Patents

Literature

32results about How to "Short process reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

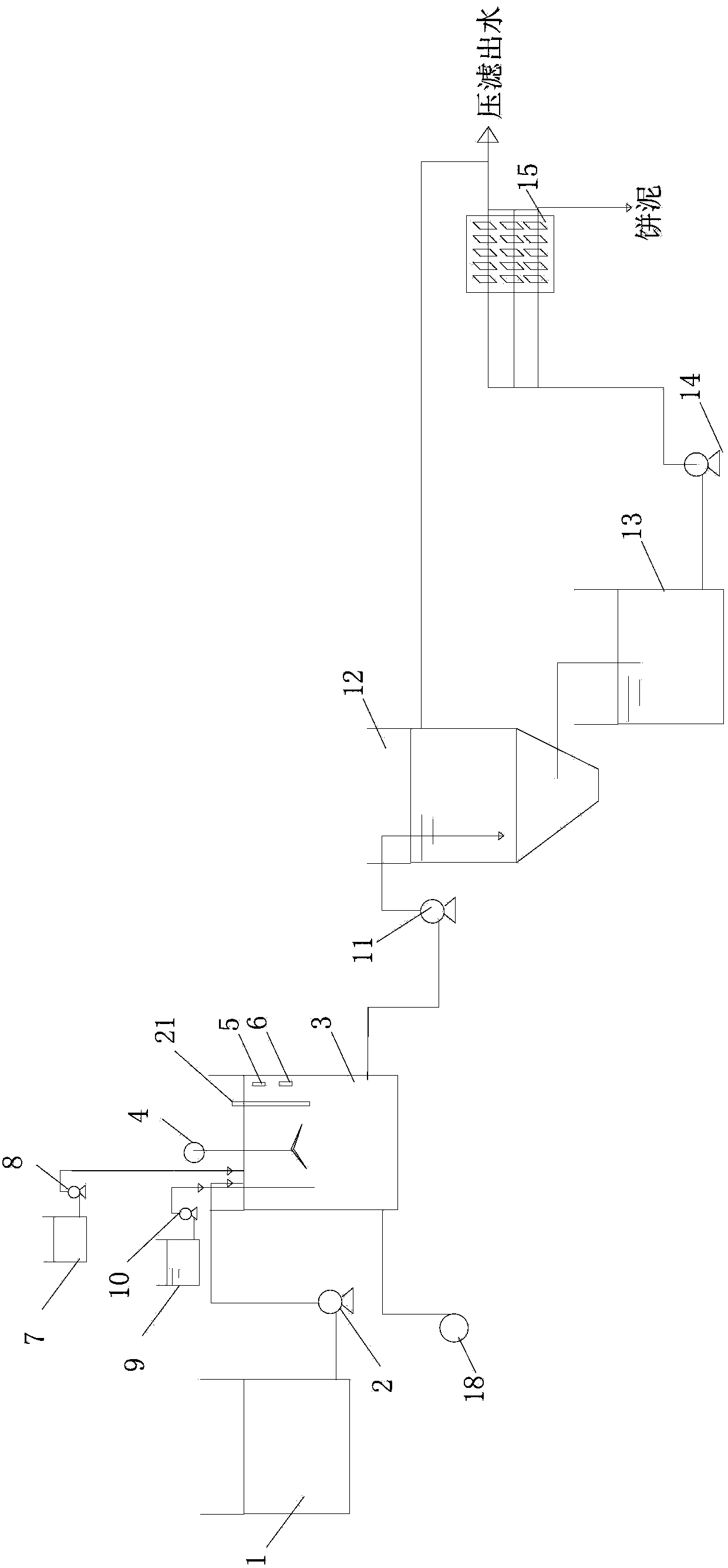

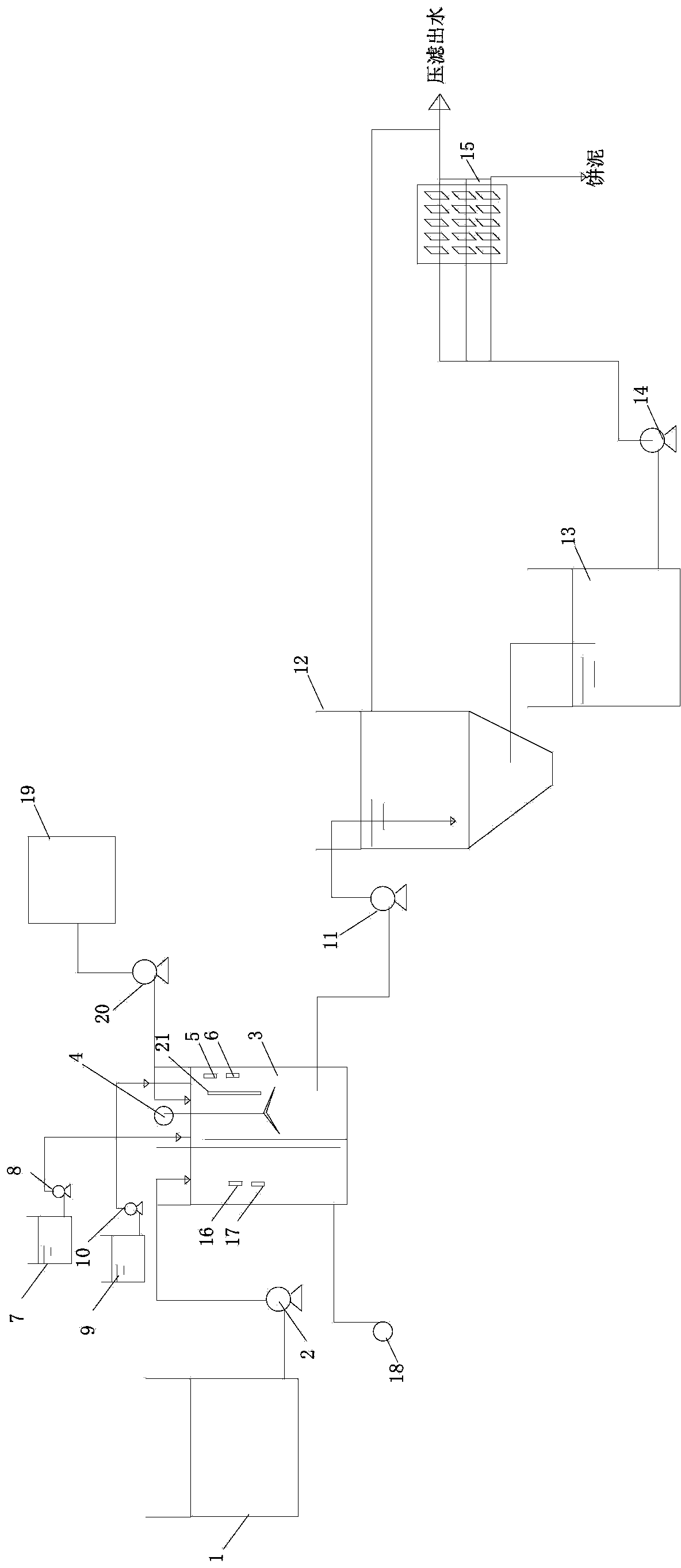

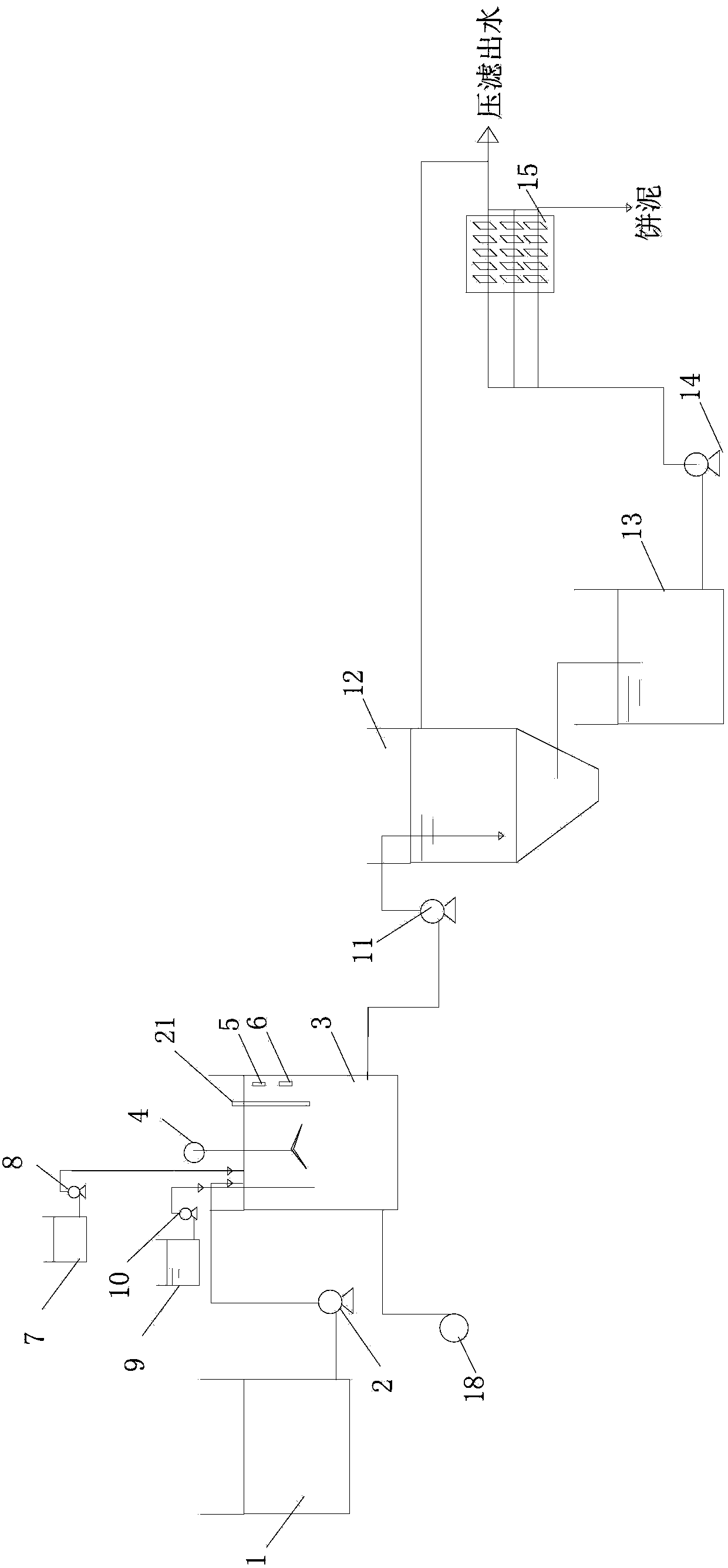

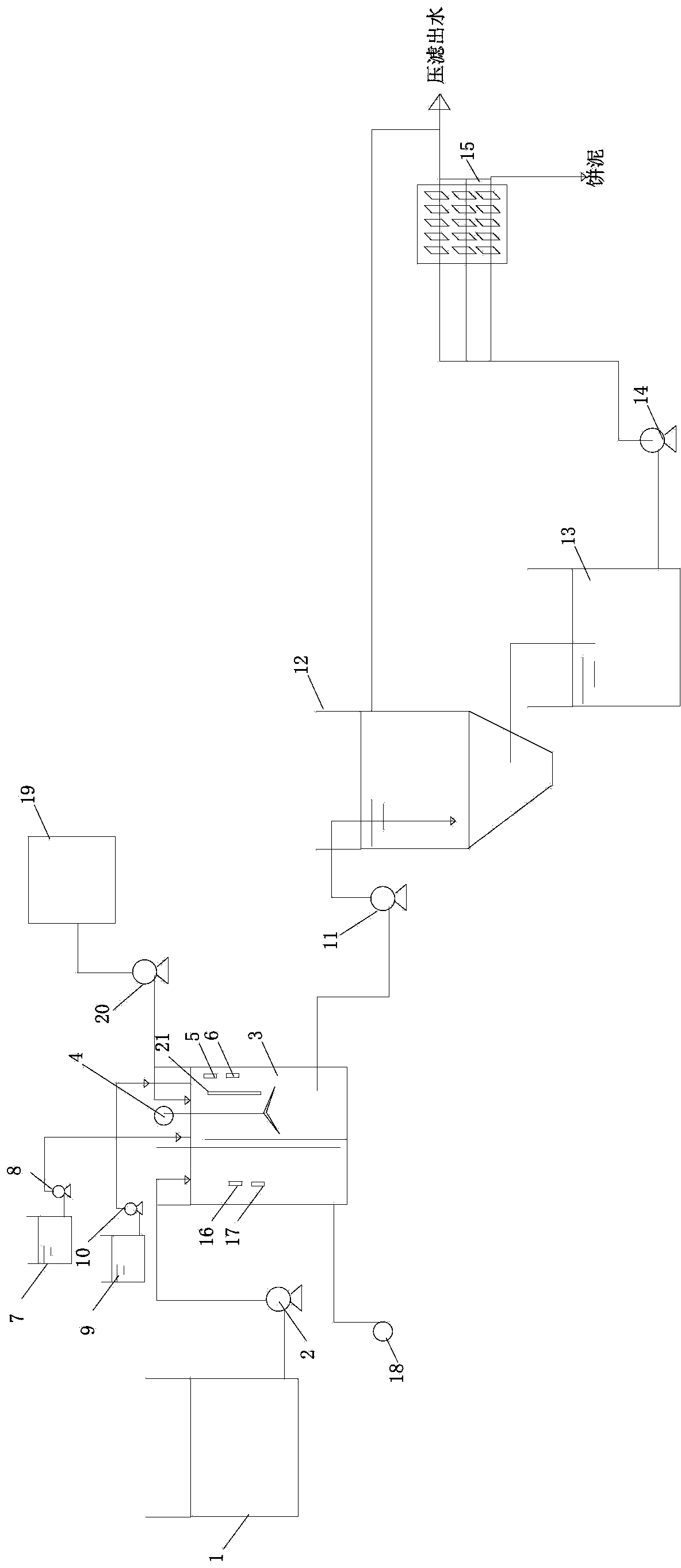

Acidic iron-containing wastewater recycling system and method for carrying out in situ modification by system

ActiveCN103408158AShort process reaction timeSmall footprintWaste water treatment from metallurgical processFerroso-ferric oxidesSludgeHigh pressure

The invention discloses an acidic iron-containing wastewater recycling system comprising a pickling wastewater storage pool, wherein the pickling wastewater storage pool is connected with a neutral oxidation reaction tank through a raw water acid proof pump, and a stirrer, a 1# online pH meter and a 1# online ORP (oxidation reduction potential) meter are fixed in the neutral oxidation reaction tank; an alkali liquor storage tank is connected with the neutral oxidation reaction tank through a 1# metering pump; a flocculant storage tank is connected with the neutral oxidation reaction tank through a 2# metering pump; the neutral oxidation reaction tank is connected with a settling tank through a slurry pump, the settling tank is connected with a sludge concentration tank, and a supernatant drain pipe is further connected to the settling tank; the sludge concentration tank is connected with a high pressure plate frame filter press through a high pressure slurry pump; and the neutral oxidation reaction tank is further connected with a blower. The invention further discloses an in situ modification method for treating wastewater by the acidic iron-containing wastewater recycling system. By adopting the acidic iron-containing wastewater recycling system disclosed by the invention, more than 55% of Fe3O4 can be stably prepared and recycled through in-situ reaction in an acidic wastewater neutralization tank under normal temperature and normal pressure conditions.

