Acidic iron-containing wastewater recycling system and method for carrying out in situ modification by system

A waste water recovery and treatment system technology, applied in metallurgical waste water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as unreliable process, difficult control, cumbersome process, etc., and achieve energy saving Low energy consumption, simple process and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

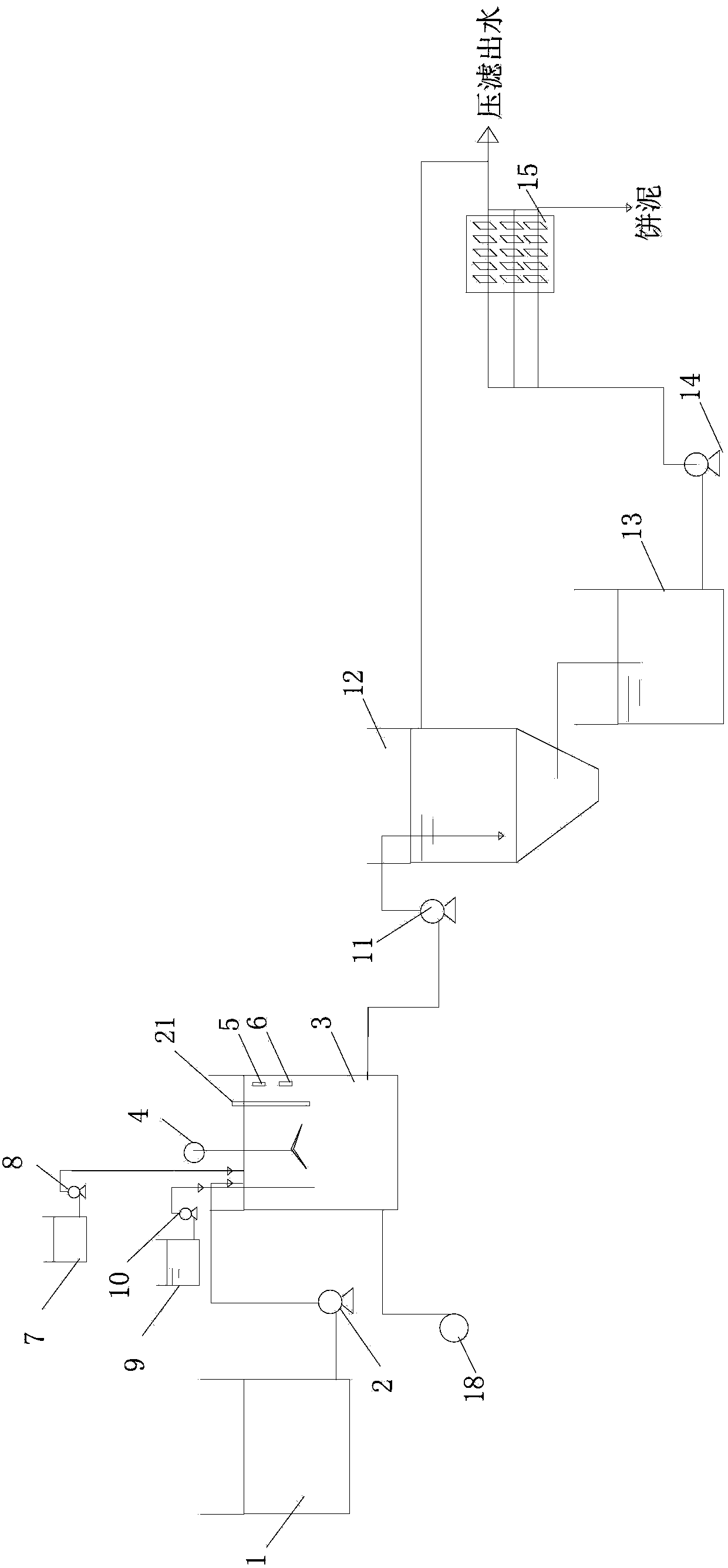

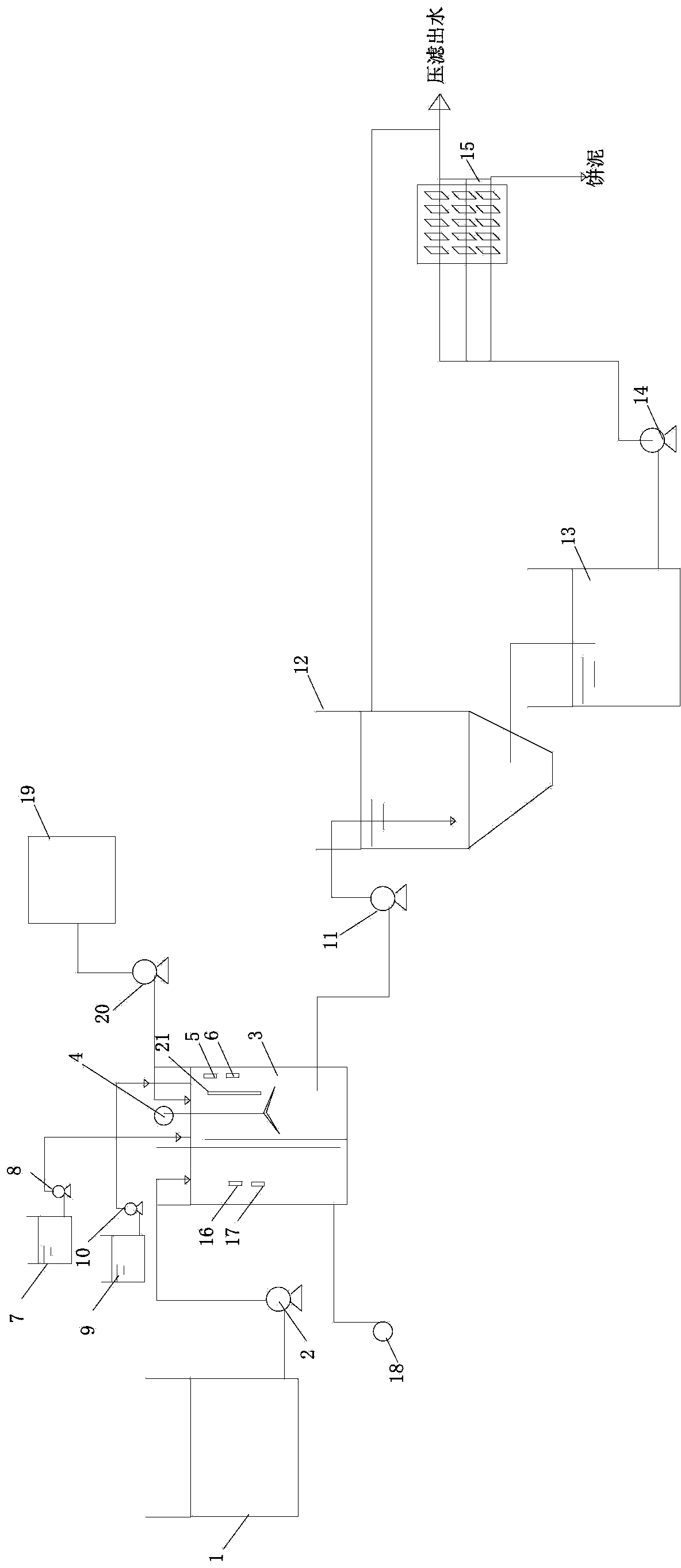

Embodiment 1

[0072] Step 1: Use an acid-resistant pump to drive the acidic wastewater into the oxidation neutralization reaction tank, add lime to neutralize the acid and alkali to a pH of 9.5, and the solution turns dark green.

[0073] Detect the ORP value of the iron and steel acid wastewater to be treated, and its ORP is -730mv, then it can be judged that the Fe content in the iron-containing acid wastewater is 2+ The molar ratio to Fe>0.65 means acid wastewater mainly composed of Fe2+, which is light green acid wastewater.

[0074] Step 2: a. Air is passed into the acidic wastewater of iron and steel to carry out oxidation reaction to it, and Fe 2+ The consumption rate is 80g / L.h, and the air intake intensity is 0.03m 3 / h, the aeration time is 20min, and the pH value is maintained at about 9.5 during the oxidation reaction;

[0075] b. When the ORP is detected to reach -670mv, the oxidation reaction is considered to be over, the air intake is stopped, and the color of the solution ...

Embodiment 2

[0079] Step 1: Detect the iron and steel acid wastewater to be treated. Add lime to neutralize the acid and alkali, and adjust the pH of the iron and steel acid wastewater to 10; 2+ The molar ratio to Fe>0.65 means the acidic wastewater mainly composed of Fe2+, which is light green acidic wastewater. The acidic wastewater is pumped into the oxidation neutralization reaction pool by an acid-resistant pump.

