Green synthesis technique of p-chloro-m-cresol

A green synthesis technology of p-chloro-m-cresol, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of large amount of neutralization and washing wastewater, restrictions on industrial production, and long reaction time. Achieve the effects of short reaction time, high degree of automation, and high solvent recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

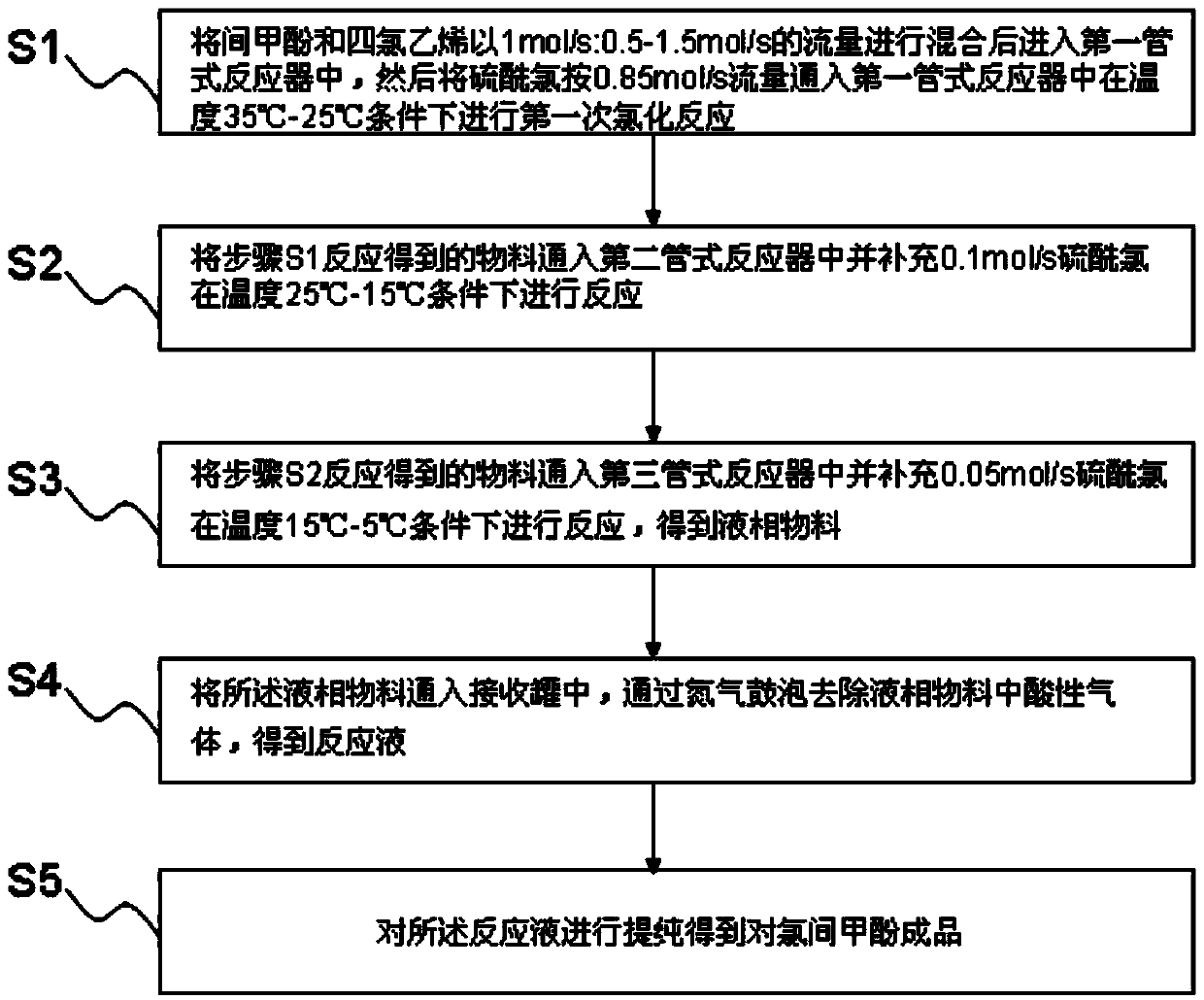

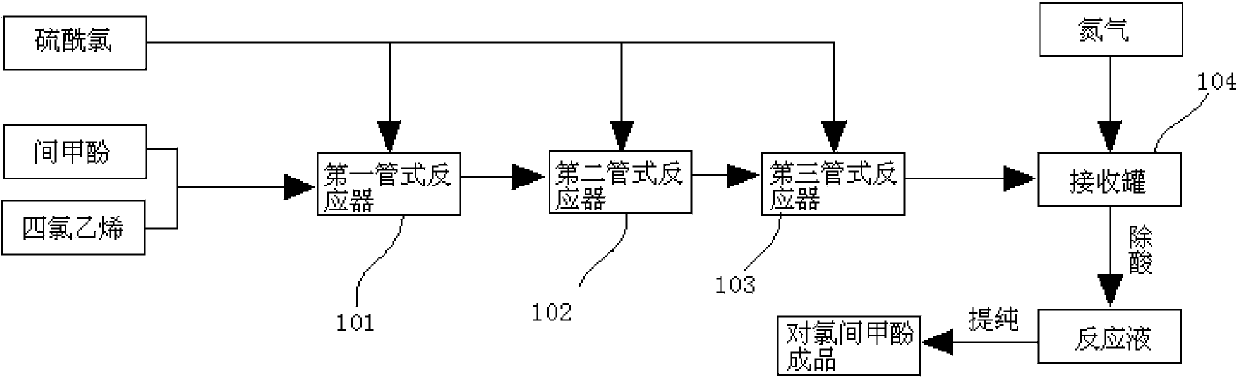

[0032] Such as figure 1 Shown, described technological process comprises the following steps:

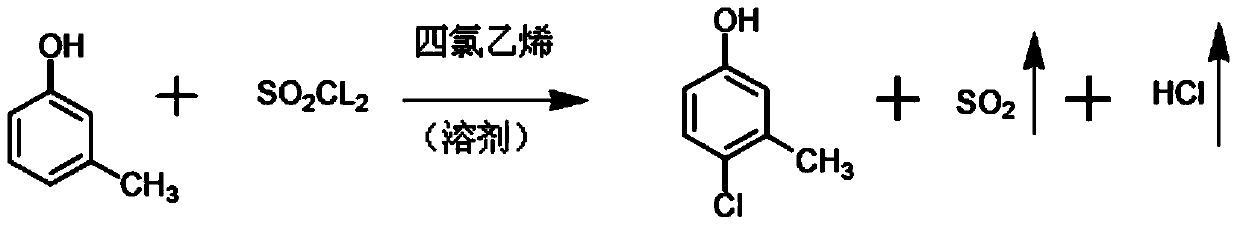

[0033] S1: After m-cresol and tetrachlorethylene are mixed through a static mixer (not shown) at a flow rate of 1mol / s:0.5mol / s, then enter the first tubular reactor 101, and sulfuryl chloride is The flow rate of 0.85mol / s is passed into the first tubular reactor 101 with a distributor interface (not shown), and the reaction temperature is controlled at 35°C-25°C to carry out the first chlorination reaction (first-order reaction). The tetrachlorethylene solvent added in the present invention can keep the reaction system in the liquid phase state all the time during the reaction process, and also has a dilution effect on the reaction product at the same time, can delay the reaction speed, improve the selectivity, and make the reaction more stable through the dispersion effect of the solvent , reduce the reaction rate, and then make the reaction more fully, greatly improving the conv...

Embodiment 2

[0040] Such as figure 1 Shown, described technological process comprises the following steps:

