Post-poured toothed groove-connected assembled floor or roof

A prefabricated, alveolar technology, applied in the direction of floors, building components, buildings, etc., can solve the problems of increasing the size and reinforcement of beams and columns, the impact of seasons and climate, and the impact of the environment, etc., to achieve weight reduction and industrialization High degree, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

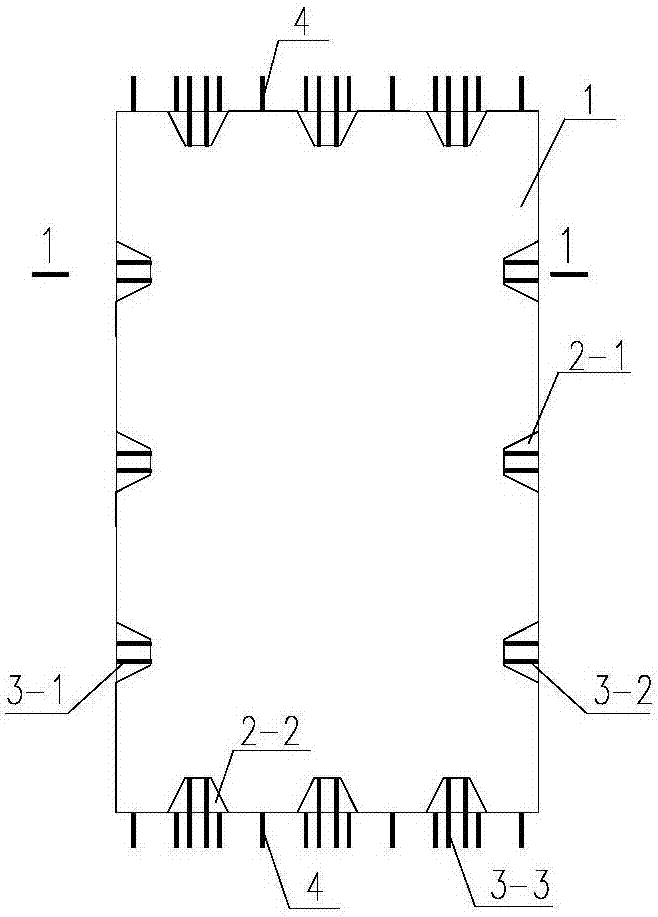

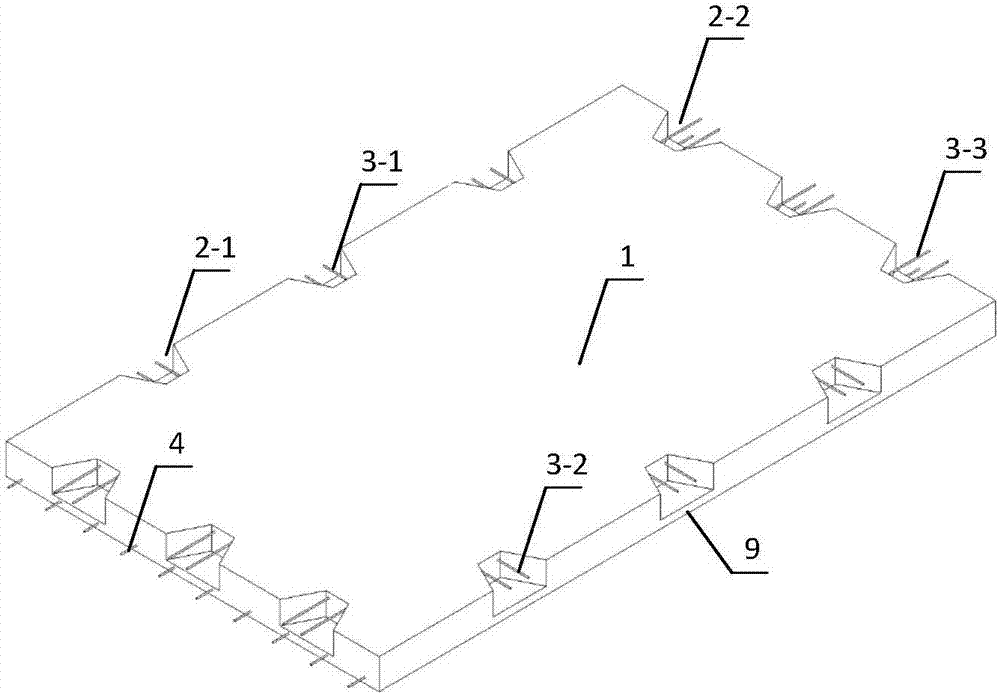

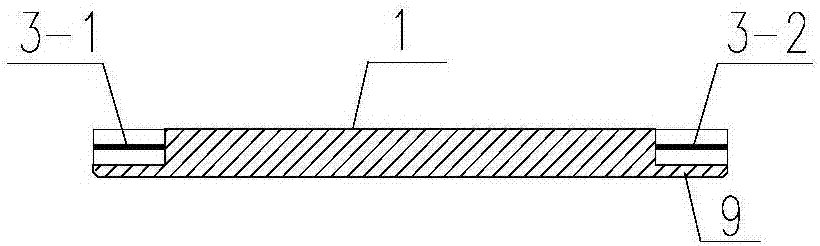

[0046] Please refer to the accompanying drawings, a post-cast tooth-groove connection prefabricated floor roof, which is formed by splicing a plurality of precast concrete slabs 1, and tooth grooves are provided on the plate end and the slab side of the precast concrete slab 1, and the slab side Both the tooth groove 2-1 and the plate end tooth groove 2-2 are provided with a bottom plate 9, and the embedded plate side connector is provided in the plate side tooth groove 2-1, which is used for the precast concrete connected with the floor beam. The embedded slab side connector on one side of the slab 1 adopts the embedded slab side connecting steel bar Ⅰ3-1 extending horizontally, and the embedded slab end connecting steel bar 3-3 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com