Pipeline mud conveying device

A technology for pipeline transportation and mud, which is applied in the direction of earth mover/shovel, construction, etc. It can solve the problems of dredger mud pipeline wear, large mud flow resistance, and rapid hydraulic drop, so as to improve wear resistance , reduce the conveying resistance, reduce the effect of impact velocity and impact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

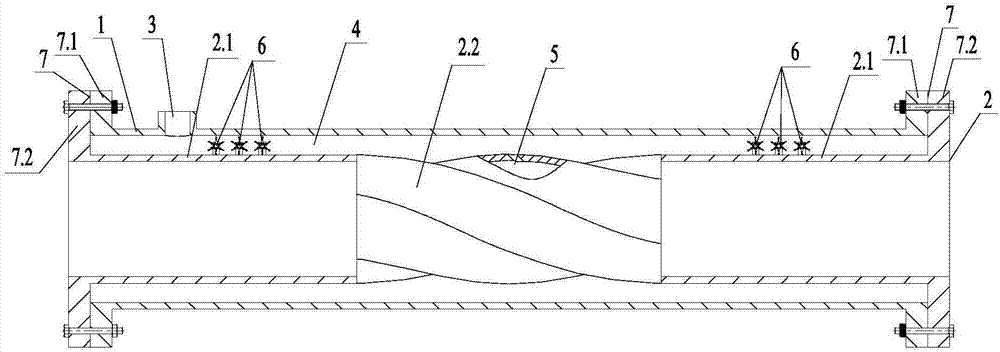

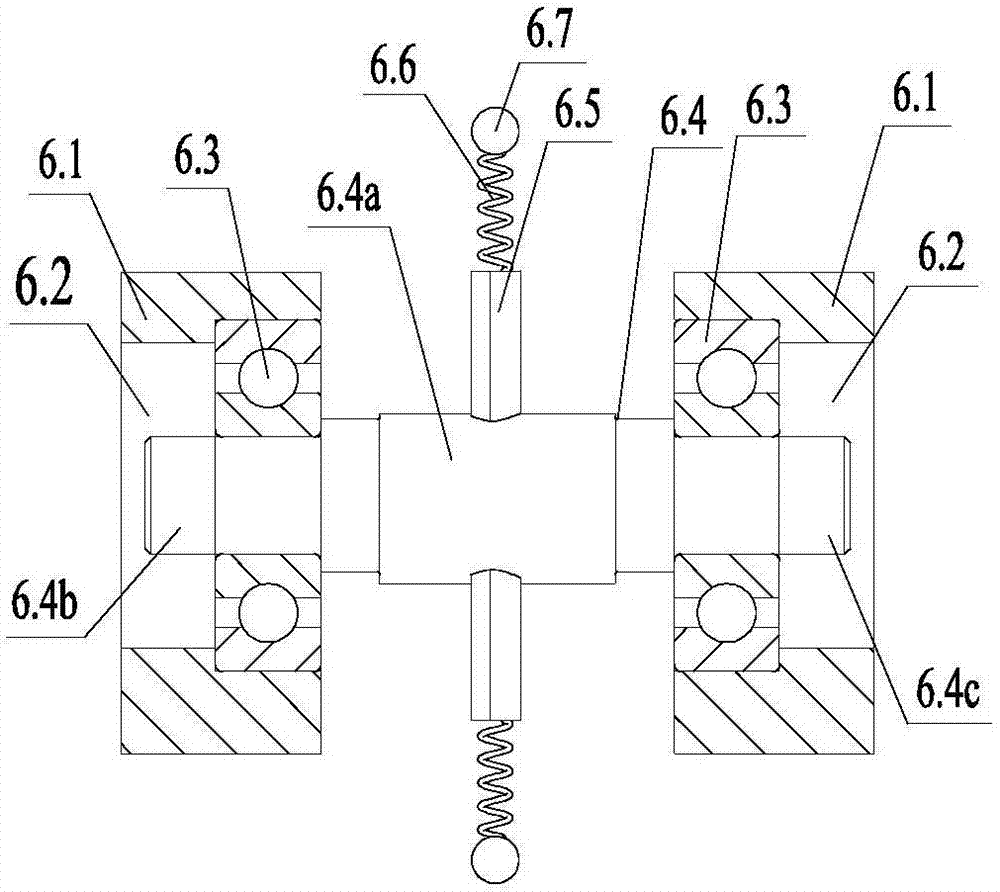

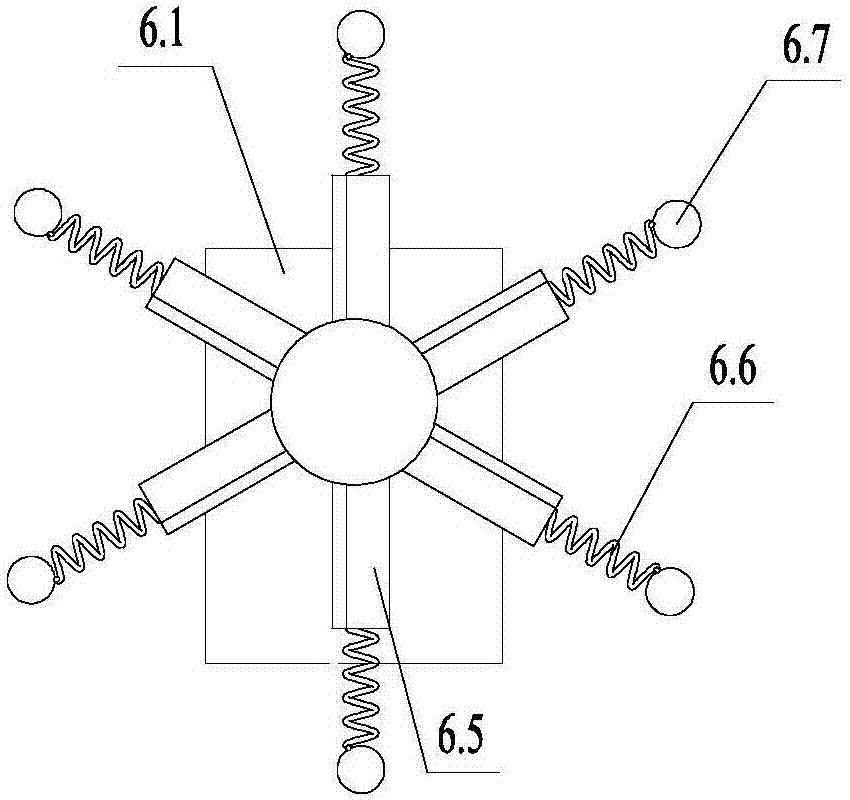

[0022] like figure 1 The shown pipe transporting mud device includes an outer pipe 1, an inner pipe 2 arranged concentrically with the outer pipe 1, and an air inlet 3 opened on the outer pipe 1. The gap between the outer pipe 1 and the inner pipe 2 is formed as a high-pressure gas. Channel 4, the air inlet 3 is communicated with the high pressure air channel 4, wherein, the wall thickness of the outer pipe 1 is the same as that of the inner pipe 2 and both are 5-7mm (preferably 6mm), and the height of the high-pressure air channel is 16-20mm (preferably 18mm); In addition, the edge of the two ends of the outer pipe 1 extends vertically outward with a circle of outer connecting disks 7.1, and the edge of both ends of the inner pipe 2 extends vertically outward with a circle of inner connecting disks 7.2, and the outer connecting disk 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com