Reinforced concrete assembly type cable duct and manufacturing method

A reinforced concrete and cable trench technology, which is applied in cable installation, ground cable installation, cable laying equipment and other directions to achieve the effect of reducing the weight of the hoisting unit, convenient and quick installation, and improving the degree of processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

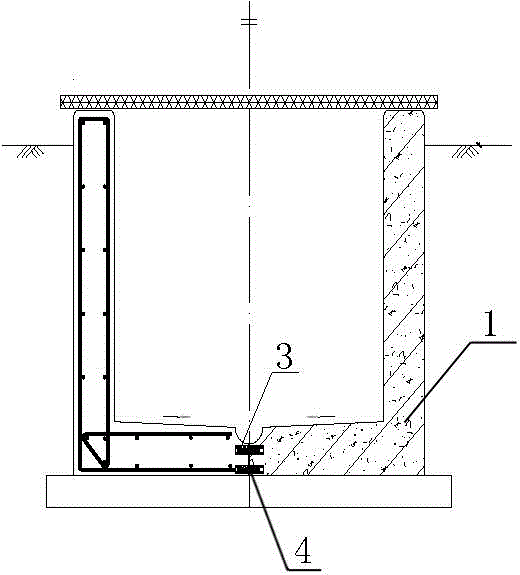

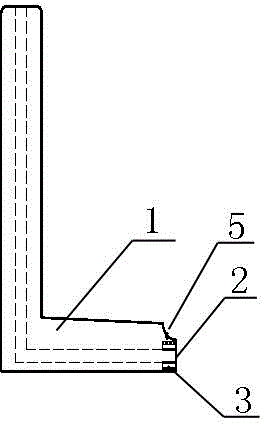

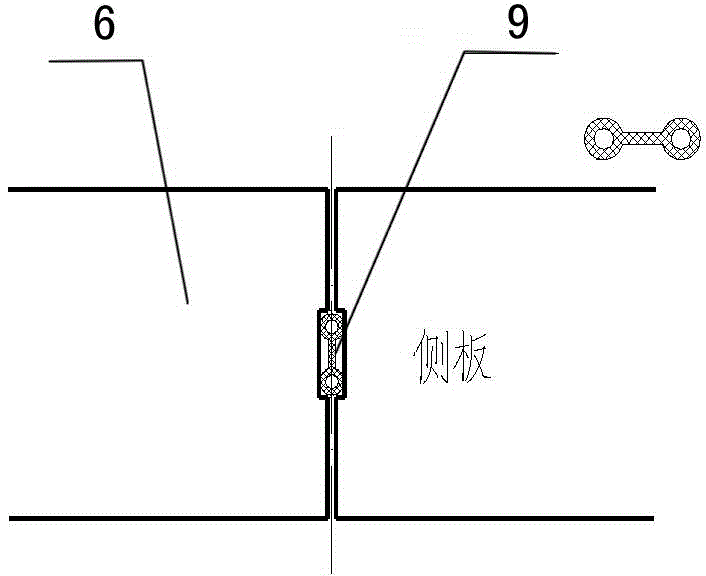

[0037] Embodiment: What the present invention adopts is two-piece type assembling scheme, and left and right are symmetrical, and its processing drawing sees figure 1 , 2 As shown, the weight of a single piece is 0.6 tons, and it can be stacked during transportation and installation, occupying a small amount of transportation and storage space, and can transport 50 tons at a time, forming a 25m long ditch. Rebar connection sleeves are reserved on the bottom plate, and Φ14 short steel bars are inserted during installation for positioning and connection. A 4x40 groove is reserved on the wall of the cable trench and the bottom plate, and the water-swellable waterproof strip is inserted during installation to prevent water seepage at the connection. There is a 1 / 4 circle in the prefabricated ditch unit, and the two pieces are spliced to form a 1 / 2 circle with a radius of 50mm. The water level difference is used to achieve longitudinal drainage, and there is no need for secondar...

specific Embodiment approach

[0038] The implementation steps of the cable trench of the present invention are: factory prefabrication → positioning and setting out → earthwork excavation → cushion layer construction → hoisting in place → pouring connection nodes → fixing cable supports → laying cables → laying slabs.

[0039] The invention is applicable to projects requiring prefabricated cable trench arrangement, such as substations, converter stations, and power plants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com