[0041]S1: after m-cresol and tetrachlorethylene are mixed in the static mixer with the flow of 1mol / s:1mol / s, then enter in the first tubular reactor 101, pass sulfuryl chloride by 0.85mol / s flow Enter into the first tubular reactor 101 with a distributor interface, control the reaction temperature at 35°C-25°C, and carry out the first chlorination reaction (first-order reaction). The tetrachlorethylene solvent added in the present invention can keep the reaction system in the liquid phase state all the time during the reaction process, and also has a dilution effect on the reaction product at the same time, can delay the reaction speed, improve the selectivity, and make the reaction more stable through the dispersion effect of the solvent , reduce the reaction rate, and then make the reaction more fully, greatly improving the conversion rate of m-cresol. Adding sulfuryl chloride ...

Embodiment 3

[0048] Such as figure 1 Shown, described technological process comprises the following steps:

[0049] S1: After m-cresol and tetrachlorethylene are mixed through the static mixer at a flow rate of 1mol / s:1.5mol / s, then enter the first tubular reactor 101, and sulfuryl chloride is mixed at a flow rate of 0.85mol / s Pass it into the first tubular reactor 101 with a distributor interface, control the reaction temperature at 35°C-25°C, and carry out the first chlorination reaction (first-order reaction). The tetrachlorethylene solvent added in the present invention can keep the reaction system in the liquid phase state all the time during the reaction process, and also has a dilution effect on the reaction product at the same time, can delay the reaction speed, improve the selectivity, and make the reaction more stable through the dispersion effect of the solvent , reduce the reaction rate, and then make the reaction more fully, greatly improving the conversion rate of m-cresol. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com