Method for producing butane diacid by fermenting sugar grass raw material

A technology of sweet sorghum and succinic acid, applied to sweet sorghum raw materials in the preparation of succinic acid, the application field of a method, which can solve the problems that there are no research reports on the production of succinic acid by fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

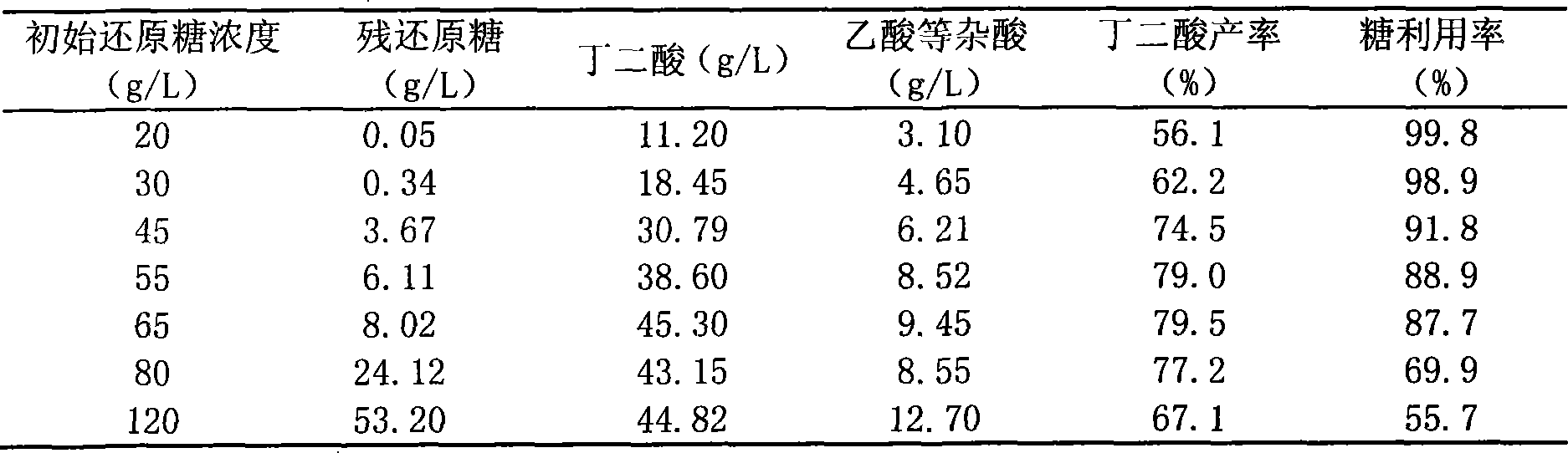

[0049] Effects of different initial reducing sugar concentrations on succinic acid fermentation of sweet sorghum juice syrup:

[0050] Preparation of sweet sorghum juice syrup: sweet sorghum stalks stored at room temperature for about 3 months after harvest (purchased from Feidong Yajin Weiye Plantation, Anhui Province, containing 48.0% total reducing sugar by dry weight), washed, cut segment, squeeze the juice, and filter to obtain sweet sorghum syrup, which contains 14.3% of total reducing sugar and a juice extraction rate of 69.3%.

[0051] Seed medium (per L): glucose 5g, yeast extract 5g, K 2 HPO 4 ·3H 2 O 1.0g, NaH2 PO 4 2H 2 O 1.0g, pH 7.0. Anaerobic culture at 37°C for 16 hours.

[0052] Fermentation medium (per L): 20-80g sweet sorghum juice syrup (total reducing sugar), 15g yeast extract, 20g corn steep liquor, pH 6.5. Anaerobic culture at 37°C for 48 hours.

[0053] Use the prepared sweet sorghum juice syrup to ferment in batches with anaerobic bottles. When t...

