Fluorinated polyurethane thickener applied to supercritical CO2 tackification and preparation method thereof

A polyurethane thickener and supercritical technology, applied in the petrochemical field, can solve the problems of increasing construction difficulty, formation damage, and large usage, and achieve the effects of increasing mutual solubility, reducing usage, and increasing molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In order to make the above-mentioned fluorine-containing polyurethane thickener, the present invention also provides a preparation method of the thickener, comprising the following steps:

[0041] 1) Add diisocyanate and polyethylene glycol into a 500mL dry three-neck flask equipped with a stirrer, condenser and dropping funnel, raise the temperature to 80°C, add the catalyst dibutyltin dilaurate, react for 2 hours, then add trimethylol Propane continued to react for 1.5h to obtain -NCO-terminated polyurethane.

[0042] 2) Add castor oil to the above product and stir well, after cooling to 30°C, add polyoxyethylene sorbitan ether and stir well to make the system evenly dispersed, then add perfluorooctylethylene and dodecafluoroheptyl acrylate, Raise the temperature to 80°C, add the initiator, and react for 2 hours to obtain the supercritical CO 2 Fluorinated polyurethane thickener for fluid viscosification.

[0043] The diisocyanate, polyethylene glycol, trimethylolpr...

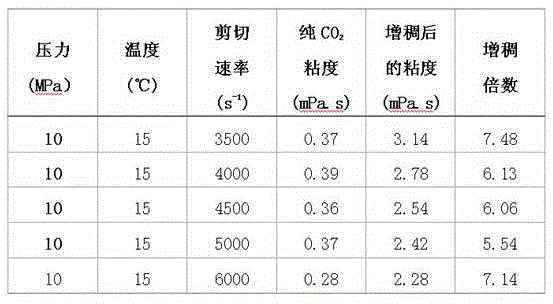

Embodiment 1

[0046] A supercritical CO 2 Fluorinated polyurethane thickener for fluid viscosification, containing 10% diisocyanate, 5% polyethylene glycol, 5% trimethylolpropane, 1% catalyst, 1% initiator by mass fraction , 3% sorbitan polyoxyethylene ether, 3% perfluorooctylethylene, 3% dodecafluoroheptyl acrylate (FA), and the balance is castor oil.

[0047] In this embodiment, the diisocyanate is toluene diisocyanate (TDI), the polyethylene glycol is polyethylene glycol 200 containing polyether bonds, the catalyst is dibutyltin dilaurate (T-12), and the initiator is potassium persulfate.

[0048] The trimethylolpropane, sorbitan polyoxyethylene ether, perfluorooctylethylene, and dodecafluoroheptyl acrylate are all industrial grades.

[0049] The purity of the castor oil is greater than 95%.

[0050] The above-mentioned unconventional oil and gas reservoir CO 2 A dry fracturing thickener and a preparation method thereof, comprising the following steps:

[0051] 1) Add 10% diisocyanat...

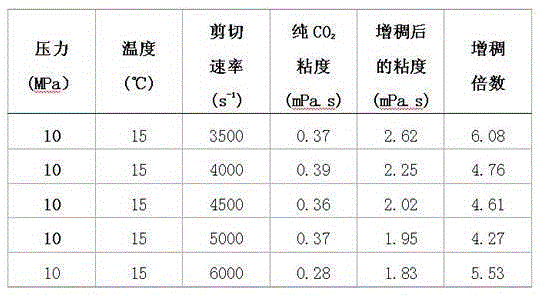

Embodiment 2

[0059] A supercritical CO 2 Fluid viscosifying fluorine-containing polyurethane thickener, by mass fraction, including 15% diisocyanate, 8% polyethylene glycol, 8% trimethylolpropane, 2% catalyst, 2% initiator , 5% sorbitan polyoxyethylene ether, 5% perfluorooctylethylene, 5% dodecafluoroheptyl acrylate (FA), and the balance is castor oil.

[0060] In this embodiment, the diisocyanate is diphenylmethane diisocyanate (MDI), the polyethylene glycol is polyethylene glycol 400 containing polyether bonds, the catalyst is dibutyltin dilaurate (T-12), and the initiator is polyethylene glycol 400. Potassium sulfate.

[0061] The trimethylolpropane, sorbitan polyoxyethylene ether, perfluorooctylethylene, and dodecafluoroheptyl acrylate are all industrial grades.

[0062] The purity of the castor oil is greater than 95%.

[0063] The above-mentioned unconventional oil and gas reservoir CO 2 A dry fracturing thickener and a preparation method thereof, comprising the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com