treatmentsPapermaking

The invention relates to reed cutting equipment for papermaking, in particular to reed cutting equipment for papermaking. The technical problem to be solved by the invention is to provide the reed cutting equipment with simple operation for the papermaking capable of reducing labor intensity and improving cutting and pulverizing efficiency. The reed cutting equipment for the papermaking comprisesa bottom plate, vertical plates, a top plate, a placing plate, a first connecting plate, a first bearing seat, a screw rod, a nut, a baffle plate, a handle and the like; left and right sides of the bottom plate are connected with the vertical plates, the top plate is connected between the tops of the two vertical plates, the upper portion of the left side surface of the vertical plate of the rightside is connected with the placing plate, and a groove is formed in the left side of the top of the placing plate. Reeds can be cut by moving a cutter up and down, the cut reeds can be pulverized through rotating cooperation of first crushing teeth and second crushing teeth, and the effects of labor intensity reduction, improved cutting and pulverizing efficiency and simple operation are achieved.

Owner:林金印

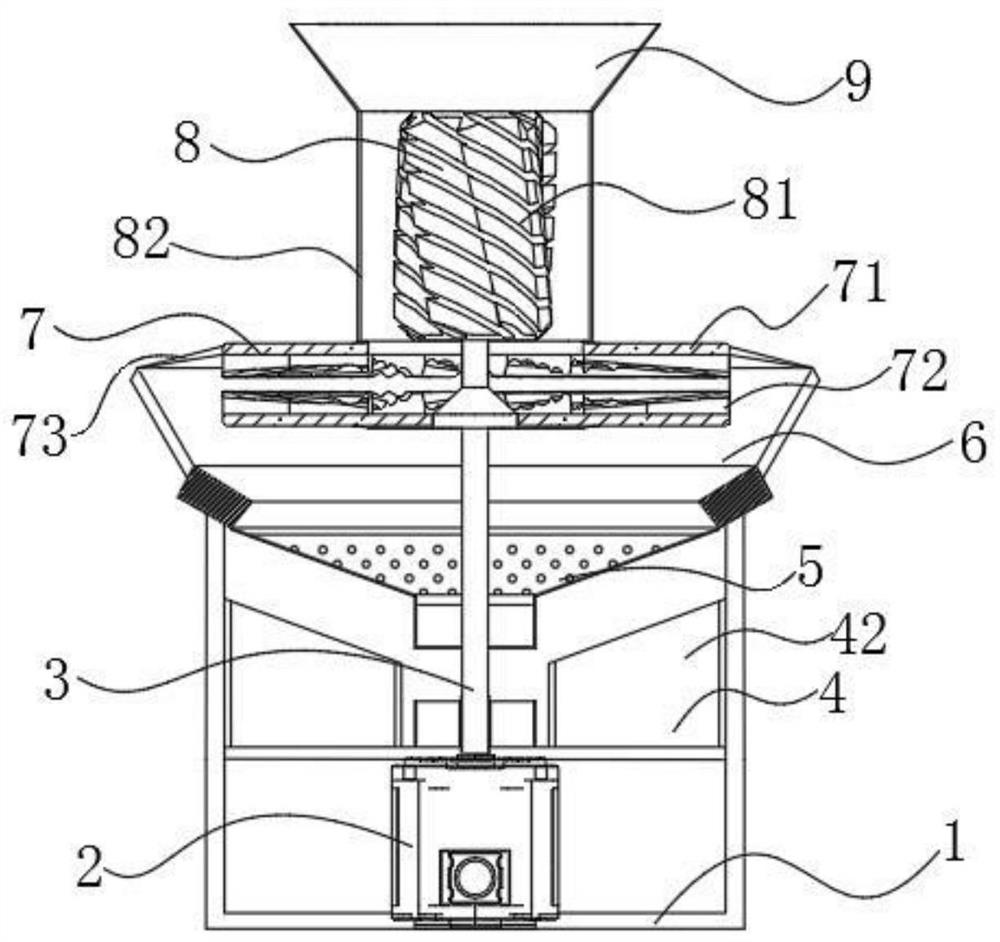

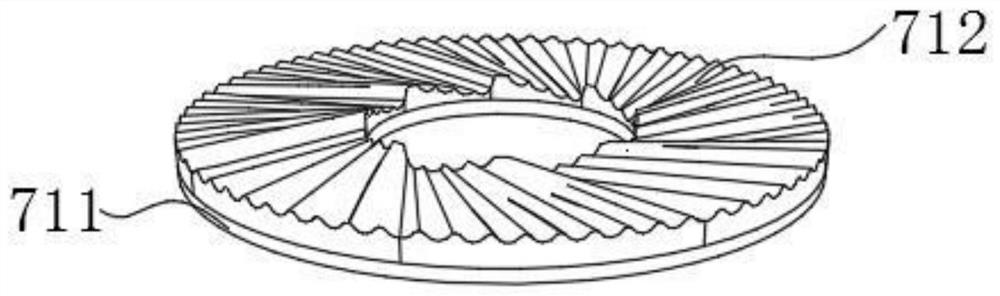

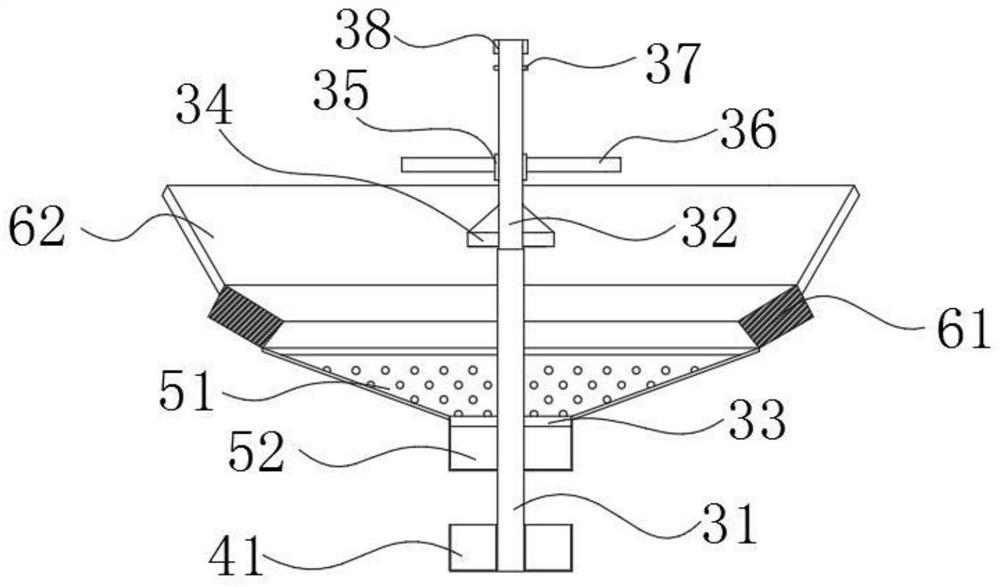

Automatic pomegranate threshing device

ActiveCN114831324AReduce fratricideImprove cutting and crushing efficiencySaving energy measuresVegetable peelingAgricultural engineeringElectric machinery

The automatic pomegranate threshing device comprises a rack, a motor, a transmission assembly, a collecting device, a screening device, a concentrating device, a crushing device, a cutting device and a feeding port, the rack bears working equipment, and the motor is arranged in the center of the bottom of the rack; the transmission assembly is fixedly connected with the motor; the collecting device is fixed to the rack and located above the motor. The screening device is arranged over the collecting device and fixedly connected with the transmission assembly. The concentrating device is fixed on the rack and is rotatably connected with the screening device; the crushing device is arranged over the screening device, the upper part of the crushing device is slidably connected with the transmission assembly, and the lower part of the crushing device is fixedly connected with the transmission assembly. The cutting device is fixed to the top of the transmission assembly and fixedly connected with the crushing device. And the feeding hole is fixed above the cutting device. Compared with the prior art, pomegranate of different sizes is separated after being cut and crushed, fruit crushing is reduced, and the screening efficiency is improved.

