Fermentation production method of succinic acid with whey

A technology of succinic acid and whey is applied in the field of bioengineering to achieve the effect of reducing the amount of nitrogen sources, reducing the composition of culture medium, and alleviating the shortage of petrochemical resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Seed culture: add seed medium to 80mL in a 100mL serum bottle, and feed N 2 and CO 2 mixed gas; after cooling, insert Actinobacillus succinogenes NJ113 for cultivation;

[0029] The culture conditions are: temperature 40°C, shaker speed 200r / min, culture time 16h;

[0030] (2) Fermentation acid production: add fermentation medium volume to 5L fermenter tank and be 4L, inoculum size is 7% (v / v), temperature is 40 DEG C, pass into containing N 2 and CO 2 The mixed gas is used to maintain the anaerobic environment of the fermentation system, and the stirring speed is 300rpm and the fermentation time is 60h.

[0031] Seed medium (g / L): Glucose 10 (dissolved), yeast extract 5, NaHCO 3 10, NaH 2 PO 4 2H 2 O 9.6, K 2 HPO 4 ·3H 2 O 15.5; pH 6.8.

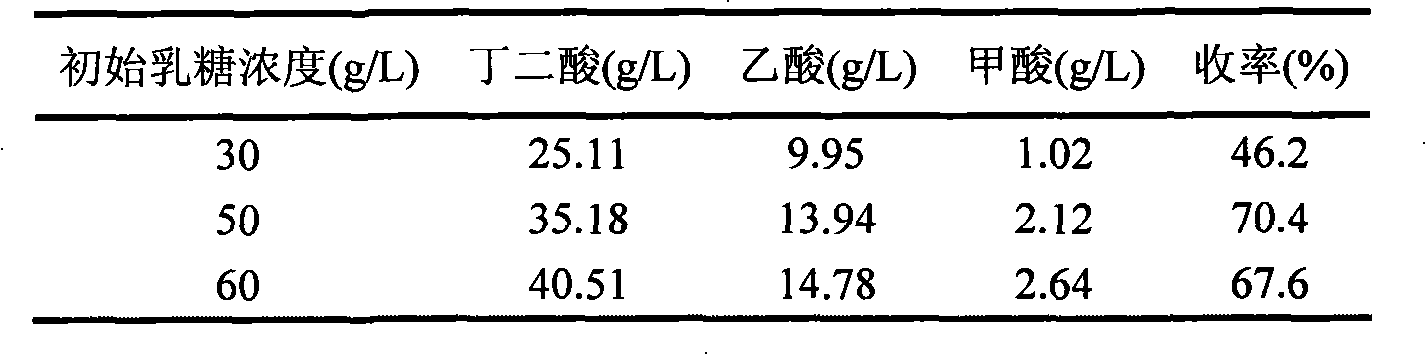

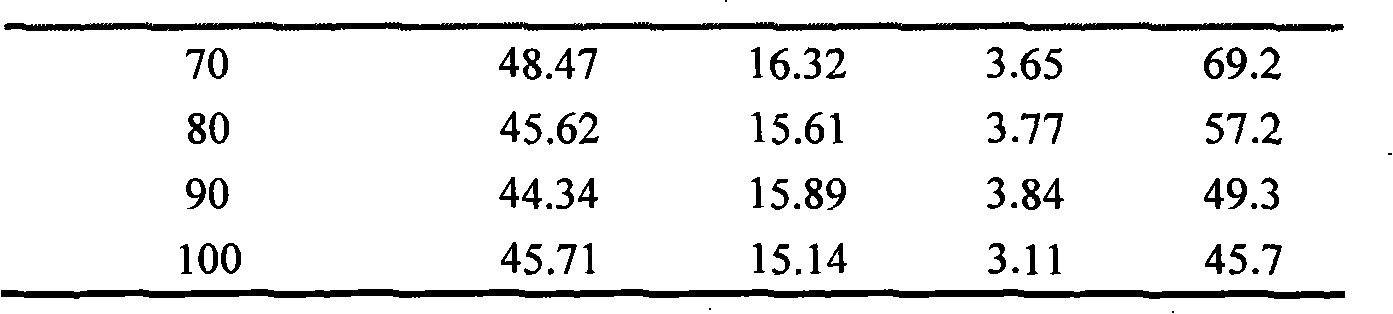

[0032] Fermentation medium (g / L): whey (based on lactose content) 30-100, yeast extract 10, KH 2 PO 4 3. MgCl 2 ·6H 2 O0.3, CaCl 2 0.3, NaCl 1, Na 2 HPO 4 0.31, NaH 2 PO 4 1.6.

