Formaldehyde purifying biological plate and manufacturing method thereof

A formaldehyde purification and ecological board technology, which is applied in the fields of wood processing and paint-free veneer furniture boards, can solve problems such as distortion of the visual effect of decorative paper, and achieve the effects of realistic surface decoration effect, simple process and improvement of environmental quality indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

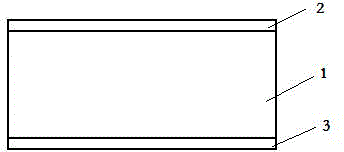

Image

Examples

Embodiment 1

[0052] a. Substrate sanding: Use a three-sand frame sander to sand the surface of 18mm ordinary poplar plywood, and the third sanding belt is 180 mesh. Measure its thickness error, the maximum error is 0.11mm. Observe its surface finish, the surface is smooth and clean, without wavy lines;

[0053] b. Formaldehyde decomposition glue preparation: fully mix the formaldehyde decomposition active ingredients and amino resin and stir evenly to obtain the formaldehyde decomposition glue; the mass ratio of the formaldehyde decomposition active ingredients to the formaldehyde decomposition glue is 5%, and the stirring time is 5min; the formaldehyde decomposition is effective The ingredients include chitin, nano-silicon chips and tourmaline powder; tourmaline powder accounts for 1wt% of the mass of formaldehyde-decomposing active ingredients;

[0054] c. Manufacture of decorative adhesive film paper: pass the decorative paper through amino resin glue and formaldehyde decomposition glue ...

Embodiment 2

[0061] a. Substrate sanding or applying veneer: Use a three-sand frame sanding machine to sand the surface of the 16.5mm blockboard core, and the third sanding belt is 200 mesh. Measure its thickness error, the maximum error is 0.22mm. Observe its surface finish, the surface is rough. Cover the surface with a layer of poplar veneer with a thickness of 0.5mm, and the moisture content of the veneer is 10%. and sanded to a smooth surface;

[0062] b. Formaldehyde decomposition glue preparation: fully mix the formaldehyde decomposition active ingredients and amino resin and stir evenly to obtain formaldehyde decomposition glue; the mass ratio of formaldehyde decomposition active ingredients to formaldehyde decomposition glue is 10%, and the stirring time is 10min; formaldehyde decomposition is effective The ingredients include chitin, nano-silicon chips and tourmaline powder; tourmaline powder accounts for 3wt% of the mass of formaldehyde-decomposing active ingredients;

[0063...

Embodiment 3

[0070] a. Substrate sanding: the substrate is blockboard core or plywood; if the surface finish of blockboard core or ordinary plywood substrate is poor or the thickness error exceeds 0.15mm, the surface needs to be covered with a layer of thickness 0.7mm, containing water The whole veneer with a content rate ≤ 5%, the veneer is usually poplar veneer or reconstituted decorative veneer;

[0071] b. Formaldehyde decomposition glue preparation: fully mix the formaldehyde decomposition active ingredients and amino resin and stir evenly to obtain the formaldehyde decomposition glue; the mass ratio of the formaldehyde decomposition active ingredients to the formaldehyde decomposition glue is 6%, and the stirring time is 8 minutes; the formaldehyde decomposition is effective The ingredients include chitin, nano-silicon flakes and tourmaline powder; tourmaline powder accounts for 5wt% of the mass of formaldehyde-decomposing active ingredients; the mass ratio of chitin, nano-silicon fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com