Vertical double-tube-pass circulation fluidized bed evaporator with separation plate

A circulating fluidized bed and double-pipe technology, which is applied to forced circulation evaporators, evaporator accessories, evaporator adjustment/control, etc., can solve the problems of heat transfer performance decline, uneven particle distribution, etc., and achieve convenient processing, Improve the effect of enhanced heat transfer and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

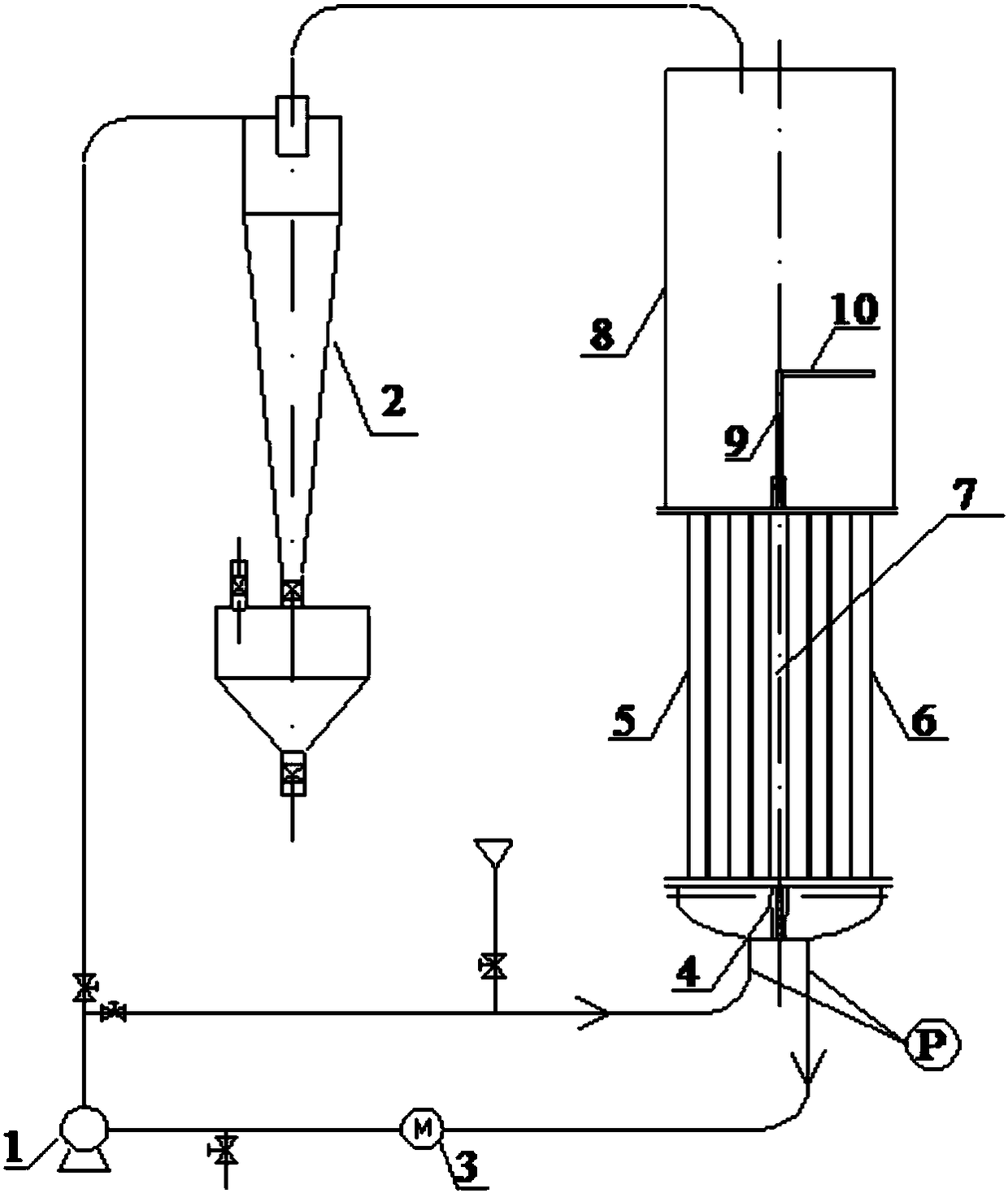

[0021] Such as figure 1 As shown, this embodiment discloses a vertical double-tube circulating fluidized bed evaporator with partitions, which is composed of a heating chamber 7 and an evaporation chamber 8, and the evaporation chamber 8 is located above the heating chamber 7, wherein the heating chamber 7 It can be divided into an ascending bed 5 and a descending bed 6 by the internal partition 4 of the head. A partition 9 is arranged in the evaporation chamber 8. The fluid flows through the ascending bed 5 of the heating chamber 7 and enters the evaporation chamber 8, and crosses the partition in the evaporation chamber 8. The plate 9 enters the lower bed 6 of the heating chamber 7 . Wherein, the height of the partition 9 is 0.05-0.2m.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com