Kitchen garbage crushing combined cutter

A technology of combining knives and kitchen waste, applied in the direction of grain processing, etc., can solve the problems of ineffective use, damaged knives, motor damage, etc., and achieve the effect of improving cutting and crushing effect, improving performance, and smooth processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

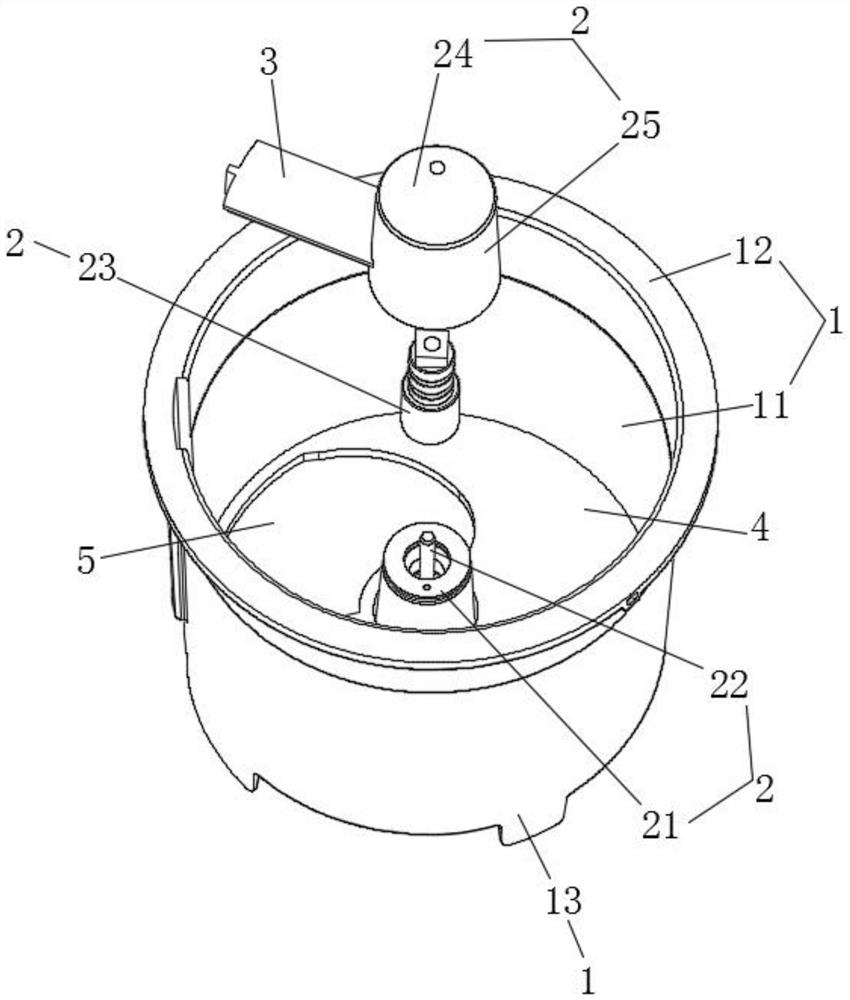

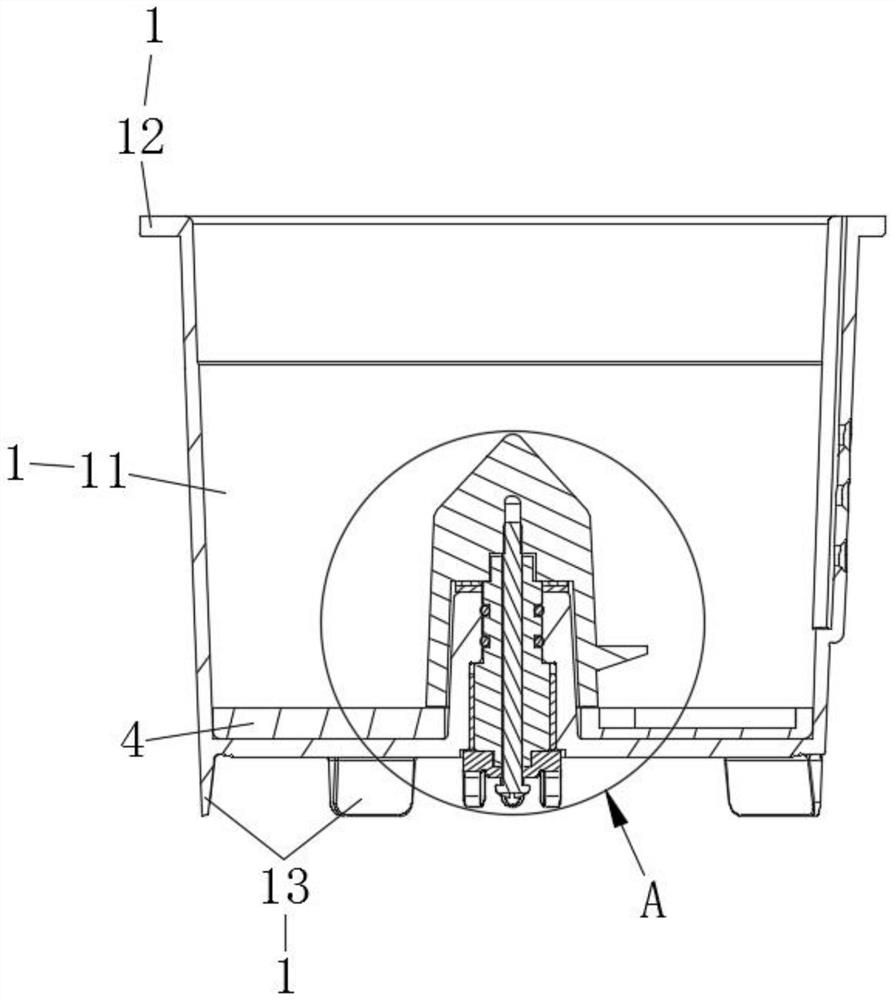

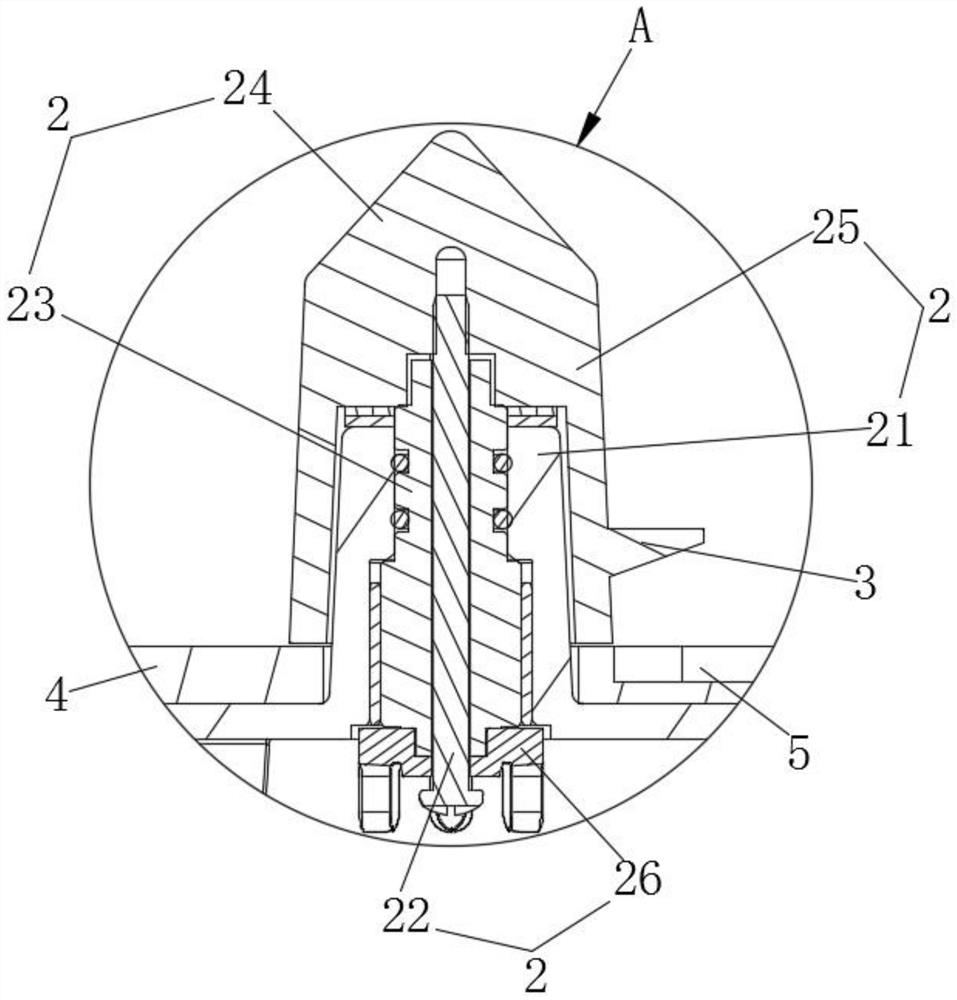

[0041] refer to figure 1 , the present embodiment discloses a kitchen waste shredding combined cutter, including a bucket 1 , a rotating assembly 2 , a cutting assembly 3 , a fixed blade 4 and an undercut 5 .

[0042] The barrel 1 includes a barrel body 11 , flanges 12 , and feet 13 . The opening of the barrel body 11 is bent outwards with a flange 12 . The bottom of the barrel body 11 is provided with three legs 13 distributed around the central axis of the barrel body 11 .

[0043] refer to Figure 4 and Figure 5 , the cutting assembly 3 includes a movable blade 31 . The movable blade 31 is welded outside the outer connecting sleeve 25 . And movable blade 31 is arranged on 2-3cm above fixed blade 4. The cutting edge of the moving blade 31 is towards the arc-shaped cutting edge of the bottom notch 5, and the cutting edge of the moving blade 31 performs a shearing movement relative to the cutting edge of the bottom cutting 5 to cut off the rubbish lump held between the ...

Embodiment 2

[0059] The difference from Embodiment 1 is that there are two sets of moving blades 31 , which are arranged up and down respectively, and the two sets of moving blades 31 are all welded on the outside of the outer connecting sleeve 25 . The fixed blades 4 have two groups, and are spaced up and down with the two groups of moving blades 31 . The bottommost fixed blade 4 is located below the bottommost movable blade 31 . Two groups of fixed blades 4 are all fixed on the barrel wall of the feed barrel 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com