Owner:WUXI XINDU ENVIRONMENTAL PROTECTION EQUIP +1

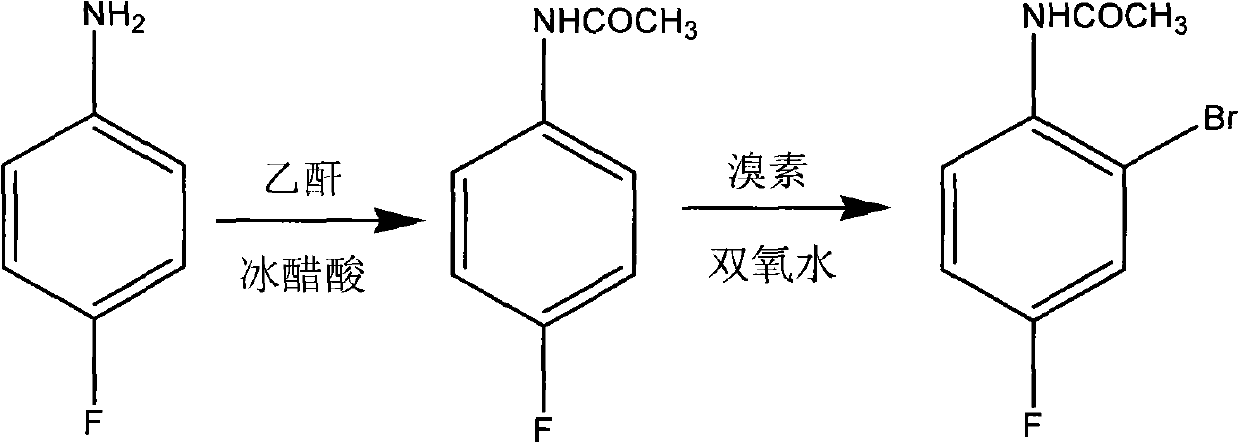

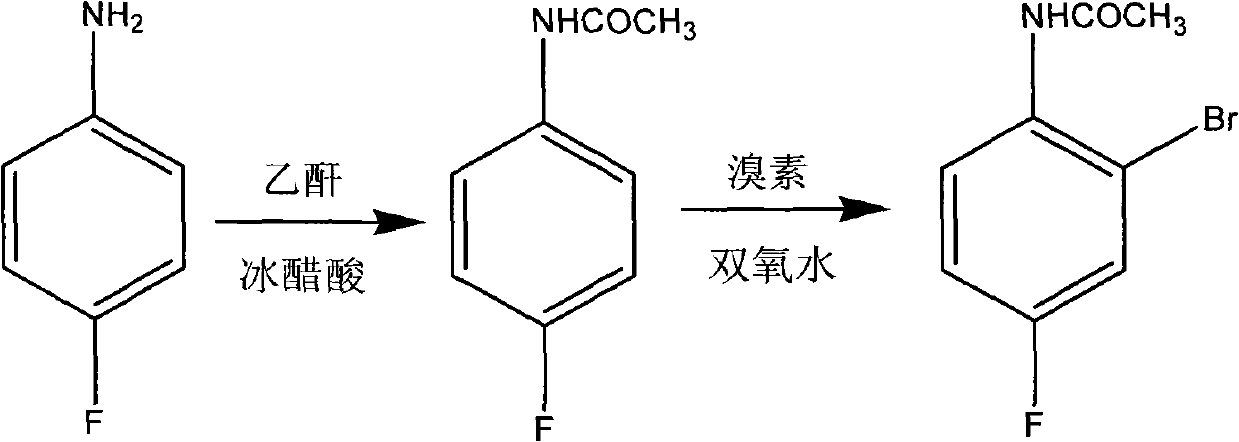

Preparation method of 2-br-4-fluoacetanilide

InactiveCN102120723AHigh reaction conversion rateHigh purityOrganic compound preparationCarboxylic acid amides preparationChemical reactionAcetic anhydride

The invention belongs to preparation of compound products of fine chemical engineering and particularly relates to a preparation method of 2-br-4-fluoacetanilide, which comprise the steps of: acetylation: adding para-fluoro aniline and glacial acetic acid into a reaction flask, heating to 50 DEG V, dropping acetic anhydride, carrying out reaction for 1-3h under the condition of 55-100 DEG C to prepare an intermediate para-fluoro acetanilide; and (2) bromination: dropping bromine at 45-55 DEG C, carrying out reaction for 1-3h under the condition of 50-60 DEG C, then dropping hydrogen peroxide at 40-55 DEG C, carrying out reaction for 1-3h under the condition of 50-60 DEG C, decolorizing and crystallizing with sodium hydrogensulfite, recrystallizing with an ethanol water solution to obtain a finished product of the 2-br-4-fluoacetanilide. The 2-br-4-fluoacetanilide has a chemical reaction formula shown in the specification, the whole process is shorter in reaction time and simple in operation, the reaction conversion rate for the acetylation and the bromination is up to above 90%, a finally obtained product has high purity, and the preparation method is suitable for enlarged industrial production; and thus, the production cost is reduced.

Owner:KINGCHEM LIAONING CHEMICAL CO LTD

Process for preparing oxidized wax from coal wax

InactiveCN105087068AIncrease economic value addedAlleviate the pressure of resource shortageMineral wax recovery/refiningParaffin waxReaction temperature

The invention relates to a process for preparing oxidized wax from coal wax. The process comprises the following steps of preparing for a raw material, namely F-T coal wax, adding F-T coal wax into a three-neck flask, gradually heating to 100 DEG C and melting the F-T coal wax; then, adding a catalyst, wherein the weight of the catalyst accounts for 0.1-1.0% of the weight of the F-T coal wax; and introducing 0.2-0.8L / h oxygen gas to each gram of F-T coal wax, controlling the reaction temperature within 125-160 DEG C at the stage, reacting for 3-8 hours, then, taking out the product while the product is hot, sampling and analyzing. According to the process, the oxidized wax is prepared from the F-T coal wax instead of the traditional wax, so that the burden of petroleum resource shortage is relieved, and the economic additional value of the coal wax is increased; materials such as a heavy metal ionic catalyst, nitrogen shielding gases, a water-carrying agent and polymerization additives are not used; the reaction time is short, the process is simple and convenient to operate, the prepared oxidized wax product is light in color and smell, and the acid value and saponification value of the prepared oxidized wax product meet the requirements of the SASOLWAX A28 index of south Africa; and no special processing equipment is required in the process.

Owner:JIANGSU LANGFU PETROLEUM & CHEM CO LTD

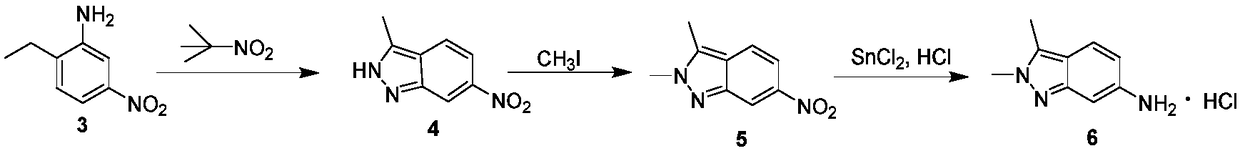

Method for preparing 2, 3-dimethyl-2H-indazole-6-benzylamine hydrochloride

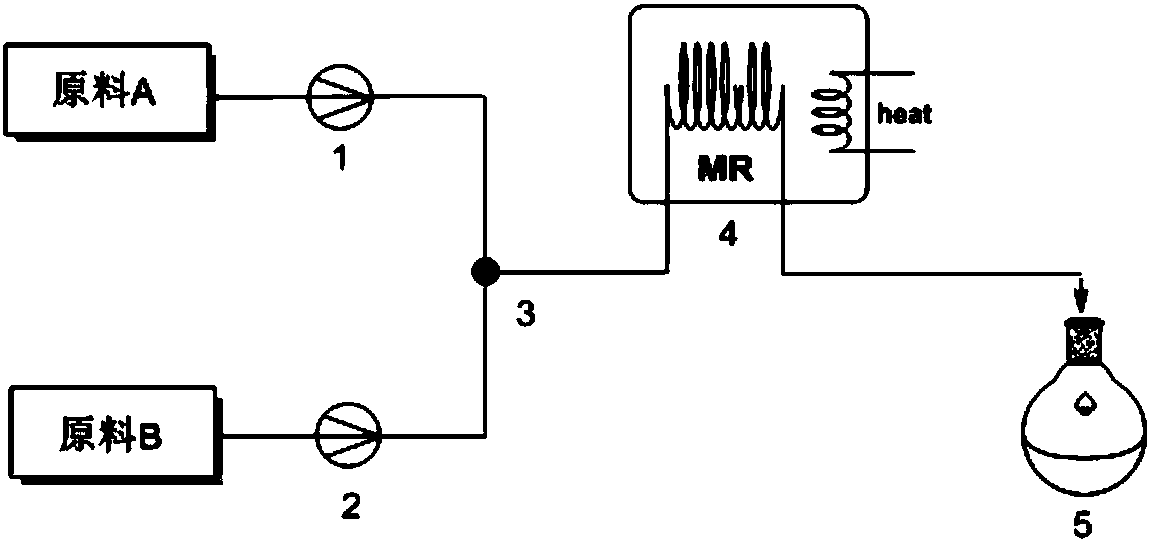

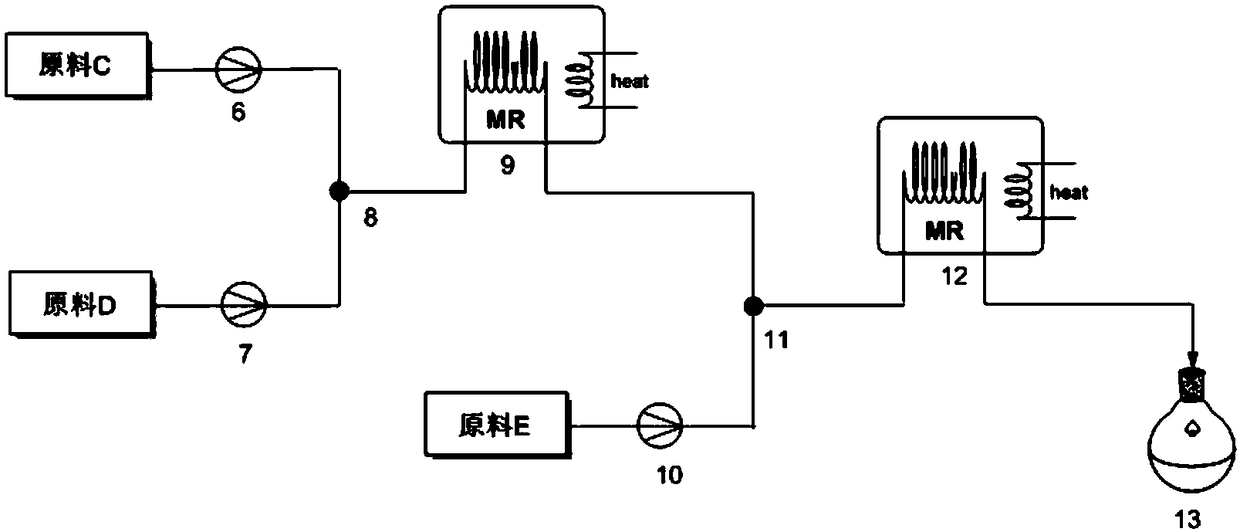

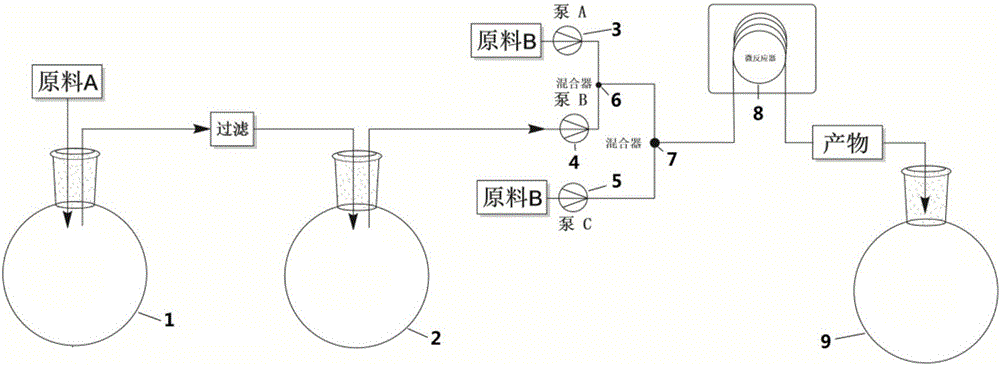

InactiveCN108299304APrecise control of reaction conditionsLess side effectsOrganic chemistryChemical/physical/physico-chemical microreactorsBenzylamine hydrochlorideSide reaction

The invention discloses a method for preparing 2, 3-dimethyl-2H-indazole-6-benzylamine hydrochloride. The method comprises the steps of reacting a glacial acetic acid solution of tert-butyl nitrite and a glacial acetic acid solution of 5-nitro-2-ethylaniline in a first microreactor to generate 3-methyl-6-nitro-1H-indazole; reacting a homogeneous solution formed by mixing the 3-methyl-6-nitro-1H-indazole and a dimethyl sulfoxide solution of methyl iodide and a dimethyl sulfoxide solution of sodium ethoxide in a second microreactor to generate 2,3-dimethyl-6-nitro-2H-indazole; then reacting withmixed liquor formed by stirring a concentrated hydrochloric acid solution of stannous chloride and ethyl alcohol in a third microreactor to generate the 2, 3-dimethyl-2H-indazole-6-benzylamine hydrochloride. The method provided by the invention has the advantages of less side reaction, high yield, simplification of a complicated multi-step synthesis process, low toxicity and pollution, low production cost, good product quality, environment friendliness, energy saving and high efficiency, and is suitable for industrialized application.

Owner:CHINA PHARM UNIV

Preparation of phenylethylene-dialkene special copolymer

The invention discloses a preparation method for a styrene-diolefin special copolymer. The preparation method comprises the following steps: taking a styrene-diolefin block random copolymer as PS-PB-PB / PS-PS; wherein PS representing a styrene copolymer block, PB representing a diolefin copolymer block, and PB / PS representing a styrene-diolefin random copolymer block; and adopting an anionic continuous polymerization method. The preparation method avoids the defects of a batch still and is characterized by low production cost, short production cycle, low operating cost, short reaction time and high yield.

