Composite antiknocking material and its production

A composite material and material technology, applied in chemical instruments and methods, building components, layered products, etc., can solve the problems of insufficient strength and stiffness of elastic and plastic structural materials, low elasticity and plasticity, etc., and achieve industrialization High production level, less wet work, and the effect of increasing the usable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

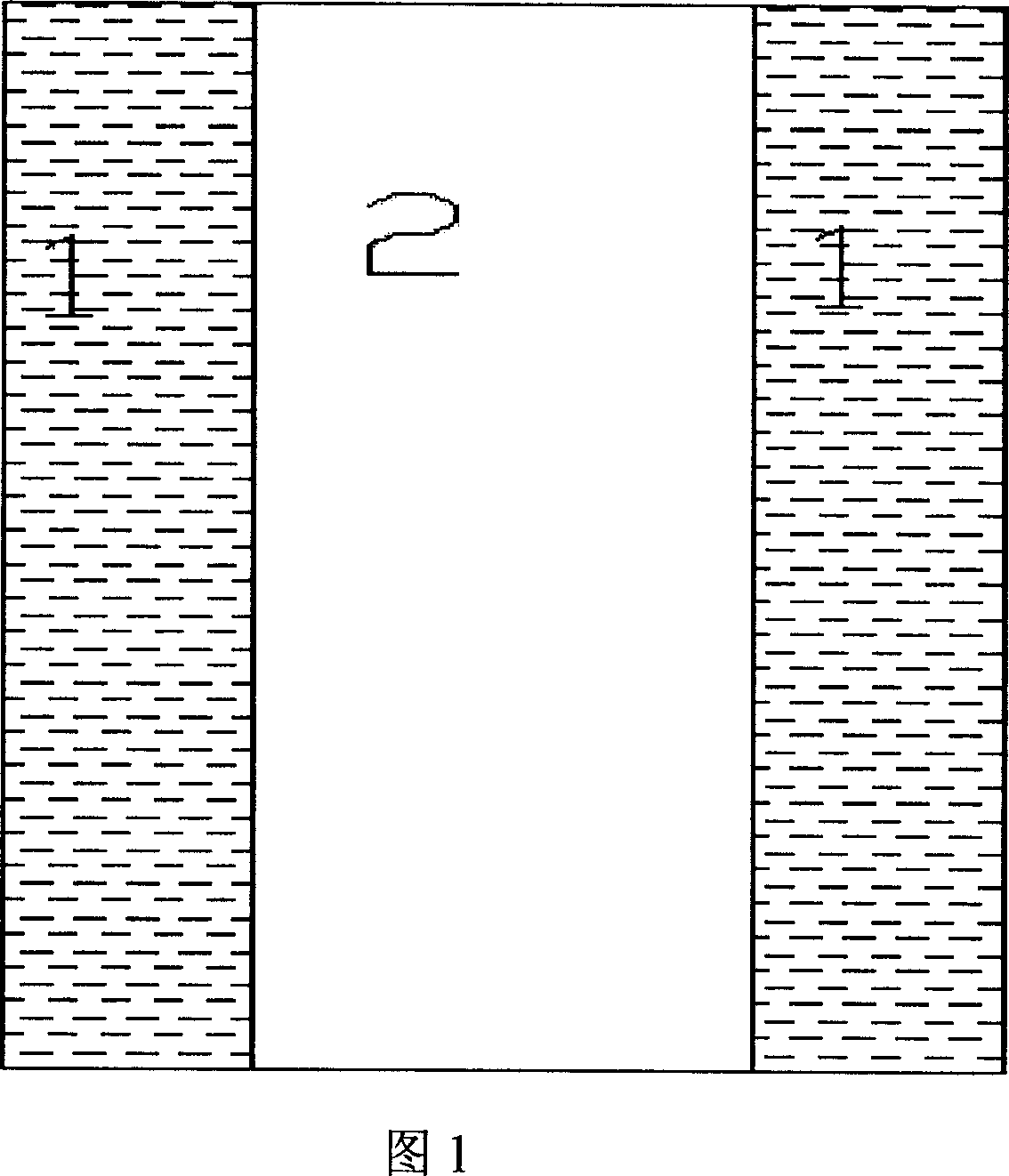

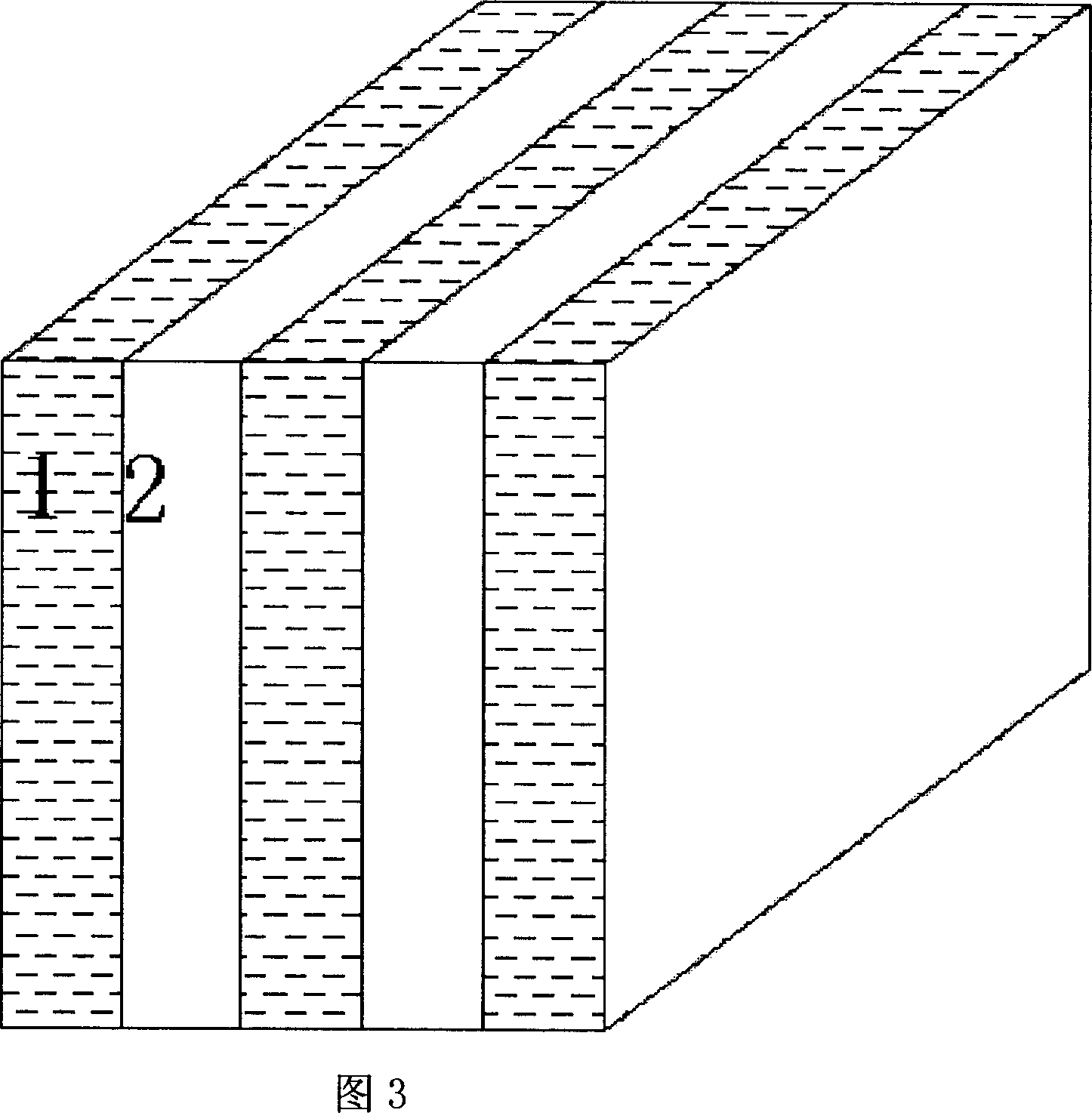

[0066] According to the design requirements, the steel member 1 of plate type, cylindrical type and square tube type 16 manganese steel is selected from the market, see Figure 3, the size of the plate type steel member 1 is 1000mm×100mm×3mm, and the number of pieces is 3 pieces; see Figure 4 As shown in Figure 5, the dimension of the two-story cylindrical steel member 1 is D 2 =D 1 / 2=75mm, the number of pieces is 1 piece, the length is 1 meter, and the dimension of multi-layer cylindrical steel member 1 is d 4 = d 3 / 2=d 2 / 3=d 1 / 4=25mm, the number of pieces is 2 pieces, and the length is 1 meter; referring to Figure 6 and Figure 7, the size of the two-layer square tubular steel member 1 is h 2 = h 1 / 2=75mm, the length is 1 meter, and the size of multi-layer square tubular steel member 1 is f 4 = f 3 / 2=f 2 / 3=f 1 / 4=25mm, the number of pieces is 2 pieces, and the length is 1 meter; the component content of 16 manganese steel is calculated as Fe. balance, C.0.17, S...

Embodiment 2

