Visible-frame curtain wall system with small picture-frame-type glue filling units

An open-frame curtain wall and small unit technology, applied in the direction of walls, building components, buildings, etc., can solve the problems that the facade cannot be spliced at 45°, the installation process is cumbersome, and the degree of industrialization is low, so as to improve the watertightness and airtightness of the curtain wall. performance, simplify the field installation process, improve the effect of the degree of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention will be defined more clearly.

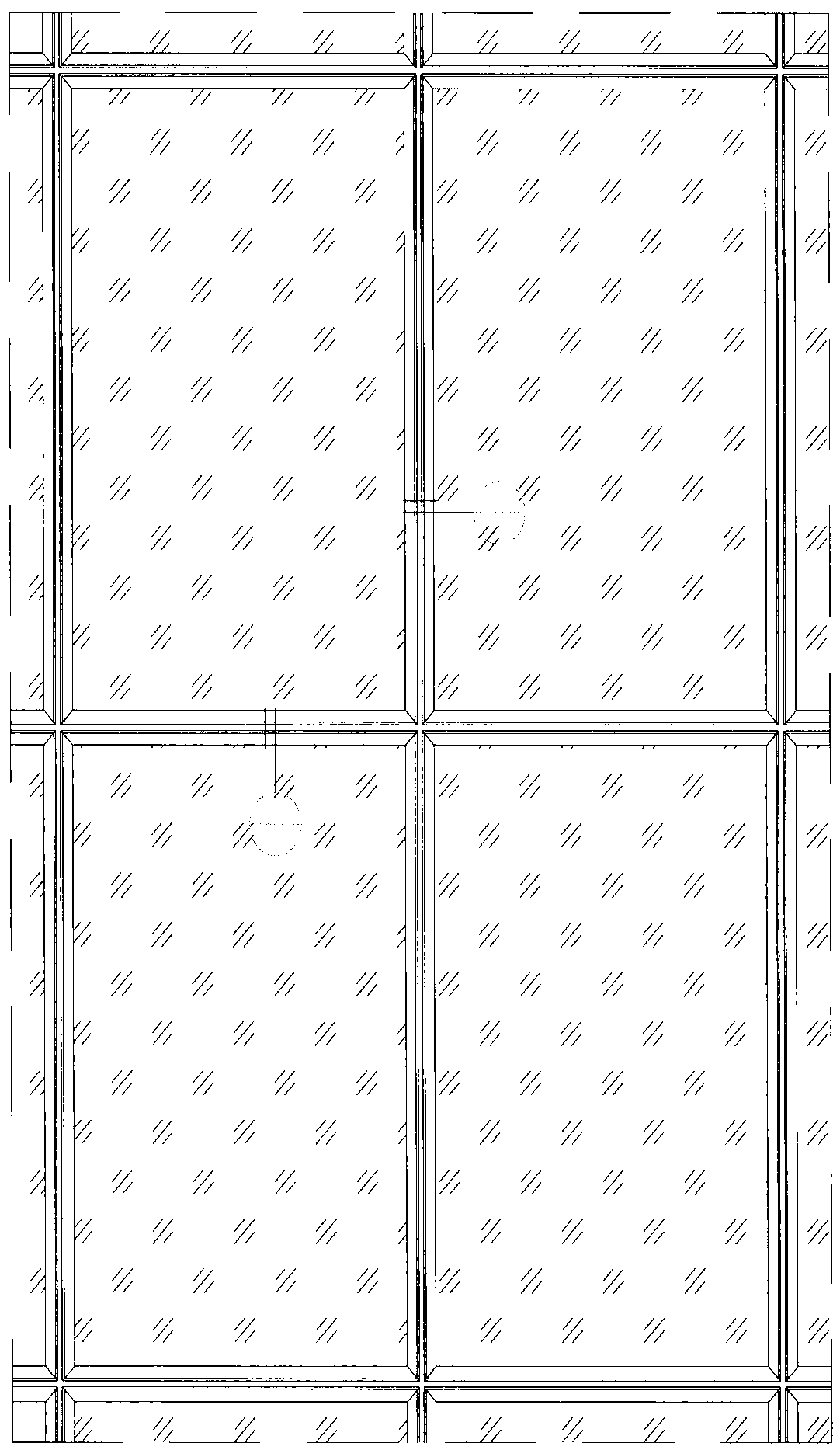

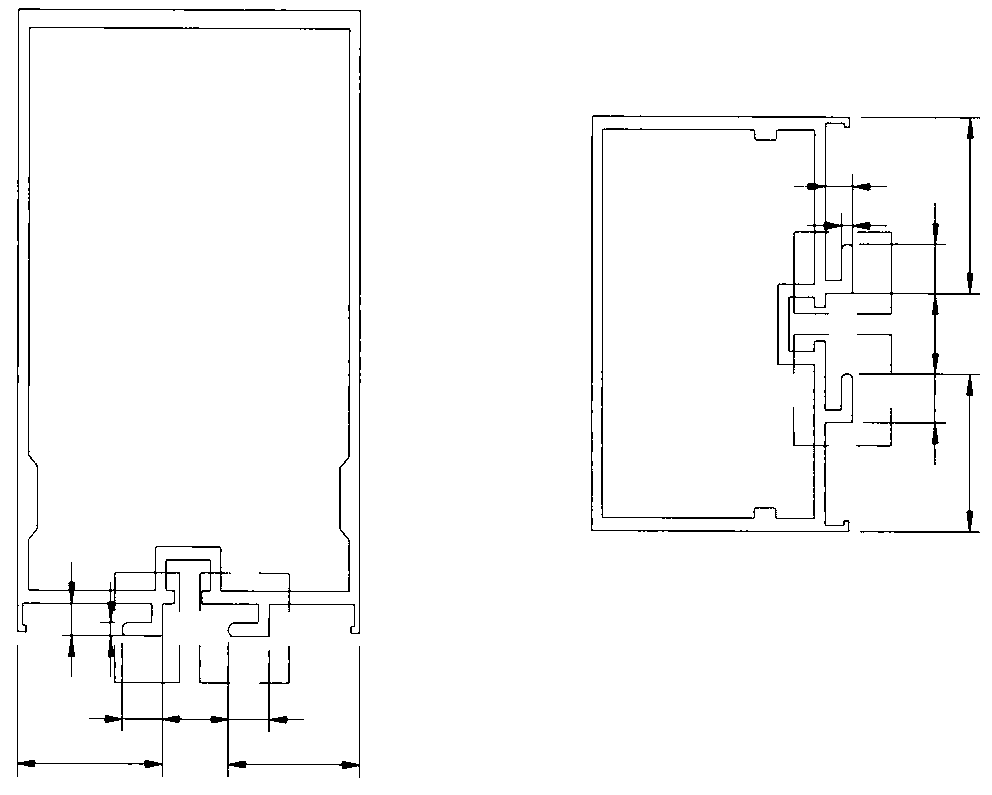

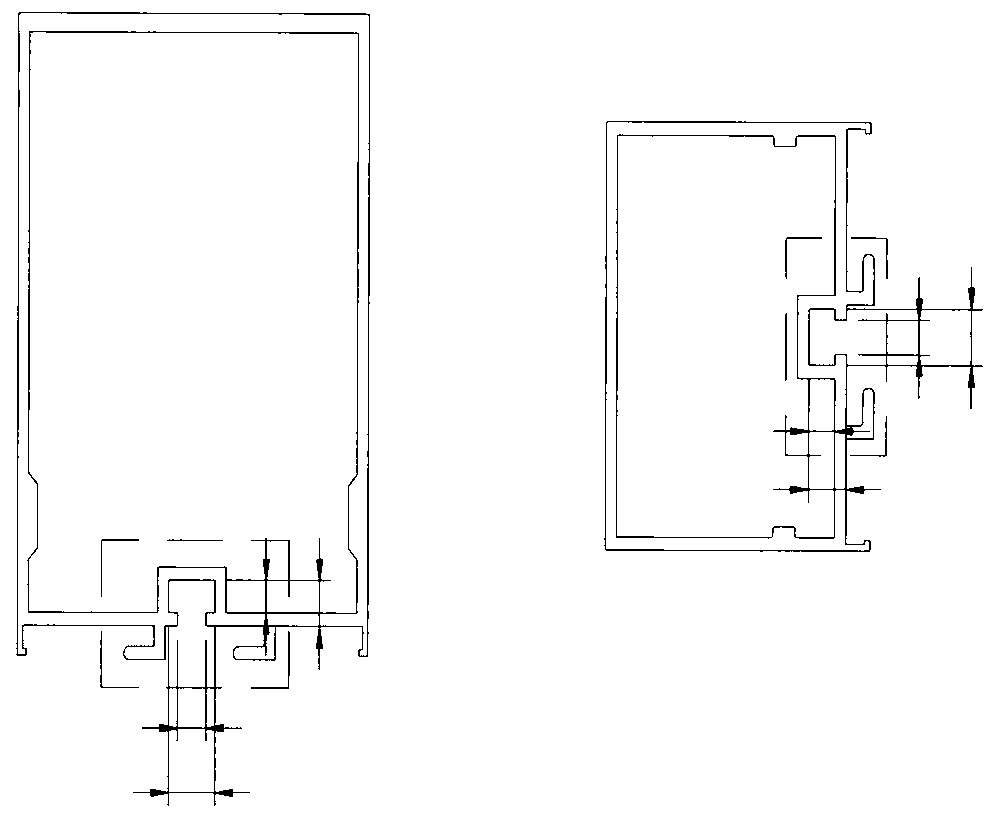

[0020] Such as figure 1 As shown, a mirror frame type glue injection small unit exposed frame curtain wall system mainly includes a beam, a column and a panel. The beam and the column are connected by spring pins. The system also includes fixed sash windows and prefabricated panels. The sash window and aluminum alloy crimping line cooperate to fix the panel. The fixed fan window is designed with a closed cavity, and the gap between the side of the prefabricated plate and the fixed fan frame is sealed by sealant. The prefabricated plate includes a drainage hole and an air pressure balance hole, which are arranged in a staggered manner, and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com