Organic silicon resin conformal coating capable of being cured at room temperature and preparation method thereof

A room temperature curing, silicone technology, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of large steric hindrance, affecting product performance, and large steric hindrance of phenyl silicone resin, to achieve increased toughness, simple preparation process, The effect of easy response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of hydroxymethyl silicone resin: Put 80g of ethyl orthosilicate, 20g of methyltrimethoxysilane and 140g of toluene into the reaction kettle, add 2g of concentrated HCl+20g of distilled water dropwise at room temperature, after the addition is complete, heat up to 60 Reflux reaction at ℃ for 5 hours, heat up to 70-80℃ to distill methanol and water produced in the reaction, then raise the temperature to 110℃ and reflux for 8 hours, then cool down to 60℃ and add 3g of hexamethyldisilazane to neutralize HCl, Then heat up to 110°C and concentrate to a resin solution with a solid content of 50%, and cool down for later use;

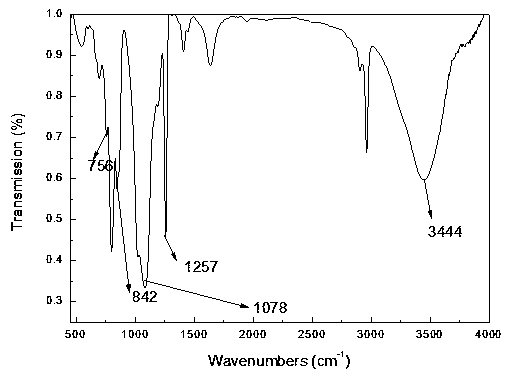

[0040] The prepared hydroxymethyl silicone resin structure is as follows:

[0041]

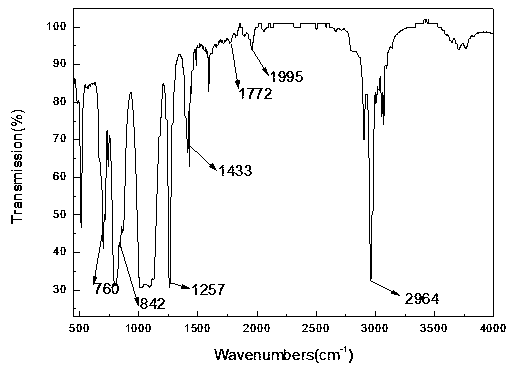

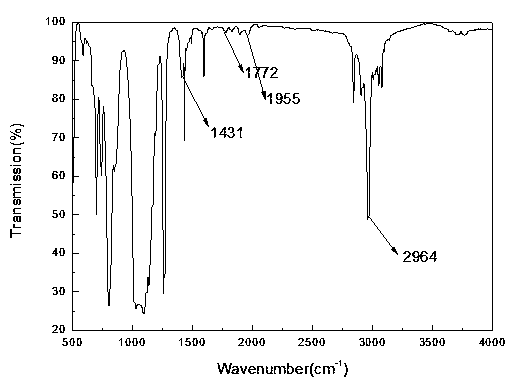

[0042]Preparation of alkoxy-terminated phenyl silicone oil: mix 100g octamethylcyclotetrasiloxane with 40g octaphenylcyclotetrasiloxane, 2g 1,3-dimethoxy-1,1,3,3-tetramethyl base disiloxane, 2g of alkali glue, mixed evenly, then reacted at 150°C for 5 hou...

Embodiment 2

[0050] Preparation of hydroxymethyl silicone resin: Put 70g of ethyl orthosilicate, 10g of dimethyldimethoxysilane and 120g of xylene into the reaction kettle, add 1g of concentrated HCl+8g of distilled water dropwise at room temperature, and the addition is complete , heat up to 60°C for reflux reaction for 5 hours, heat up to 70-80°C to evaporate the methanol and water produced in the reaction, then raise the temperature to 110°C for 8 hours, then cool down to 60°C and add 3g of hexamethyldisilazane Neutralize HCl, then heat up to 110°C and concentrate to a resin solution with a solid content of 50%, cool down for later use;

[0051] Preparation of alkoxy-terminated phenyl silicone oil: mix 140g octamethylcyclotetrasiloxane with 40g octaphenylcyclotetrasiloxane, 6g 1,3-dimethoxy-1,1,3,3-tetramethyl 1.5g base disiloxane and 1.5g of alkali glue were mixed evenly, then reacted at 150°C for 5 hours, heated to 180°C for 30min, and then vacuumed at this temperature for 8 hours to ...

Embodiment 3

[0054] Preparation of hydroxymethyl silicone resin: put the mixture of 100g ethyl orthosilicate and 150g toluene into the reaction kettle, add 3g concentrated HCl+15g distilled water dropwise at room temperature, after the addition is completed, heat up to 60°C for reflux reaction for 5 hours, then heat up to Distill the methanol and water produced by the reaction at 70-80°C, then raise the temperature to 110°C and reflux for 8 hours, then cool down to 60°C and add 3g of hexamethyldisilazane to neutralize HCl, then raise the temperature to 110°C and concentrate to solid The resin liquid with a content of 50% is cooled for later use;

[0055] Preparation of alkoxy-terminated phenyl silicone oil: mix 140g octamethylcyclotetrasiloxane with 80g octaphenylcyclotetrasiloxane, 2g 1,3-dimethoxy-1,1,3,3-tetramethyl base disiloxane and 4g of alkali gel were mixed evenly, then reacted at 150°C for 5 hours, heated to 180°C for 30min, and then vacuumed at this temperature for 8 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com