Owner:ZHEJIANG SANPO POLYMER

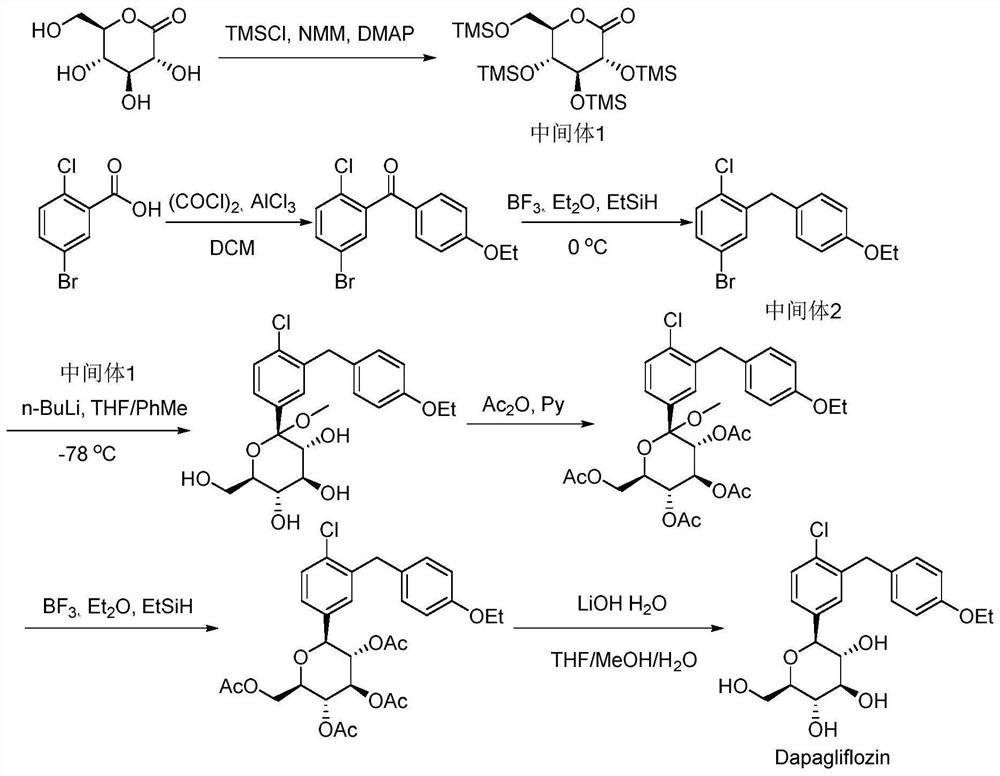

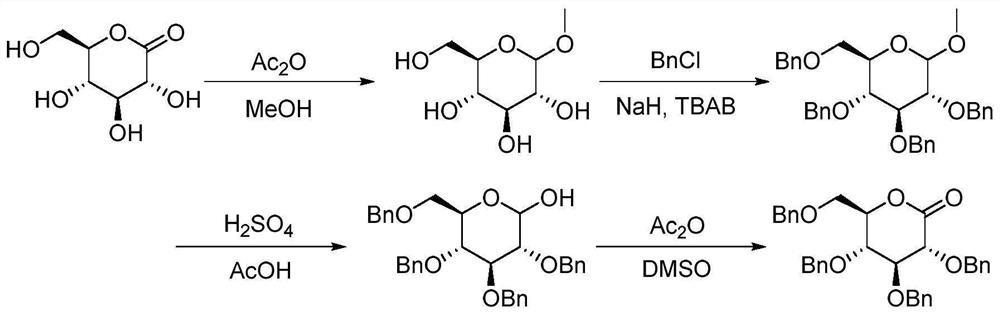

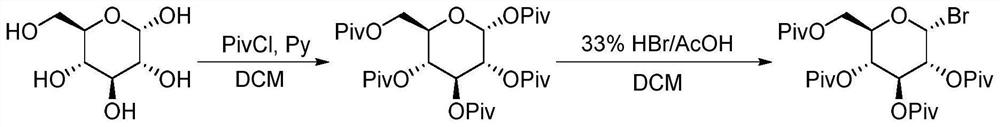

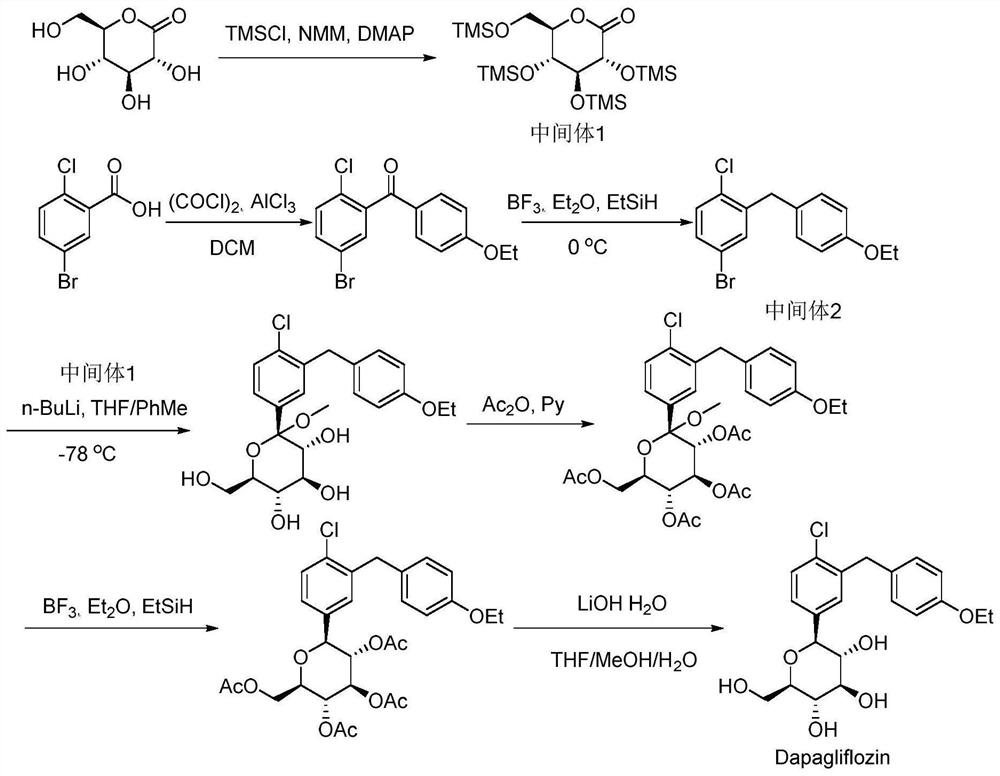

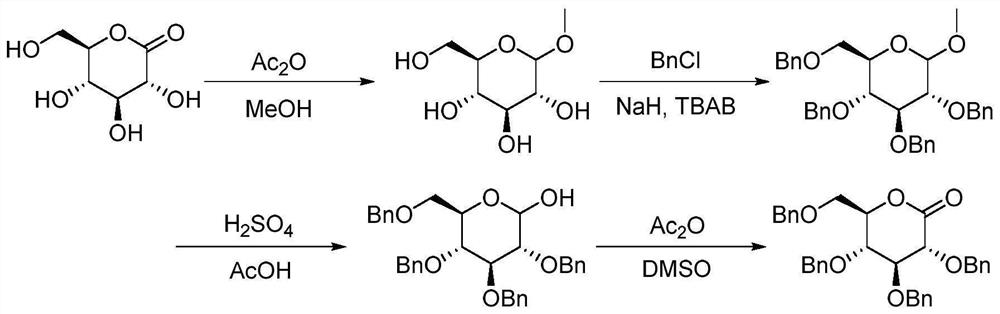

Method for continuously synthesizing benzyl-substituted glucolactone by adopting microchannel reaction device

ActiveCN112961135ADoes not reduce consumptionReduce consumptionOrganic chemistryGluconic acidBenzyl chloride

The invention discloses a method for continuously synthesizing benzyl-substituted glucolactone by adopting a microchannel reaction device. The method comprises the following steps: taking methyl-alpha-D-mannopyranoside as an initial raw material, preparing the methyl-alpha-D-mannopyranoside into an old organic solvent solution, and reacting the old organic solvent solution with an organic solvent solution of benzyl chloride in a first microreactor to generate methyl glucose with hydroxyl protected by benzyl; reacting a homogeneous solution formed by mixing a reaction solution of benzyl-substituted gluconic acid and a small amount of hydrochloric acid solution in a second microreactor for demethylation to generate hydroxyl benzyl-substituted glucose; and finally, reacting the reaction solution with an aqueous solution of hydrogen peroxide and sodium hydroxide and an organic solvent solution of tetramethylpiperidine nitrogen oxide in a third microreactor to generate the high-purity hypoglycemic drug Dapagliflozin intermediate benzyl substituted glucolactone. The method disclosed by the invention is higher in heat and mass transfer efficiency and easier to industrially amplify, the initial materials are simple, cheap and easily available, the process is simple, the obtained intermediate is high in purity and high in yield, the production cost can be effectively reduced, and the method is suitable for industrial production.

Owner:安庆奇创药业有限公司

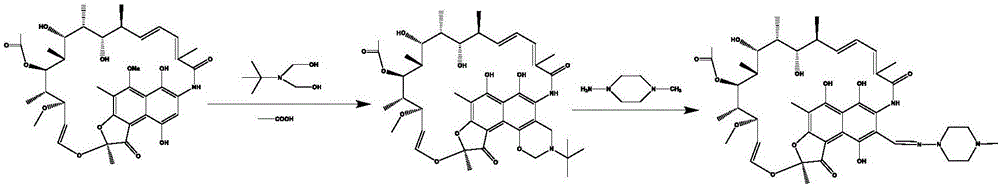

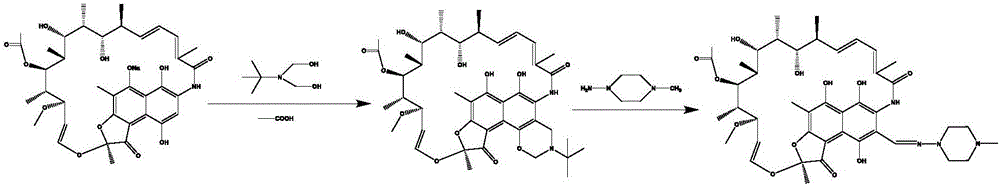

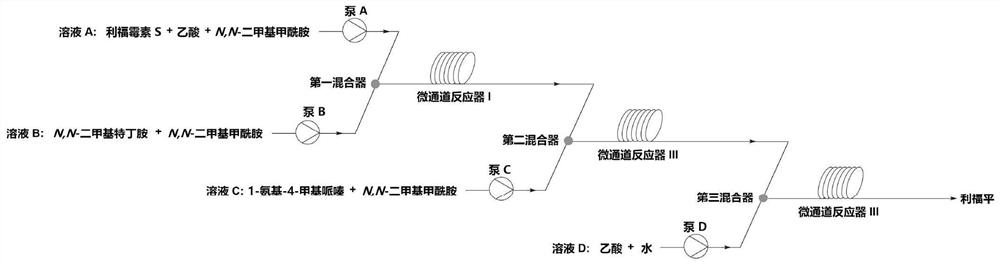

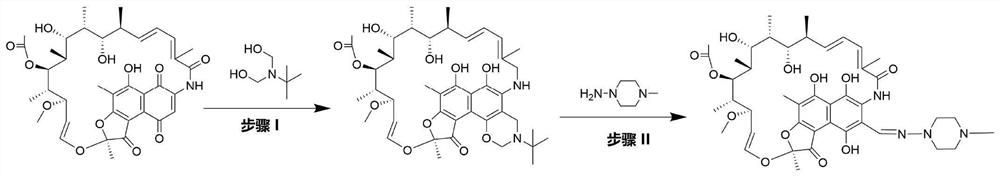

Method for preparing rifampicin by utilizing cascade reaction of kettle type reaction device and microchannel reaction device

InactiveCN106632394ASave heatLow costOrganic chemistryChemical/physical/physico-chemical microreactorsSodium saltPiperazine

The invention provides a method for preparing rifampicin by utilizing cascade reaction of a kettle type reaction device and a microchannel reaction device. In the kettle type reaction device, rifamycin S sodium salt is used as a raw material to obtain N-tedin-1,3-oxazine (5,6-C) rifamycin through reaction, and the N-tedin-1,3-oxazine (5,6-C) rifamycin reacts with 1-methyl-4-amino-piperazine in the microchannel reaction device to obtain the rifampicin. Continuous production of the rifampin is achieved, the product quality is good, the cost is low, the profit is high, and the method is green, environmentally friendly, capable of saving energy, efficient and suitable for industrial application.

Owner:NANJING UNIV OF TECH

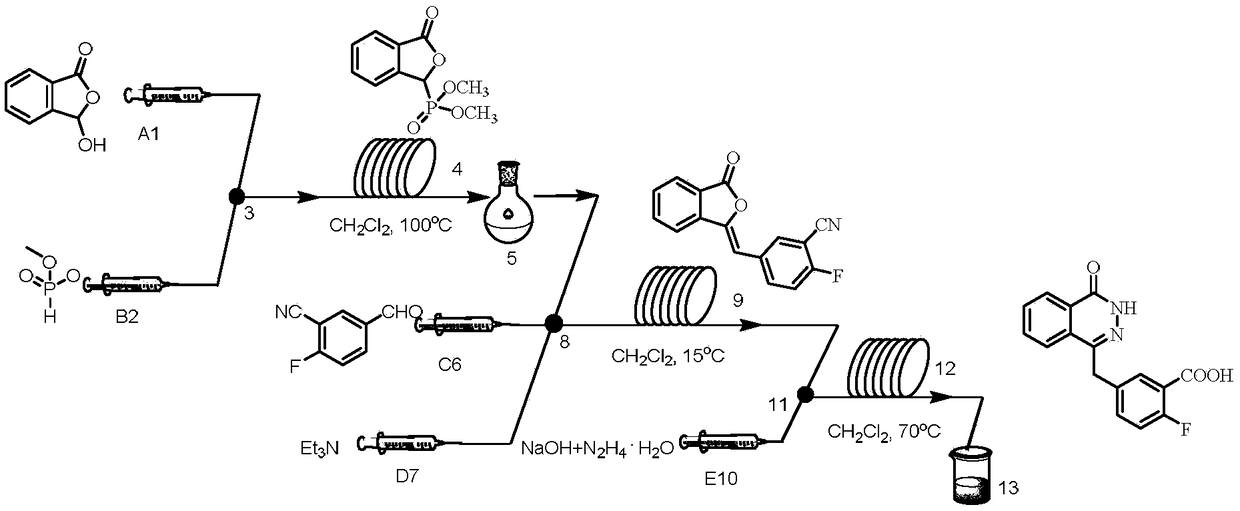

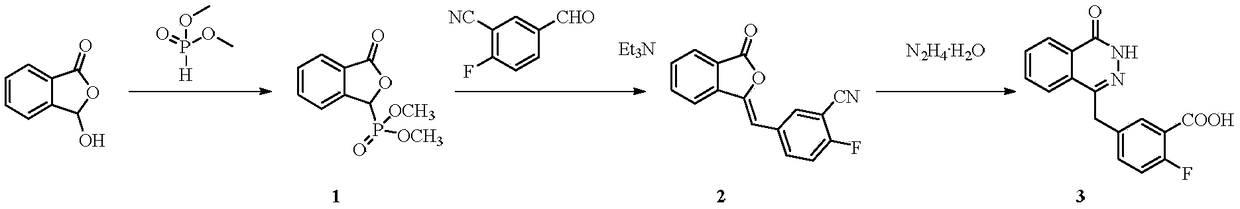

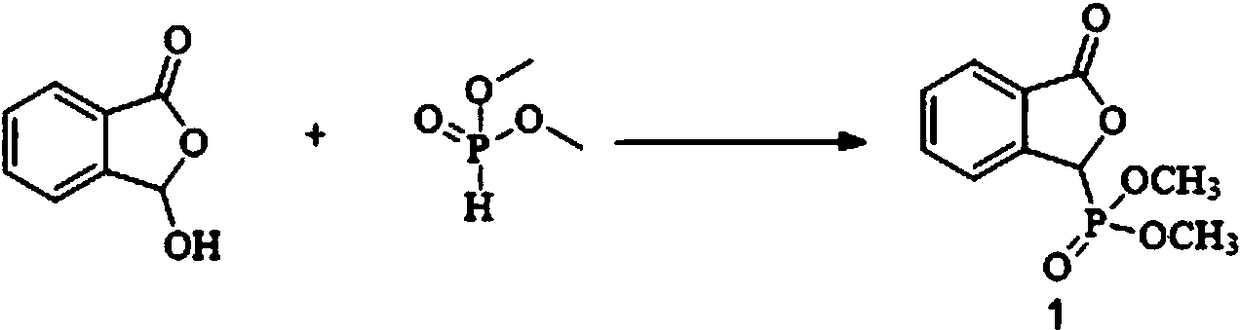

Method for continuously preparing Olaparib intermediate by microchannel modular reaction device

