Method for preparing Ni-Fe/Fe compound powder film with high magnetic conductivity

A technology of composite powder and high magnetic permeability, applied in the field of materials, can solve the problems of difficulty in preparing particle gaps, affecting the magnetic permeability of magnetic powder, and high bulk density, and achieve high saturation magnetization and high magnetic permeability. , the effect of low coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] FeCl 2 and NiCl 2 Added to ethylene glycol, FeCl 2 The molar concentration is 0.1M, NiCl 2 The molar concentration of the solution is 0.1M, the NaOH solution is added dropwise to adjust the pH value to 7, and the concentration of the NaOH solution is 0.5M. Heat and stir at 80±5°C until the iron salt and nickel salt are completely dissolved in ethylene glycol to obtain a mixed alcohol solution.

[0037] Heat the mixed alcohol solution to 150°C and keep it warm for 180min to obtain a suspension.

[0038] Cool the suspension to room temperature, put it in a centrifuge tube, and centrifuge at a speed of 5000 rpm. The microparticles are attached to the wall of the centrifuge tube under the action of gravity and centrifugal force, and the liquid phase is poured out to obtain a solid phase of Ni-Fe. Fine particles; the average particle diameter of the Ni-Fe fine particles is 440 nm.

[0039]Wash the Ni-Fe microparticles with water to remove residual ethylene glycol, then ...

Embodiment 2

[0043] Fe(acac) 2 and Ni(acac) 2 Added to ethylene glycol, Fe(acac) 2 The molar concentration of Ni(acac)2 is 0.5M, and the molar concentration of Ni(acac)2 is 0.5M. NaOH solution is added dropwise to adjust the pH value to 8, and the concentration of NaOH solution is 1M. Stir under the condition that the heating temperature is 80±5°C until the iron salt and the nickel salt are completely dissolved in ethylene glycol to obtain a mixed alcohol solution.

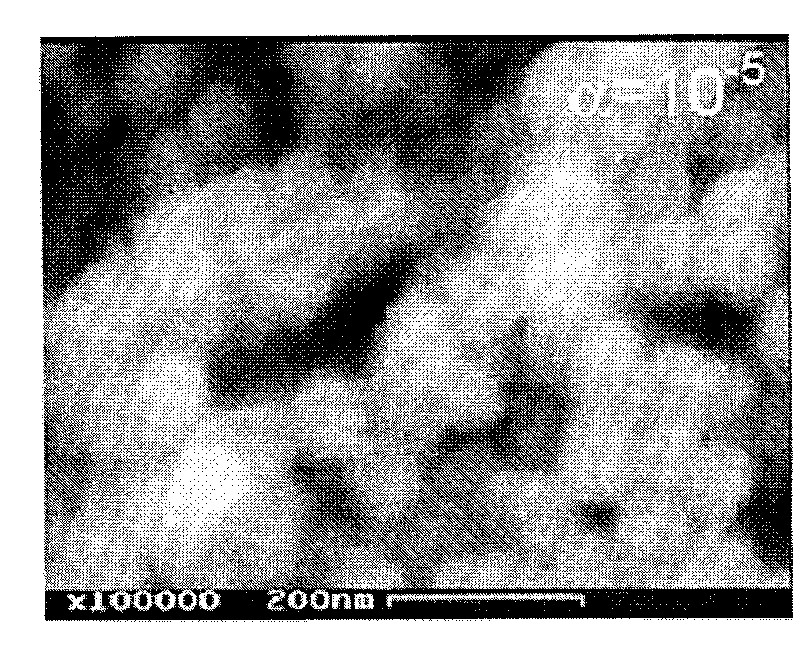

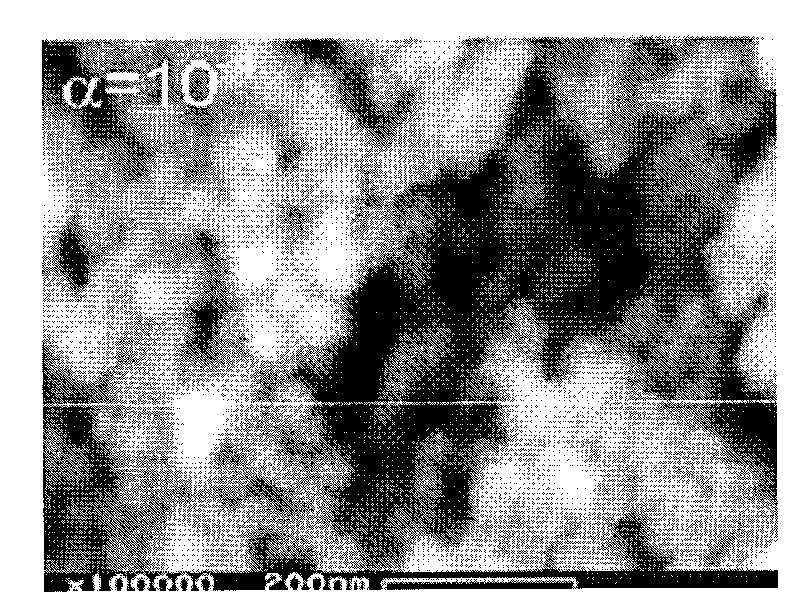

[0044] Add K to the mixed alcohol solution 2 PtCl 4 As a nucleating agent, the molar ratio of the Pt ions in the nucleating agent to the Ni ions and Fe ions in the mixed alcohol solution is Pt: (Ni+Fe)=1×10 -4 : 1, then heated to 160° C., kept for 150 minutes, and synthesized to obtain a suspension.

[0045] Cool the suspension to room temperature, place it in a centrifuge tube, and centrifuge at a speed of 6000rpm. The microparticles are attached to the wall of the centrifuge tube under the action of gravity and centrifu...

Embodiment 3

[0050] FeCl 2 and NiCl 2 Added to ethylene glycol, FeCl 2 The molar concentration is 0.2M, NiCl 2 The molar concentration of the solution is 0.2M, the NaOH solution is added dropwise to adjust the pH value to 9, and the concentration of the NaOH solution is 2M. Stir under the condition that the heating temperature is 80±5°C until the iron salt and the nickel salt are completely dissolved in ethylene glycol to obtain a mixed alcohol solution.

[0051] Add K to the mixed alcohol solution 2 PtCl 4 As a nucleating agent, the molar ratio of the Pt ions in the nucleating agent to the Ni ions and Fe ions in the mixed alcohol solution is Pt: (Ni+Fe)=1×10 -5 : 1, then heated to 180° C., kept for 120 minutes, and synthesized to obtain a suspension.

[0052] Cool the suspension to room temperature, place it in a centrifuge tube, and centrifuge at a rotation speed of 5000 rpm. The microparticles are attached to the wall of the centrifuge tube under the action of gravity and centrifu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com