Bifunctional glutathione synthetase and method for producing glutathione by using same

A glutathione and synthetase technology, applied in the direction of microbial-based methods, biochemical equipment and methods, bulk chemical production, etc., to achieve the effect of improving production levels and improving production levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Synthesis of glutathione using Actinobacillus succinate

[0042] 1. Cultivation of Actinobacillus succinogenes

[0043] Connect Actinobacillus succinogenes 130Z (CICC 11014) stored at -20°C into the fermentation medium at a 1% inoculum. The specific ingredients are (contained in 1L): 5g xylose, 5g yeast extract, 5g corn steep liquor, Na 2 HPO 4 ·12H 2 O 0.5g, NaH 2 PO 4 ·2H 2 O 0.5g, pH 6.5, 37°C, 220 rpm, shaking culture for 24 hours.

[0044] 2. Cell pretreatment

[0045] The cultured Actinobacillus succinate culture solution was centrifuged at 8000 rpm for 5 min to collect the cells, washed and centrifuged three times with 0.05 mol / L, pH 7.0 phosphate buffer under the same conditions. The cells were frozen at -20°C for 2 hours for permeabilization.

[0046] 3. Glutathione synthesis reaction

[0047] Weigh 2g of the permeabilized wet bacteria into 20mL reaction solution, the reaction solution is 0.2mol / L (pH7.0) potassium phosphate buffer, containing 40mmol / L L-gluta...

Embodiment 2

[0048] Example 2 Synthesis of Glutathione by Bacillus cereus

[0049] The glycerol tube of Bacillus cereus (CGMCC 1.932) stored at -20°C was inserted into the fermentation medium at an inoculum of 1%. The specific ingredients (contained in 1L): tryptone 10g, yeast extract 5g, NaCl10g, 37°C, 220 rpm, shaking culture for 12 hours, permeabilizing Bacillus cereus and glutathione synthesis reaction according to the method described in Example 1. After 8 hours of reaction, glutathione can accumulate 163 mg / L.

