Method for producing succinic acid by simultaneous saccharification and fermentation of straw raw material

A technology of simultaneous saccharification fermentation and succinic acid, applied in the field of bioengineering, can solve the problem of no succinic acid, etc., and achieve the effects of promoting utilization, good application value, and reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Fermentation of corn stalk enzyme hydrolyzate by dilute alkali pretreatment to produce succinic acid

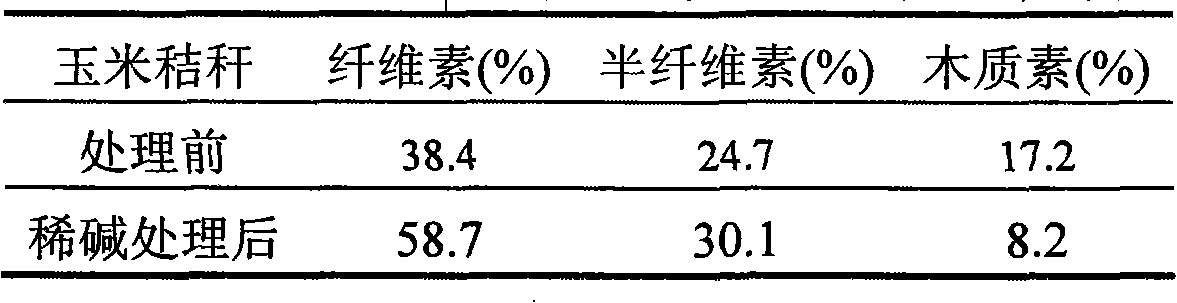

[0032] Take 80g of dried and pulverized corn stalks, mix them with 1200mL of 1% (w / w) sodium hydroxide solution, treat at 120°C for 1h, filter the residue, wash the residue with water until neutral, and dry at 60°C to obtain The weight loss of 41.3g of treated straw particles was 48.3%. The composition analysis of corn straw before and after dilute alkali treatment is shown in Table 1.

[0033] Table 1 Analysis of corn stalk components before and after dilute alkali treatment

[0034]

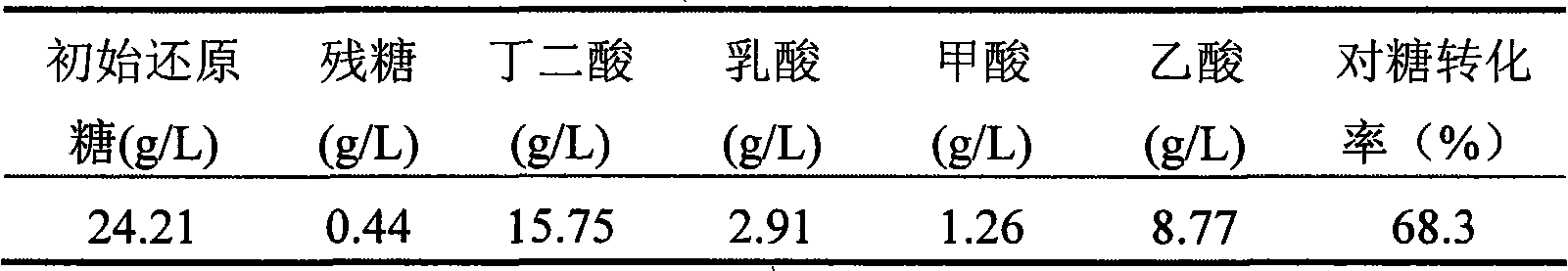

[0035] Take 2g of the treated straw particles, put it into a 150mL Erlenmeyer flask, add 42mL pH4.8 citrate buffer, 6mL cellulase solution, add enzyme amount at 20IU / g (substrate), total liquid volume 50mL, Hydrolysis was carried out on a water bath shaker at 50°C for 36 hours, and the sugar content in the hydrolyzed solution was determined as follows:

[0036] Table 2 Co...

Embodiment 2

[0041] Example 2 Synchronous fermentation of corn stalks after dilute alkali pretreatment to produce succinic acid

[0042] Weigh 2g of dry straw particles pretreated by dilute alkali into a 150mL anaerobic bottle, add 50mL of culture solution, which contains: yeast extract 10g / L, sodium dihydrogen phosphate 1.5g / L, dipotassium hydrogen phosphate 1.5g / L , anhydrous calcium chloride 0.2g / L, MgCl 2 0.15g / L, sodium acetate 0.5g / L, adjusted to pH 6.8, stirred evenly, sterilized at 121°C for 15min, then inserted 2.5mL of Actinobacillus succinicum CGMCC1593 anaerobic seeds, and added commercially available Celluclast 1.5L Weixin cellulase, the dosage is 20IU / g substrate. Shake well in 100% CO 2 Under these conditions, the fermentation broth was cultured statically for 72 hours, and the content of succinic acid in the fermentation broth was determined to be 20.8g / L.

Embodiment 3

[0043] Embodiment 3 Trichoderma reesei shake flask liquid fermentation produces cellulase

[0044] Fermentation medium: peptone 0.3%, ammonium sulfate 0.2%, yeast extract 0.05%, KH 2 PO 4 0.4%, CaCl 2 2H 2 0 0.03%, MgSO 4 ·7H 2 O 0.03%, Tween-80 0.02%, microcrystalline cellulose (Avicel) 1%-2.5%, bran 2%-6%. Fermentation conditions: culture temperature 28~30℃, pH 5.5, culture time 5~6 days, shaker rotation speed 180r·min -1 , 250mL Erlenmeyer bottle liquid 50mL.

[0045] Rinse the well-grown Trichoderma reesei viridans CICC40359 slant with 20mL of normal saline, transfer the rinsing solution into a conical flask equipped with glass beads, shake it well, and inoculate it into the fermentation medium at 5% as seed solution, and measure the enzyme after 6 days of fermentation The live results are shown in Table 4.

[0046] Table 4 Enzyme production with different microcrystalline cellulose and bran content

[0047]

[0048] Example 4-9 Synchronous saccharification an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com