Single-shaft deep mixing pile drilling tool with inner-layer and outer-layer mixing teeth

An inner and outer double layer, stirring tooth technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of single shaft deep stirring pile body quality defect, large disturbance of adjacent stratum, etc., to improve cutting and crushing efficiency, stratum The effect of small disturbance and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

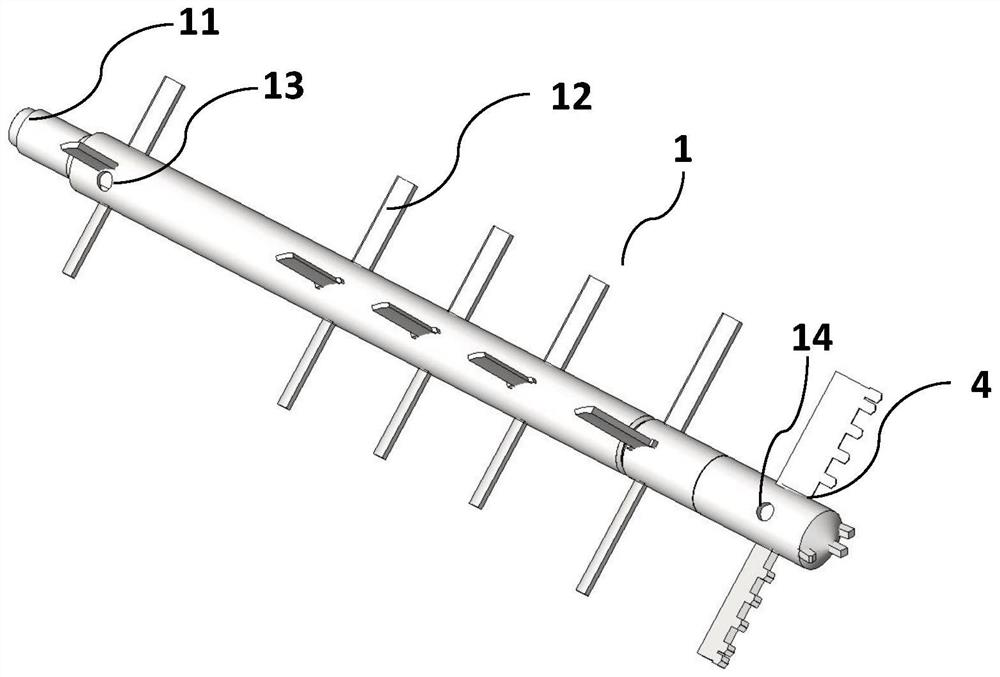

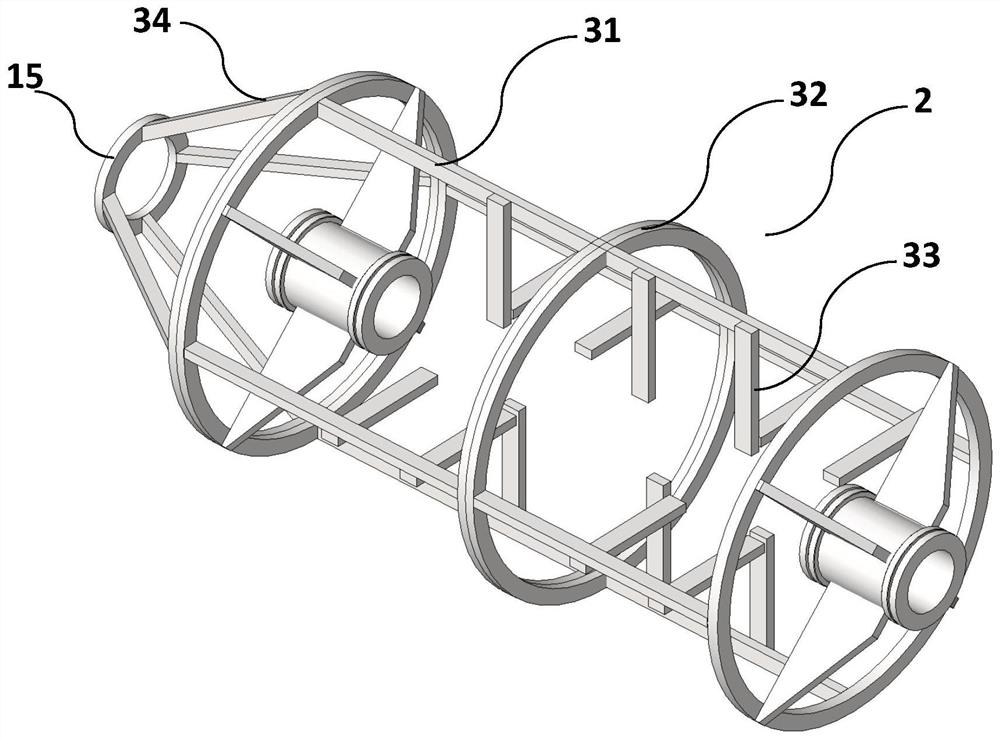

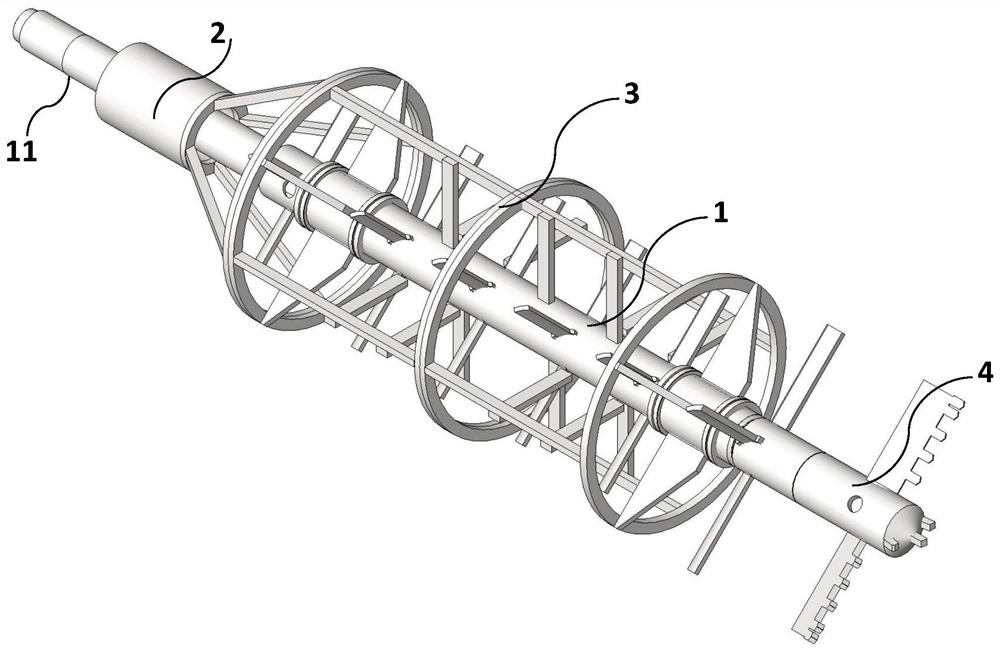

[0034] Example 1. Construction method of deep-stirring piles to reduce disturbance by isolating the ground outside the borehole

[0035] When the stirring teeth of the traditional mixing pile cut and break the formation, there is still a large disturbance to the formation outside the borehole, thus affecting the construction facilities near the mixing pile. Using the single-axis stirring pile drilling tool of the present invention, the stirring cover 3 of the outer layer can isolate the broken soil body in the borehole from the formation outside the borehole, and when the stirring shaft 1 of the inner layer rotates together with the drill pipe, it is distributed in the stirring The stirring teeth 12 on the shaft 1 rotate inside the stirring cover 3, so that cutting and breaking rock and earth blocks can greatly reduce the disturbance of the formation outside the borehole.

example 2

[0036] Example 2. Construction method of deep-stirring pile with bottom spraying grouting to reduce drilling resistance and top spraying grouting fully mixed

[0037] A drill bit 4 is connected to the lower end of the stirring shaft 1, and a bottom grout port 14 is arranged at the bottom. When drilling down, the bottom grout port 14 sprays slurry to lubricate the drill bit in time, reducing the resistance of the drilling process. Simultaneously, the inner stirring tooth 12 and the outer stirring tooth 33 that the slurry of injection encounters in the drilling process give mixing, so that the soil solidifying agent (slurry) is mixed together with the broken rock and soil particles.

[0038] When the drill pipe is lifted up, the top grouting port 13 starts to spray grout, and the sprayed grout encounters the inner stirring teeth 12 and the outer stirring teeth 33 during the drilling process, giving mixing, so that the soil solidifying agent (slurry) and the crushing The rock and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com