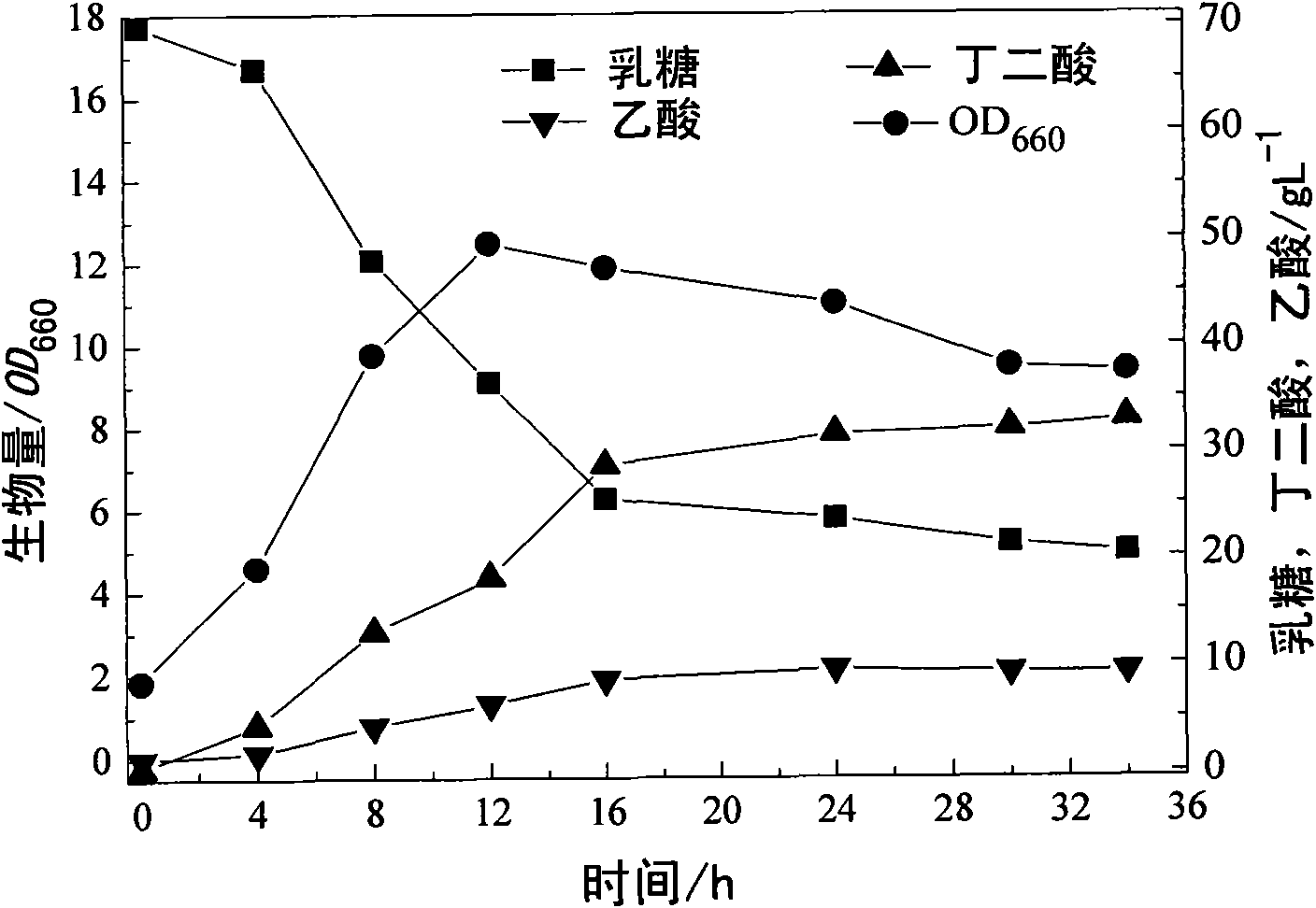

[0033] Fermentation exper...

Embodiment 2

[0039] (1) Seed culture: add seed medium to 20mL in a 100mL serum bottle, and feed N 2 and CO 2 mixed gas; after cooling, insert Actinobacillus succinogenes NJ113 for cultivation;

[0040]The culture conditions are: temperature 30°C, shaker speed 100r / min, culture time 10h;

[0041] (2) Fermentation acid production: Add fermentation medium volume to 5L fermenter tank and be 2L, inoculum size is 3% (v / v), temperature is 35 ℃, pass into containing N 2 and CO 2 The mixed gas is used to maintain the anaerobic environment of the fermentation system, and the stirring speed is 100rpm and the fermentation time is 30h.

[0042] According to the method of example 1, carry out fermentation experiment in serum bottle, with the whey after the vacuum drying as carbon source, add the yeast extract of different concentration in fermentation medium, its content is (g / L): 0g, 2g , 4g, 5g, 6g, 6.5g, 7g, 8g, 9g, 10g. The effects of different yeast extract concentrations on the production of ...

Embodiment 3

[0047] In this example, whey is used as a carbon source in the process of preparing succinic acid by the biological method, and the ability of bacterial cell fermentation to prepare succinic acid is realized by using it in combination with a small amount of yeast extract (6g / L). Bacterial classification, concrete culture method are with embodiment 1. The initial whey is 70g / L (calculated as lactose).

[0048] (1) Seed culture: add seed medium to 50mL in a 100mL serum bottle, and feed N 2 and CO 2 mixed gas; after cooling, insert Actinobacillus succinogenes NJ113 for cultivation;

[0049] The culture conditions are: temperature 37°C, shaker speed 150r / min, culture time 12h;

[0050] (2) Fermentation acid production: Add fermentation medium volume to 5L fermenter tank and be 3L, inoculum size is 5% (v / v), temperature is 37 ℃, pass into containing N 2 and CO 2 The mixed gas is used to maintain the anaerobic environment of the fermentation system, and the stirring speed is 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com