Novel crushing and dehydrating feed processing equipment

A feed processing and equipment technology is applied in the field of new crushing and dehydrating feed processing equipment, which can solve the problems of difficult cutting and straw slippage, and achieve the effects of low cost, strong practicability, and improved cutting and crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment, further illustrate the present invention.

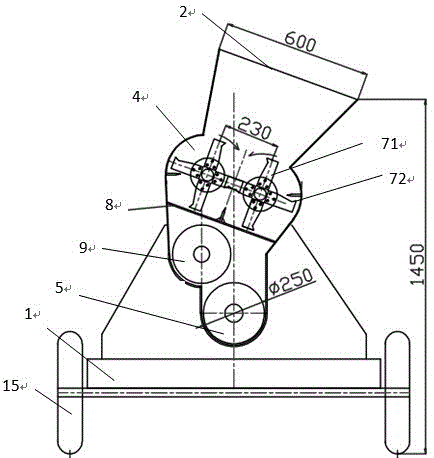

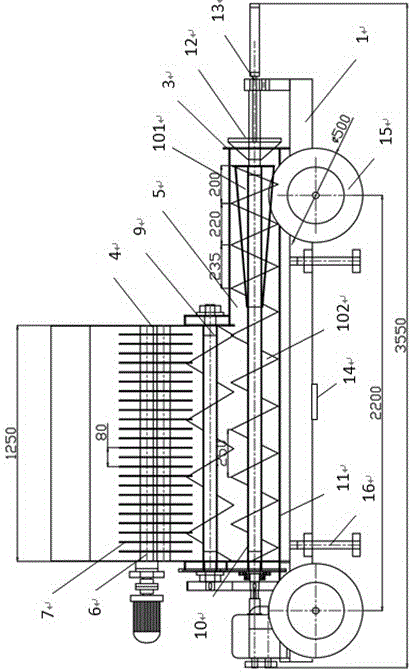

[0024] like Figure 1-2 As shown, a new crushing and dehydrating feed processing equipment includes a frame 1, a feed inlet 2, a discharge outlet 3, a crushing mechanism 4 and a dehydration mechanism 5. The feed inlet 2 is inclined at an acute angle with the horizontal plane.

[0025] The crushing mechanism 4 includes two rotating shafts 6 that rotate relatively from top to bottom and from outside to inside, and movable knife sets 7 arranged axially at intervals along the rotating shafts 6 . The line connecting the axes of the two counter-rotating rotating shafts 6 is inclined at an acute angle to the horizontal plane. The moving knife sets 7 on the two rotating shafts 6 are staggered from each other and partially overlap along the axial direction, that is, the two moving knife sets 7 change the linear cutting of the material into a zigzag cutting to improve the chopping efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com