[0084] According to the design requirements, the steel member 1 of plate type, cylinder type and square tube type 16 manganese steel material is selected on the market, the size and number of selected various steel members are the same as those selected in embodiment 1, the composition of 16 manganese steel The content is calculated by weight percentage as Fe. Balance, C.0.17, Si.0.5, Mn.1.57, S.0.05, P.0.045. Then the first step carries out pretreatment to the selected steel member 1, this step is the same as item (1) to (7) of the first step of embodiment 1, and the second step is also the same as the second step of embodiment 1.

[0085] The third step is to heat the whole steel component 1 welded into the box model to 250°C and keep the temperature constant, then heat the aluminum to 660°C to melt, and its component content is calculated by weight percentage: Al. balance, Fe .0.07, Si.4.0, Cu.3.0, Mn.0.5, Mg.0.25, Ni.0.3, Zn.0.55, Sn.0.05, Ti.0.20, Pb.0.15, Cr.0.15, castin...

Embodiment 3

[0087] According to the design requirements, the steel member 1 of plate type, cylinder type and square tube type 16 manganese steel material is selected on the market, the size and number of selected various steel members are the same as those selected in embodiment 1, the composition of 16 manganese steel The content is calculated by weight percentage as Fe. Balance, C.0.17, Si.0.5, Mn.1.57, S.0.05, P.0.045. Then the first step carries out pretreatment to the selected steel member 1, this step is the same as item (1) to (7) of the first step of embodiment 1, and the second step is also the same as the second step of embodiment 1.

[0088]The third step is to heat the whole steel member 1 welded into the box model to 250°C and keep the temperature constant, then heat the magnesium to 650°C to melt, and its component content is calculated by weight percentage: Mg. balance, Al .2.5, Zn.0.60, Mn.0.20, Si.0.10, Fe.0.002, Cu.0.001, Ni.0.001, the magnesium liquid is poured into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com