Sealing method of petrifaction ethylene pyrolysis furnace tube and furnace roof liner portion

A technology for ethylene cracking furnaces and furnace tubes, which is applied in the fields of lining repair, organic chemistry, hydrocarbon cracking and hydrocarbon production, etc. It can solve the problems of failure to ensure the expansion and swing gap of the furnace tube, burnout of the shunt tube of the support plate of the furnace body, and normal production and other problems, to achieve the effect of facilitating the transformation, construction and popularization of use, the method is simple and easy, and the service life is extended

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

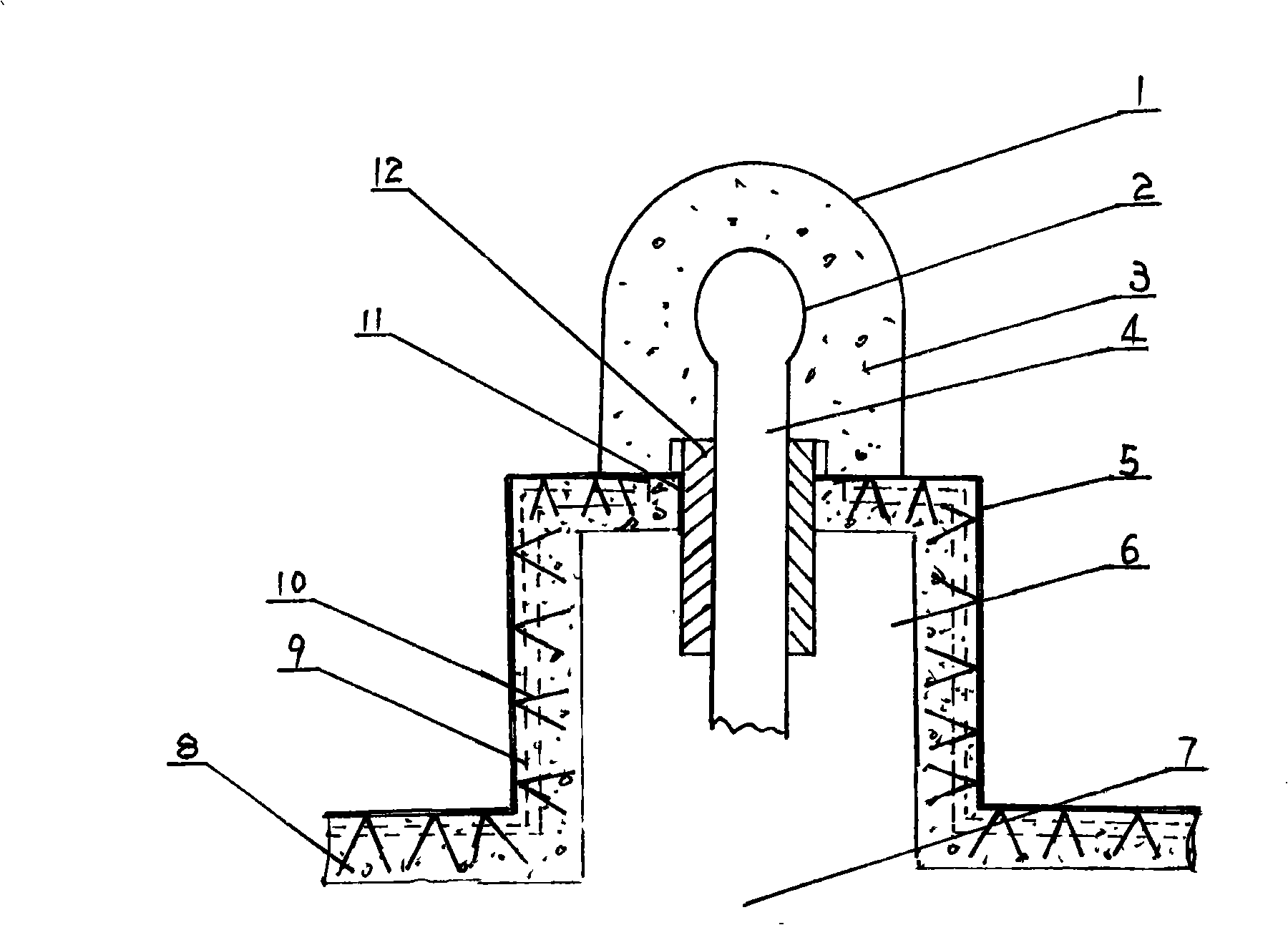

[0017] Such as figure 1 and figure 2 Shown, a kind of sealing method of petrochemical ethylene cracking furnace furnace tube and roof lining position, in the inner wall of lining position 6 that protrudes on this furnace furnace roof welding anchor nail 10, and anchor nail is herringbone shape, and its effect is to be beneficial to containing The zirconium fiber insulation layer 8 is fixed as a whole with the furnace body 5 inner wall of this position. The distance between adjacent anchor nails is 100-200mm, and the length is about 10-20mm smaller than the total thickness of the zirconium-containing fiber insulation layer, so as to ensure that its ends are located in the zirconium-containing fiber insulation layer and avoid forming thermal bridges. Wrap combustible material 12 on the corresponding furnace tube that passes through the furnace roof perforation, for example, wrap the furnace tube 4 at this position with newspaper, the thickness of the newspaper is the allowable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com