A method and special equipment for removing hydrogen sulfide by supergravity liquid phase redox

A liquid-phase oxidation and hydrogen sulfide technology, which is applied in the preparation/purification of sulfur, chemical instruments and methods, separation methods, etc. The effect of high mass transfer efficiency, good catalytic reaction effect and short process reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

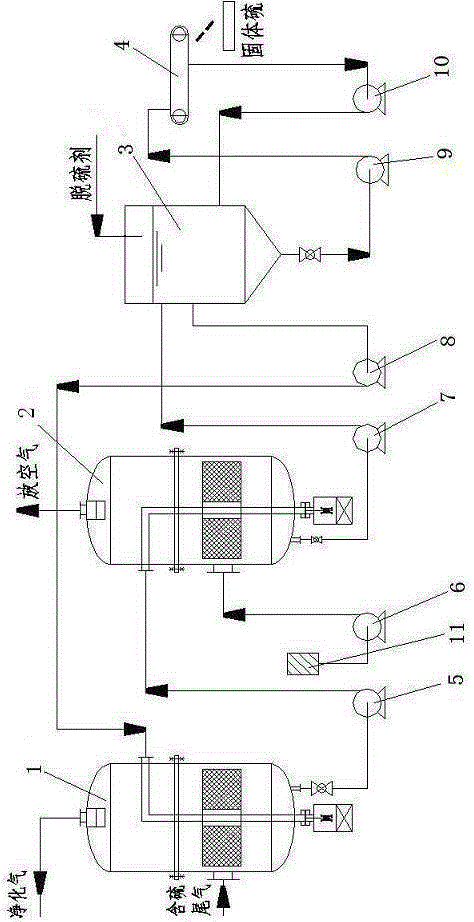

Method used

Image

Examples

Embodiment approach

[0037] Have implementation mode: the specific implementation mode of the present invention is described in detail below:

[0038] Preparation of desulfurizer:

[0039] 1. FeCl 3 , NTA, potassium tartrate, and tert-butanol were mixed according to a molar ratio of 1:2.5:1:1.5 to prepare a chelated iron catalyst concentrate with a total iron concentration of 14g / L. Get chelated iron catalyst concentrate 37.5mL, NTA chelating agent concentrate 56.25mL and dilute to 1500mL, total iron concentration in the diluent is 350ppm, add C 5 h 12 o 2 0.15g, KCl0.15g, KOH8.5g make desulfurizer;

[0040] 2. Fe 2 (SO 4 ) 3 , EDTA, HEDTA, sodium citrate, and isoamyl alcohol are mixed according to a molar ratio of 1:2:1.5:1:1:1.5 to make a chelated iron catalyst concentrate with a total iron concentration of 56g / L. Get 267mL of chelated iron catalyst concentrate, 321mL of EDTA and HEDTA chelating agent concentrate and dilute to 1500mL, the total iron concentration in the diluent is 10000p...

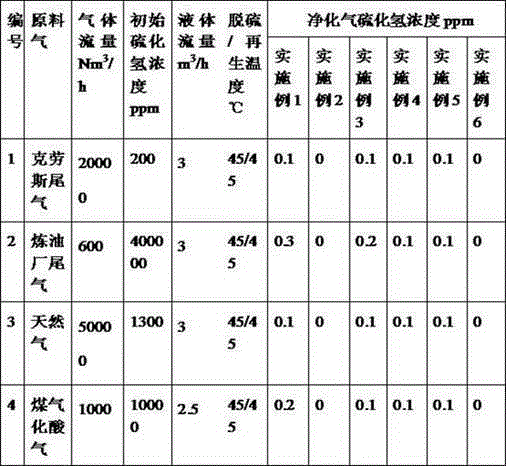

Embodiment 1

[0045] Embodiment 1: a kind of method that supergravity liquid phase redox removes hydrogen sulfide, it comprises the steps:

[0046] (1) Add the desulfurizing agent in the preparation 1 of the above desulfurizing agent into the liquid storage tank;

[0047] (2) Pump the desulfurization agent into the desulfurization supergravity reactor through the absorption liquid pump. The reaction temperature range in the desulfurization supergravity reactor is 10~53℃, and the pressure is 50 KPa ~3.5 MPa The hydrogen sulfide gas that enters the desulfurization supergravity reactor contacts with the desulfurizer on the surface of the wire mesh packing of the rotor of the desulfurization supergravity reactor, and the hydrogen sulfide gas is oxidized to elemental sulfur by the desulfurizer, and the Fe in the desulfurizer 3+ is reduced to Fe 2+ ;

[0048] (3) The hydrogen sulfide removal gas is emptied through the built-in filter of the supergravity reactor, and the sulfur-containing desu...

Embodiment 2

[0051] Embodiment 2: A method for removing hydrogen sulfide by supergravity liquid phase redox, its steps are basically the same as in Embodiment 1, the difference is that in step 1, the desulfurizer in the preparation 2 of the above desulfurizer is added to the liquid storage tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com