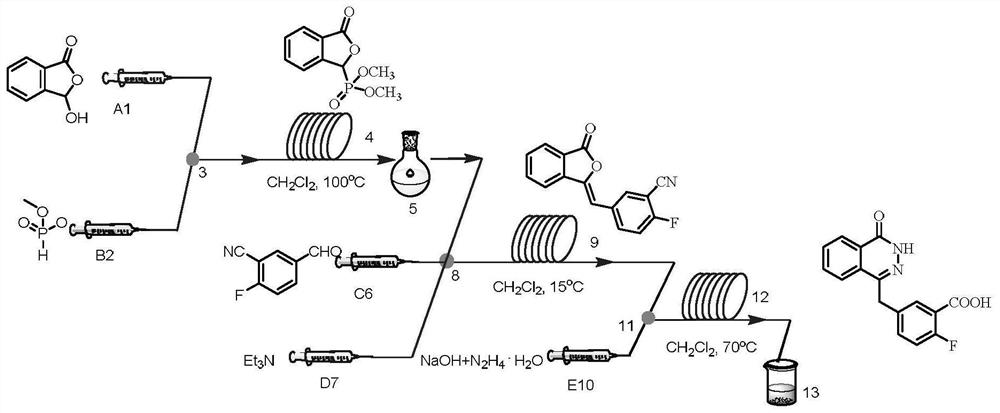

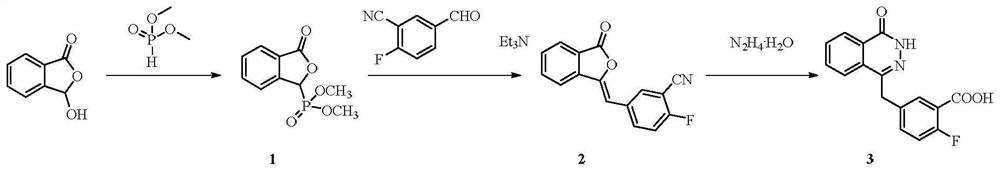

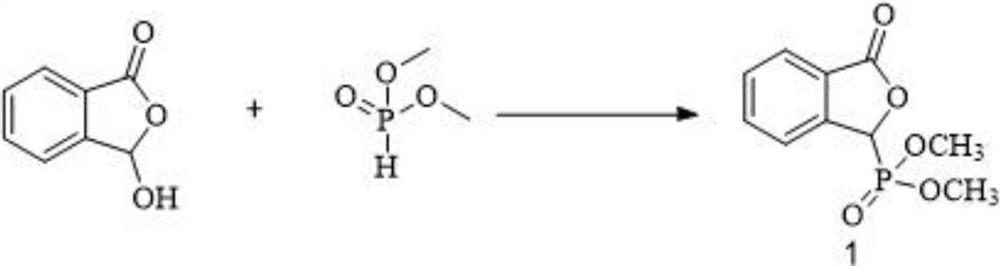

The invention discloses a method for continuously preparing an olaparib intermediate by a microchannel modular reaction device. The method comprises the following steps: performing reaction on a dichloromethane solution of 3-hydroxyisobenzofuran-1(3H)-ketone and a dichloromethane solution of dimethyl phosphate in a first microreactor, and performing liquid separation to obtain effluent of (3-oxo-1,3-dihydroisobenzyfuran-1-yl)dimethyl phosphate; performing reaction on the effluent, a dichloromethane solution of 2-fluorine-5-formyl benzene nitrile and a dichloromethane solution of triethylaminein a second microreactor to generate reaction liquid of 2-fluorine-5-(3-oxo-3H-isobenzofuran-1-yl methylene)benzyl cyanide; and performing reaction on the reaction liquid and a homogenous mixed solution which is obtained by stirring an ethanol solution of sodium hydroxide and hydrazine hydrate in a third microreactor and treating the effluent to obtain the olaparib intermediate 2-fluorine-5-[(4-oxo-3,4-dihydrodiazene-1-yl-)methyl]benzoic acid.

Owner:NANJING UNIV OF TECH

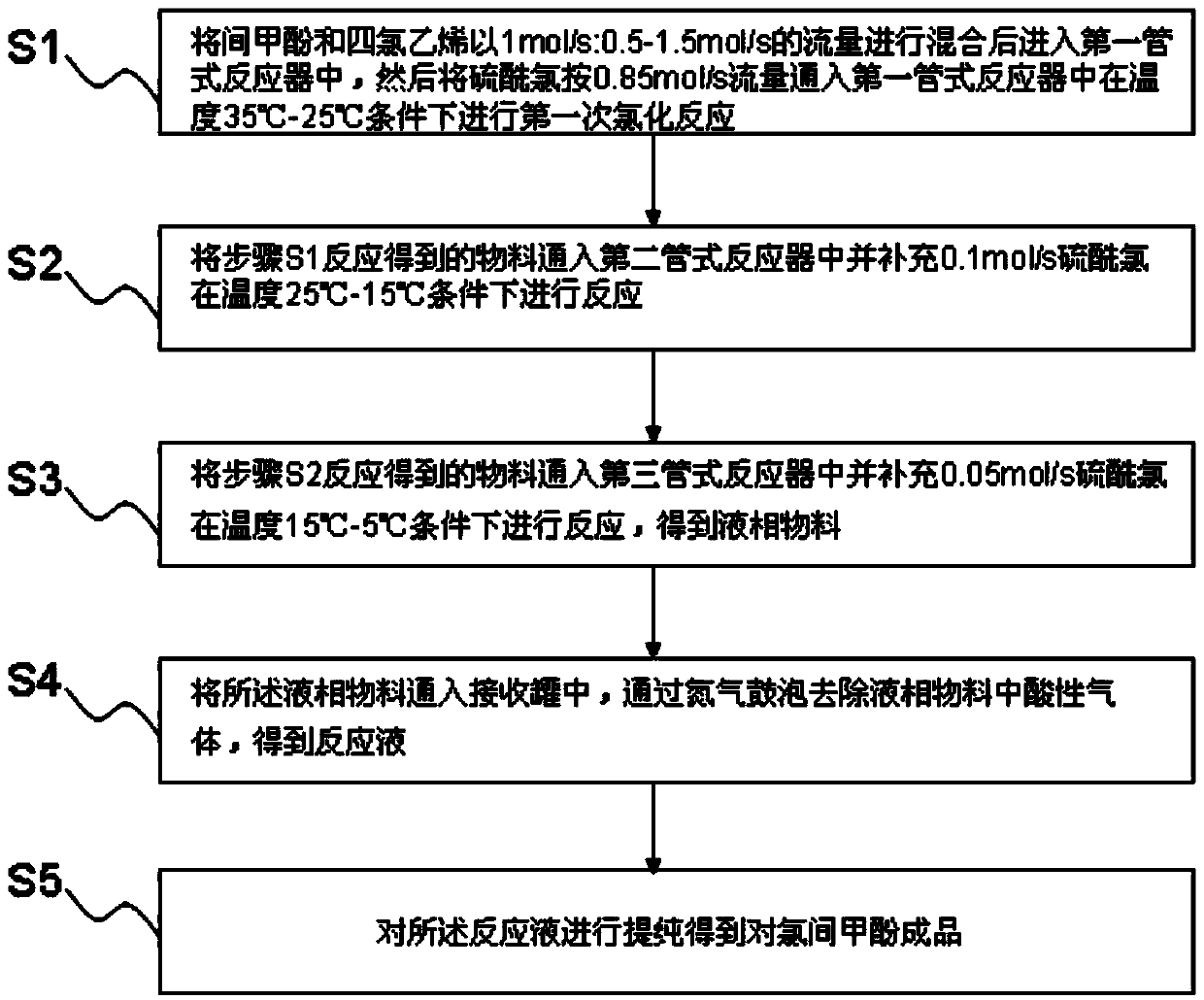

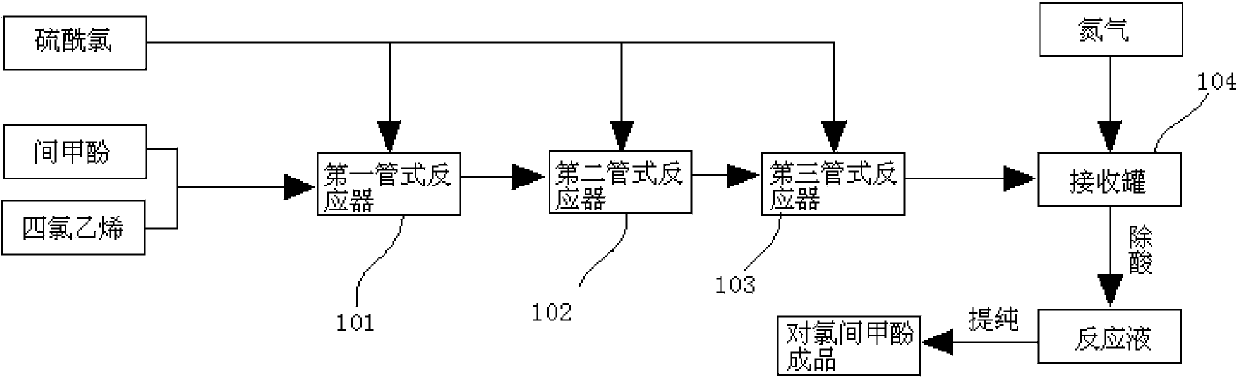

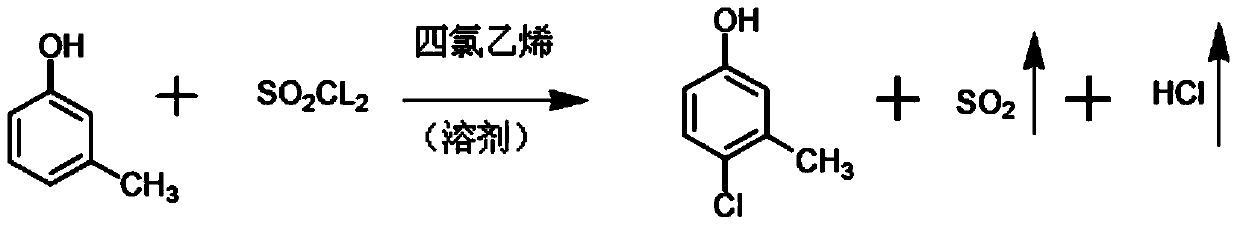

Green synthesis technique of p-chloro-m-cresol

ActiveCN104045521AHigh recovery rateImprove conversion rateOrganic chemistryOrganic compound preparationEthyl ChlorideSolvent

The invention provides a green synthesis technique of p-chloro-m-cresol, which comprises the following step: reacting by using m-cresol as a raw material, tetrachloroethylene as a solvent and sulfuric chloride as a chlorinating agent to prepare the p-chloro-m-cresol, wherein the mole ratio of the m-cresol to the tetrachloroethylene is 1:(0.5-1.5), and the mole ratio of the m-cresol to the sulfuric chloride is 1:(0.9-1.1).Compared with the prior art, the technique provided by the invention has the advantages of short reaction time, high solvent recovery rate, clean and environment-friendly production process and high degree of automation, and the m-cresol conversion rate after the reaction finishes is up to 98%; and thus, the technique has favorable industrialization prospects.

Owner:JIANGSU HUANXIN NEW MATERIAL CO LTD

Continuous production method for polyoxymethylene resin

The invention discloses a serial production method of acetaldehyde resin, belonging to the production technique of acetaldehyde resin technical field, firstly monomer metaformaldehyde of liquid state and polymer solvent are premixed according to 100:1 to 1:100 volume ratio; subsequently the mixed solution is transported to a consecutive reactor by a pump at 0 to 150 DEG C, and processes the polymerization at 30 to 200 DEG C in the condition of positive ion catalyst existing, the polymerization time is 0.5 to 100 min; after the polymerization being over, the obtained product can be processed with continual process. The serial production method of acetaldehyde resin of the invention produces polyformat dehyde of good quality, the whole production process can be continuously carried out, the assembly line type is used for work, the yield is large, and the unconverted monomer and the polymer solvent in the production process are not leaked, and can be repeatedly used.

Owner:ZHEJIANG SANPO POLYMER

Method for synthesizing esterified wax

InactiveCN102503820AShort reaction timeSimple and efficient operationOrganic compound preparationCarboxylic acid esters preparationMicrocrystalline waxCarnauba wax

The invention relates to a method for synthesizing an esterified wax, in particular to a method for synthesizing an esterified wax from a microcrystalline wax used as a raw material through oxidation and esterification in one step. The product prepared by adopting the method can partially replace the natural carnauba wax and has the general formula of Cn-1H2n +1COOCmH2m-1 (n=30 to 60, and m=18 to 24), the acid value of 2-10mgKOHg / and the esterification value of 70-86mgKOH / g. The method for synthesizing the esterified wax comprising the following steps: adding the microcrystalline wax and a high-carbon alcohol (CnH2n +1OH, wherein n=8 to 24) at the mass ratio of 5-20:1 into a three-mouth flask, heating to melt the microcrystalline wax, adding weak-acid esterification catalyst, introducing quantitative oxygen, controlling reaction temperature, taking out the product while the product is hot after the reaction of a certain period of time finishes, and weighting. The product synthesized by adopting the method has a higher esterification value and a lower acid value than the product synthesized by steps.

