Prefabricated steel structure and construction method thereof

A steel structure and prefabricated technology, applied in basic structure engineering, building components, building structures, etc., can solve the problems of embedded walls that affect the beauty of buildings, low prefabrication rate and on-site assembly rate, and large solid waste noise pollution, etc. problems, to achieve the effect of improving factory prefabrication rate and on-site assembly rate, short construction period, and green and environmental protection in construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

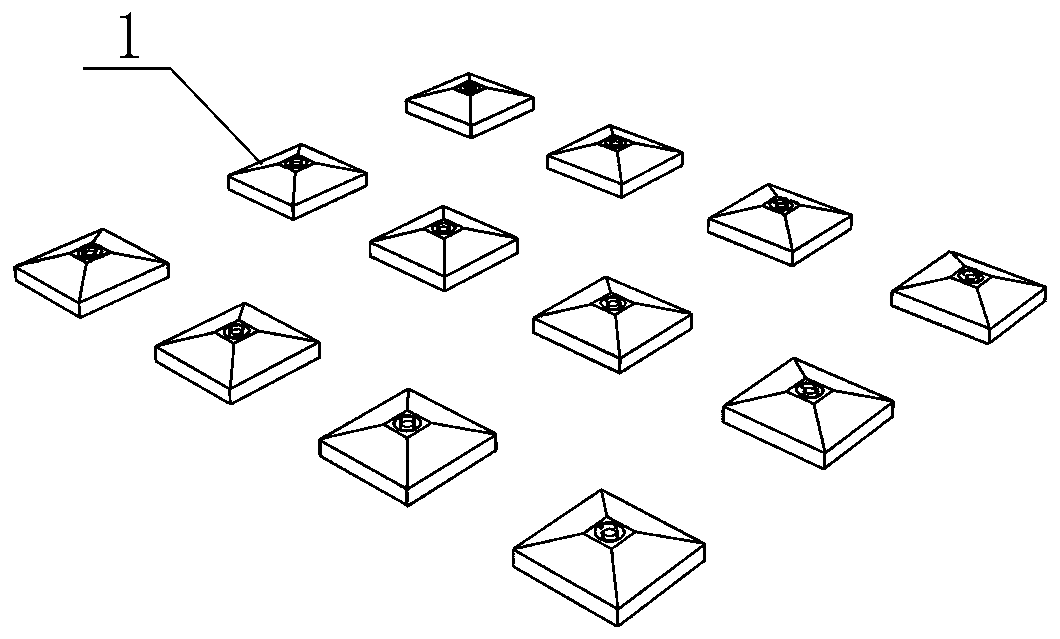

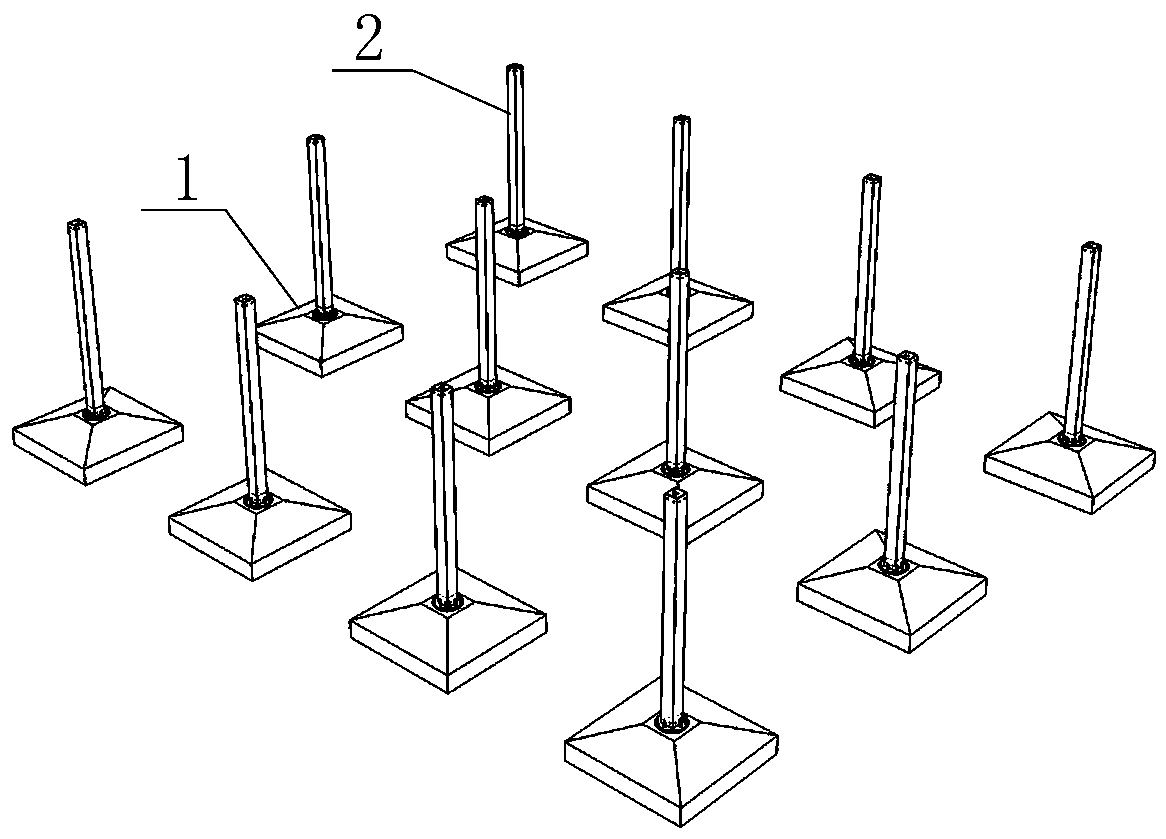

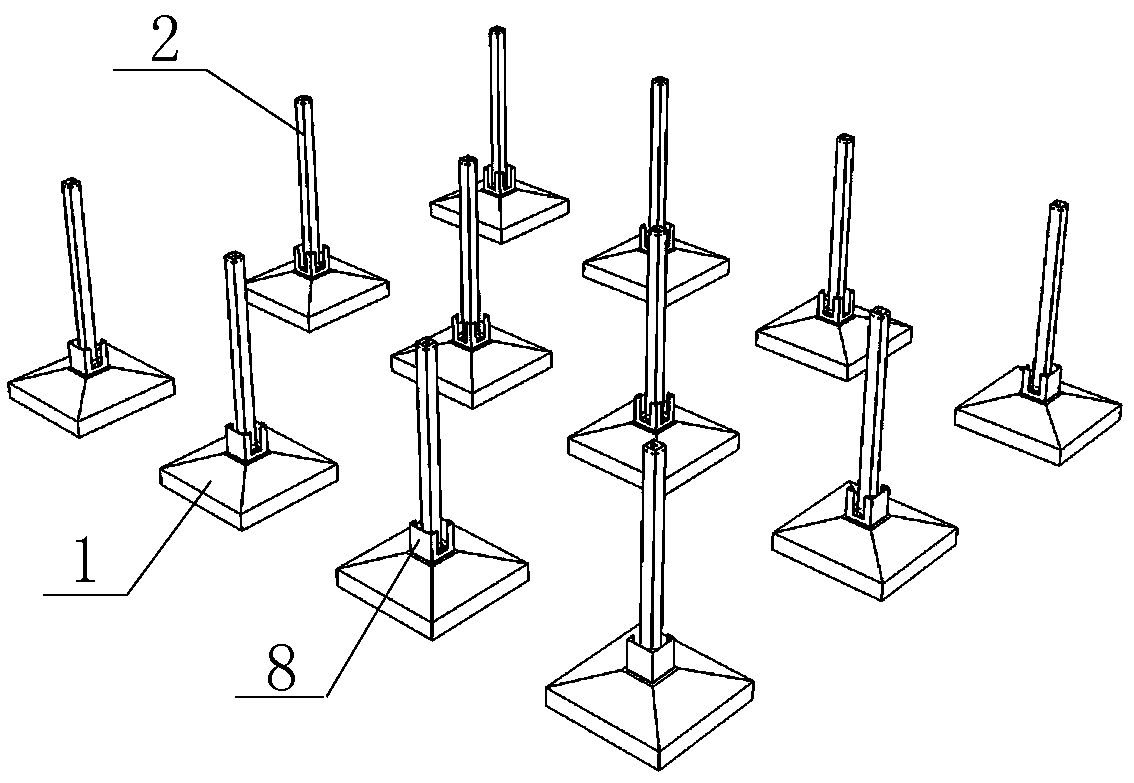

[0057] like Figure 1-23 As shown, this prefabricated steel structure includes an independent foundation 1, steel columns 2, foundation beams 3, I-shaped steel beams 4, laminated floor slabs 5 and wall panel structures 6; the independent foundation 1 is a prefabricated reinforced concrete independent foundation, and the independent foundation 1 is provided with a group and arranged in a matrix; embedded parts 7 are buried in the independent foundation 1; the embedded parts 7 include an embedded part bottom plate 7.1, a vertical anchor rod 7.2 and a sleeve 7.3; , there is a group of vertical anchor rods 7.2, which are connected at intervals to the top of the embedded bottom plate 7.1; the upper part of the outer wall of the sleeve 7.3 is provided with an external thread 13, and a horizontal annular plate is provided inside the sleeve 7.3 near the upper end. 7.4; the first connection hole 10 passing through the vertical anchor rod 7.2 is opened on the surface of the annular plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com