Smashing nail removing machine for building plastic formwork

A technology for plastic formwork and construction, applied in grain processing and other directions, can solve the problems of low efficiency, high power and high cost, and achieve the effects of high efficiency, high speed and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

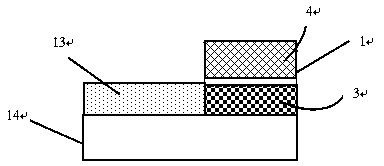

[0029] See attached image 3 , a building plastic formwork crushing and nail removal machine, comprising a bracket 1, a feeding table 12, an upper cutter roller, and a lower cutter roller.

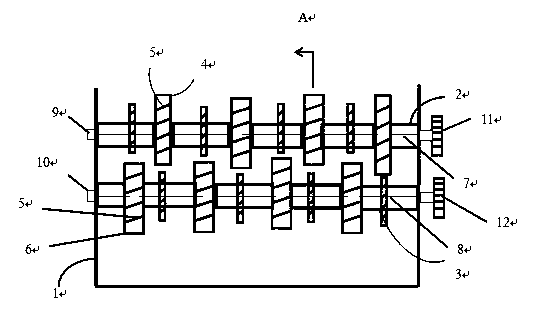

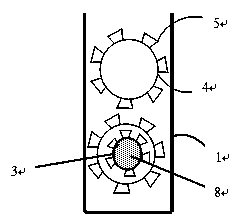

[0030] See attached figure 1 , figure 2 and image 3 , a building plastic formwork crushing nail remover, comprising a bracket 1, a feeding table 12, an upper cutter roller, a lower cutter roller, the upper cutter roller and the lower cutter roller are arranged on the support up and down; the upper cutter roller includes an upper cutter roller Knife roller frame 2, upper main shaft 7, upper bearing seat 9 and upper driving wheel 12, said upper knife roller frame 2 is installed on the upper main shaft 7, and upper bearing seat 9 is 2 respectively arranged on the upper knife roller frame 2 Both ends and the upper knife roller frame 2 are fixedly arranged on the support 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com