Breaking machine

A crusher and casing technology, applied in the field of bulk crushers, can solve the problems of shortening the service life of blades 4-4, time-consuming downtime for replacement, and reducing crushing efficiency, so as to improve cutting and crushing efficiency and reduce the number of times of downtime to replace blades. , Improve the effect of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

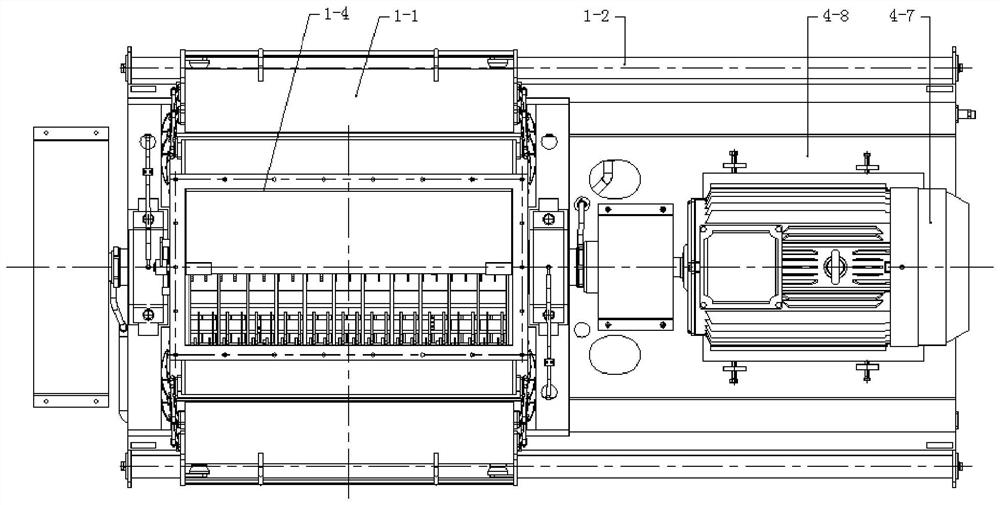

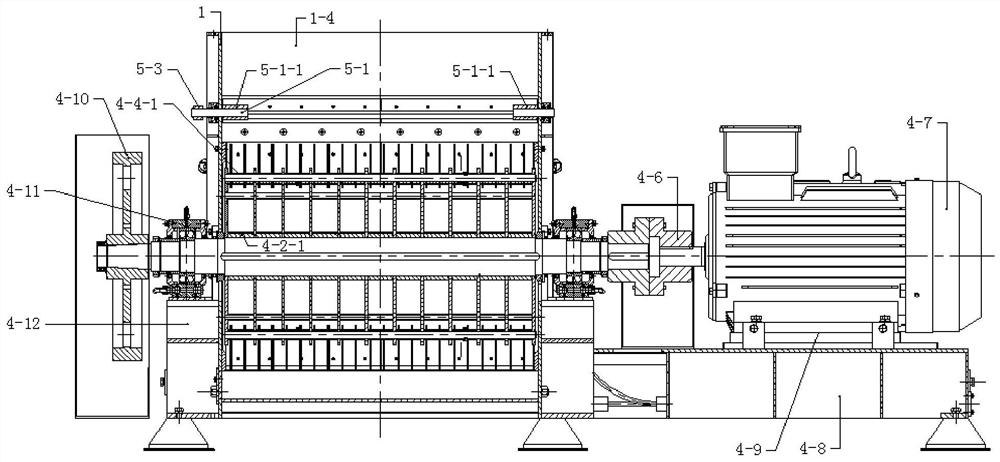

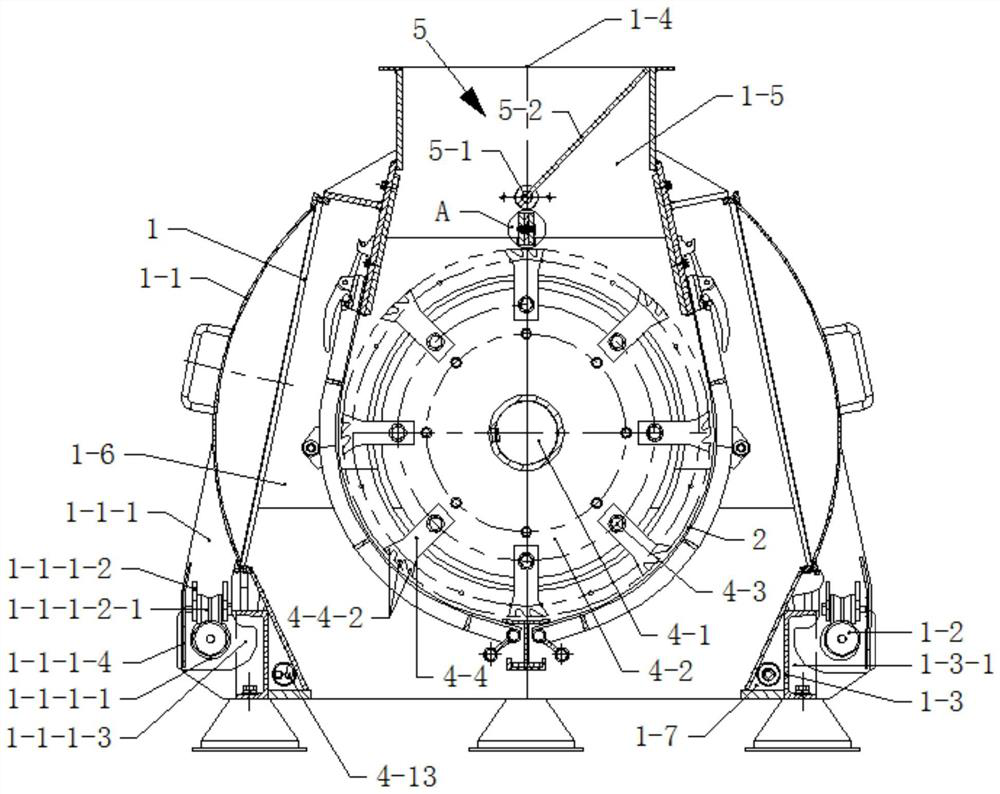

[0049] A chip breaker, comprising a casing 1. Such as image 3 As shown, the casing 1 can be placed directly on the ground without a base, thereby lowering the center of gravity of a kind of breaking machine of this embodiment, making the running of a kind of breaking machine of this embodiment more stable and reliable.

[0050] Such as image 3 As shown, the side wall of the casing 1 is provided with an operation door 1-1. The lower end of the casing 1 is fixed with a guide rod 1-2 and a limiting plate 1-3 by bolts, and the limiting plate 1-3 is provided with a limiting long groove 1-3-1 on a side away from the casing 1 . The lower end of the operating door 1-1 is welded with a slide plate 1-1-1, the slide plate 1-1-1 is provided with a guide hole 1-1-1-1, and the guide hole 1-1-1-1 cooperates with the guide rod 1-2 . Sliding seat 1-1-1-2 is welded on the sliding plate 1-1-1, and roller 1-1-1-2-1 is installed on the sliding seat 1-1-1-2, and roller 1-1-1-2 -1 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com