Method for continuously preparing rosuvastatin intermediate by micro-channel modular reaction device

A microchannel module, rosuvastatin technology, applied in chemical recovery, organic chemistry and other directions, can solve the problems of low yield, difficult to purify, many by-products, etc., and achieve high yield, easy operation, and less side reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

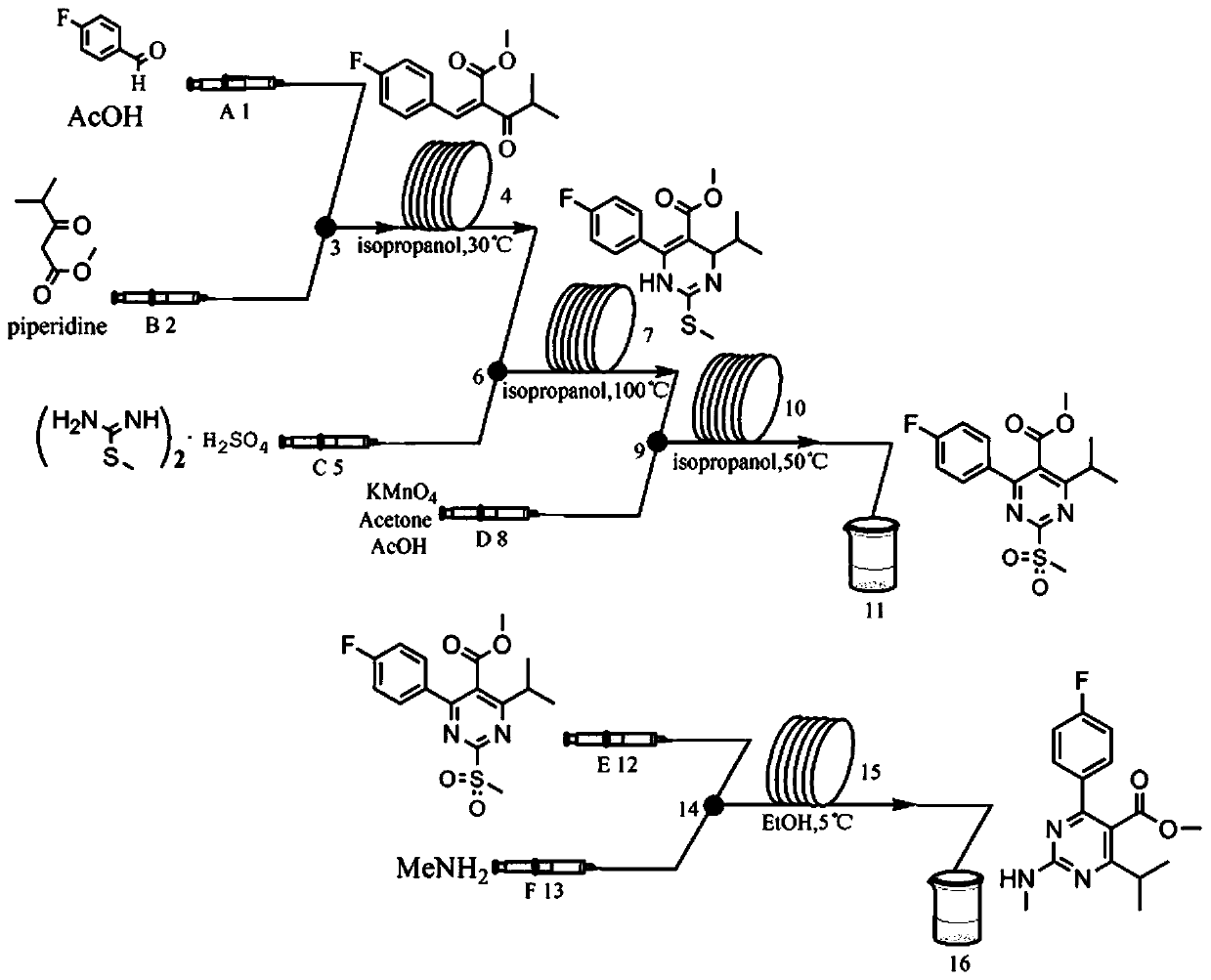

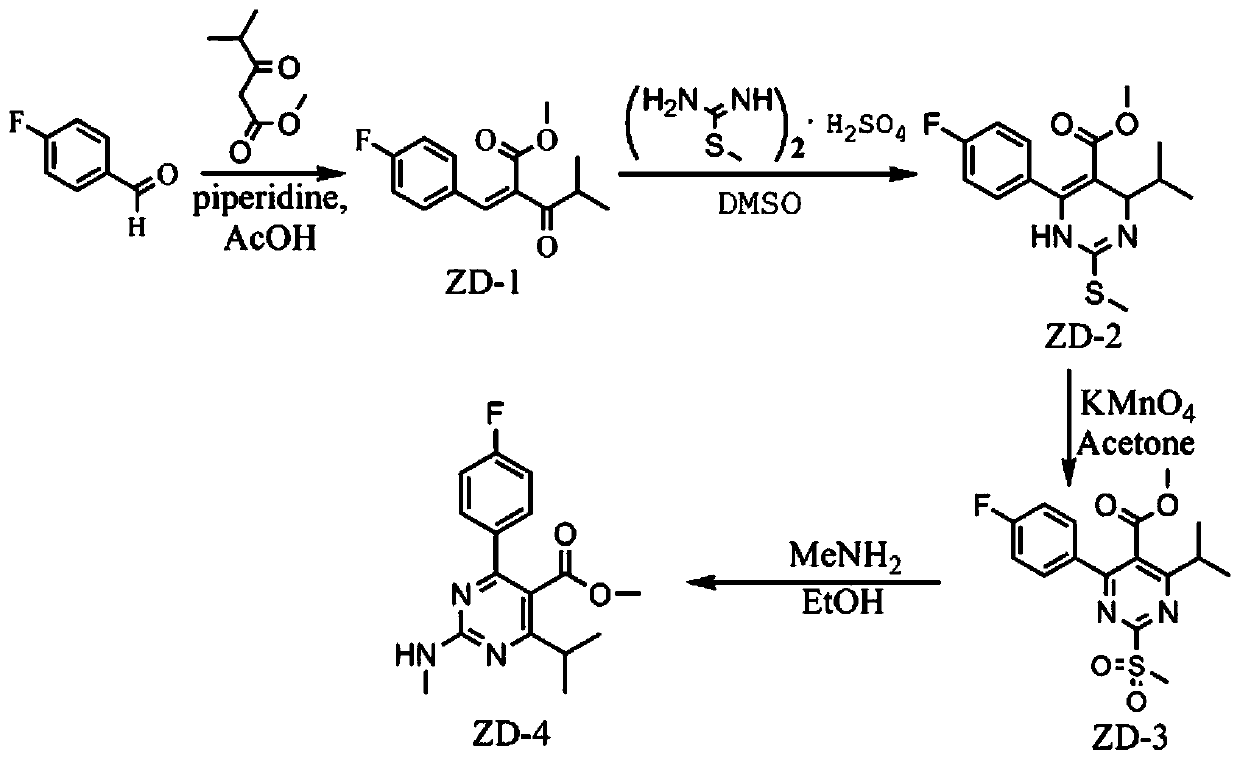

Method used

Image

Examples

Embodiment 1

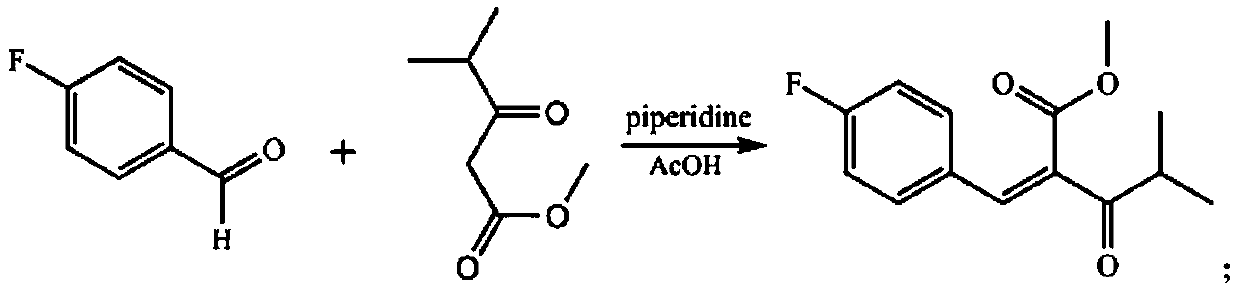

[0046] (1) In the microchannel reaction device, the isopropanol solution (11.5mL) of p-fluorobenzaldehyde (0.04mol) and the isopropanol solution (0.135mL) of acetic acid catalyst (0.135mL), methyl isobutyrylacetate (0.04mol) Solution (11.5mL) and catalytic amount of piperidine (0.225mL) were pumped into the first mixer 3 from pump A1 and pump B2 respectively, the flow rate of pump A1 was 0.38mL / min, and the flow rate of pump B2 was 0.38mL / min min. After fully mixing, enter the first microreactor 4. The volume of the first microreactor 4 is 40mL, the reaction residence time is 30min, and the reaction temperature is 30°C. The obtained reaction effluent is 2-(4-fluorophenyl)methylene - Methyl 3-oxo-4-methylpentanoate (ZD-1).

[0047] (2) along with the reaction solution that step (1) obtains flows into the second mixer 6, flow velocity is 1.24mL / min, S-methylisothiouronium sulfate (2.08mol) is added into equimolar amount of saturated sodium bicarbonate ( 2.08mol) free isopropan...

Embodiment 2

[0060] The operation is the same as in Example 1, the only difference is:

[0061] In step (1), the reaction temperature in the first microreactor is 20°C, and finally 2-(4-fluorophenyl)methylene-3-oxo-4-methylpentanoic acid methyl ester (ZD- 1) The reaction effluent has a yield of 75%.

Embodiment 3

[0063] The operation is the same as in Example 1, the only difference is:

[0064] In step (1), the reaction temperature in the first microreactor is 40°C, and finally 2-(4-fluorophenyl)methylene-3-oxo-4-methylpentanoic acid methyl ester (ZD- 1) The reaction effluent has a yield of 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com