Method for producing succinic acid by multistage continuous fermentation

A succinic acid and fermenter technology, which is applied in the field of succinic acid preparation, can solve problems such as high cost, serious pollution, and unsustainable development, and achieve the effects of easy operation, simple method, and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

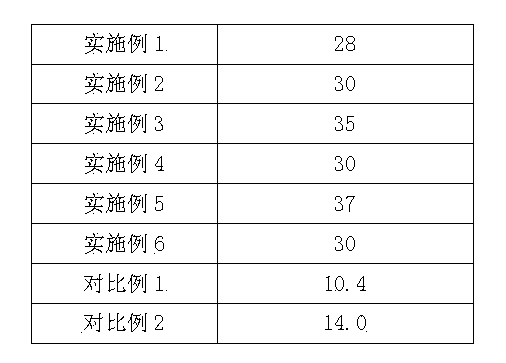

Embodiment 1

[0028] A method for producing succinic acid by a multistage continuous fermentation device, comprising the following steps:

[0029] The first step is to match the seed medium, the initial fermentation medium, the carbon source feed tank culture solution and the medium feed tank culture solution. The formula is as follows:

[0030] Seed medium (g L -1 ): glucose 10 (dissolved), yeast extract 5, corn steep liquor 5, NaHCO 3 10. NaH 2 PO 4 ·2H 2 O 9.6, K 2 HPO 4 ·3H 2 O 15.5, pH 7.0.

[0031] Initial fermentation medium (g L -1 ): glucose 40 (dissolved), yeast extract 10, corn steep liquor 10, sodium acetate 1.36, KH 2 PO 4 3. MgCl 2 ·6H 2 O 0.2, CaCl 2 0.2, NaCl 1, Na 2 HPO 4 ·12H 2 O 0.31, NaH 2 PO 4 ·2H 2 O 1.6, pH 7.0.

[0032] Carbon source feeding tank culture solution (g L -1 ): Glucose 750.

[0033] Medium feed tank culture solution (g L -1 ): yeast extract 30, corn steep liquor 30, sodium acetate 4.08, KH 2 PO 4 9. MgCl 2 ·6H 2 O 0.6,...

Embodiment 2

[0038] The first to third steps are the same as in Example 1, wherein the carbon source feeding tank culture solution is a 200 g / L sucrose solution.

[0039] The fourth step, after connecting five sterilized fermenters in series, insert 600ml of initial fermentation medium into the primary fermenter, and feed CO with a volume ratio of 1:1. 2 and H 2 Mixed gas, use the air storage tank to control the ventilation volume to 0.01L / (min·L), and insert the fermentation strain according to the inoculation volume of 10% (v / v), and the initial fermentation medium flows from the primary fermenter to the secondary, From the third level to the fifth level, the carbon source feeding tank and the medium feeding tank are used to control the inflow rate of the fermentation broth to 120-150 ml / h, the sucrose supplementation rate to be 30 ml / h, and the outflow rate of the fermentation broth to be 150-160 ml / h h, so that the initial sugar concentration in the primary fermenter is 150g / L, and in...

Embodiment 3

[0041] The first to third steps are the same as those in Example 2.

[0042] The fourth step is to connect the five sterilized fermenters in series, insert 600ml of initial fermentation medium into the primary fermenter, use the gas storage tank to control pure N2, and the ventilation rate is 0.04 L / (min·L) , according to the inoculum amount of 10% (v / v), the fermentation strain is inserted, and the initial fermentation medium flows from the first-level fermenter to the second-level, third-level to the fifth-level, and is controlled by the carbon source feeding tank and the medium feeding tank. The inflow rate of the fermentation broth is 90-110 ml / h, the sugar supplementation rate of sucrose is 20 ml / h, and the outflow rate of the fermentation broth is 110-140 ml / h, so that the initial sugar concentration in the primary fermentor is 80g / L. In the continuous fermentation process The sugar concentration in the fermenters of the middle and different levels relative to the initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com