Owner:WENZHOU UNIV OUJIANG COLLEGE

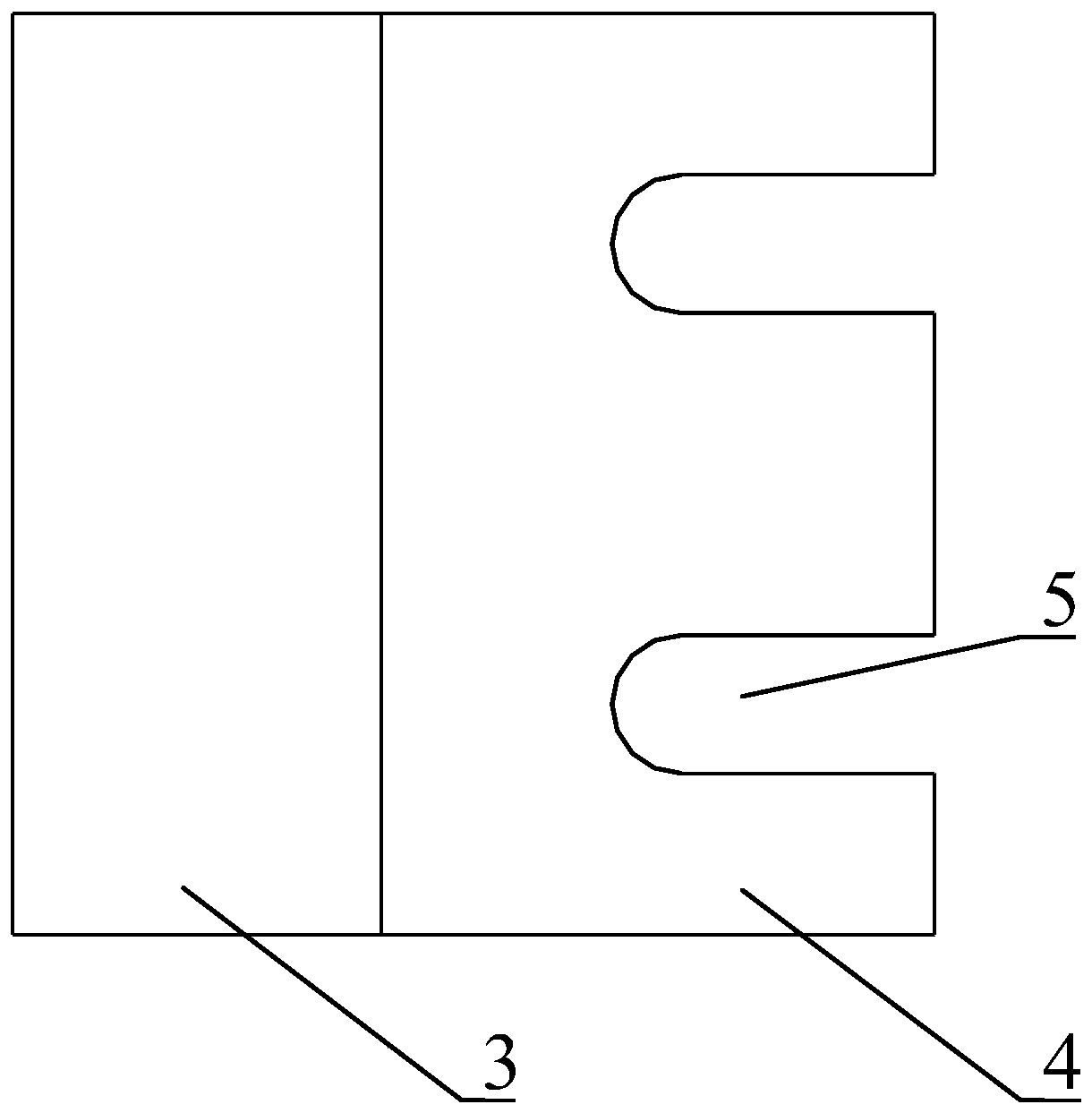

Cutter of traditional Chinese medicine pulverizer

InactiveCN107899693APrevent throwingReduce cutting and tearing forceGrain treatmentsDrive shaftEngineering