Owner:CHANGZHOU UNIV

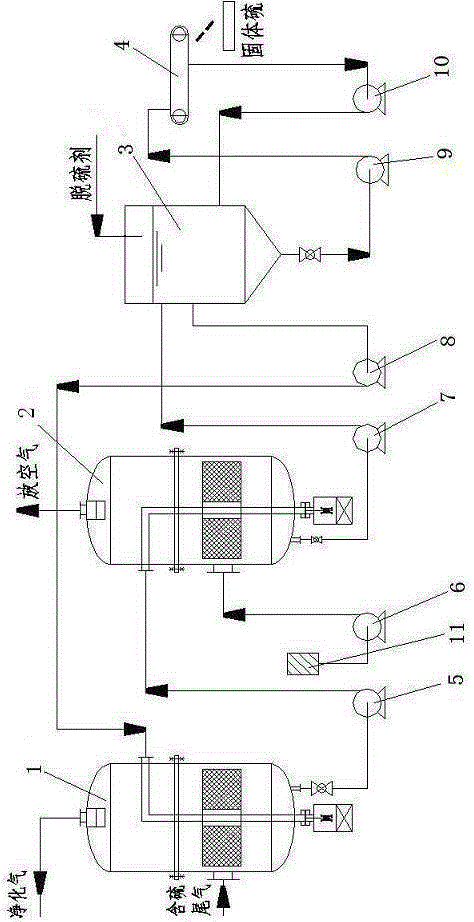

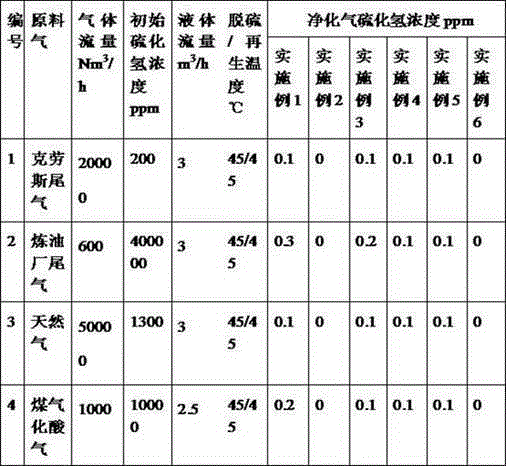

A method and special equipment for removing hydrogen sulfide by supergravity liquid phase redox

ActiveCN103599682BEfficient removalHigh total iron ion concentrationDispersed particle separationSulfur preparation/purificationFluid phaseLiquid storage tank

The present invention disclosed a method of removing hydrogen sulfide and its dedicated equipment for the oxidation and restoration of hydraulic liquid -phase hydraulic fluid.The desulfurization agent is in contact with the surface of the rotor's silk mesh; the sulfur -containing desulfurization agent enters the surface of the wire filler of the air in the regenerative hyper -gravity reactor; the sulfur -containing desulfurization agent is pumped into the storage tank after the regeneration, and the settlement is settled.When the sulfur gross grinding at the bottom of the storage tank is pumped into the vacuum filter, the sulfur sulfur is formed, and the filter liquid pump back into the storage tank.The process response time is short, the process efficiency is high, and the hydrogen sulfide removal effect is good; the scope of application is wide, the selectivity is high, and the safety performance is high.The process cycle time and stable operation.

