Automatic pomegranate threshing device

A threshing device and automatic technology, which is applied in the fields of vegetable or fruit peeling, agricultural machinery and equipment, food science, etc., can solve the problems of difficulty in accurately finding the part of the membrane flap, damaged pomegranate seeds, and laborious peeling, so as to improve the cutting and crushing efficiency. , the effect of reducing accidental injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

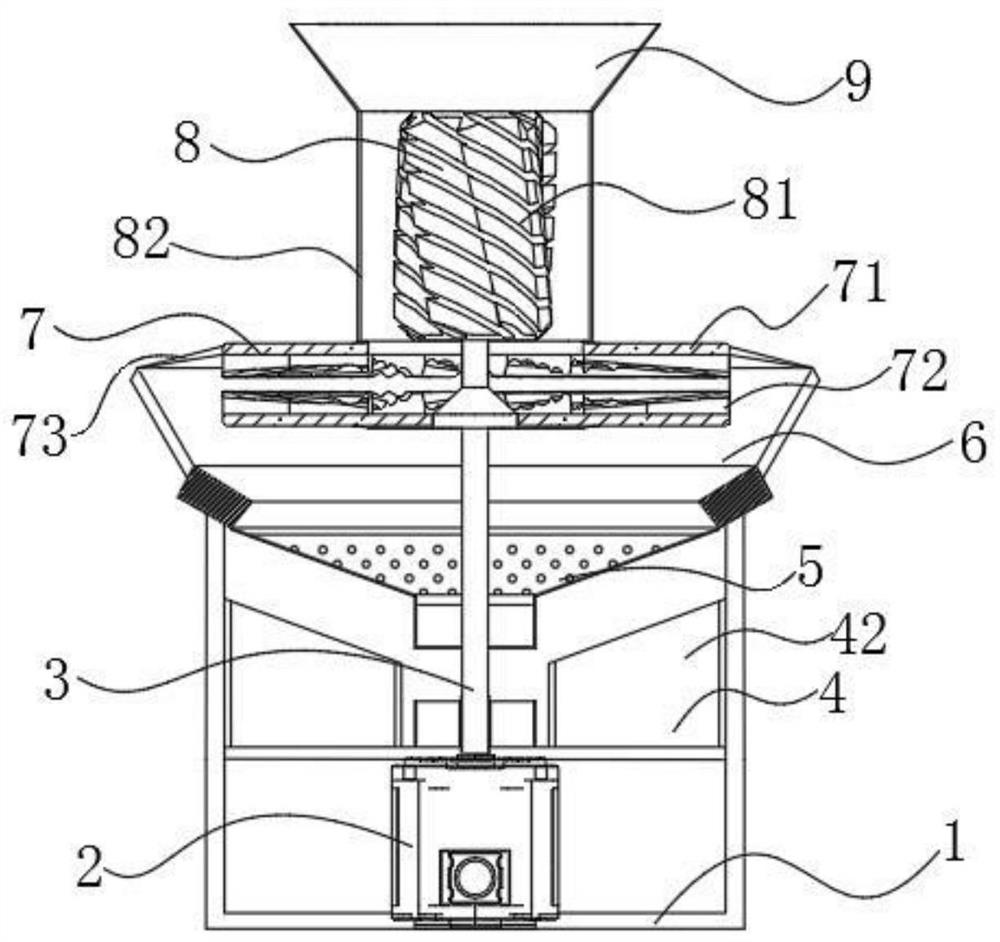

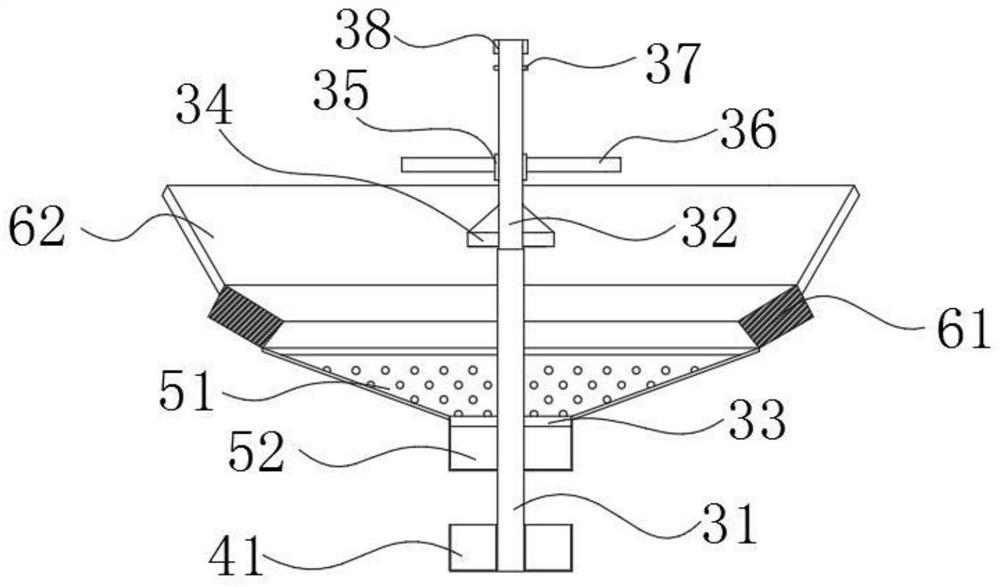

[0051] see Figures 1 to 4 , In the embodiment of the present invention, a pomegranate automatic threshing device includes:

[0052] Rack 1, carrying working equipment;

[0053] Motor 2, fixed at the bottom center of frame 1;

[0054] The transmission assembly 3 is fixedly connected with the motor 2;

[0055] The collecting device 4 is fixed on the frame 1 and is located above the motor 2;

[0056] The screening device 5 is arranged just above the collecting device 4 and is fixedly connected with the transmission assembly 3;

[0057] The concentration device 6 is fixed on the frame 1 and is rotatably connected with the screening device 5;

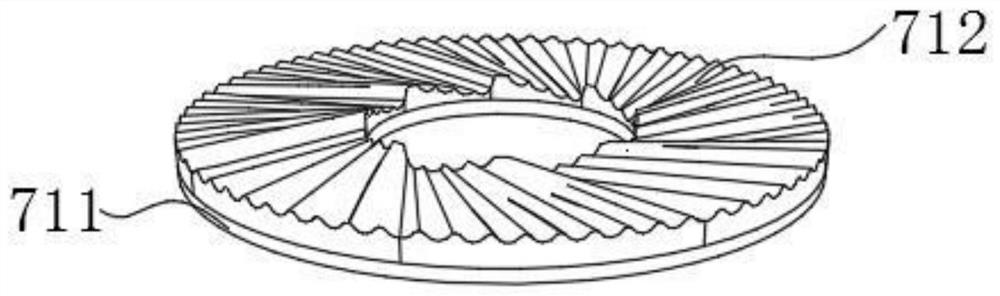

[0058]The crushing device 7 is arranged just above the screening device 5, the upper part is slidably connected with the transmission assembly 3, and the lower part is fixedly connected with the transmission assembly 3;

[0059] The cutting device 8 is fixed on the top of the transmission assembly 3 and is fixedly connected with the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com