Dry method pelletizing machine

A dry granulation and granulation technology, applied in the extrusion granulation of raw materials, etc., can solve the problems of poor quality, hardness and disintegration of finished granules, high content of fine powder in finished products, and low degree of automated production. Low powder rate, improved granulation efficiency, and improved granulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

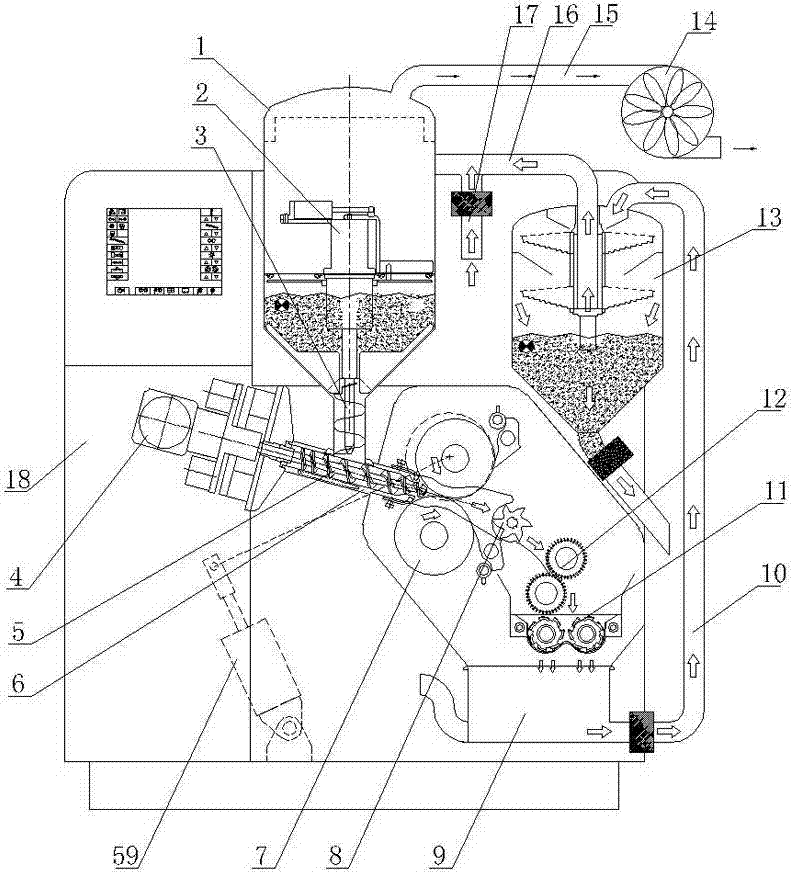

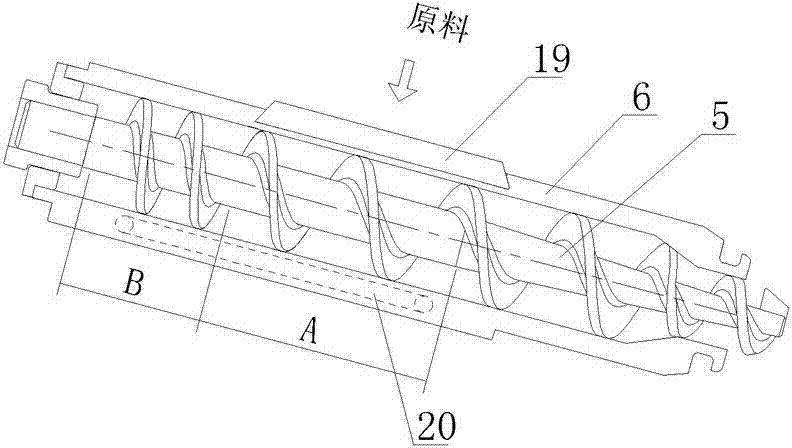

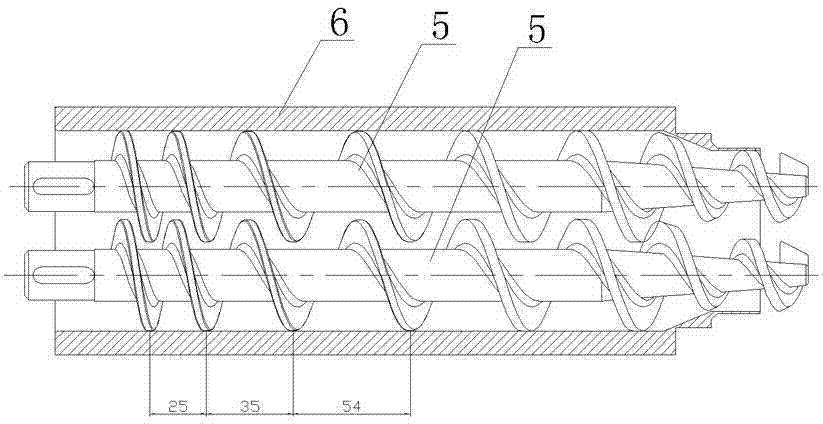

[0029] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0030] Such as figure 1 As shown, the dry granulator of the present invention includes a feeding mechanism, a vertical feeding mechanism, an oblique feeding mechanism, a tabletting mechanism, a crushing mechanism, a granulation mechanism and a sub-sieving mechanism arranged before the frame panel 18. Mechanism 13, the feeding mechanism includes a material barrel 1, which is connected to the vacuum system, that is, connected to the exhaust fan 14 through the connecting pipe 15. When the exhaust fan 14 is working, a vacuum is formed in the material barrel 1, so that the powder is passed from the powder bin through the connecting pipe 17 is pumped into the material barrel 1; the vertical feeding mechanism is located in the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com