The invention relates to a traditional Chinese medicine pulverizer cutter, comprising a cutter head, a bowl-shaped cover is provided on the top of the cutter head, and the bowl-shaped cover and the cutter head are fixedly connected by bolts, and the top of the bowl-shaped cover is provided with a feeding The side of the cutter head is symmetrically provided with a discharge port, the inner wall of the cutter head is symmetrically provided with a support plate, the top of the support plate is provided with a lower blade, and the bottom of the cutter head is provided with a sleeve, The casing inner cavity is provided with a transmission shaft, and the transmission shaft and the casing are connected by bearings, the top of the transmission shaft is provided with a chassis, the top of the chassis is provided with a column, and the top of the column is provided with a triangular head. And the chassis, column, and triangular head are all located in the inner cavity of the cutter head, the side of the column is symmetrically provided with two supporting plates, the bottom of the two supporting plates is equipped with an upper blade, and the gap between the upper blade and the second supporting plate is It is connected by bolts and can be disassembled for easy maintenance or blade replacement.

Owner:潍坊金聖铸造材料有限公司

a food processor

ActiveCN108309085BLiquid level stabilityGuarantee the efficiency of cutting and crushingKitchen equipmentProcess engineeringSlurry

The invention relates to a small kitchen appliance, in particular to a food processing machine. The crushing device for the food processing machine includes a container, which is characterized in that: the container includes a crushing chamber located at the bottom of the container, a mixing chamber arranged above the crushing chamber and It is used to connect the crushing chamber and the converging port of the mixing chamber. The crushing chamber is provided with a crushing blade, and the crushing blade has a pressing part that drives the slurry to move toward the bottom of the crushing chamber. The capacity of the crushing chamber is 22mL~ 380mL. The material of the present invention will be concentrated in the crushing chamber in a small space, and the crushing chamber is provided with crushing blades, therefore, most of the materials will be concentrated in the crushing chamber for crushing. Compared with the prior art, the structure is simple and the cost is low. It is relatively low, and the crushing device can crush the materials intensively, the crushing efficiency is high, there will be no bean lumps, and it is easy to clean.