Owner:烟台新瑞环保科技有限公司

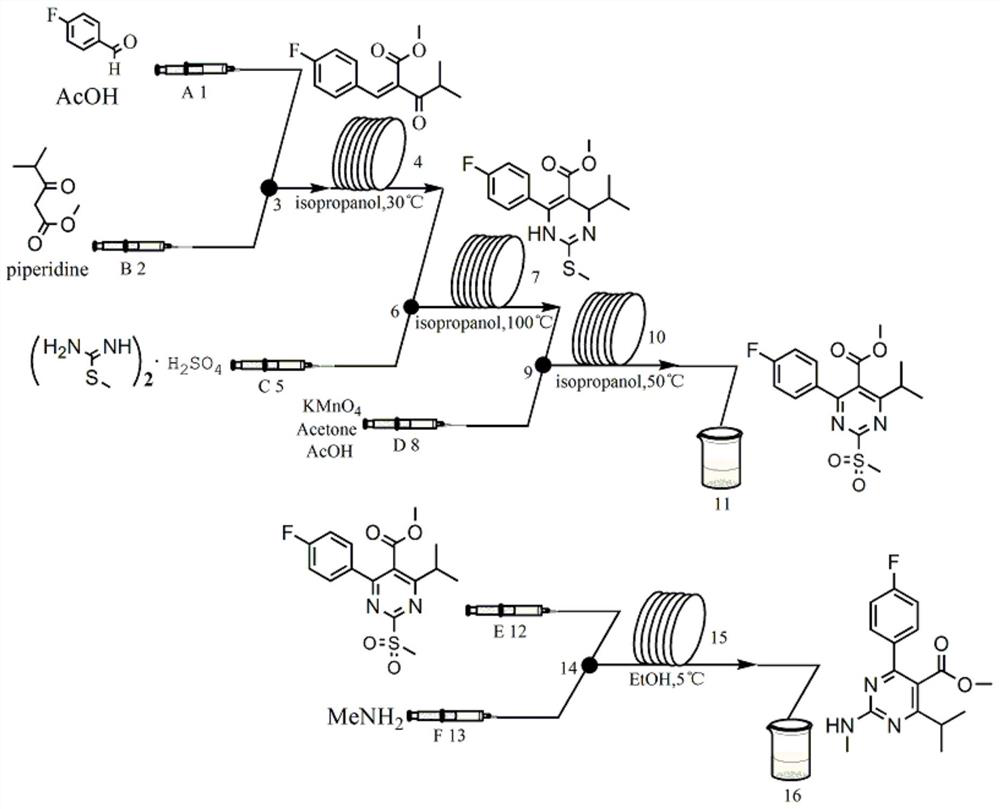

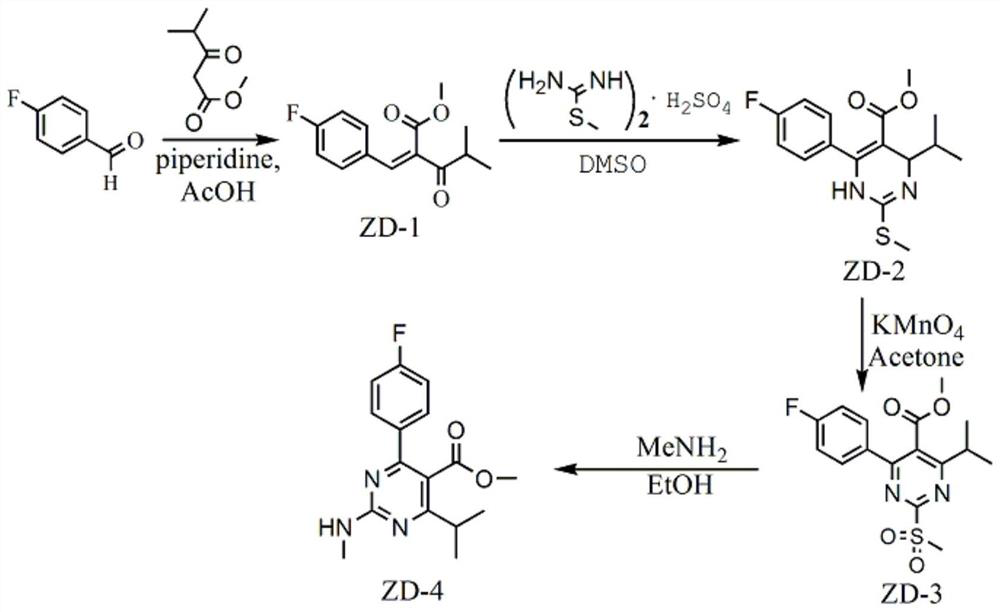

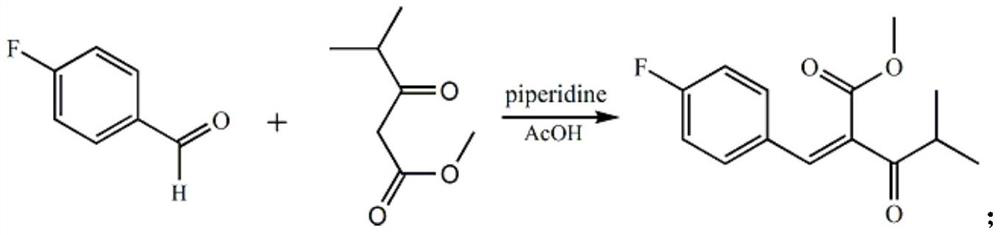

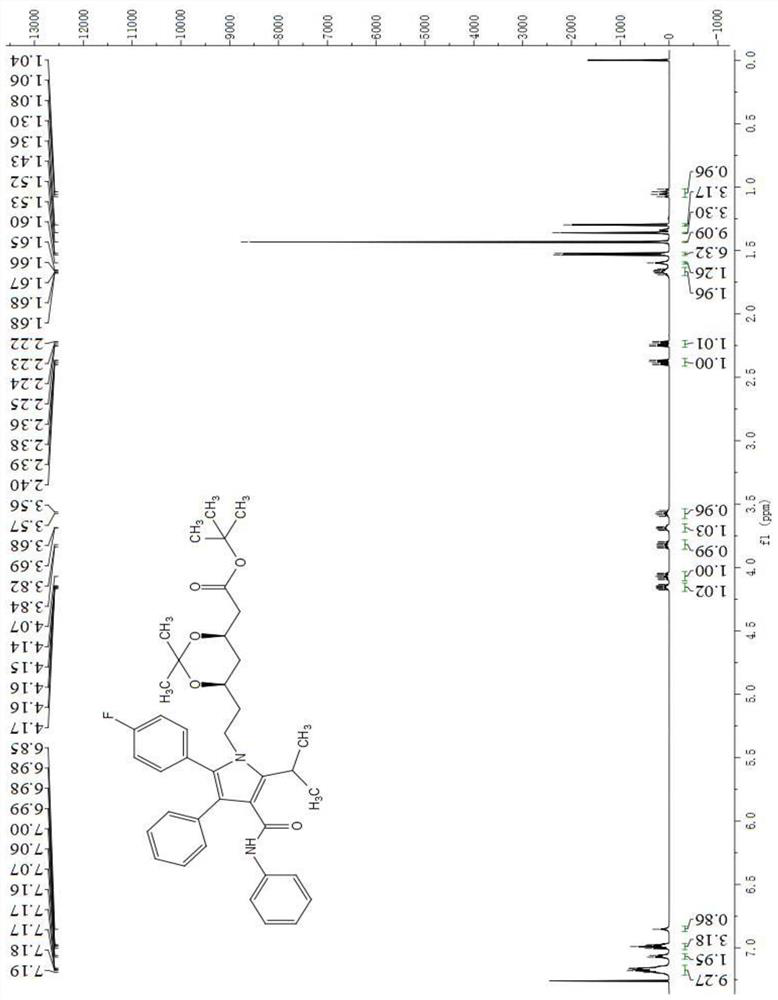

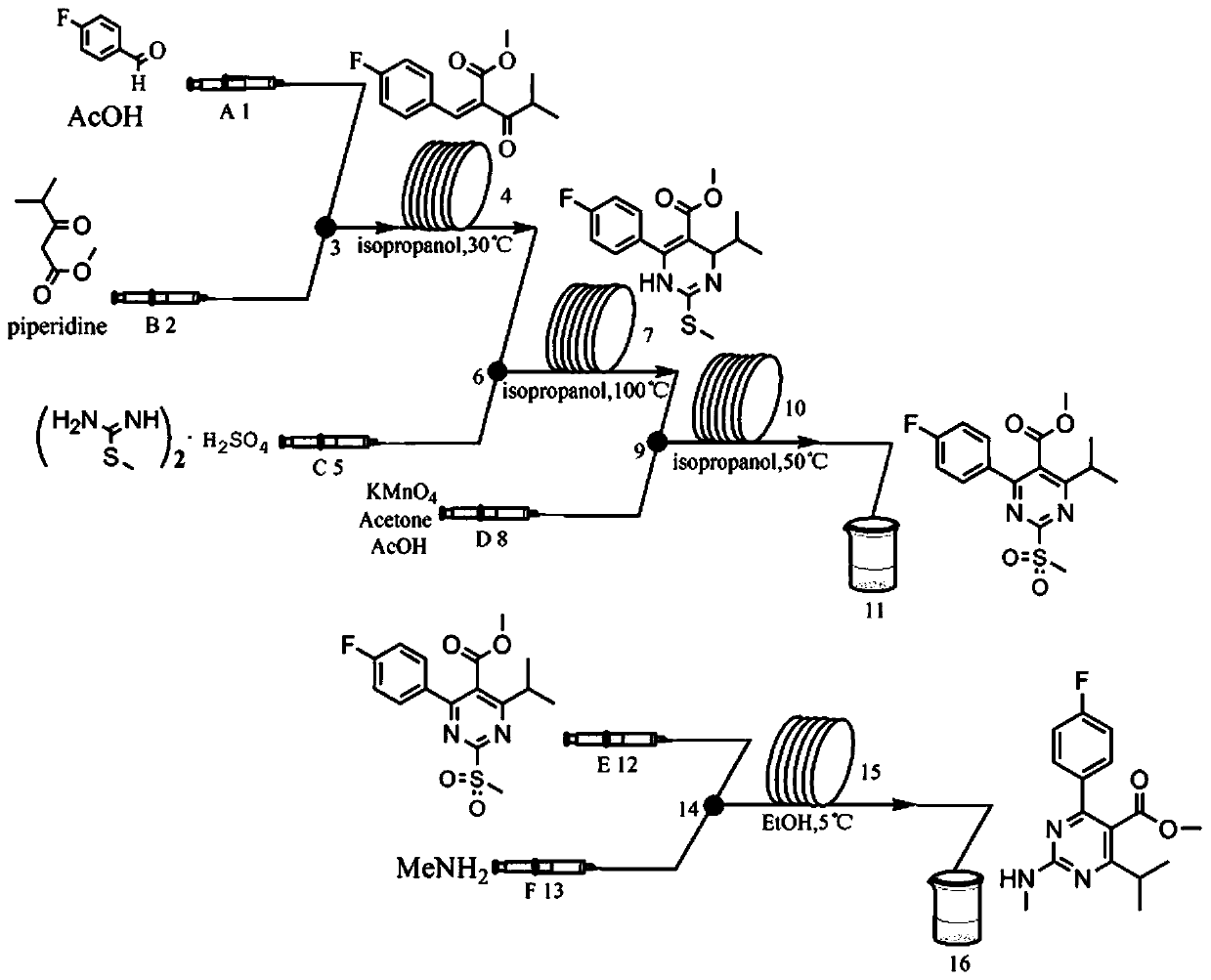

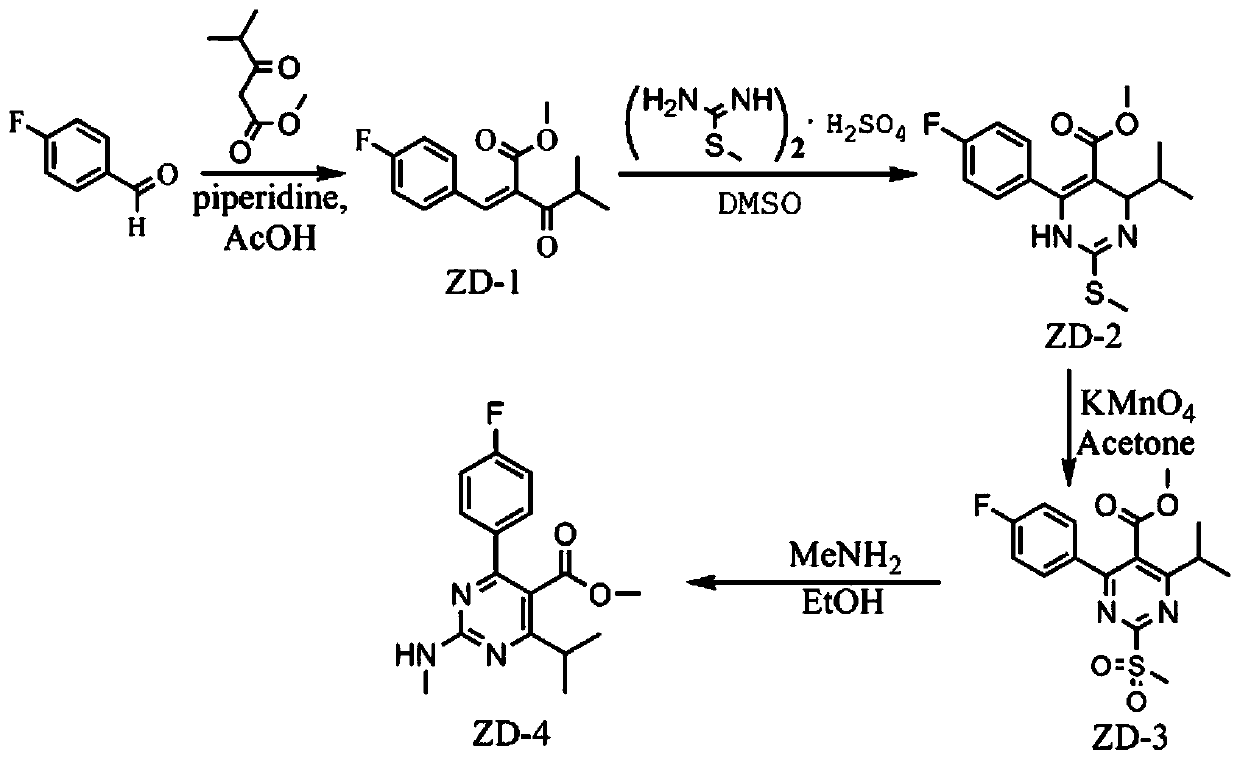

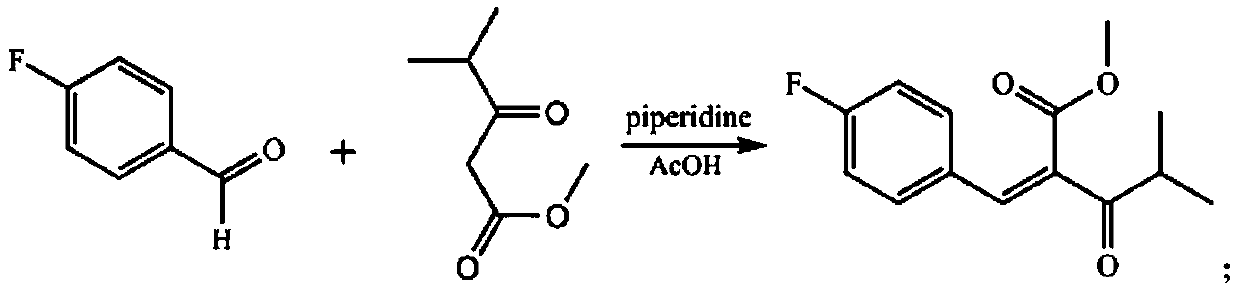

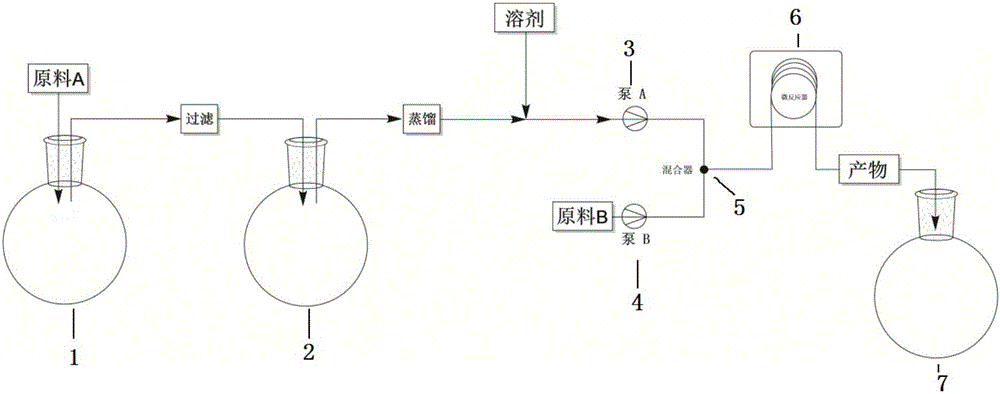

Method for continuously preparing rosuvastatin intermediate by micro-channel modular reaction device

ActiveCN109796414ASimple responsePost-processing is simpleOrganic chemistryChemical recyclingChemistryToxicity

The invention discloses a method for continuously preparing a rosuvastatin intermediate by a micro-channel modular reaction device. The method includes the steps: performing reaction on isopropanol solution of fluorobenzaldehyde and isopropanol solution of isobutyrylacetic acid methyl ester in a first micro-reactor under catalysis of acetic acid and piperidine to generate a first product; performing reaction on the first product and isopropanol solution with free S-methyl isothiourea salt in a second micro-reactor to generate a second product; performing reaction on the second product, acetonesolution of potassium permanganate and acetic acid in a third micro-reactor to generate a third product; performing reaction on the third product and methylamine ethanol solution in a fourth micro-reactor to obtain the rosuvastatin intermediate. The rosuvastatin intermediate is low in toxicity, less in pollution, low in production cost, good in quality, high in profit, green and environmentally friendly and efficient in energy and has industry enlargement potential.

Owner:CHINA PHARM UNIV

Method for continuous production and preparation of rifampicin from rifamycin S sodium salt

The invention provides a method for continuous production and preparation of rifampicin from a rifamycin S sodium salt. The continuous production of the rifampicin is achieved by taking rifamycin sodium salt, dihydroxymethyl tert-butyl amine, 1-methyl-4-amino-piperazine as raw materials, and connecting a tank reactor with a microreactor in series. Compared with the prior art, the method provided by the invention achieves continuous production of the rifampicin, the steps of solvent replacement during reaction, solid precipitation and the like are omitted, raw materials and heat energy are greatly saved, the cost is saved, and profits are increased. Meanwhile, according to the method provided by the invention, the characteristics high-efficiency heat transferring capability and easy and direct amplification of a microchannel reactor are utilized, and on the premise that 1 / 3 of the raw material, namely 1-methyl-4-amino-piperazine, is reduced, the conversion rate of the rifampicin is high and reaches 85% or above, the product quality is good, and the energy consumption is low, so that the method is an environmentally friendly and efficient method for synthesizing the rifampicin, and is suitable for industrial production.

Owner:NANJING UNIV OF TECH

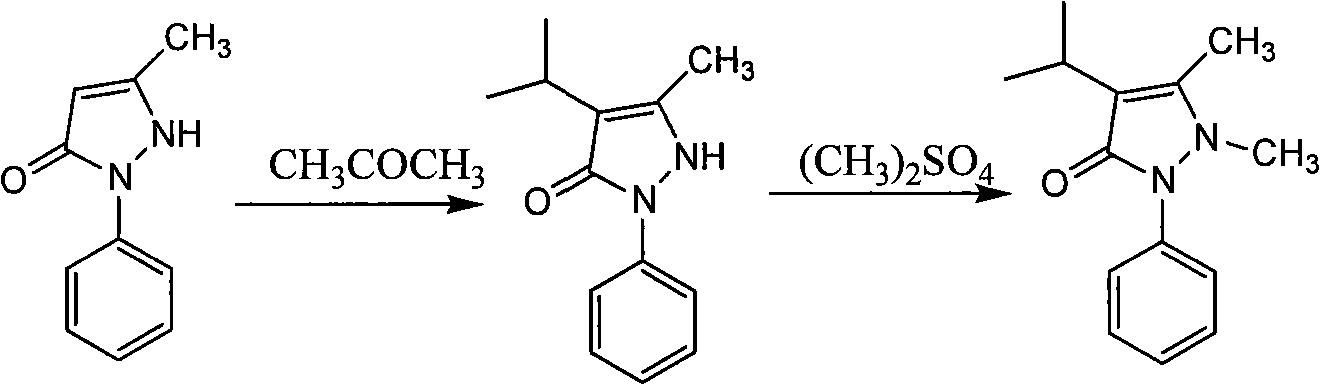

Low-voltage hydrogenation process of isopropyl pyrazolone

The invention provides a novel low-pressure hydrogenation technique for synthesizing isopropyl pyrazolone. Acetone and pyrazolone are condensed and hydrogenated, the acetone is taken as a solvent and Raney nickel is taken as a catalyst. The technique adopts the Raney nickel as the catalyst in the hydrogenation reaction, thereby achieving the same effect of using noble metal catalyst, lowering the cost, avoiding the pollution caused by the zinc powder process production and having the characteristics of cleanness and environment protection. The acetone is taken as the solvent of the hydrogenation reaction and serves as both the reactant and the solvent, thereby greatly increasing the concentration of the reactant and making the hydrogenation reaction easier; and the reaction pressure is low, the reaction speed is fast, the time is short and the product quality is good. Meanwhile, the solvent can be reclaimed and used intervalically, thereby having obvious cost advantage and the characteristics of low cost and environment protection. The pressure of the hydrogenation reaction is reduced, thereby increasing the safety coefficient of the reaction and reducing the requirement on a device.

Owner:SHANDONG XINHUA PHARMA

A kind of method utilizing microchannel reaction device to prepare rifampicin

The invention discloses a method for preparing rifampicin by using a microchannel reaction device. Through a microchannel reactor, rifamycin S is used as a raw material to undergo cyclization, hydrolysis, condensation and crystallization processes without post-treatment process, and directly obtains Rifampicin crude. The invention realizes complete continuous production of rifampicin, has high yield, low cost, high profit, environmental protection, energy saving and high efficiency, and is suitable for industrial application.

Owner:NANJING TECH UNIV

Transparent phenylethylene-dialkene star shaped copolymer and continuous preparation thereof

The invention discloses a transparent styrene-diolefin star copolymer and a continuous preparation method thereof. The copolymer has the following structure: (PS-PB-PB / PS-PS) n-R or (PS-PB-PB / PS) n-R, wherein PS represents a polystyrene block, PB represents a polydiolefin block, PB / PS represents a styrene-diolefin random copolymer block, and R represents the core of the star structure. The invention also discloses the continuous preparation method for the copolymer. The preparation method has a high monomer conversion rate above 99.999 percent. The preparation method is characterized by low production cost, short reaction time, high yield, low operating cost, simple maintenance, no leakage of unconverted monomers and solvents during the production, reutilization, safety and environmental protection, and wide application range.

Owner:ZHEJIANG SANPO POLYMER

A method for the continuous preparation of olaparib intermediates using a microchannel modular reaction device

The invention discloses a method for continuously preparing an olaparib intermediate by a microchannel modular reaction device. The method comprises the following steps: performing reaction on a dichloromethane solution of 3-hydroxyisobenzofuran-1(3H)-ketone and a dichloromethane solution of dimethyl phosphate in a first microreactor, and performing liquid separation to obtain effluent of (3-oxo-1,3-dihydroisobenzyfuran-1-yl)dimethyl phosphate; performing reaction on the effluent, a dichloromethane solution of 2-fluorine-5-formyl benzene nitrile and a dichloromethane solution of triethylaminein a second microreactor to generate reaction liquid of 2-fluorine-5-(3-oxo-3H-isobenzofuran-1-yl methylene)benzyl cyanide; and performing reaction on the reaction liquid and a homogenous mixed solution which is obtained by stirring an ethanol solution of sodium hydroxide and hydrazine hydrate in a third microreactor and treating the effluent to obtain the olaparib intermediate 2-fluorine-5-[(4-oxo-3,4-dihydrodiazene-1-yl-)methyl]benzoic acid.

Owner:NANJING TECH UNIV

Acidic iron-containing wastewater recycling system and method for carrying out in situ modification by system

ActiveCN103408158BShort process reaction timeSmall footprintWaste water treatment from metallurgical processFerroso-ferric oxidesSludgeHigh pressure

Owner:WUXI XINDU ENVIRONMENTAL PROTECTION EQUIP +1

Clean synthesis method for di-tert-butyl disulfide

InactiveCN101838228BMeet the requirements of cleaner productionLow priceHydropoly/poly sulfide preparationSynthesis methodsOrganic synthesis

The invention belongs to the field of organic synthesis and particularly relates to a clean synthesis method for di-tert-butyl disulfide, which comprises the following steps: adding tert-butyl mercaptan, a catalyst and a solvent, i.e. acetone, into a reactor container, or only adding the tert-butyl mercaptan and the catalyst into the reactor container firstly and then adding an oxidizer, i.e. oxyful, or a mixture of acetone and oxyful into the reactor container with stirring; controlling a reaction temperature between minus 20 DEG C and 70 DEG C to perform a reaction sufficiently; after the reaction is completed, post-processing the obtained product to obtain the di-tert-butyl disulfide, wherein the catalyst is cuprous chloride, copper chloride or a mixture of the cuprous chloride and thecopper chloride in random mass proportion. The invention meets the requirement for clean production. The catalyst and the reaction solvent have low price, can be conveniently recycled, have small usage in the reaction and have excellent catalytic performance. Meanwhile, the process has short reaction time, the conversion rate of the tert-butyl mercaptan reaches 98 to 100 percent, the selectivity of the di-tert-butyl disulfide is between 90 and 96 percent, the reaction yield is high and the clean synthesis method is suitable for industrial production.

Owner:ZHENGZHOU UNIV

A method for continuously synthesizing benzyl-substituted gluconolactone using a microchannel reaction device

ActiveCN112961135BDoes not reduce consumptionReduce consumptionOrganic chemistryOrganosolvGluconic acid

The invention discloses a method for continuously synthesizing benzyl-substituted gluconolactone by using a microchannel reaction device. The method uses methyl-α-D-mannopyranoside as a starting material, and prepares it into an old machine solvent solution and The organic solvent solution of benzyl chloride reacts in the first microreactor to generate methylglucose whose hydroxyl group is protected by benzyl; React demethylation in middle to generate hydroxybenzyl substituted glucose; finally react the reaction solution with aqueous solution of hydrogen peroxide and sodium hydroxide, and organic solvent solution of tetramethylpiperidine nitrogen oxide in the third microreactor to generate high-purity The intermediate of the hypoglycemic drug Dapagliflozin is benzyl substituted gluconolactone. The method of the invention has higher heat and mass transfer efficiency, is easier to scale up industrially, has simple, cheap and easy-to-obtain starting materials, simple process, high purity of obtained intermediates, and high yield, can effectively reduce production costs, and is suitable for industrialized production.

