Universal Feed Grinder

A pulverizer, general-purpose technology, applied in feed, application, grain processing and other directions, can solve the problems of single processing form, dust pollution, high energy consumption, and achieve the effects of high versatility, improved utilization efficiency, and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] The specific embodiment: the present invention will be further described below in conjunction with accompanying drawing:

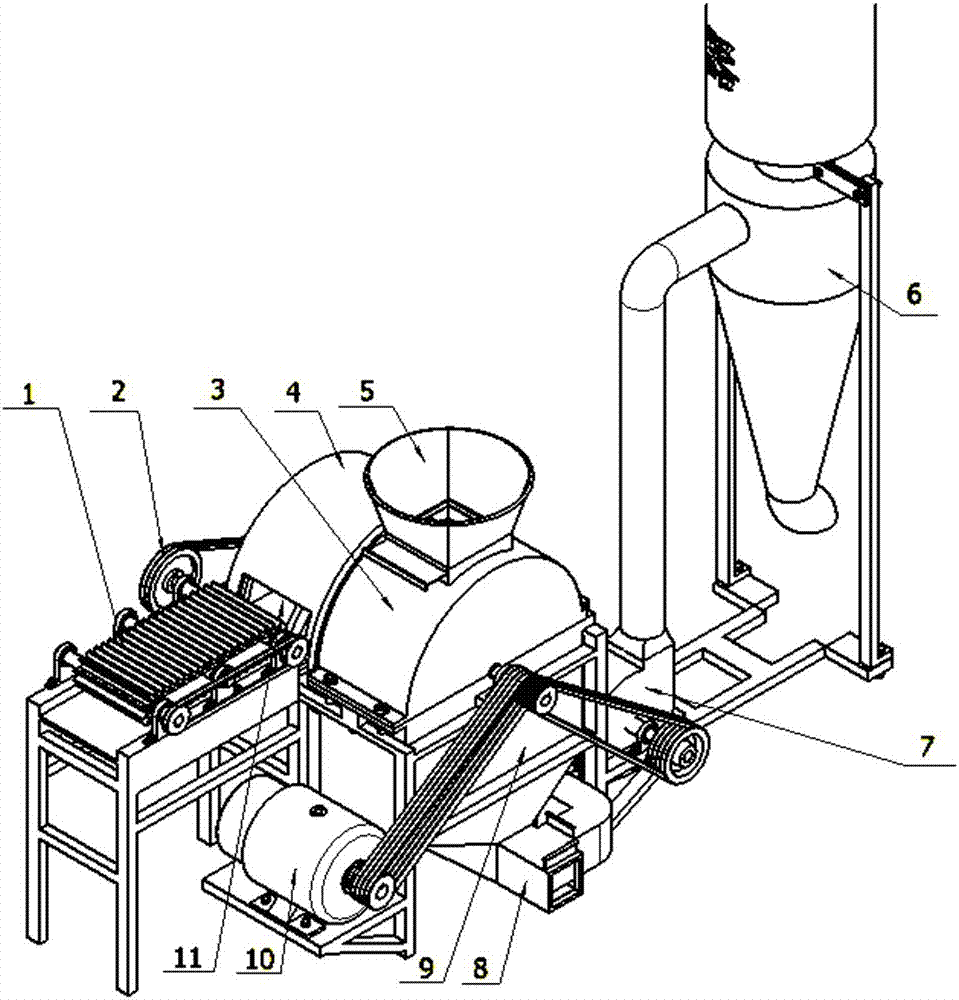

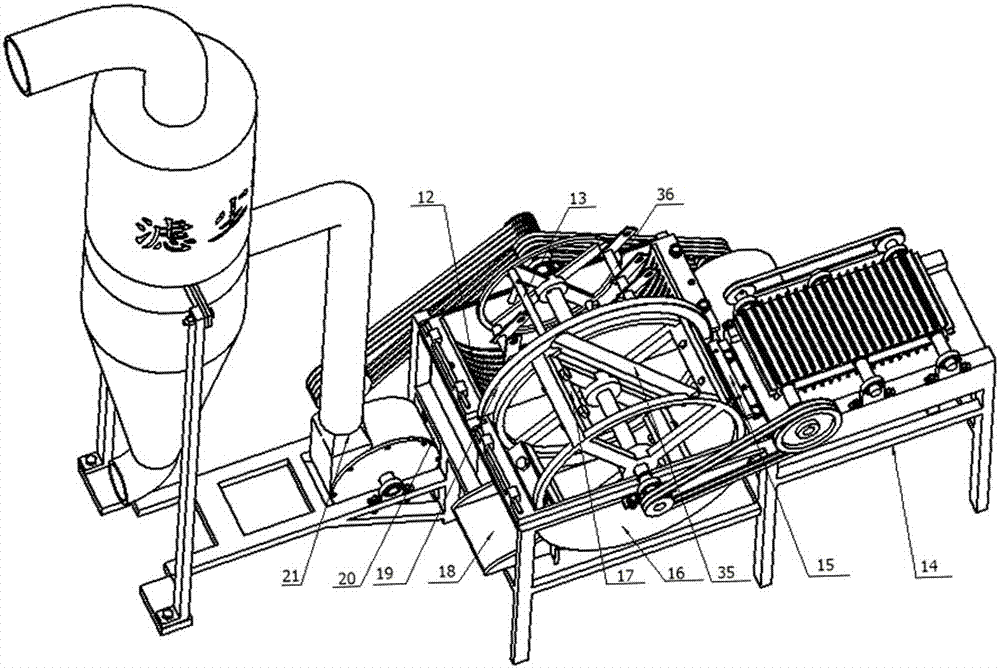

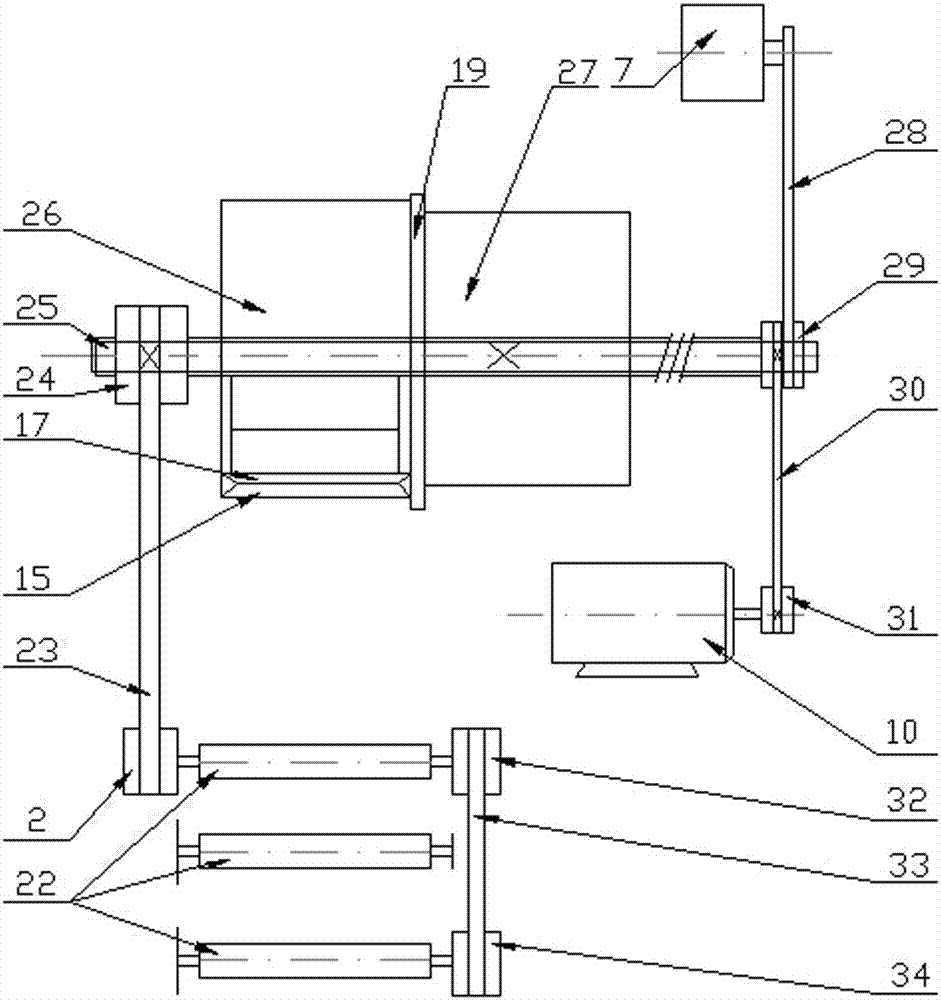

[0025] Such as figure 1 As shown, the present invention provides a kind of universal feed pulverizer, and this pulverizer comprises cutting working room 26, pulverizing working room 27, feeding device and material collection device; Cutting working room 26, pulverizing working room 27 and feeding device are arranged on machine On the frame 14; the cutting studio 26 and the crushing studio 27 are arranged side by side, the feeding device is arranged at the corresponding place of the cutting feed port 11 of the cutting studio 26, and the material collecting device is docked with the fan interface 20 of the crushing studio 27; the cutting work The chamber 26 and the crushing studio 27 are connected by the main shaft 25, the main shaft 25 is connected to the motor 10 through the V-belt 30, and the main shaft 25 is driven by the motor 10 through the V-be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com