Raw material asphalt for carbon-based new material and production process thereof

A production process and new material technology, which can be used in chemical processing of tar pitch/petroleum pitch/natural pitch, petroleum industry, hydrocarbon oil treatment, etc. The effect of excellent aggregate structure, variety and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

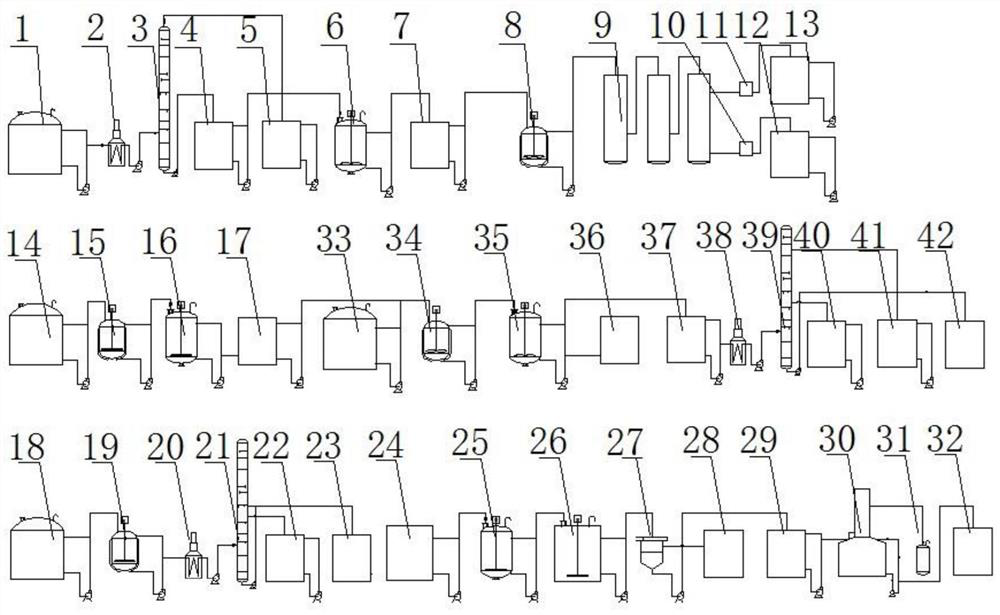

[0077] Such as figure 1 As shown, in the present embodiment, the raw material low-temperature coal tar that is stored in the raw oil storage tank 1 and whose quinoline insoluble matter content is 1.53wt% is sent into No. 1 vacuum distillation tower 3 through No. 1 heating furnace 2, The temperature at the top of the tower is controlled at 240°C, the temperature at the bottom of the tower is controlled at 350°C, and the vacuum degree is controlled at 0.08MPa. The gas phase line at the top of the tower gets by-product light oil and sends it to light oil storage tank 5; the remaining product at the bottom of the tower is sent to heavy oil storage tank 4. The heavy oil in the heavy oil storage tank 4 is sent to the polymerization reactor 6 for asphalting reaction. First, high-purity nitrogen is used to replace the air in the polymerization reactor 6 so that the initial pressure is 0.05 MPa, and the pressure is self-boosted; Raise the temperature from normal temperature to 360°C at...

Embodiment 2

[0085] The raw material medium-temperature coal tar with quinoline insoluble matter content of 2.78% is sent to No. 1 vacuum distillation tower through No. 1 heating furnace. The temperature at the top of the tower is controlled at 238 ° C, the temperature at the bottom of the tower is controlled at 340 ° C, and the vacuum degree is controlled at 0.08 MPa, the gas phase line at the top of the tower obtains light oil as a by-product, and the remaining product at the bottom of the tower is sent to the polymerization reactor for asphaltization reaction. First, high-purity nitrogen is used to replace the air in the polymerization reactor so that the initial pressure is 0.1MPa, and the pressure is self-boosted, and then the temperature is raised from normal temperature to 360°C at a rate of 2°C / min, and the constant temperature is kept for 7 hours. The final pressure in the kettle is maintained At 0.85MPa, the polymerized asphalt is prepared, the softening point of the polymerized a...

Embodiment 3

[0093] The raw material high-temperature coal tar with quinoline insoluble matter content of 3.98% is sent to No. 1 vacuum distillation tower through No. 1 heating furnace. MPa, the gas phase line at the top of the tower obtains light oil as a by-product, and the remaining product at the bottom of the tower is sent to the polymerization reactor for asphaltization reaction. First, high-purity nitrogen is used to replace the air in the polymerization reactor so that the initial pressure is 0.4MPa, and the pressure is self-boosted, and then the temperature is raised from normal temperature to 340°C at a rate of 5°C / min, and the constant temperature stays for 6 hours. The final pressure in the kettle remains At 1.0MPa, polymerized asphalt is prepared, the softening point of polymerized asphalt is 46°C, and the density is 1.12g / cm 3 .

[0094] Cool the polymerized asphalt to about 200°C, and send it to the No. 1 mixing tank with the mass ratio of 4:1 with the washing oil. The mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com