Owner:安庆奇创药业有限公司

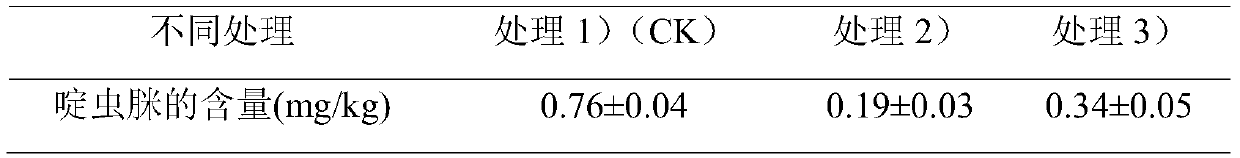

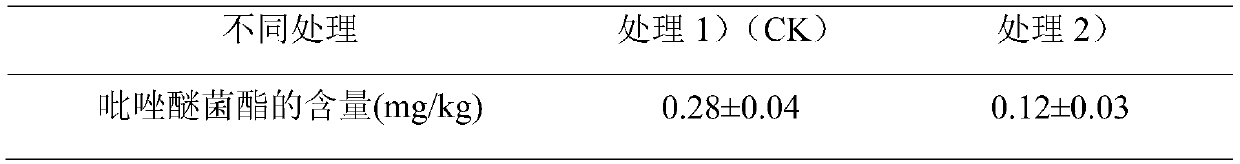

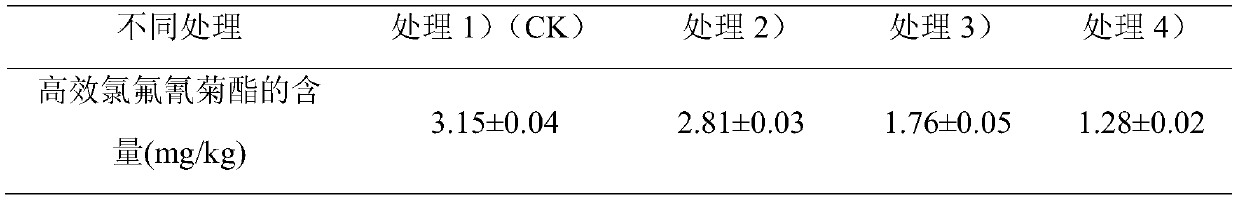

A titanium-selenium composite sol for degradation of agricultural product residue pesticides and its preparation method and application

ActiveCN106818737BEasy to prepareAvoid postprocessingBiocideAnimal repellantsSoil sciencePesticide residue

The invention belongs to the technical field of functional sol preparation and application, and discloses a titanium selenium composite sol for agricultural product residual pesticide degradation, a preparation method of the sol and an application of the sol. The preparation method includes the steps: jointly dissolving or dispersing inorganic titanium sources and inorganic selenium salt in water; adding alkaline solution under a stirring condition until pH (potential of hydrogen) of the solution is 9-11; filtering and washing deposits to remove impurity ions, adding water, uniformly mixing the water and the deposits and performing beating; adding acid solution and adjusting the pH value to range from 1 to 2; performing water-bath heating for 15-25 hours under the stirring condition at the temperature of 60-70 DEG C to obtain the titanium selenium composite sol. Selenium is doped into titanium dioxide sol, the selenium-doped titanium dioxide sol with an appropriate concentration displays higher photocatalytic activity, has good synergistic effects and can be applied to pesticide residues in agricultural products.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

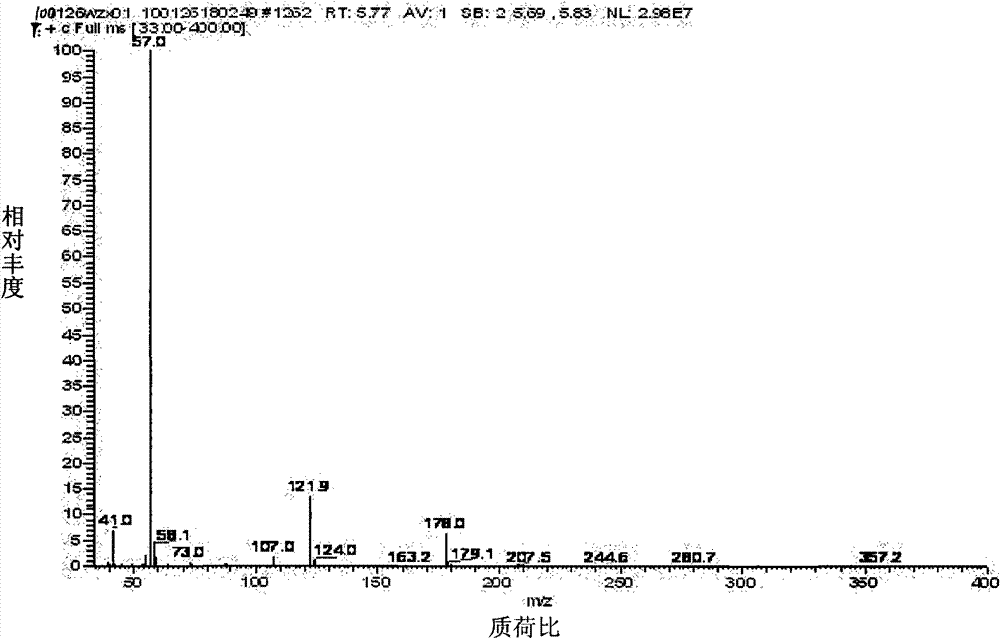

Method for diazotization of 5-methyl-4,5,6, 7-tetrahydrothiazolo [5, 4-c] pyridine by use of micro reaction device

InactiveCN106243129APrecise control of reaction temperatureShort process reaction timeOrganic chemistrySodium nitriteOperation safety

The invention discloses a method for diazotization of 5-methyl-4,5,6,7-tetrahydrothiazolo[5,4-c] pyridine by use of a micro reaction device, sulphate 5-methyl-4,5,6,7-tetrahydro[1,3]thiazolo[5,4-c]pyridine-2-amine is used as a raw material, and concentrated sulfuric acid, hypophosphorous acid and sodium nitrite are used for preparing the 5-methyl-4,5,6,7-tetrahydrothiazolo[5,4-c] pyridine in the micro reaction device. Compared with the prior art, the diazotization of the 5-methyl-4,5,6, 7-tetrahydrothiazolo [5, 4-c] pyridine is realized by use of the micro reaction device, and the method has the advantages of simple process, continuous production, small reaction volume, short time, smaller equipment corrosion, higher operation safety and higher selectivity and the like. At the same time, through use of the high efficient heat transfer ability and easy direct amplification characteristic of a micro channel reactor, the method has high conversion rate, the conversion rate is above 75%, the product quality is good, energy consumption is low, and the method is a green, environmentally-friendly and efficient method for synthesis of the 5-methyl-4,5,6,7-tetrahydrothiazolo[5,4-c] pyridine, and is suitable for industrial application.

Owner:NANJING UNIV OF TECH

Continuous production method for polyoxymethylene resin

The invention discloses a serial production method of acetaldehyde resin, belonging to the production technique of acetaldehyde resin technical field, firstly monomer metaformaldehyde of liquid state and polymer solvent are premixed according to 100:1 to 1:100 volume ratio; subsequently the mixed solution is transported to a consecutive reactor by a pump at 0 to 150 DEG C, and processes the polymerization at 30 to 200 DEG C in the condition of positive ion catalyst existing, the polymerization time is 0.5 to 100 min; after the polymerization being over, the obtained product can be processed with continual process. The serial production method of acetaldehyde resin of the invention produces polyformat dehyde of good quality, the whole production process can be continuously carried out, theassembly line type is used for work, the yield is large, and the unconverted monomer and the polymer solvent in the production process are not leaked, and can be repeatedly used.

Owner:ZHEJIANG SANPO POLYMER

A method for continuously preparing rosuvastatin intermediates using a microchannel modular reaction device

ActiveCN109796414BSimple processExtended reaction timeOrganic chemistryChemical recyclingEthylic acidMethyl palmoxirate

The invention discloses a method for continuously preparing rosuvastatin intermediates by adopting a microchannel modular reaction device. The isopropanol solution of p-fluorobenzaldehyde and the isopropanol solution of methyl isobutyryl acetate are prepared in acetic acid and piperidine Under catalysis, react in the first microreactor to generate the first product; the first product and the free isopropanol solution of S-methyl isothiourate react in the second microreactor to generate the second product; the second The product is reacted with an acetone solution of potassium permanganate and acetic acid in the third microreactor to obtain the third product; finally the third product is reacted with methylamine ethanol solution in the fourth microreactor to obtain the rosuvastatin intermediate. The invention has low toxicity and pollution, low production cost, good product quality, high profit, environmental protection, energy saving and high efficiency, and has the potential of industrial scale-up.

Owner:CHINA PHARM UNIV

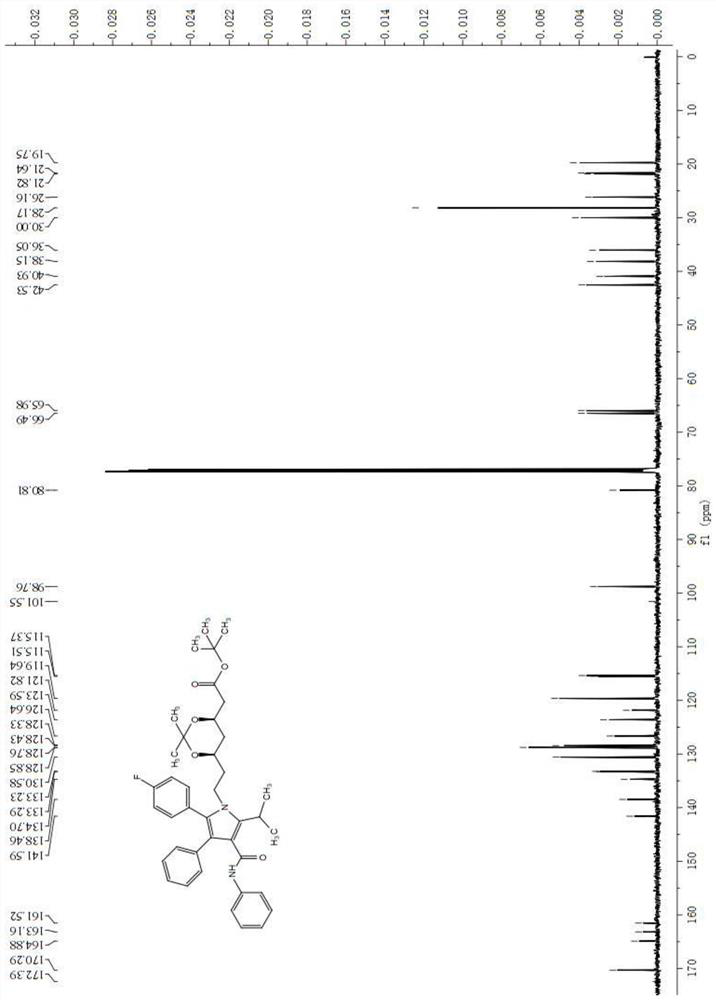

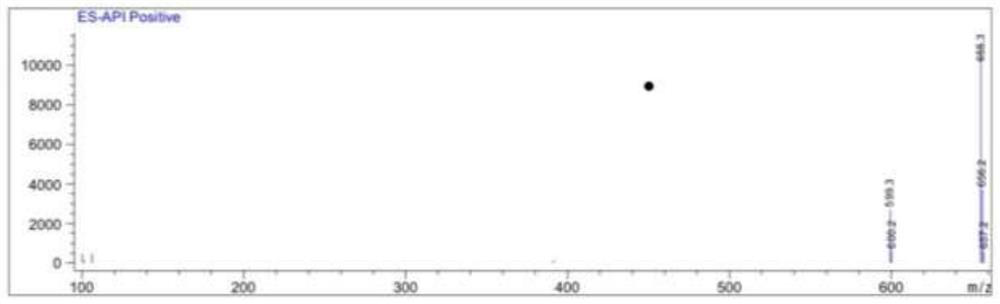

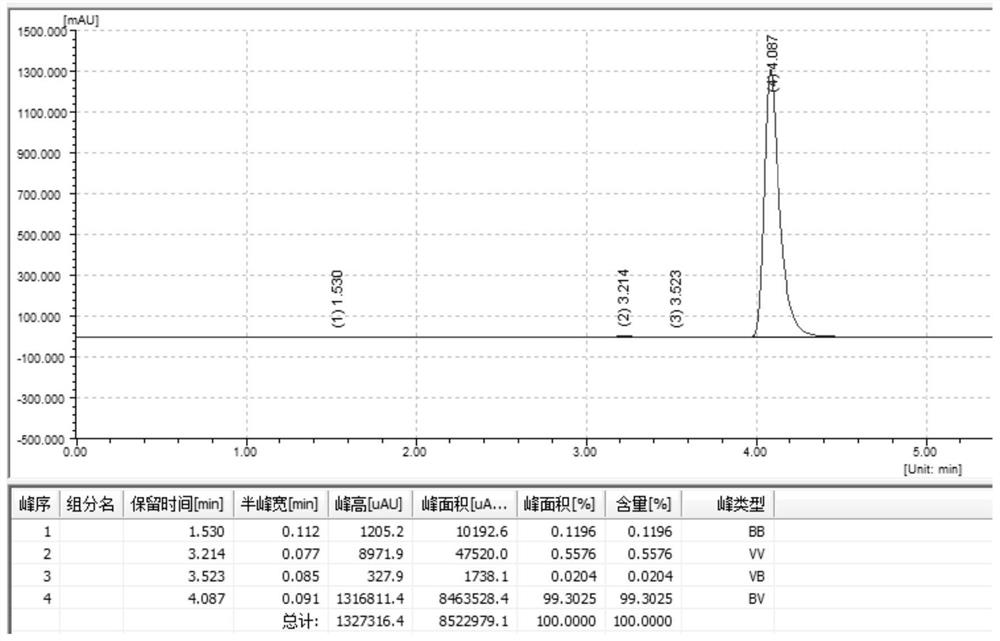

A method for preparing atorvastatin key intermediate l1 by a solvent-free method

The invention discloses a novel method for preparing an atorvastatin key intermediate L1 through a solvent-free method and belongs to the technical field of drug chemical synthesis. The novel method comprises the following steps that M4 and A9 are taken as raw materials, under the effects of a phase transfer catalyst and an acid catalyst, constant-temperature stirring melting reaction is directlyconducted for 5-7 hours under the solvent-free condition, the reaction temperature is 80-140 DEG C, water distribution is conducted in the reaction process, after reaction is completed, cooling is conducted, then recrystallization is conducted, and thus the atorvastatin key intermediate L1 is obtained. According to the novel method, the phase transfer catalyst and the acid catalyst are adopted, aparent nucleus M4 and a chiral side chain A9 are subjected to stirring melting reaction under the solvent-free condition, after reaction, recrystallization is conducted directly through ethyl alcohol / water, and thus L1 is obtained; and as for the process, the reaction time can be shortened to be 5 h, the conversion rate can reach up to 90%, operation and aftertreatment are easy, no mixed solvent is recovered, pollution is reduced remarkably, and the method is suitable for amplification production.

