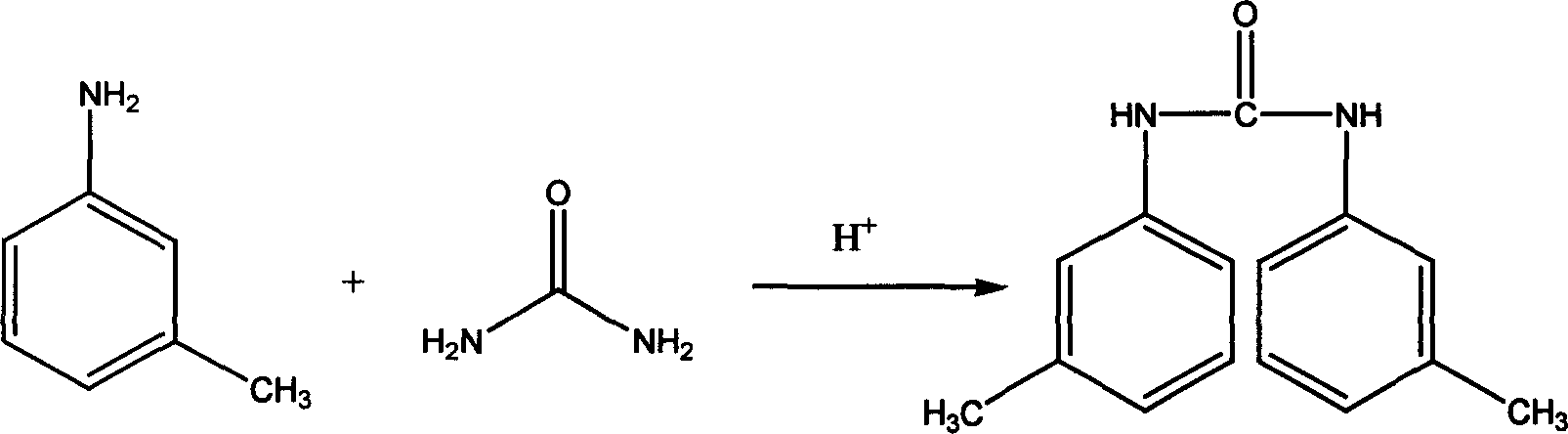

Water phase high pressure method for preparing N,N'-di (m-tolyl) urea

A technology of tolyl and m-toluidine, applied in the N field, can solve the problems of troublesome recovery, high synthesis cost, expensive amyl alcohol, etc., and achieve the effect of simple reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) After m-toluidine is mixed with water, add sulfuric acid dropwise to form a salt reaction, add urea after dropping, and stir; the equivalent ratio of m-toluidine to sulfuric acid is 1:0.95, and the molar ratio of m-toluidine to urea is 1: 0.5, the salt-forming reaction temperature is 0°C;

[0018] 2) Add the above reaction solution into the autoclave, the pressure of the autoclave reaches 2atm, keep the pressure for 5 hours, release the pressure, discharge the material, centrifuge, wash with hot water, and get the finished product N,N'-di(m-tolyl)urea , The molar yield is 90%, based on m-toluidine.

Embodiment 2

[0020] 1) After mixing m-toluidine with water, add hydrochloric acid dropwise to form a salt reaction, add urea after dropping, and stir; the equivalent ratio of m-toluidine to hydrochloric acid is 1:1.05, and the molar ratio of m-toluidine to urea is 1: 1. The salt-forming reaction temperature is 80°C;

[0021] 2) Add the above-mentioned reaction liquid into the high-pressure reaction kettle, and the pressure of the high-pressure reaction kettle is 10 atm, keep the pressure for 1 hour, release the pressure, discharge the material, centrifuge, wash with hot water, and obtain the finished product N,N'-di(m-tolyl)urea , The molar yield is 91%, based on m-toluidine.

Embodiment 3

[0023] 1) After m-toluidine is mixed with water, add phosphoric acid dropwise to form a salt reaction, add urea after dropping, and stir; the equivalent ratio of m-toluidine to phosphoric acid is 1:1, and the molar ratio of m-toluidine to urea is 1: 0.5, the salt-forming reaction temperature is 0°C;

[0024] 2) Add the above reaction solution into the autoclave, the pressure of the autoclave reaches 4atm, keep the pressure for 2 hours, release the pressure, discharge the material, centrifuge, wash with hot water, and get the finished product N,N'-bis(m-tolyl)urea , The molar yield is 92%, based on m-toluidine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com