[0080] Step 2:

[0081] a. Oxygen is introduced into the acidic wastewater of iron and steel to carry out the oxidation reaction, and Fe is controlled during the oxidation reaction. 2+ The consumption rate is 100g / L.h, and the air intake intensity is 0.03m 3 / h, the aeration time is 20min, and the pH value is maintained at 10 during the oxidation reaction;

[0082] b. When the ORP is detected to reach -680mv, the oxidation reaction is considered to be over, the air intake is stopped, and the color of the solution turns completely black;

[0083] c. Add Fe-containing wast...

Embodiment 3

[0086] Step (1): First adjust the pH of acidic iron and steel wastewater to about 9.7, then detect the ORP value of the acidic iron and steel wastewater after adjustment, and its ORP is -560mv, then it is known that Fe 2+ Molar ratio to Fe <0.45;

[0087] Step (2):

[0088] a. will contain Fe 2+ Add the mud into the iron and steel acid wastewater, stir at a speed of 100rpm / min for 50s, and maintain the pH at about 9.7 during the reaction process;

[0089] b. When the ORP reaches -650mv, stop adding Fe 2+ mud, and then continue to stir at a speed of 70rpm / min for 5min;

[0090] c. Continue to add Fe-containing iron and steel acid wastewater 2+ For acidic raw wastewater, stir at a speed of 70rpm / min for 50S, carry out neutralization reaction, and adjust the pH to about 7; if ORP2+ The consumption rate is about 200g / L.h, and stop aeration when the ORP reaches -680mv±10mv;

[0091] Step (3): Add 5 / million polymer flocculants of the total weight to the acid wastewater of iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com