Owner:ZHEJIANG HAISEN PHARMACY CO LTD

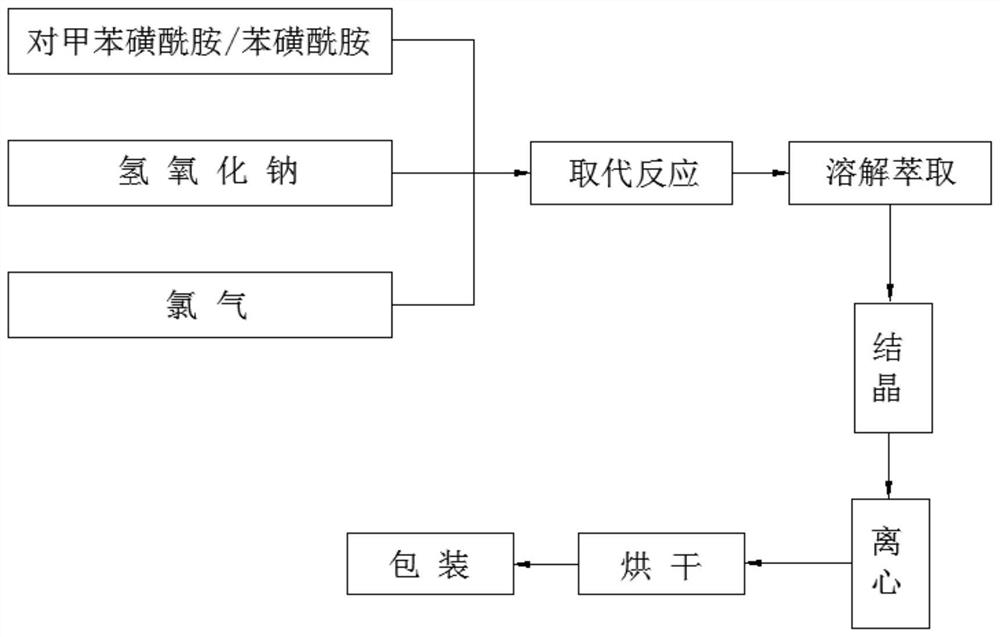

Preparation method of dichloramine T or dichloramine B

PendingCN114524755AWide variety of sourcesLow priceOrganic compound preparationSulfonic acid amide preparationPhenylsulfonamideSodium hydroxide

The invention belongs to the technical field of chemical production, and particularly relates to a preparation method of dichloramine T or dichloramine B. The preparation method comprises the following steps: (1) substitution reaction: mixing p-toluene sulfonamide or benzenesulfonamide with a sodium hydroxide solution, heating and dissolving, introducing chlorine, and carrying out substitution reaction; (2) dissolving and extracting: adding dichloromethane for dissolving and extracting, and standing for layering to form a salt water layer and a feed liquid layer; and (3) refining: cooling and crystallizing a feed liquid layer, centrifuging and drying. The method is wide in raw material source, low in price and short in process reaction time, after the reaction, sodium chloride brine is extracted and separated from the materials through the solvent, then recrystallization is conducted in the solvent, the materials and impurities can be thoroughly separated, the product content is high, the available chlorine content can reach 58% or above, the yield can reach 97% or above, and through the recrystallization process, the product purity is high. And the crystallized product is not easy to decompose, long in preservation time and stable in quality.

Owner:SHOUGUANG NUOMENG CHEM

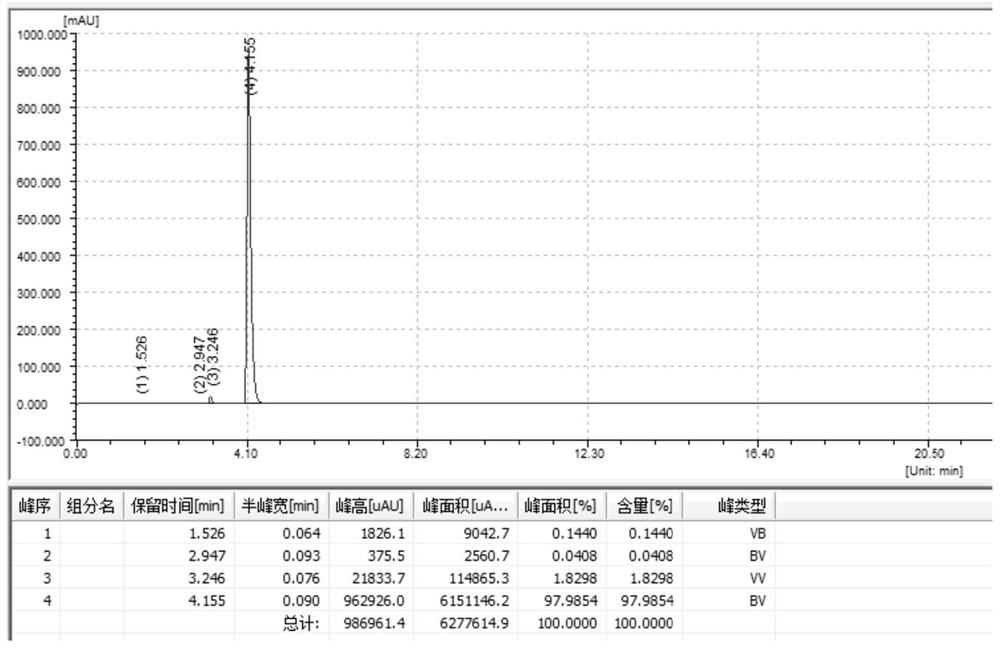

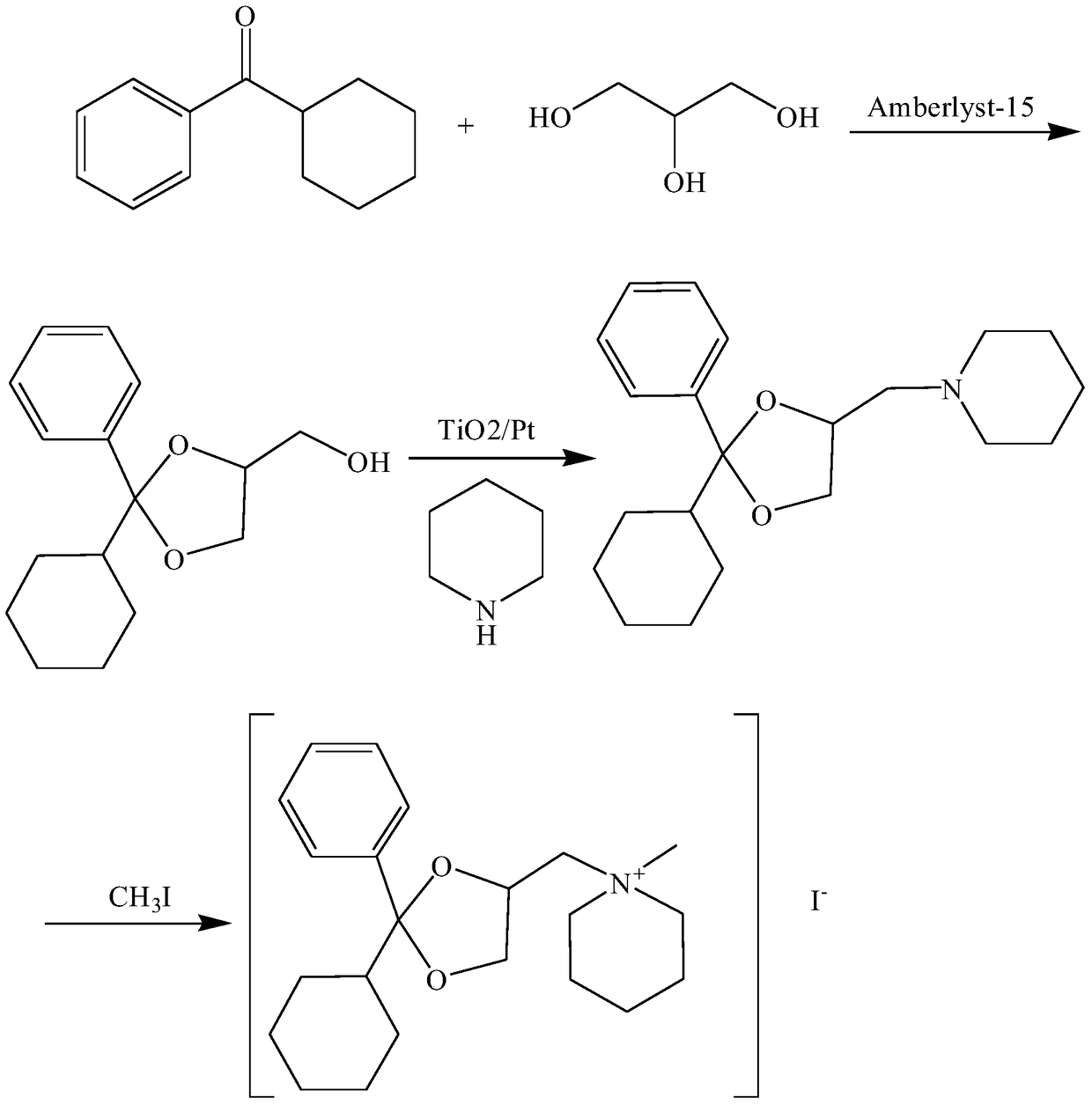

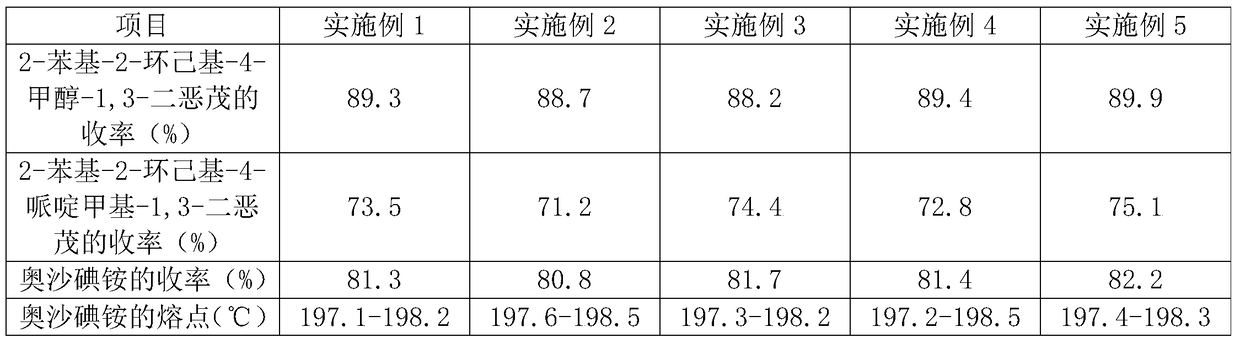

A kind of preparation method of oxalum iodide

The invention discloses an oxapium iodide preparation method. The method comprises the steps of S1, preparing 2-phenyl-2-hexamethylene-4-methanol-1,3-dioxolane, S2, preparing 2-phenyl-2-hexamethylene-4-piperidinemethyl-1, 3-dioxolane, and S3, preparing the oxapium iodide. The step S1 comprises the steps of mixing uniformly cyclohexyl phenyl ketone, glycerol, Amberlyst-15 exchange resin and allochroic silicagel, heating, maintaining the temperature, stirring, filtering, taking the filtered solution, adding saturated sodium hydrogen carbonate aqueous solution for washing, keeping static, taking organic layer, drying, releasing pressure, distilling to acquire material A, purifying material A, drying to acquire 2-phenyl-2-hexamethylene-4-methanol-1, 3-dioxolane. The method has the advantages of being mild in reaction condition, simple in operation, suitable for industrialized production, low in material toxicity, easy and cheap for material access, low in cost and good in comprehensive yield rate.

Owner:HEFEI PINGGUANG PHARMA

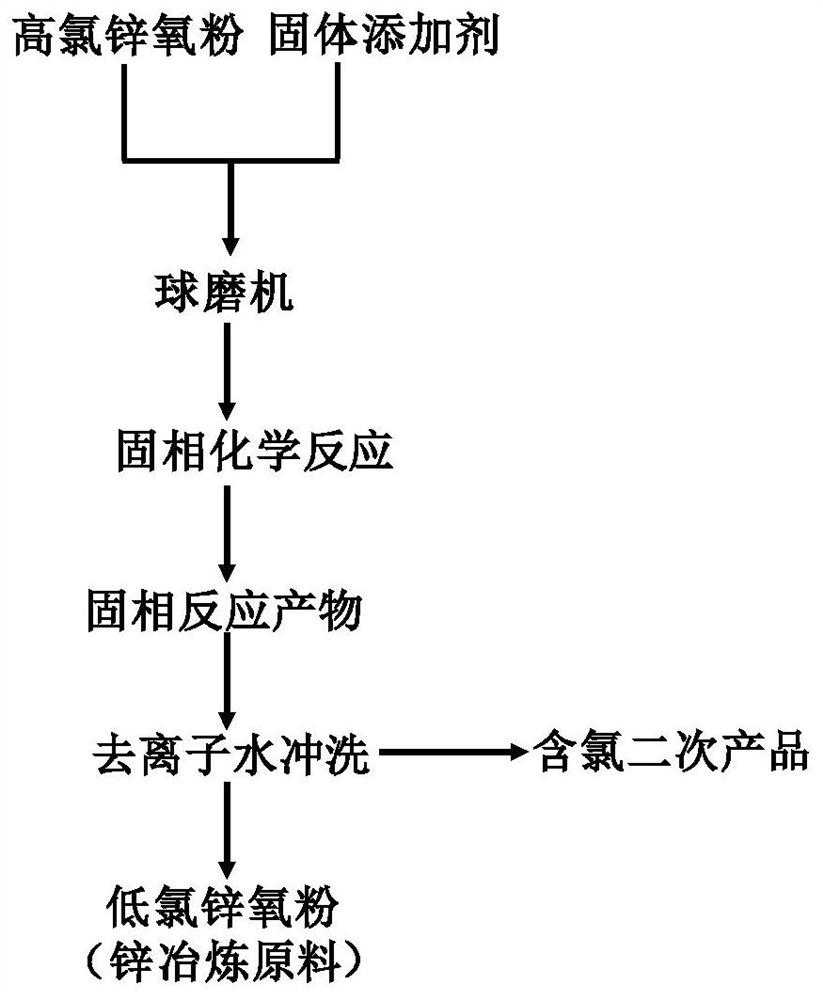

A kind of method adopting solid-state reaction to promote chlorine removal in high-chloride zinc oxide powder

ActiveCN110172590BEasy to removeSolve the removal problemProcess efficiency improvementPhysical chemistryReaction temperature

The invention relates to a method for promoting the removal of chlorine in high-chloride zinc oxide powder by adopting solid-phase reaction. The method comprises: mixing high-chloride zinc oxide powder with a solid-phase additive and then performing ball milling; drying the material obtained after ball milling Dry to obtain the zinc oxide powder product after dechlorination. The invention promotes the removal of chlorine in the high-chloride zinc oxide powder by using mechanical force to induce solid-phase reaction, and the removal efficiency of chlorine can reach more than 99%. Compared with the traditional alkaline cleaning process, it has the advantages of high dechlorination efficiency, low reaction temperature, short reaction time, less reagent addition and less rinsing times, and can effectively solve the problem of chlorine removal in high-chloride zinc oxide powder. In actual production The production cost and operation cost can be reduced, and the method has the characteristics of wide application range, and has good economic benefits and application prospects.

Owner:唐山鑫联环保科技有限公司

Preparation of phenylethylene-dialkene special copolymer

The invention discloses a preparation method for a styrene-diolefin special copolymer. The preparation method comprises the following steps: taking a styrene-diolefin block random copolymer as PS-PB-PB / PS-PS; wherein PS representing a styrene copolymer block, PB representing a diolefin copolymer block, and PB / PS representing a styrene-diolefin random copolymer block; and adopting an anionic continuous polymerization method. The preparation method avoids the defects of a batch still and is characterized by low production cost, short production cycle, low operating cost, short reaction time andhigh yield.

Owner:ZHEJIANG SANPO POLYMER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for diazotization of 5-methyl-4,5,6, 7-tetrahydrothiazolo [5, 4-c] pyridine by use of micro reaction device Method for diazotization of 5-methyl-4,5,6, 7-tetrahydrothiazolo [5, 4-c] pyridine by use of micro reaction device](https://images-eureka.patsnap.com/patent_img/86313d4d-a331-4d0d-bf34-d16096e73b8f/HDA0001060872390000011.PNG)

![Method for diazotization of 5-methyl-4,5,6, 7-tetrahydrothiazolo [5, 4-c] pyridine by use of micro reaction device Method for diazotization of 5-methyl-4,5,6, 7-tetrahydrothiazolo [5, 4-c] pyridine by use of micro reaction device](https://images-eureka.patsnap.com/patent_img/86313d4d-a331-4d0d-bf34-d16096e73b8f/BDA0001060872380000031.PNG)