Method for producing amber acid by continuous fermentation or semi-continuous fermentation

A semi-continuous, succinic acid technology, applied in the field of bioengineering, to achieve the effects of high production intensity, saving energy and water consumption, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

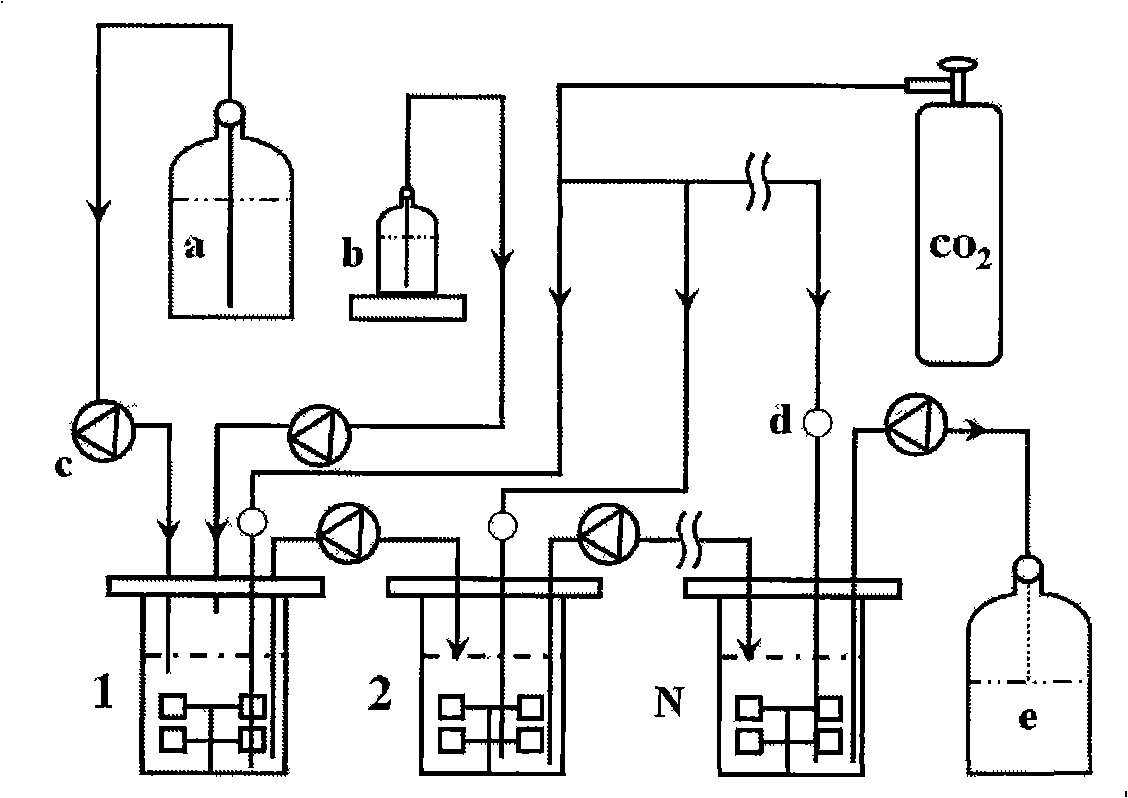

[0054] Embodiment 1, single-stage continuous fermentation

[0055] 1) Carry out single-stage continuous fermentation in a reactor with a liquid content of 200mL, the total sugar concentration of molasses in the fed-batch medium is 30g / L, adjust the medium flow velocity (12mL / h), and carry out continuous culture, the fermentation time curve See Figure 4 . Depend on Figure 4 It can be seen that the continuous fermentation lasted for 10 days, and the average dilution rate was 0.053h -1 , the concentration of succinic acid and the concentration of bacteria remained stable at 19.2g / L respectively, and the OD of the fermentation broth was diluted 10 times 660 0.51 or so, the production intensity of succinic acid is 1.15g / (L·h).

