Preparation method of dichloramine T or dichloramine B

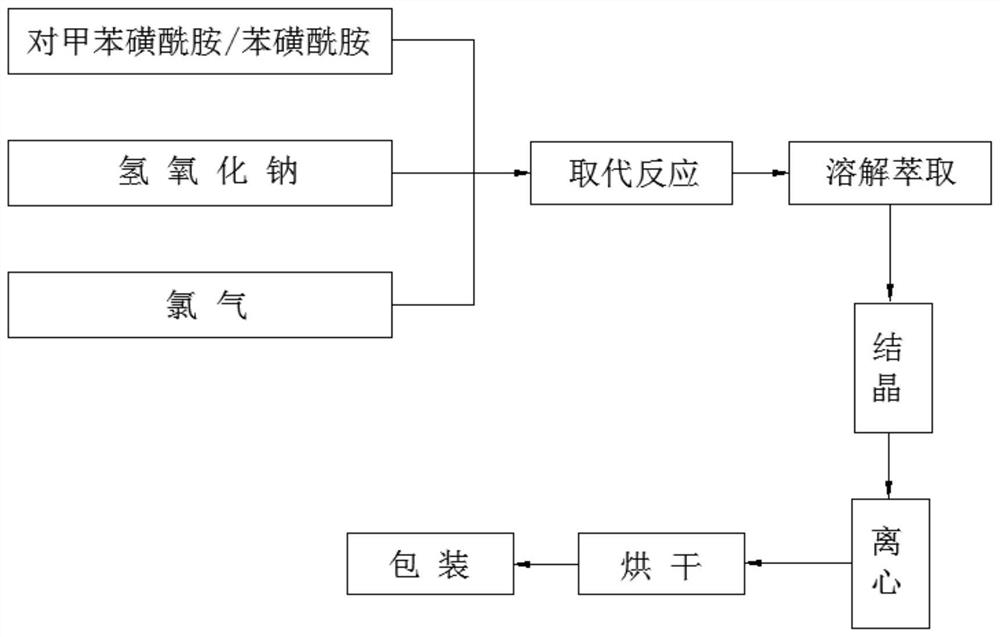

A technology of dichloramine and chlorine gas is applied in the preparation of sulfonic acid amide, the preparation of organic compounds, chemical instruments and methods, etc., to achieve the effects of short process reaction time, stable quality and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

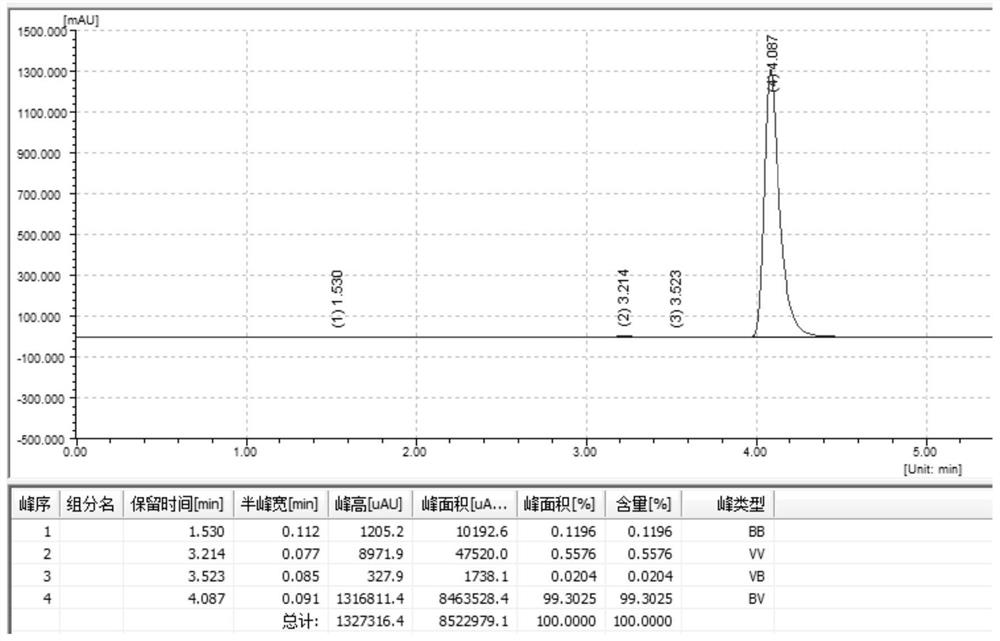

Embodiment 1

[0024] Add 86.04g of p-toluenesulfonamide (content 99.5%, 0.5mol), 136.7g of 30%wt sodium hydrogen hydride solution into a 500ml four-neck flask, stir and dissolve, cool down to 10°C in a water bath, and add 74.6g of chlorine gas (99.95% chlorine gas content ) into a four-necked bottle (the molar ratio of the reaction materials is 1:2.05:2.1), the temperature is controlled at 10°C for about 3 hours, the pH value is detected at 10-11, and the first stage of chlorine flow is completed; add 4.3 grams of catalyst sodium acetate (for The mass ratio of toluenesulfonamide: sodium acetate = 1:0.05), continue to feed the remaining chlorine gas, control the temperature at 10°C, and pass chlorine for about 3 hours. The detected pH value is less than 4, and the reaction is complete. Naturally raise the temperature to about 30°C, add 60 grams of dichloromethane, dissolve and extract, let the material dissolve and separate into layers, separate the brine layer, cool the material liquid to 0°...