Owner:JOYOUNG CO LTD

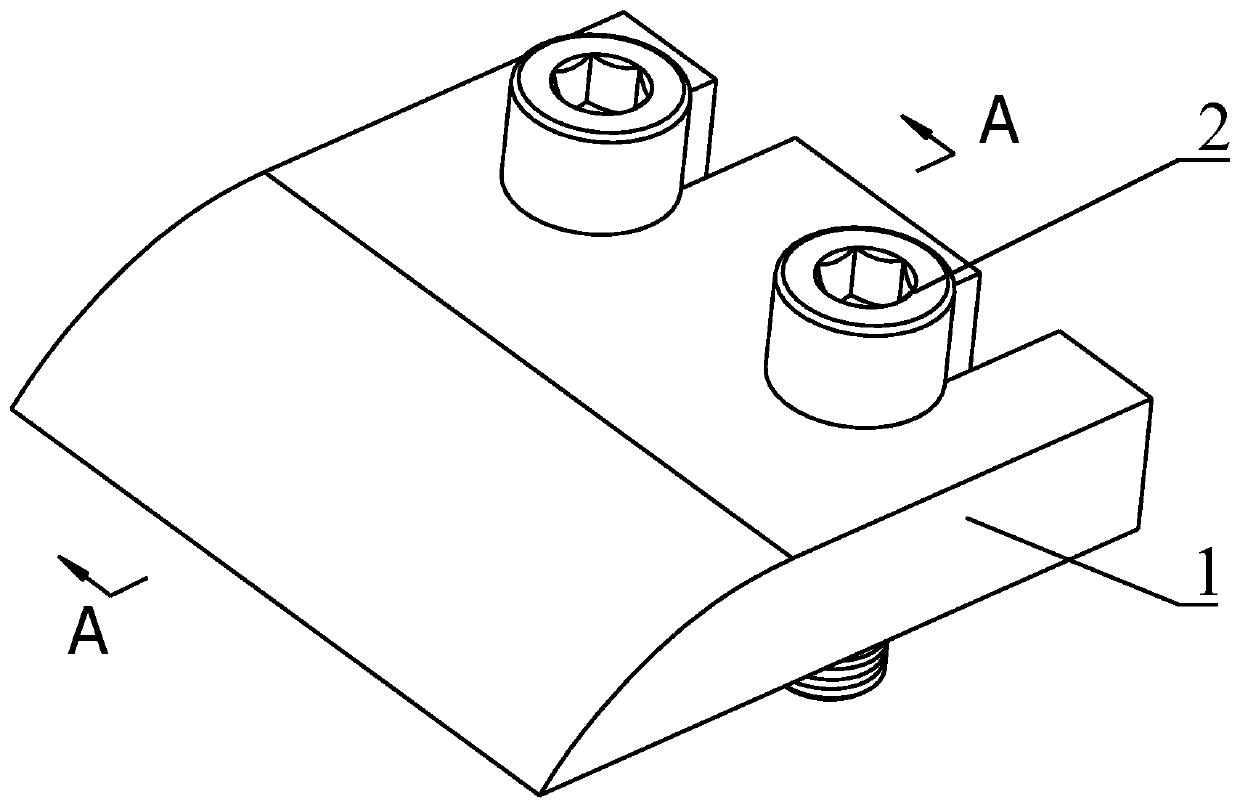

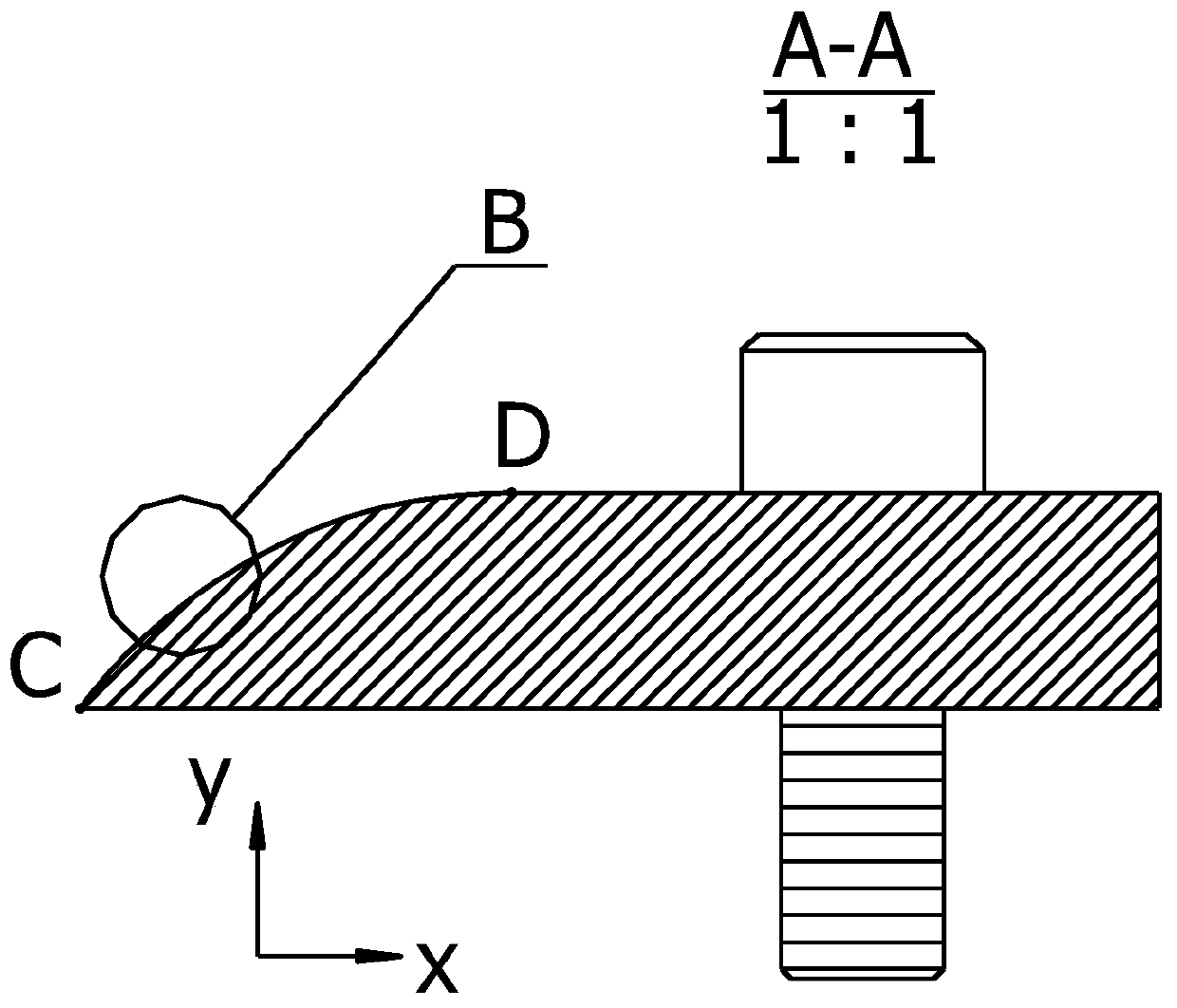

Corrosion-resistant tree branch crushing cutter imitating the structure of beaver incisors

The invention provides a beaver incisor structure-imitated anti-corrosion branch crushing tool. The anti-corrosion branch crushing tool consists of a bionic blade and positioning bolts, wherein the bionic blade consists of a bionic cutting edge and a tool holder; U-shaped positioning holes 5 are formed in the tool holder 4; each positioning bolt 2 is arranged in the corresponding U-shaped positioning hole 5 in manner of being perpendicular to the tool holder 4, thereby realizing fixed connection between the bionic blade 1 and a body of a crusher; the profile curve of the upper cutting surfaceof the bionic cutting edge 3 of the bionic blade 1 is a beaver incisor structure-imitated curve, and the curvilinear equation is as shown as follows: f(x)=a1x<2>+a0x; wherein the value range of a1 is-0.012 to -0.008, the value range of a0 is 0.55 to 0.70, and the value range of x is 0mm to 30mm; an MoS2 microballoon structure covers the upper surface of the bionic cutting edge; and nanopillars are distributed on the surface of the MoS2 in the radial direction. As a beaver incisor structure is imitated by the tool provided by the invention, during branch crushing, working resistance of the branch crushing tool is reduced, and crushing efficiency is increased.

Owner:JILIN UNIV

Crusher for drying debris

ActiveCN107263765AImprove cutting and crushing efficiencyPlastic recyclingMechanical material recoveryEngineeringCrusher

The invention relates to the technical field of crushers, and discloses a crusher for drying debris. The crusher comprises a base, a charging barrel, a rotating shaft, blades and a motor, and the charging barrel is rotatably connected to the base; the crusher also comprises a driving bevel gear, a driven bevel gear, a cylindrical gear and a rack, and the top of the charging barrel is rotatably connected to a lug of which one side is provided with a motor; the top of the charging barrel is provided with a round hole, and a cylindrical cavity with the same radius as that of the round hole is formed at the contact surface between the lug and the round hole correspondingly; the top of the cavity is provided with a circumferential convex wavy structure, and the rotating shaft penetrates through the round hole and is fixedly arranged in the charging barrel; the other end of the rotating shaft extends into the base, and is also provided with a groove for a connecting rod to be inserted; one end of the connecting rod in the rotating shaft extends out of the rotating shaft, and comes into contact with the top of the cavity; and the other end of the connecting rod is connected to a spring arranged in the groove. The inventions aims to provide the crusher for drying the debris, with the crushing efficiency improved effectively; and the crusher can be used for drying plastic debris.

Owner:桐城市建设投资发展有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com