Embodiment 3

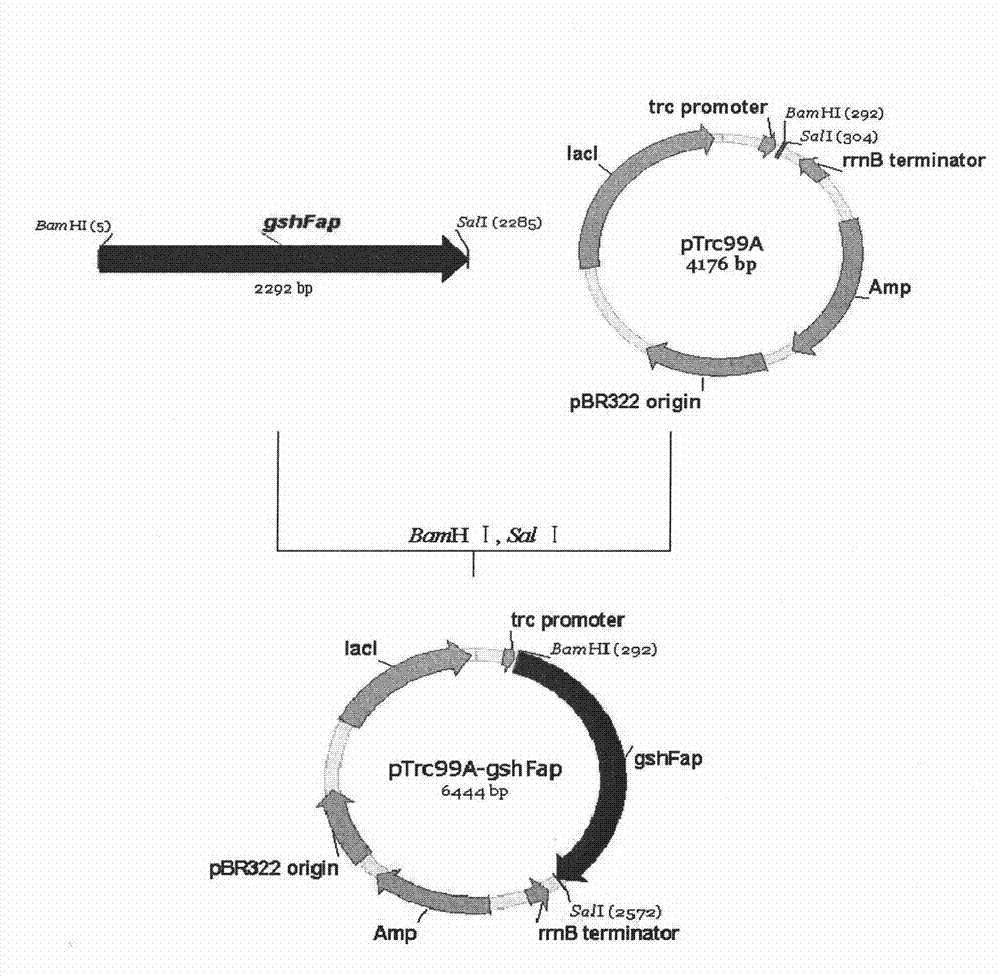

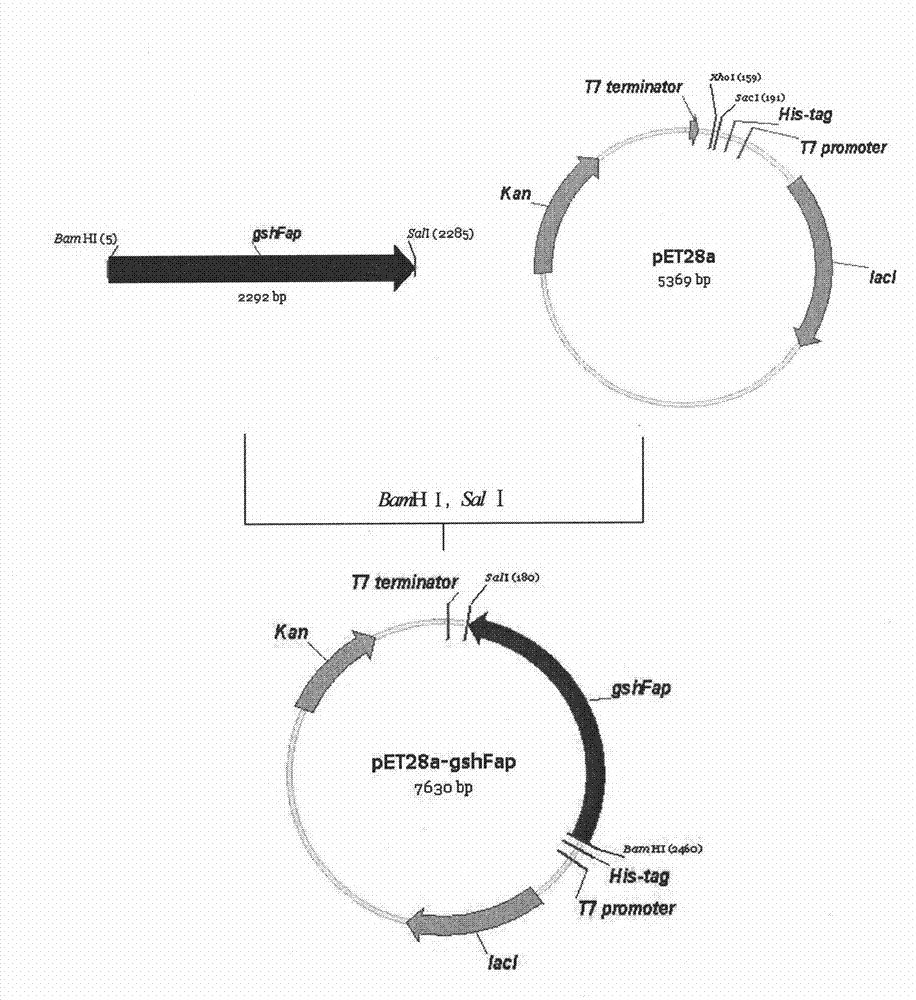

[0050] Example 3 Construction of recombinant E. coli JM109 (pTrc99a-gshFap)

[0051] 1. Extraction of genomic DNA of Actinobacillus pleuropneumonia

[0052] The glycerol tube of Actinobacillus pleuropneumonia (CVCC 259) stored at -20°C was inserted into the fermentation medium at an inoculum of 1%. The specific ingredients (contained in 1L): peptone 10.0g, yeast extract 5g, NaCl 10g, NAD 0.2 g, pH 7.4, 37°C, static culture for 24 hours, centrifuge at 13400×g, 4°C for 2 minutes to collect the bacteria. The whole genome DNA of Actinobacillus pleuropneumonia was extracted using BBI whole genome DNA extraction kit.

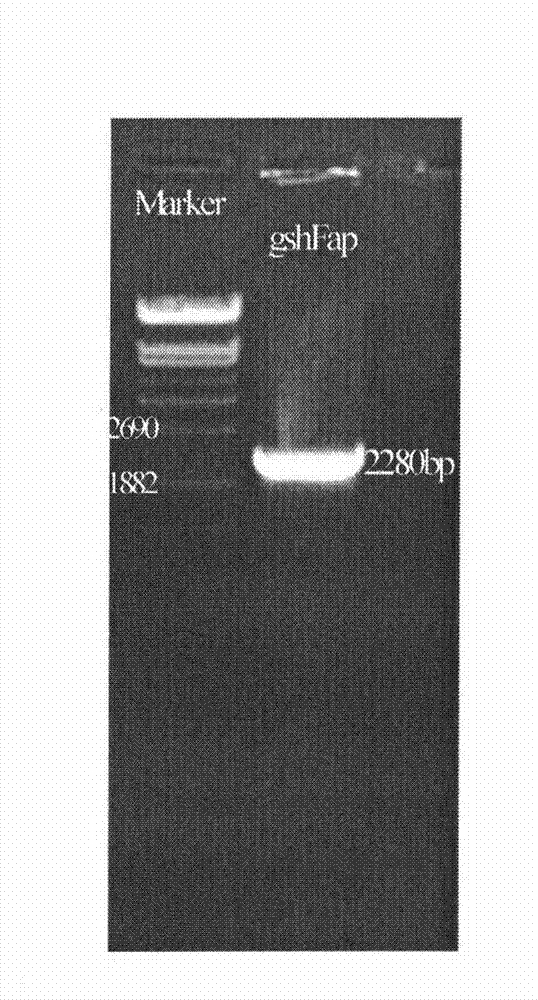

[0053] 2. Cloning of gshF gene of Actinobacillus pleuropneumoniae

[0054] The upstream primer is: 5’-GCGC GGATCC ATGAAATTACAACAAC-3', the underlined part is the BamH I restriction site.

[0055] Downstream primer is 5’-GAT GTCGAC TTAAGGCAGTTCTGGGAA-3', the underlined part is the Sal I restriction site.

[0056] Using the whole genome of Actinobacillus pleuropneumonia as a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com