A kind of method adopting solid-state reaction to promote chlorine removal in high-chloride zinc oxide powder

A high-chloride zinc-oxygen powder, solid-phase reaction technology, applied in the direction of improving process efficiency and the like, can solve the problems of loss of metal mass, unsatisfactory effect of dechlorination by water, etc., and achieves short reaction time, good economic benefits and application prospects. , the effect of less reagent addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

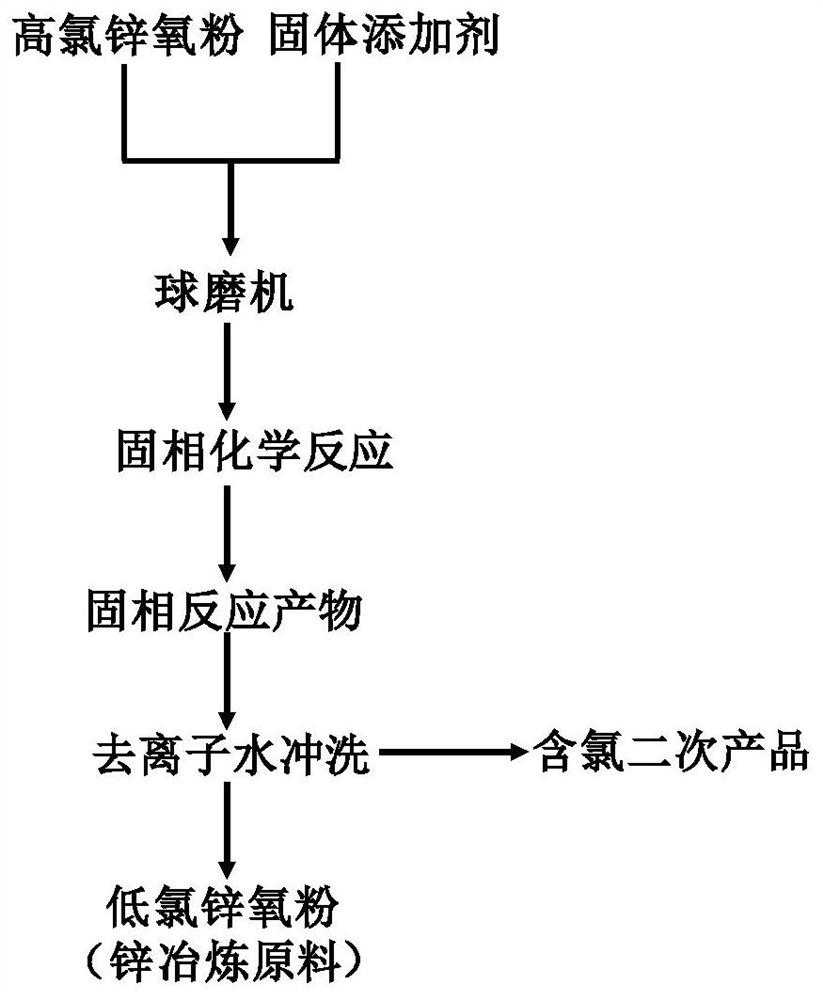

[0041] The present embodiment provides a kind of method adopting solid state reaction to promote chlorine removal in high-chloride zinc oxide powder, described method comprises the following steps:

[0042](1) Take 1000g of high-chloride zinc oxide powder as the experimental raw material, mix it with the solid-phase additive sodium hydroxide at a mass ratio of 100:1, and then put the mixture in a planetary ball mill to control the ball-to-material ratio to 40:1 , the ball milling speed is 400 rpm, and the mechanochemical reaction is carried out for 2.0h;

[0043] (2) After the reaction is completed, the obtained material is taken out and rinsed once with deionized water, and then the solid-phase product obtained is separated from the solid-liquid by a vacuum filtration device, and the solid-phase product after vacuum filtration is placed in an oven for 80 Dry at ℃ to obtain the zinc oxide powder product after dechlorination by solid-state reaction.

[0044] The energy spectru...

Embodiment 2

[0046] The present embodiment provides a kind of method adopting solid state reaction to promote chlorine removal in high-chloride zinc oxide powder, described method comprises the following steps:

[0047] (1) Take 1000g of high-chloride zinc oxide powder as the experimental raw material, mix it with the solid-phase additive sodium hydroxide at a mass ratio of 80:1, and then put the mixture in a planetary ball mill to control the ball-to-material ratio to 30:1 , the milling speed is 500 rpm, and the mechanochemical reaction is carried out for 1.5h;

[0048] (2) After the reaction is completed, the obtained material is taken out and rinsed once with deionized water, and then the solid-phase product obtained is separated from the solid-liquid by a vacuum filtration device, and the solid-phase product after vacuum filtration is placed in an oven for 85 Dry at ℃ to obtain the zinc oxide powder product after dechlorination by solid-state reaction.

[0049] The energy spectrum ana...

Embodiment 3

[0051] The present embodiment provides a kind of method adopting solid state reaction to promote chlorine removal in high-chloride zinc oxide powder, described method comprises the following steps:

[0052] (1) Take 1000g of high-chloride zinc oxide powder as the experimental raw material, mix it with the solid-phase additive sodium hydroxide at a mass ratio of 60:1, and then place the mixture in a planetary ball mill to control the ball-to-material ratio to 20:1 , the ball milling speed is 600 rpm, and the mechanochemical reaction is carried out for 1.0 h;

[0053] (2) After the reaction is completed, the obtained material is taken out and rinsed once with deionized water, and then the solid-phase product obtained is separated from the solid-liquid by a vacuum filtration device, and the solid-phase product after vacuum filtration is placed in an oven for 90 Dry at ℃ to obtain the zinc oxide powder product after dechlorination by solid-state reaction.

[0054] The energy spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com