Actinobacillus succinogenes capable of producing succinic acid

A technology of actinobacillus and succinic acid, applied in the biological field, can solve the problems of high cost and unreachable, and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Mutagenesis with acriflavine, ultraviolet light, ultraviolet-diethyl sulfate and nitrosoguanidine A. succinogenes f 3-21, 1056 single colonies were obtained; these single bacteria were subjected to "96-well plate culture-HPLC concentrated detection-anaerobic bottle re-screening" to obtain 11 mutant strains (Ⅲ-9-H, Ⅳ -7-A, Ⅳ-7-C, Ⅴ-12-B, Ⅵ-10-C, Ⅶ-11-H, Ⅷ-10-H, Ⅸ-2-C, Ⅹ-8-E, Ⅺ-8 -B and Ⅻ-7-B), the average shake flask produced succinic acid more than F 3 -21 improved by 13.9%. The 11 mutant strains were used as the starting bacterial library.

Embodiment 2

[0025] 11 mutagenized high-yielding strains were used as the starting bacterial library for the first round of fusion. The enzymatic hydrolysis conditions of the 11 strains were 0.25 mg / mL enzyme concentration, 60 min enzymatic hydrolysis time, double inactivation by ultraviolet light and heat killing, PEG After fusion, the selective regeneration double-layer plate was coated, and a total of more than 360 single colonies grew on the plate, and then these single colonies were picked into 96-well plates for flux screening. The first round of genome shuffling resulted in 4 strains of F 1 Generation of high-yielding recombinant bacteria (F 1 -Ⅰ-3-F, F 1 -Ⅱ-7-B, F 1 -Ⅲ-2-E and F 1 -IV-9-D), whose average shake flask produced succinic acid more than F 3 -21 increased by 20.2% to F 1 The second round of shuffling was carried out with the first-generation shuffled bacteria as the female parent, and 4 strains of F 2 Generation of high-yielding recombinant bacteria (F 2 -Ⅰ-5-B, F...

Embodiment 3

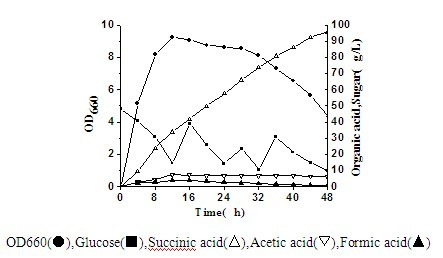

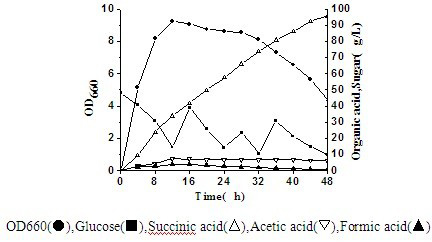

[0027] Put the F3-ZK seed liquid into a 5L fermenter with 3.5L fermentation liquid according to the inoculation amount of 10%, and ferment anaerobically at 37°C with a stirring speed of 200 r / min. During the fermentation process, the sugar concentration is maintained by supplementing glucose syrup 10-30 g / L, and use alkaline salt to control the pH to maintain between 5.8-6.4. Among them, seed medium (per L): glucose 5 g, yeast extract 5 g, K 2 HPO 4 ·3H 2 O 1.0 g, NaH 2 PO 4 2H 2 O 1.0 g, pH 7.0. Incubate anaerobically at 37°C for 16 hours. Fermentation medium (per L): sweet sorghum juice syrup (total reducing sugar) 20-80 g, yeast extract 0-15 g, corn steep liquor 20 g, MgCl 2 0.2 g, Na 2 HPO 4 12H 2 O 1.5 g, NaH 2 PO 4 2H 2 O 1.5 g, pH 6.5. Anaerobic culture at 37°C for 48 hours.

[0028] Fermentation curve as figure 1 . 95.6 g / L of succinic acid was produced in 48 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com