Embodiment 2

[0026] Add 86.04g of p-toluenesulfonamide (content 99.5%, 0.5mol), 140g of 30%wt sodium hydrogen hydride solution into a 500ml four-necked bottle, stir and dissolve, cool down to 10°C in a water bath, and add 78.14g of chlorine gas (99.95% of chlorine gas content) Pass it into a four-necked bottle (the molar ratio of the reaction materials is 1:2.1:2.2), control the temperature at 10°C for about 3 hours, check the pH value of 10-11, and complete the first stage of chlorine passage; add 3.44 grams of catalyst sodium acetate (p-toluene The mass ratio of sulfonamide: sodium acetate = 1:0.04), continue to feed the remaining chlorine gas, control the temperature at 10°C, and pass the chlorine for about 3 hours. The detected pH value is less than 4, and the reaction is completed. Naturally raise the temperature to about 30°C, add 60 grams of dichloromethane, dissolve and extract, let the material dissolve and separate into layers, separate the brine layer, cool the material liquid to...

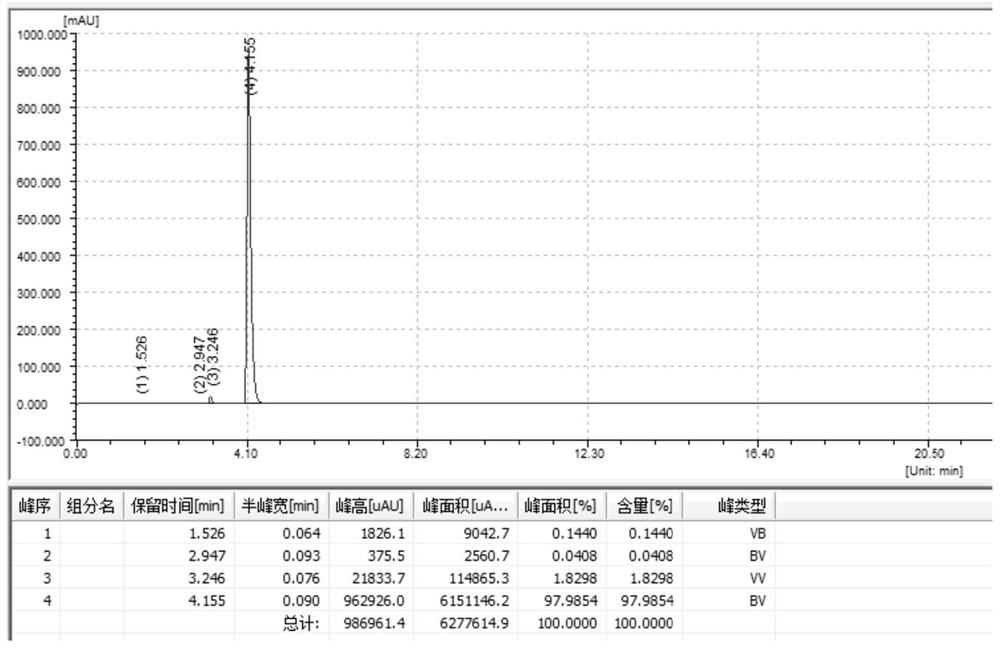

Embodiment 3

[0028] Add 86.04g of p-toluenesulfonamide (content 99.5%, 0.5mol), 136.7g of 30%wt sodium hydrogen hydride solution into a 500ml four-neck flask, stir and dissolve, cool down to 10°C in a water bath, and add 74.6g of chlorine gas (99.95% chlorine gas content ) into a four-necked bottle (the molar ratio of the reaction materials is 1:2.05:2.1), the temperature is controlled at 10°C for about 3 hours, the pH value is detected at 10-11, and the first stage of chlorine flow is completed; add 4.3 grams of catalyst sodium acetate (for The mass ratio of toluenesulfonamide: sodium acetate = 1:0.05), continue to feed the remaining chlorine gas, control the temperature at 10°C, and pass chlorine for about 3 hours. The detected pH value is less than 4, and the reaction is complete. Naturally raise the temperature to about 30°C, add 60 grams of dichloromethane, dissolve and extract, let the material dissolve and let it stand for stratification, separate the brine layer, cool the material l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com