Thick and thin matched blades of rotary grinder

A pulverizer and blade technology, which is applied in the field of rotating pulverizers with thick and thin blades, can solve the problems of incomplete pulverization and low efficiency of food cutting and pulverization, and achieve the effects of shortening pulverizing time, improving pulverizing efficiency and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in combination with specific embodiments.

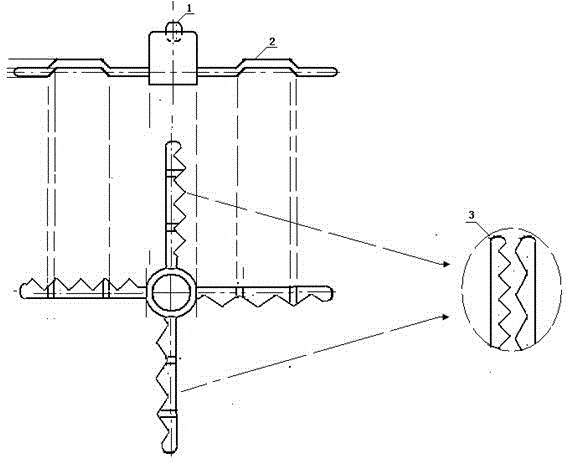

[0010] see figure 1 , a rotary shredder with blades in thickness, including a connecting shaft 1, a blade 2, and a blade 3, characterized in that: the blade 2 is fixed in the shredder through the connecting shaft 1, and the center of the blade 2 has a protrusion, so The blade 3 is serrated, and the number of the blades 2 is 4, which are installed symmetrically at 180 degrees.

[0011] When in use, the blade should be sharper, the shape is basically the same as the bottom of the pulverizer, and it should work for about 5 seconds each time. The crushed material should not be too much, and it should not be overloaded for a long time and work at low speed, which is easy to damage the motor. Above, you should rest for a while, the grinder is suitable for working under dry and long temperature.

[0012] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com