Method for producing succinic acid by utilizing fermentation of actinobacillus succinogenes

A technology for actinobacteria and succinic acid production, which is applied in the field of fermentation and can solve the problems of poor palatability of canna taro, which has not yet been developed and utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

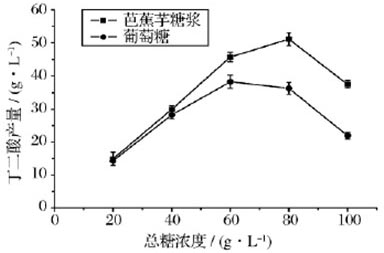

[0023] This example illustrates the impact of different carbon source concentrations on the production of succinic acid by fermentation. Glucose and plantain taro syrup are used as different carbon sources respectively, according to the total sugar concentration of 20g / L, 40g / L, 60g / L, 80g / L and 100g / L to prepare fermentation medium, compare A. succinogenes The utilization of canna syrup and glucose by CICC11014, the experimental results are as follows figure 1 shown.

[0024] figure 1 the result shows, A. succinogenes The effect of using canna taro syrup as a carbon source was significantly better than that of glucose. When using glucose as a carbon source, the succinic acid yield was the highest when the initial fermentation medium contained 60g / L total sugar, reaching 36.45g / L; while using plantain taro syrup as a carbon source, the initial fermentation medium contained 80g / L The yield of succinic acid was the highest at L total sugar, reaching 52.14g / L.

Embodiment 2

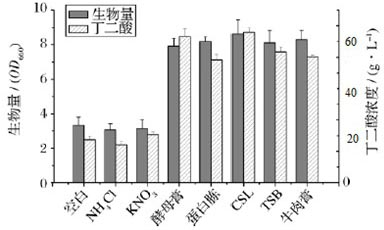

[0026] This embodiment illustrates the impact of different nitrogen sources on the production of succinic acid by fermentation of canna taro syrup, wherein the addition of each organic or inorganic nitrogen source in the fermentation medium is based on the same nitrogen content, respectively: NH 4 Cl4.5g / L, KNO 3 8g / L, yeast extract 12.5g / L, peptone 10g / L, corn steep liquor (CSL) 20g / L (solid content 55%), tryptone soy protein (TSB) 15g / L, beef extract 12g / L , blank (without adding any nitrogen source).

[0027] Depend on figure 2 It can be seen that when no additional nitrogen source is added, 13.69 g / L of succinic acid can be produced by fermentation with canna taro syrup; while under the same conditions, succinic acid is hardly produced when using glucose fermentation (data not listed ). This phenomenon shows that in addition to the rich carbon source in the plantain taro syrup, it also contains some carbon sources that can be A. succinogenes The nitrogen source nutri...

Embodiment 3

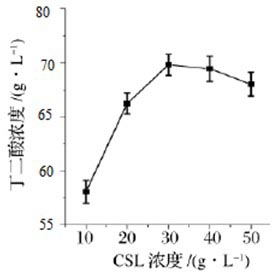

[0029] This embodiment illustrates the influence of different CSL concentrations on the production of succinic acid by fermentation of canna taro syrup, so that the CSL concentrations are respectively: 10g / L, 20g / L, 30g / L, 40g / L, 50g / L, and the determination of succinate after fermentation acid content.

[0030] Depend on figure 2 It can be seen that when the concentration of CSL is 30g / L, the highest yield of succinic acid is 68.42g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com