[0056] 2) According to the fermentation conditions of 1), the total sugar concentration of molasses in the fed-batch medium is 35g / L, respectively at a dilution rate of 0.06-0.91h -1 Continuous fermentation was carried out within the range, and the r...

Embodiment 2

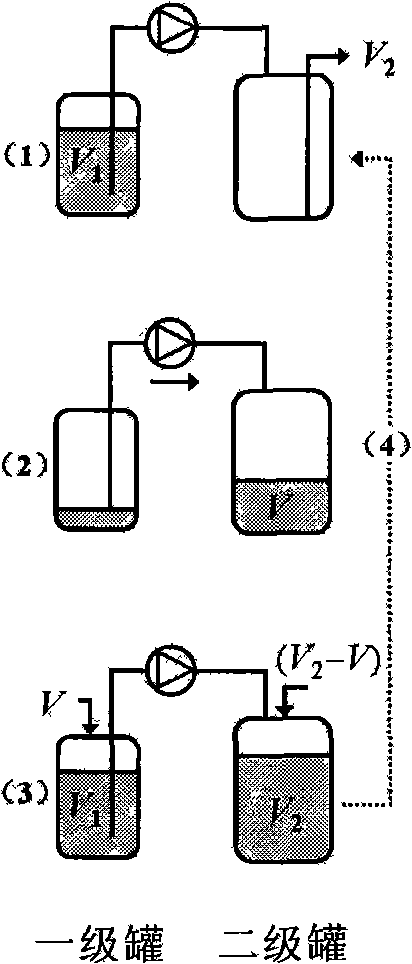

[0060] Embodiment 2, multistage continuous fermentation

[0061] A multi-stage single-flow continuous fermentation device is adopted, the effective liquid volume of a single tank is 200mL, the total sugar concentration of molasses in the feeding medium is 35g / L, and the total dilution rate is controlled at 0.11h -1 , 0.21h -1 and 0.30h -1 , the results are shown in Table 2.

[0062] Table 2 Production of succinic acid by multi-stage single-flow continuous fermentation

[0063]

[0064] From Table 2, it can be found that the succinic acid output of increasing the number of stages of the reactor is higher than that of the single-stage continuous fermentation, and the dilution rate of the two-stage continuous fermentation is 0.11h -1 The maximum concentration of succinic acid reaches 19.0g / L, which is 0.11h higher than that of single-stage continuous fermentation -1 increased by 42.3%; the dilution rate is 0.30h -1 , the production intensity reaches up to 4.29g / (L h), whi...

Embodiment 3

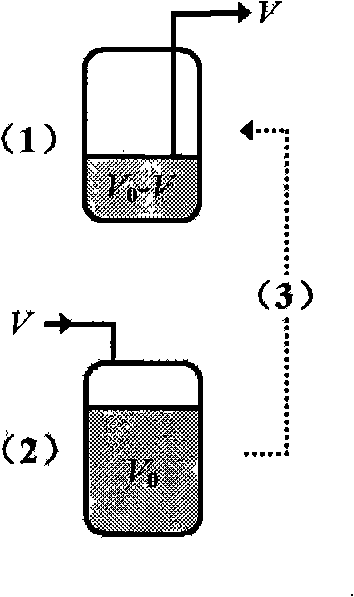

[0066] Embodiment 3, single stage semi-continuous fermentation produces succinic acid

[0067] Fermentation was carried out in a 250 mL reactor with a feed bottle volume of 2 L. With the initial total sugar concentration of 40g / L and 60g / L respectively, each batch of fermentation time is 8-24h, extract the fermentation broth volume (V) / reactor liquid volume (V 0 )=50%, and the growth and acid production of the bacteria are shown in Table 3.

[0068] Table 3 Production of succinic acid by single-stage semi-continuous fermentation of sugarcane molasses

[0069]

[0070] As can be seen from Table 3, the semi-continuous fermentation time is 10-12h, and the yield and production intensity of succinic acid are relatively high, which can reach 33.67g / L and 1.63g / (L h) respectively. Affect the next batch of acid production speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com