Embodiment 2-11

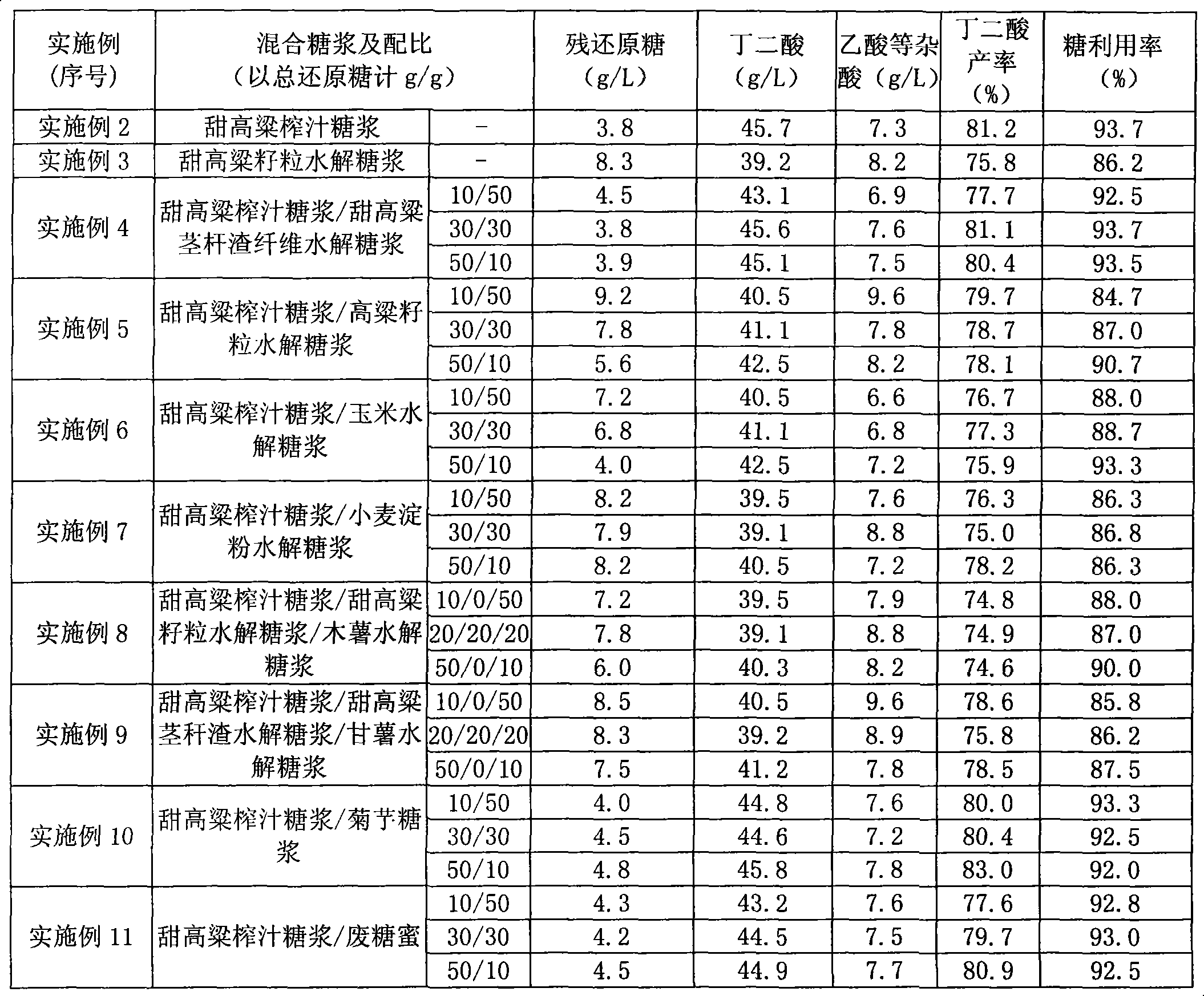

[0058] Succinic acid fermentation of sweet sorghum syrup mixed with other biomass raw materials such as grains and sweet sorghum grain hydrolyzed syrup.

[0059] Preparation of sugar residue fiber hydrolysis syrup from sweet sorghum stalk after juicing: crush the sugar residue fiber of sweet sorghum stalk after juicing, treat with 1%% NaOH dilute lye, soak at 90°C for 1 hour, hydrolyze lignin, Filter to remove the black liquor residue, filter out fiber and semi-fiber; then add 50 FPU of cellulase enzyme solution for 48 hours according to the total sugar content of sugar residue fiber per g, and then use 0.5mol / L NaOH solution to adjust the pH to 6.5, directly Used for fermented ingredients.

