Wear-resistant axial flow pump impeller designing method

An axial-flow pump, wear-resistant technology, applied to parts, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve the problem of service life, flow and head parameters decrease, impeller medium delivery capacity decrease, Problems such as circulation system failure and failure can be achieved to save equipment maintenance and replacement costs, reduce replacement frequency and times, and prolong life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

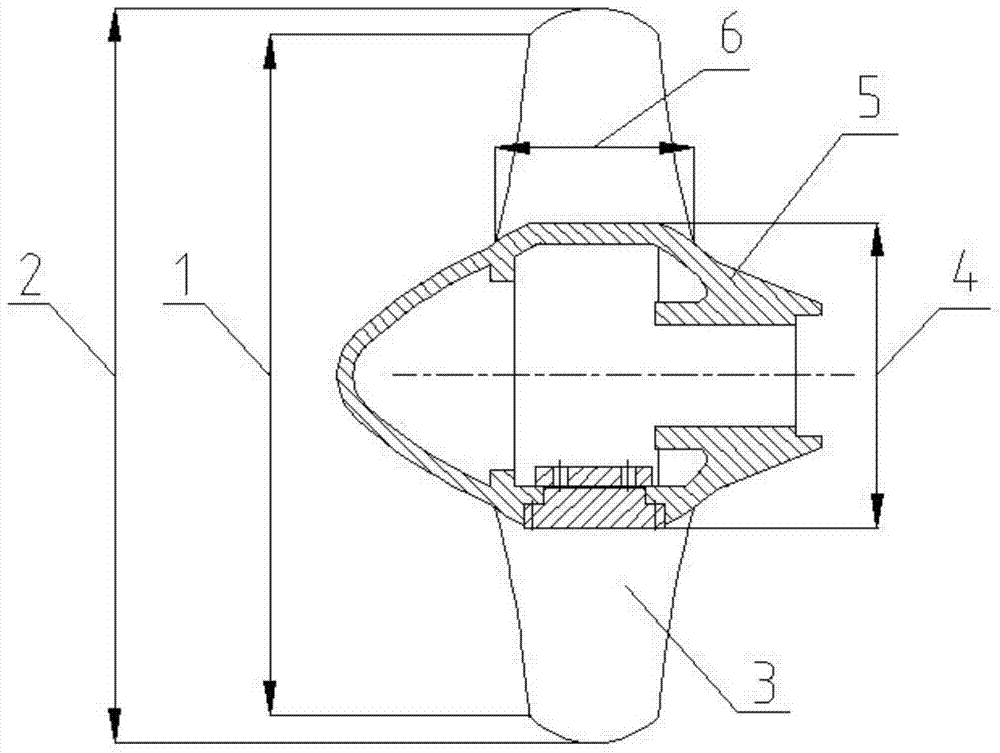

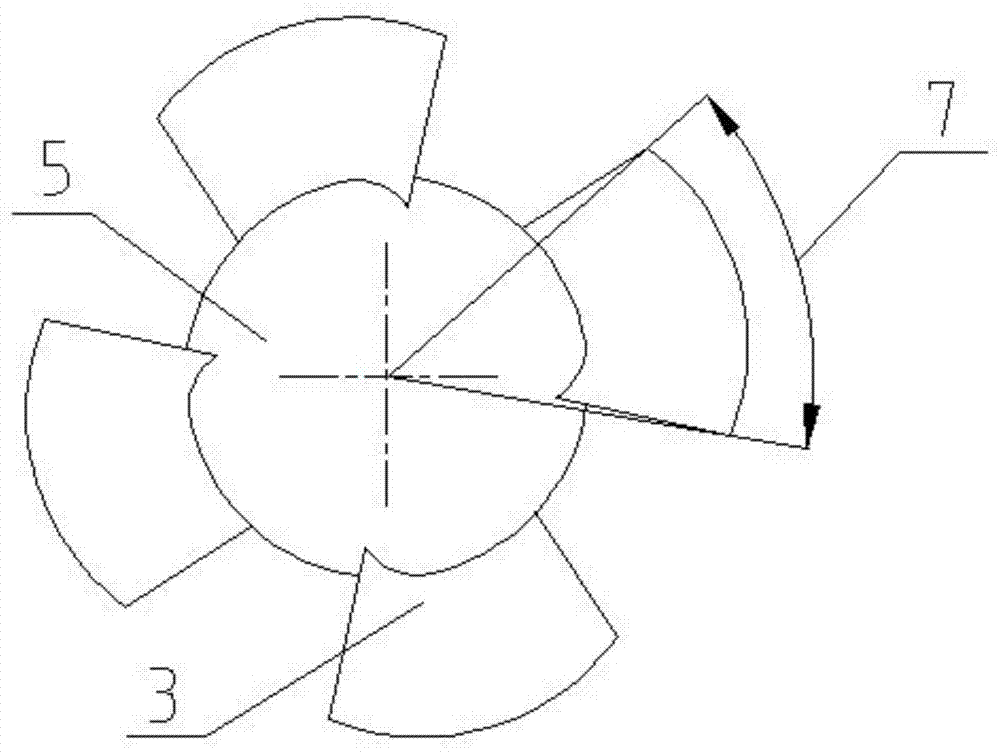

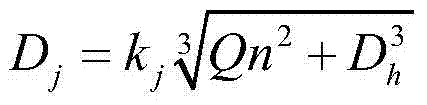

[0037] figure 1 and figure 2 Together determine the impeller shape and geometry for this embodiment. It is a high specific speed impeller. The blades (3) are evenly fixed on the impeller hub (5). The outer edge of the blade axial surface is a circular arc, which is beneficial to increase the internal passage area of the impeller and relieve the solid in the solid-liquid two-phase flow. The impeller inlet diameter (1) is smaller than the maximum diameter of the impeller (2) due to the overcurrent wear of the particles on the axial flow pump, which can reduce the pressure drop and wear at the outer edge of the impeller inlet, and improve the anti-cavitation and wear resistance of the impeller. In order to improve the wear resistance and hydraulic performance of the axial flow pump, the present invention determines the impeller inlet diameter (1) D through the following relations j , the maximum diameter of the impeller (2) D, the diameter of the hub (4) D h , blade axial l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com