[0060] Sweet sorghum grains, corn, wheat, sweet potato, cassava, etc. are used to prepare glucose syrup by the same crushing, liquefaction, and saccharification methods, and then used as fermentation medium ingredients.

[0061] According to the method of Example 1, use the sweet sorghum...

Embodiment 12

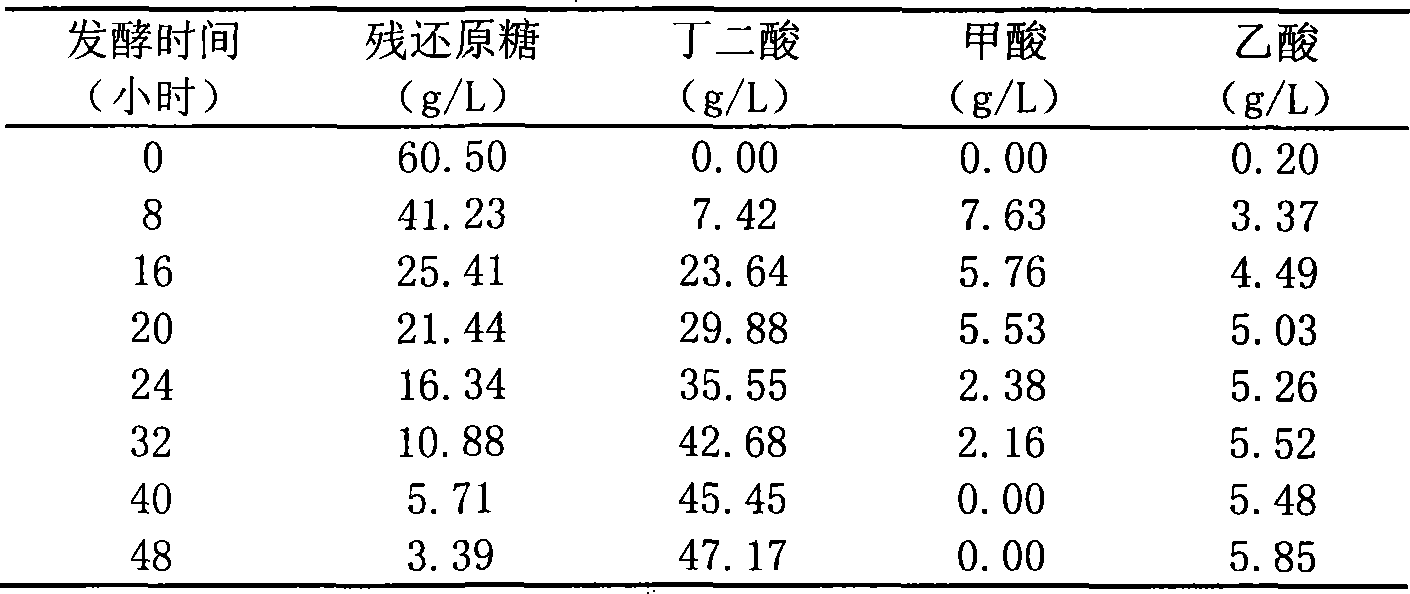

[0066] Production of succinic acid by batch fermentation of sweet sorghum juice syrup (5L mixing tank)

[0067] According to the method of Example 1, using the sweet sorghum juice extract prepared in Example 1, the initial reducing sugar concentration is 60.5g / L, in a 5L stirred fermenter (BIOFLO 110, New Brunswick Scientific, Edison, NJ, USA, using two groups of Batch fermentation is carried out in disc six straight blade turbine stirring paddles). The inoculum size is 5%, the fermentation temperature is 37°C, the stirring speed is 200 rpm, and the aeration is 100% CO 2 . The experimental results are shown in Table 3:

[0068] Table 3 Results of Batch Fermentation of Sweet Sorghum Juicing Syrup to Produce Succinic Acid (5L Stirred Tank)

[0069]

[0070] Batch fermentation in 5L stirred tank, 48 hours of total input into acid hydrolyzed sweet sorghum syrup is 60.5g / L in terms of final volume reducing sugar concentration, the remaining reducing sugar concentration of fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com